Description:

| Alloy: | 5454 |

| Temper: | O, H32/H34, H111/H112, H22/H24 |

| Coating Types: | PE, PVDF, etc. |

| Coating Thickness: | Single-sided 5-25μm, Double-sided 5-35μm |

| MOQ: | 1-3 tons |

| Alloy: | 5454 |

| Temper: | O, H32/H34, H111/H112, H22/H24 |

| Coating Types: | PE, PVDF, etc. |

| Coating Thickness: | Single-sided 5-25μm, Double-sided 5-35μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

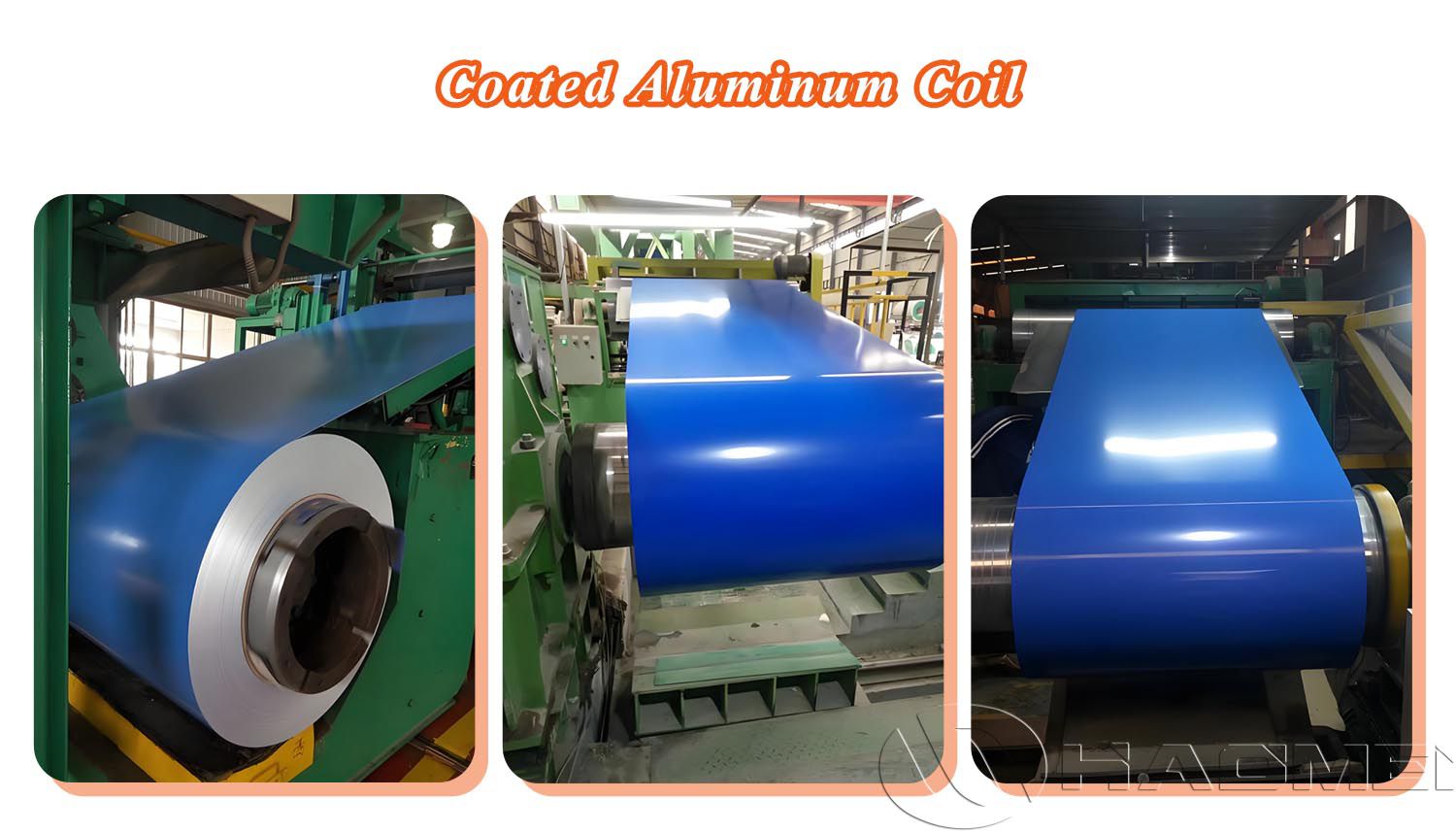

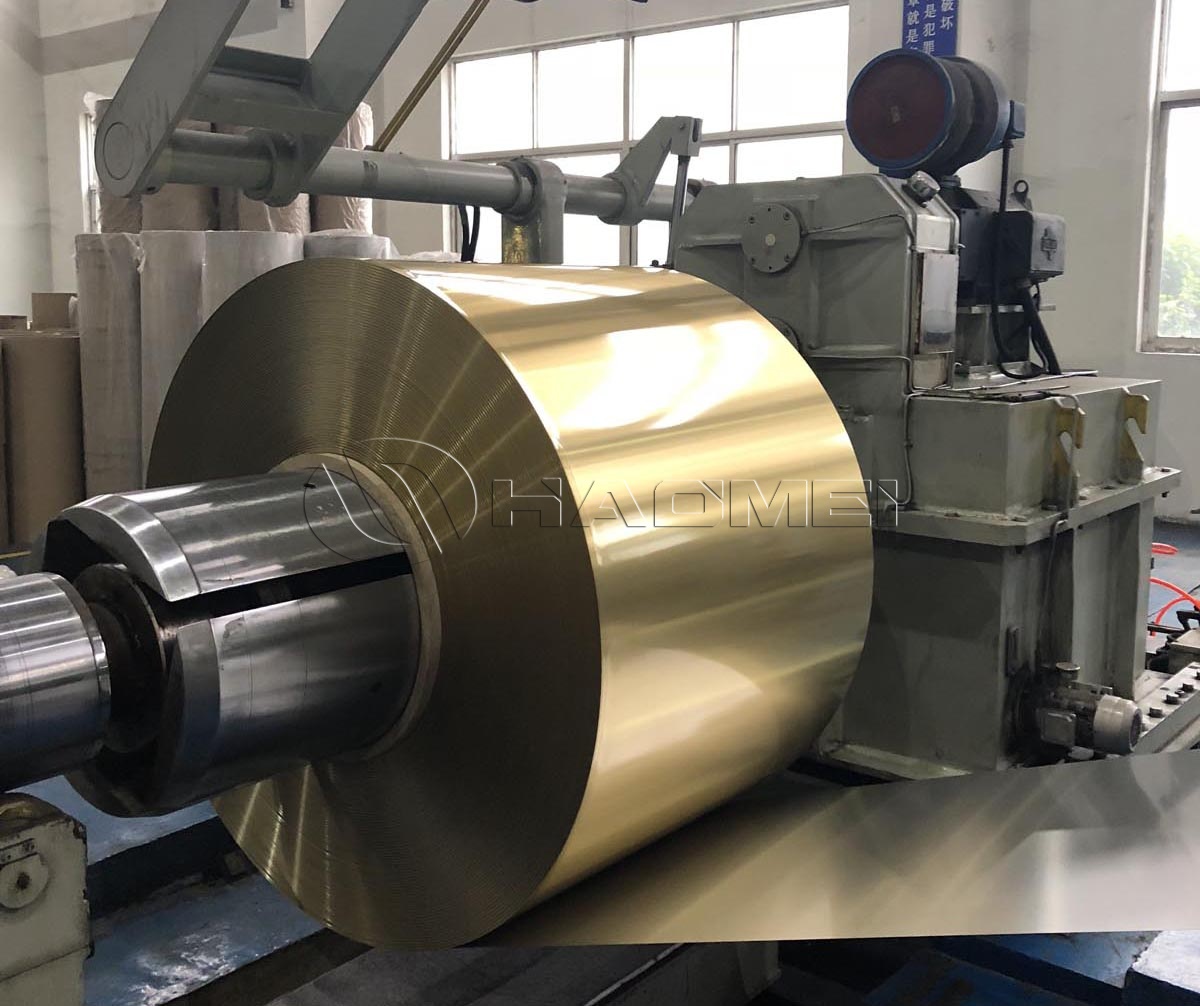

The 5454 color coated aluminum coil is a high-performance decorative metal coil made from 5454 aluminum-magnesium alloy. Its surface undergoes degreasing, chemical conversion film treatment, roll coating, and baking to form a durable and vibrant color layer. This material combines the high strength, excellent corrosion resistance, and good weldability of 5454 alloy with a colorful protective coating, making it a composite material suitable for both structural and decorative applications.

As a typical medium-strength Al-Mg series alloy, 5454 aluminum contains 2.4%-3.0% magnesium with small amounts of manganese to enhance corrosion resistance and fatigue performance. Compared to 5052 alloy, 5454 offers superior high-temperature strength and better resistance to stress corrosion cracking, making it widely used in storage tanks, automotive fuel tanks, ship structures, curtain wall decorations, and transportation facilities.

After color coating, 5454 color coated aluminum coils not only have a rich and bright appearance but also resist oxidation, acid rain, UV radiation, and sea salt corrosion, making them ideal for high-end industrial and architectural applications.

| Alloy | 5454 |

| Temper | O, H32/H34, H111/H112, H22/H24 |

| Thickness | 0.25mm - 2.5mm (customizable) |

| Width | 20mm - 1600mm |

| Length | 1000mm - 16000mm |

| Coating Types | PE, PVDF, etc. |

| Coating Thickness | Single-sided 5-25μm, Double-sided 5-35μm |

| Glossiness | 10%-90% (high gloss/matte optional) |

| Inner Diameter | 150mm / 405mm / 505mm |

| Surface Effects | Smooth, embossed, wood grain, stone grain, brushed, matte, etc. |

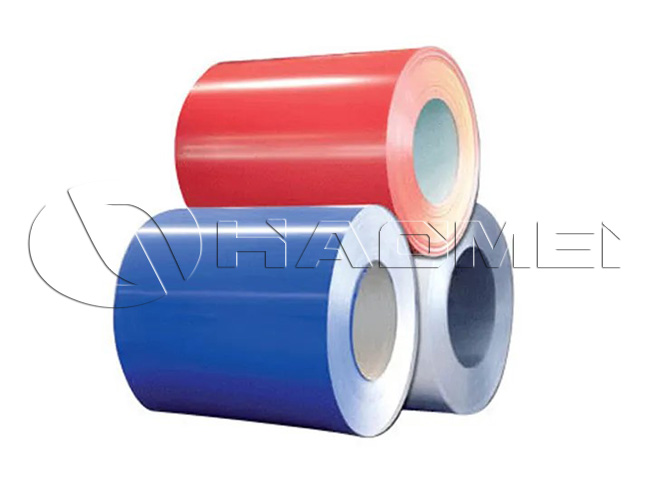

| Color Options | Any RAL color, supports custom textures or metallic finishes |

| Packaging | Standard export packaging |

| Origin | Zhengzhou, China |

| MOQ | 1-3 tons |

Mechanical Properties

| Tensile Strength | 220-270 MPa |

| Yield Strength | 90-150 MPa |

| Elongation | ≥12% |

| Elastic Modulus | 70 GPa |

| Density | 2.69 g/cm³ |

| Thermal Conductivity | 135 W/m·K |

| Melting Point | 595-640°C |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Other:Each | Other:Total | Al |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.2 | - | 0.25 | 0.2 | - | - | 0.05 | 0.15 | remainder |

Excellent Thermal Stability: Maintains high tensile strength under medium-to-high temperature conditions (e.g., engine compartments, high-temperature piping) and reduces thermal softening.

Outstanding Corrosion Resistance: Inherits the exceptional resistance of 5xxx marine aluminum alloys to marine atmosphere, salt spray, and various chemical media; suitable for humid, saline, or chemical environments.

High Strength and Toughness: Higher tensile and yield strength compared to 5052 and 5754 alloys; suitable for structural components requiring load-bearing and impact resistance.

Good Weldability: 5454 alloy is easily weldable, suitable for complex structural manufacturing such as tanks and piping systems.

Long-lasting Decorative Appearance: High-quality color coating provides rich visual effects and extra protection in high-temperature or corrosive environments.

Environmentally Friendly and Recyclable: Lead-free, mercury-free, chromium-free; complies with RoHS and REACH standards; 100% recyclable.

Construction and Decoration

Curtain wall panels, roofing systems, aluminum honeycomb panels, aluminum composite panels, window frames, ceiling panels.

PVDF-coated versions can last over 25 years on high-rise building exteriors with long-lasting color.

Transportation and Automotive

Automotive fuel tanks, tanker truck bodies, trailer panels, rail vehicle interior panels.

Lightweight, reduces fuel consumption, increases load efficiency.

Marine and Offshore Engineering

Excellent salt spray corrosion resistance for ship hulls, bulkheads, deck panels, and offshore platform components.

Color coating further enhances rust protection.

Storage Tanks and Chemical Equipment

Ideal for liquid storage tanks, chemical containers, pressure vessel shells due to high corrosion and compression resistance.

Home Appliances and Industrial Equipment

Refrigerator panels, washing machine casings, water heaters, industrial equipment panels; combines corrosion resistance and aesthetic appeal.

Versus 5052 Alloy: 5454 has higher tensile strength and better heat resistance, suitable for high-temperature or high-pressure environments; 5052 is lighter, better for general decorative applications.

Versus 5754 Alloy: Similar corrosion resistance, but 5454 slightly outperforms in weldability and structural strength, better for storage tank manufacturing.

Versus 3004 Alloy: 5454 is Al-Mg series with much higher strength and better salt spray resistance than the Al-Mn 3004 alloy.

Versus 6061 Alloy: 6061 is stronger but less formable; 5454 is preferable for forming complex structures.

Store in a dry, ventilated, flat area, away from direct sunlight and humidity.

Avoid impact or scratches on the coil edges during handling.

Clean surface oils or debris before use to ensure proper coating adhesion.

Recommended processing at room temperature to prevent coating deformation.

Q1: What is the difference between 5454 and 5052 color coated aluminum coils?

A1: Both are Al-Mg alloys, but 5454 has slightly higher magnesium content and strength, suitable for high-load structures like tanks and tanker trucks, whereas 5052 is mainly used for building facades and decorative applications.

Q2: What is the service life of 5454 color coated aluminum coil?

A2: With high-quality PVDF coating under normal conditions, it can last 20-30 years; in marine or industrial corrosive environments, 15+ years.

Q3: Can 5454 color coated aluminum coil be welded?

A3: Yes, it has excellent weldability and is compatible with TIG, MIG, and arc welding; weld joints are strong and smooth.

Q4: Can colors and sizes be customized?

A4: Yes. RAL colors, metallic finishes, wood or stone textures, as well as custom thickness, width, and coil inner diameter are available.

Q5: Is 5454 color coated aluminum environmentally friendly?

A5: Yes. The alloy is non-toxic, RoHS-compliant, and 100% recyclable, making it ideal for green construction and sustainable manufacturing.

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

What Is Color Coated Aluminum Coil?Color coated aluminum coil is produced by applying one or multiple layers of organic coating onto an aluminum alloy substrate through continuous roll-coating followed by high-temperature curing.The coating is the core of

2025-12-01

This article introduces color coated aluminum coil engineered for roofing sheets, positioning it as a lightweight, corrosion-resistant, and formable substrate for roll-formed roof panels in industrial, commercial, and residential buildings.

2026-01-07