Description:

| Alloy: | 3105 |

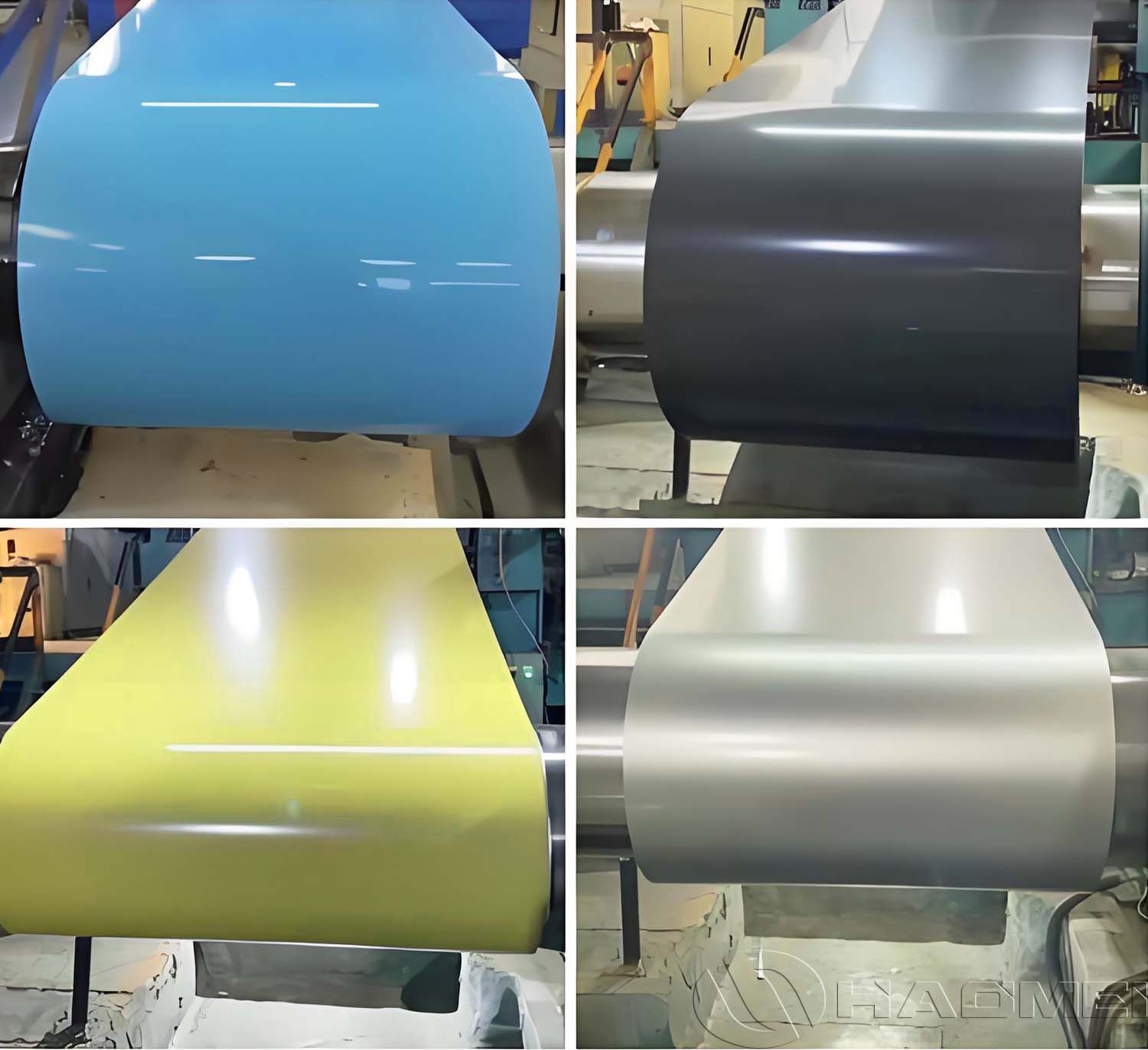

| Surface Treatment: | Color coated, multiple colors available |

| Paint Type: | PE, PVDF, HDP, SMP |

| Coating Thickness: | Front: 15-25 μm / Back: 5-10 μm |

| Alloy: | 3105 |

| Surface Treatment: | Color coated, multiple colors available |

| Paint Type: | PE, PVDF, HDP, SMP |

| Coating Thickness: | Front: 15-25 μm / Back: 5-10 μm |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

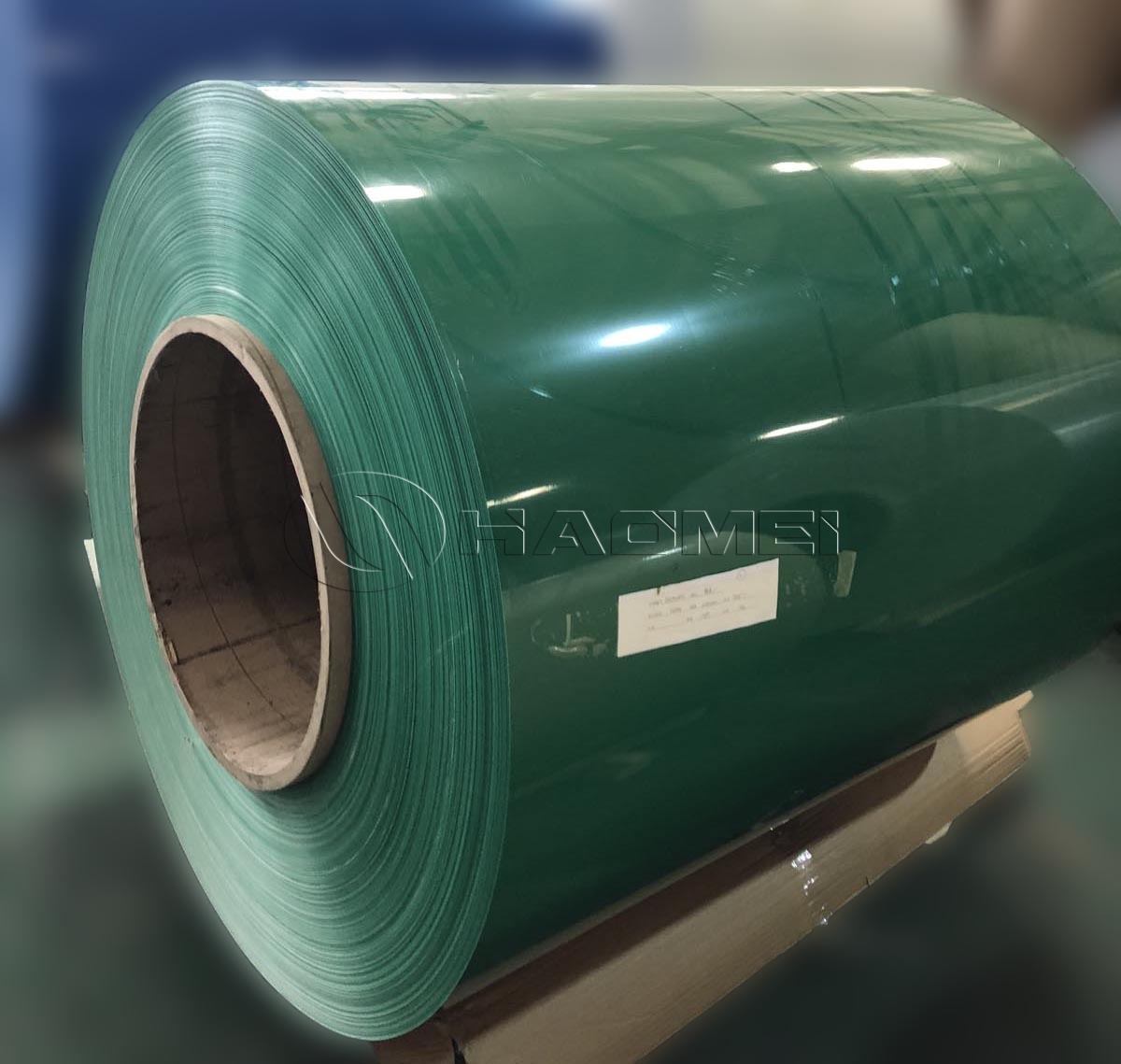

3105 color coated aluminum coil is a new type of metal material made from 3105 aluminum-manganese alloy as the base. Its surface is treated with a color coating for decorative and protective purposes.

The 3105 aluminum alloy belongs to the Al-Mn series. Compared with pure aluminum coils (1050, 1060), the addition of 0.3%-0.8% manganese increases strength and corrosion resistance by approximately 20%, making it widely used in construction, decoration, and industrial applications.

This color coated aluminum coil is produced using advanced pre-roller coating technology. On a continuous production line, the aluminum substrate is first chemically pretreated, then coated using primer and topcoat processes. This method ensures even coating distribution, excellent adhesion, and a decorative yet protective colored surface.

Compared with traditional spray coating, pre-roller coating provides more uniform coating, better quality stability, and lower environmental impact. The continuous production line also improves efficiency and ensures consistent product quality, making it ideal for architectural curtain walls, roofing panels, decorative materials, and various industrial applications.

| Alloy | 3105 |

| Temper | HO, H12, H14, H16, H18, H22, H24, H26, H28 |

| Thickness | 0.2mm-6.0mm |

| Width | 80mm-2300mm |

| Length | 1000mm-16000mm |

| Coil Type | DC or CC |

| Surface Treatment | Color coated, multiple colors available |

| Paint Type | PE, PVDF, HDP, SMP |

| Coating Thickness | Front: 15-25 μm / Back: 5-10 μm |

| ID | Φ505mm |

| OD | Φ1200mm |

| Weight per Pallet | ~2 tons |

| Packaging | Standard export packaging with wooden pallet |

| Delivery Time | Within 30 days |

| Origin | Henan, China |

| MOQ | 1-3 tons |

Mechanical Properties

| Property of alloy 3015 | O | H12 | H14 | H16 | H18 | H22 | H24 | H24 | H28 |

| Tensile Strength | 95-130 MPa | 130-165 Mpa | 145-185Mpa | 170-210Mpa | 195-230Mpa | 130-165 Mpa | 145-185Mpa | 170-210Mpa | 195-230Mpa |

| Yield Strength (0.2% offset) | 35-60 MPa | 110-145 MPa | 125-165 MPa | 150-190 MPa | 175-210 MPa | 100-135 MPa | 115-155 MPa | 140-180 MPa | 165-205 MPa |

| Elongation at Break | 18-22% | 8-12% | 6-10% | 4-8% | 3-6% | 8-12% | 6-10% | 4-8% | 3-6% |

| Hardness (Rockwell B) | 30-40HB | 40-50HB | 45-55HB | 55-75HB | 60-70HB | 40-50HB | 45-55HB | 55-75HB | 60-70HB |

Physical Properties

| Property | Value |

| Density | 2.7 g/cm³ |

| Melting Point | 643-657°C |

| Thermal Conductivity | 209 W/m·K |

| Electrical Conductivity | 61% IACS |

| Thermal Expansion Coefficient | 23.1×10⁻⁶/°C (20-100°C) |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | remainder |

Excellent Mechanical Performance:

Higher tensile strength than industrial pure aluminum, able to withstand moderate stretching without cracking.

Outstanding Corrosion Resistance:

Manganese addition refines grain structure, reduces electrochemical corrosion tendencies, and, combined with the coating, significantly enhances corrosion resistance and service life.

Good Workability:

High plasticity in annealed state; moderate plasticity in semi-cold hardened state. Can be cold-rolled, stamped, bent, or formed into curved or shaped components.

Decorative Excellence:

Wide color selection: white, metallic, dark, gold series. Custom colors available.

Lightweight:

Maintains aluminum's low density (~2.73 g/cm³), roughly 1/3 of steel, reducing structural load.

Eco-Friendly:

Aluminum is fully recyclable.

Cost-Effective:

Lower manganese content compared to 3003 alloy reduces material cost while maintaining good performance.

Vs 1060: 3105 has higher strength and better corrosion resistance; 1060 is cheaper and more ductile but weaker in load-bearing and outdoor durability.

Vs 3003: 3105 offers slightly higher strength and improved formability, while retaining excellent corrosion resistance; ideal for exterior walls, roofs, and home appliance panels requiring medium strength.

Vs 5052: 5052 has superior strength and corrosion resistance but higher cost, mainly used in marine and industrial applications; 3105 balances cost and performance for large-scale architectural and decorative use.

Overall, 3105 color coated aluminum coil combines strength, weather resistance, and economic efficiency, making it suitable for mid- to high-end applications.

Q1: Is 3105 color coated aluminum coil suitable for long-term outdoor use?

A1: Yes. With high-quality PE or PVDF coating, it resists UV radiation and corrosion, making it ideal for exterior walls, roofs, and curtain wall systems.

Q2: Can 3105 color coated aluminum coil undergo secondary processing?

A2: Yes. It has good formability and ductility, suitable for bending, stamping, cutting, rolling, welding, and other operations for industrial and architectural needs.

Q3: How to select the thickness of 3105 color coated aluminum coil?

A3: Thickness usually ranges from 0.3mm-1.5mm:

0.3-0.5mm: Decorative applications like ceilings and appliance shells

0.5-1.0mm: Exterior walls and roofing panels

1.0-1.5mm: Structural components requiring higher load-bearing capacity

Q4: Can the colors of 3105 color coated aluminum coil be customized?

A4: Yes. Standard colors include silver, champagne, red, blue, gray, and others. Custom colors according to RAL color charts are available.

Q5: How is quality ensured?

A5: High-quality production includes surface pretreatment, coating application, high-temperature baking, and multiple tests: adhesion, impact resistance, salt spray, UV resistance, and color difference inspections to ensure long-term stability and aesthetic appearance.

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

Learn what shapes 1100 H14 prepainted aluminum coil price: alloy and temper basics, PE/PVDF coating processes, key specifications, and typical applications.

2026-01-13