Description:

| Alloy: | 1350 |

| Coating Type: | PE / PVDF |

| Coating Thickness: | 15μm - 25μm |

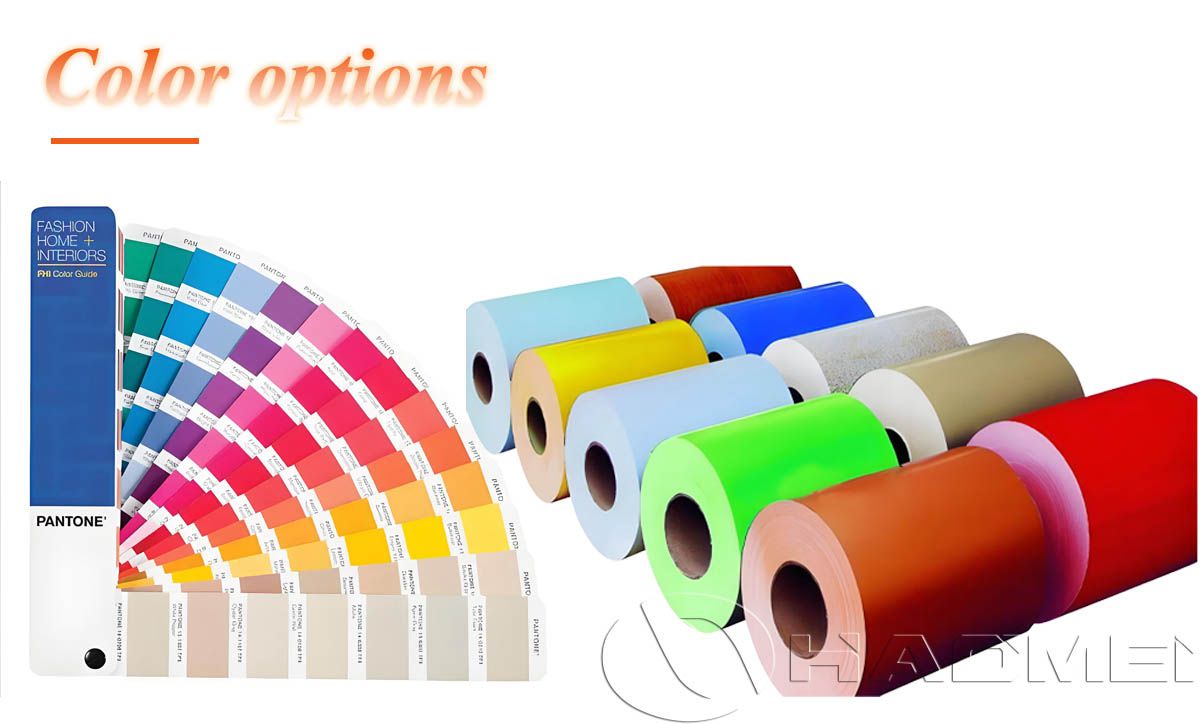

| Colors: | Silver, red, blue, black, gold, etc. |

| Surface Finish: | Oxidized, sandblasted, mirror, colored coating, wood grain, etc. |

| Alloy: | 1350 |

| Coating Type: | PE / PVDF |

| Coating Thickness: | 15μm - 25μm |

| Colors: | Silver, red, blue, black, gold, etc. |

| Surface Finish: | Oxidized, sandblasted, mirror, colored coating, wood grain, etc. |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

The 1350 color coated aluminum coil uses 1350 aluminum alloy as the base material. After pretreatment (such as chemical cleaning, chromating, or non-chromating treatment), one or more layers of organic coating are applied to the surface and cured by baking to form a composite material. It integrates the excellent properties of aluminum alloy with the beauty and durability of color coatings. It is widely used in construction, home appliances, advertising, automotive manufacturing, and other industries.

Its outstanding corrosion resistance, UV resistance, rich color options, and excellent processing performance make 1350 color coated aluminum coil one of the most popular aluminum materials in the market.

1350 aluminum alloy belongs to the aluminum-copper series, featuring high electrical and thermal conductivity. Compared with other pure aluminum alloys, it offers stronger oxidation resistance and better mechanical strength. With high-quality coatings, 1350 color coated aluminum not only retains the advantages of the alloy but also provides diverse visual effects to meet different design needs.

HAOMEI's production process mainly includes roller coating and spray coating technologies. Roller-coated aluminum coils offer more uniform coating distribution and more stable quality. Compared with traditional single-piece spraying or brushing, this continuous production process ensures uniformity and stability, providing high reliability for architectural and industrial applications.

1. Excellent Weather Resistance

The surface coating of the color-coated aluminum coil is baked at high temperature, resulting in high gloss retention and good color stability. The polyester coating can be used for 20 years, while the fluorocarbon coating can last for more than 30 years, effectively resisting the effects of climatic factors such as ultraviolet rays, wind, rain, frost, snow, and ice.

2. Outstanding Mechanical Properties

The coil has excellent flatness, no high-temperature composite indentations, no residual stress, and does not deform after shearing.

3. Excellent Decorative Effects

Can be coated in a wide variety of colors, including metallic, silver, striped, changeable colors, and even realistic wood grain or stone grain finishes.

4. Environmental Performance

The coil resists corrosion from salt, alkali, and acid rain. It does not corrode or produce bacteria, does not release toxic gases, and typically meets B1-level flame retardant requirements.

5. Easy Processing

Strong plasticity allows fabrication into fan-shaped panels, curved panels, and various creative forms.

6. High Temperature Resistance

The coating maintains performance in high-temperature environments, suitable for a wide range of industrial and outdoor applications.

| Alloy | 1350 |

| Aluminum Purity | ≥ 99.5% |

| Thickness | 0.2mm - 3.0mm |

| Width | 500mm - 1500mm |

| Length | 1000mm - 16000mm |

| Coating Type | PE / PVDF |

| Coating Thickness | 15μm - 25μm |

| Colors | Silver, red, blue, black, gold, etc. |

| Surface Finish | Oxidized, sandblasted, mirror, colored coating, wood grain, etc. |

| Minimum Coil ID | 508mm |

| Delivery Form | Sheet, coil, strip |

| Origin | Henan, China |

| Samples | Available |

| Packaging | Standard export packaging or customized packaging |

| MOQ | 1-3 tons |

Mechanical Properties

| Thickness (mm) | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 0.2-0.3 | H14 | 130-150 | 110-130 | 2-4 |

| 0.3-0.5 | H16 | 140-160 | 120-140 | 3-5 |

| 0.5-1.0 | H18 | 160-180 | 140-160 | 5-7 |

| 1.0-2.0 | H24 | 180-210 | 160-180 | 6-8 |

| 2.0-3.0 | H32 | 200-230 | 180-200 | 8-10 |

Chemical Composition of 1350 Alloy (%)

| Element | Fe | Si | Mn | Cr | Cu | Ti | V | B | Zn | Ga | Al |

| Min | - | - | - | - | - | - | - | 99.12 | |||

| Max | 0.4 | 0.1 | 0.01 | 0.01 | 0.05 | 0.01 | 0.01 | 0.05 | 0.05 | 0.03 | 99.5 |

1. Construction Industry

Used for exterior wall panels, roofing, ceilings, curtain walls, window frames, etc., due to its durability and decorative value.

2. Home Appliances

Used for refrigerators, air conditioners, washing machines, TVs, and interior structures, enhancing product appearance and durability.

3. Advertising Industry

Ideal for billboards, signage, light boxes, and displays due to its lightweight, durability, and vibrant colors.

4. Automotive Manufacturing

Used for exterior trims, body components, and interior panels.

With PVDF coating, it offers superior weather and abrasion resistance.

5. Electronics

Used for shells and structural components of TVs, audio systems, displays, computers, etc.

6. Other Uses

Lighting equipment, solar panel frames, tableware, packaging, and more.

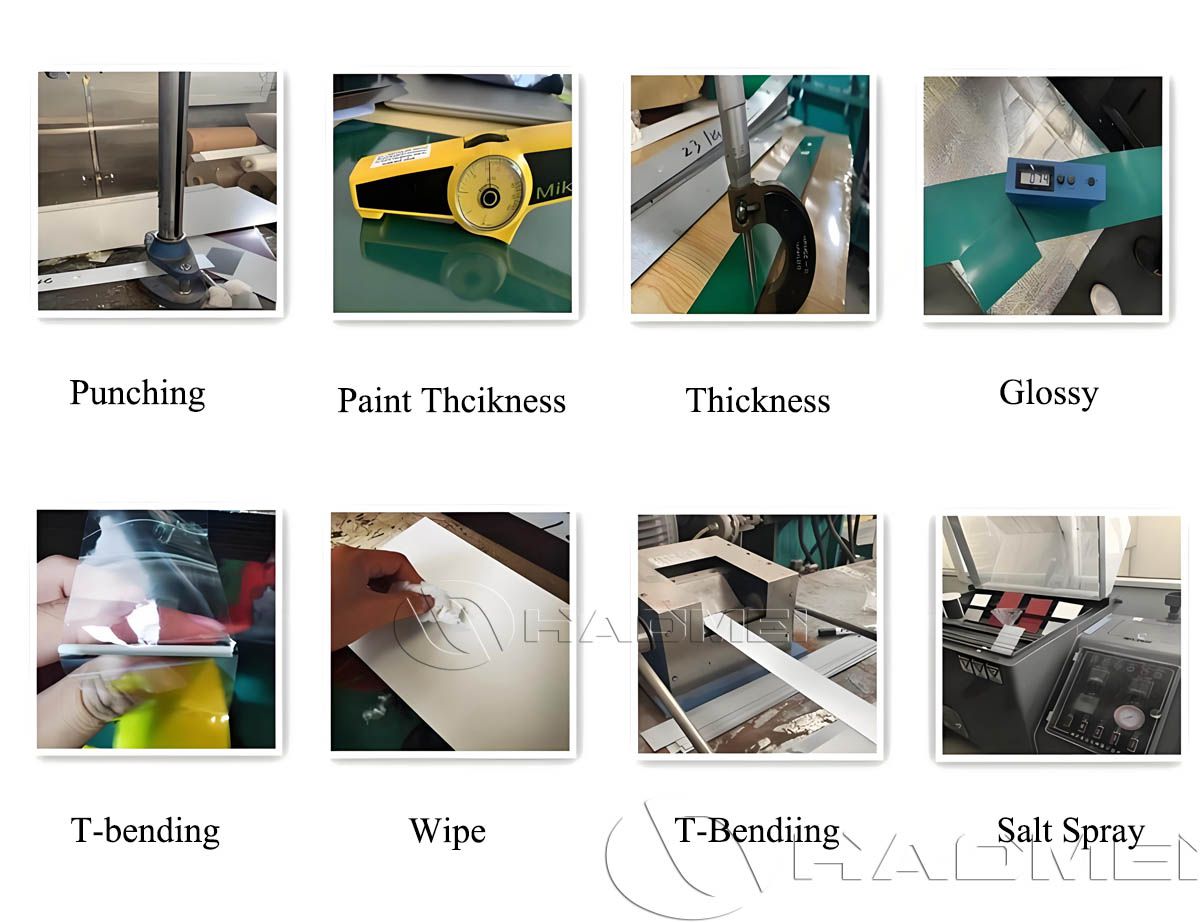

Every coil undergoes strict quality inspections including:

Coating adhesion test : ensures strong adhesion and uniform coating

Corrosion resistance tests : salt spray, acid, and alkali resistance

Color uniformity inspection : ensures no color difference and no surface defects

Dimensional accuracy inspection : thickness, width, and coil weight meet standards

Q1. What are the most common coating types for 1350 color coated aluminum? What are their differences?

A1: The most common types are PE (polyester) and PVDF (fluorocarbon) coatings.

PE coating:

Lower cost, bright colors, good gloss, suitable for indoor or mild outdoor environments.

PVDF coating:

Higher cost, but excellent UV resistance, anti-corrosion ability, and long-term color retention.

Ideal for curtain walls, roofing, and harsh outdoor applications

Q2. What is the typical service life (fade and chalk resistance) of 1350 color coated aluminum?

A2:

PE coating: Indoor applications can last for over 10 years; outdoor applications typically guarantee 5-8 years without significant fading or chalking.

PVDF coating: Offers excellent outdoor durability, typically guaranteeing 15-20 years or even longer, making it the preferred choice for outdoor construction projects.

Q3. How does 1350 alloy compare with 3003 and 5052 in performance?

A3:

1350 (pure aluminum): Low cost, high conductivity, easy processing; strength is lower.

3003 (Al-Mn): Better strength and corrosion resistance; the most common for color coated coils.

5052 (Al-Mg): Higher strength and excellent marine corrosion resistance.

Summary:1350 has low strength but high cost-effectiveness; 3003 is the mainstream balanced choice; 5052 is suitable for high-strength or special corrosion-resistant applications.

Q4. Can color coated aluminum coils be made with wood grain, stone grain, or other decorative effects?

A4: Yes. Using roller coating or heat transfer technology, highly realistic wood grain, stone grain, camouflage, and brushed finishes can be produced.

Q5. How to clean and maintain the surface of color-coated aluminum coils?

A5: For daily cleaning, simply rinse with water to remove dust and general dirt. For stubborn stains, use a neutral detergent and a soft cloth or sponge to wipe them away. However, never use strong acids, strong alkalis, or abrasive cleaners, as these may damage the coating.

In architectural decoration, home appliance housings, advertising signage, and industrial decoration, cold rolled color-coated aluminum coils are gradually replacing traditional steel materials due to their attractive appearance, excellent processability,

2025-12-30

The 5052 H32 aluminum coil uses a color coating process that involves continuously rolling a polyester (PE), fluorocarbon (PVDF), or other coatings onto the aluminum coil substrate and then baking and curing it.

2025-12-05

Learn what shapes 1100 H14 prepainted aluminum coil price: alloy and temper basics, PE/PVDF coating processes, key specifications, and typical applications.

2026-01-13