Description:

| Alloy: | 5083 |

| Temper: | O,H32,H34,H36,H38,H112,H116,H321,et c |

| Coatings: | Polyester (PE), Fluorocarbon (PVDF), Epoxy resin |

| Coating thickness: | 5-8 μm, 15-18 μm, 25-28 μm |

| MOQ: | 1-3 tons |

| Alloy: | 5083 |

| Temper: | O,H32,H34,H36,H38,H112,H116,H321,et c |

| Coatings: | Polyester (PE), Fluorocarbon (PVDF), Epoxy resin |

| Coating thickness: | 5-8 μm, 15-18 μm, 25-28 μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

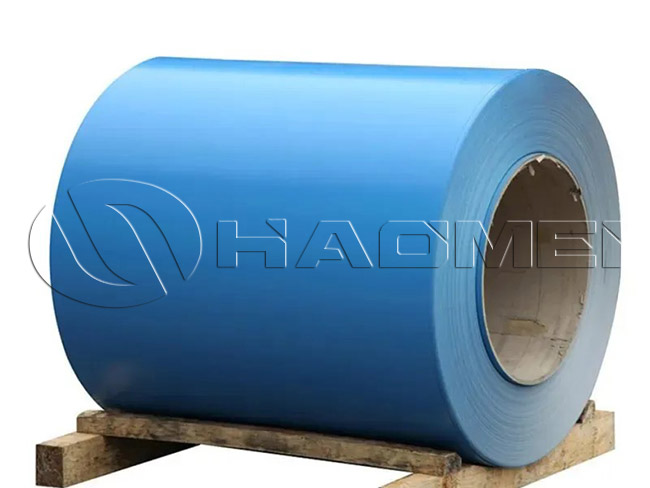

5083 color-coated aluminum coil is a composite material made by applying chemical pretreatment and a colored coating on the surface of 5083 aluminum coil substrate. It not only inherits the excellent corrosion resistance of the 5083 alloy (especially against seawater and industrial environments), high strength, and superior weldability, but also gains outstanding decorative properties and additional protection through the color coating layer.

5083 aluminum alloy belongs to the Al-Mg series and is one of the highest-strength alloys in this group. It is often known as a "marine-grade aluminum alloy." The addition of magnesium significantly increases the strength of aluminum while maintaining good ductility; the addition of manganese and chromium further enhances corrosion resistance and processability.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

| Coating Type | Main Component | Coating Thickness (μm) | Performance Features |

| PVDF | Fluorocarbon resin | ≥25 | Exceptional weather resistance, UV resistance, acid/alkali corrosion resistance, long-lasting color, long service life, ideal for high-end outdoor applications. |

| PE | Polyester resin | 15-20 | Good adhesion, rich colors, economical, suitable for indoor or outdoor applications with moderate weathering requirements. |

Excellent corrosion resistance & long service life:

The marine-grade corrosion resistance of 5083 substrate combined with the superior weatherability of PVDF coating ensures long-term structural stability and appearance even in harsh environments such as coastal regions, high-salt areas, or heavy industrial pollution.

High strength with lightweight performance:

Retains the high strength of 5083 alloy, suitable for load-bearing structural parts, while benefiting from aluminum's inherent lightweight nature to reduce overall structural weight.

Cold-working capability:

Thin-walled parts such as fuel tanks and lubrication pipes can be formed through deep-drawing processes. Plasticity remains good in semi-cold-worked conditions, but decreases after extensive cold-work hardening.

Aesthetic and functional integration:

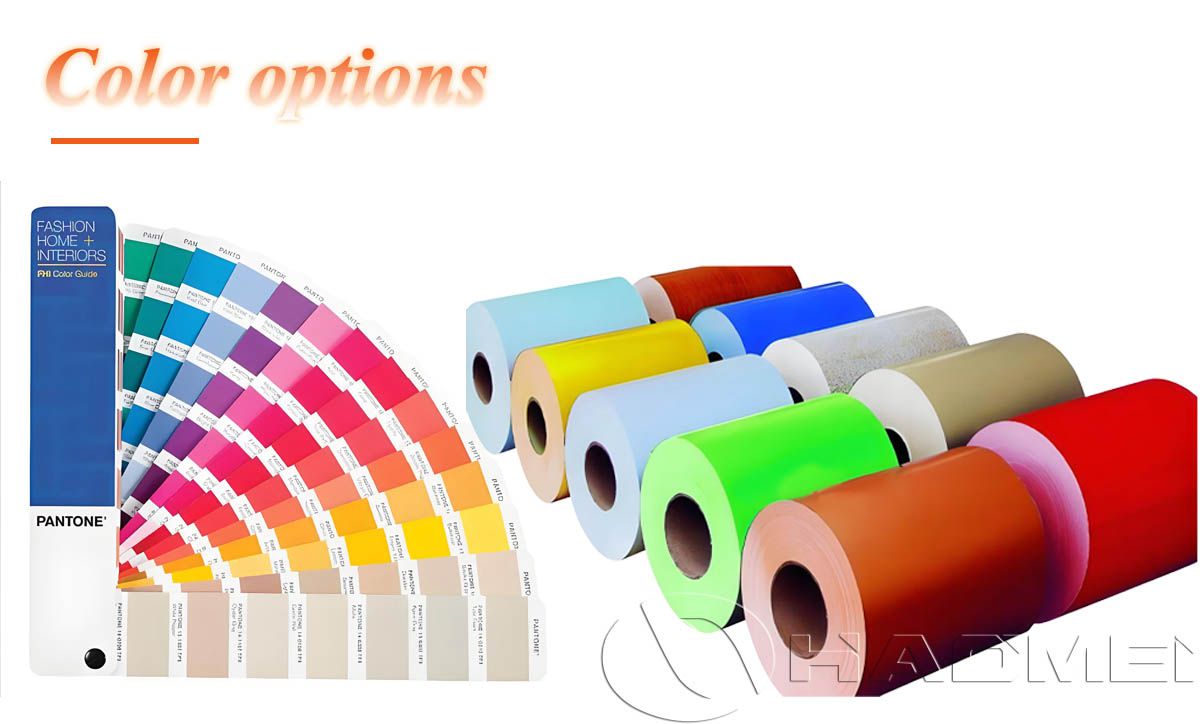

The color coating offers rich colors and surface effects (glossy, matte, metallic, brushed), meeting personalized design needs for architectural and transportation applications.

Excellent processing performance:

Maintains good formability and can be stamped, bent, or deeply fabricated without damaging the coating.

Environment-friendly performance:

Resistant to salt, alkali, and acid rain; does not corrode, produce toxic bacteria, release harmful gases, or cause corrosion of keels and fasteners. Fire resistance meets or exceeds national B1 rating.

Flatness:

No high-temperature composite indentations, no residual stress, and the sheet remains flat without deformation after cutting.

| Alloy | 5083 |

| Temper | O,H32,H34,H36,H38,H112,H116,H321,etc |

| Thickness | 0.18-3.0 mm |

| Width | 100-1500 mm |

| Length | Customized per customer request |

| Coatings | Polyester (PE), Fluorocarbon (PVDF), Epoxy resin |

| Coating thickness | 5-8 μm, 15-18 μm, 25-28 μm |

| Colors | Solid colors, metallic colors, wood-grain, marble-grain |

| Film | Optional protective film available |

| MOQ | 1-3 tons |

| Production Process | Cast-rolled or hot-rolled |

| Applications | Automobiles, machinery, aluminum composite panels, aluminum solid panels, aluminum ceiling systems, interior decoration, etc. |

Mechanical Properties

| Property (5083) | Temper: O | Temper: H32 | Temper: H34 | Temper: H36 | Temper: H38 |

| Tensile Strength | ≥275MPa | ≥315MPa | ≥350MPa | ≥370MPa | ≥390MPa |

| Yield Strength (0.2% offset) | ≥125MPa | ≥245MPa | ≥275MPa | ≥305MPa | ≥335MPa |

| Elongation at Break | ≥16% | ≥8% | ≥6% | ≥5% | ≥4% |

| Hardness (Rockwell B) | No work hardening | Low work hardening | Medium work hardening | High work hardening | Very high work hardening |

Physical Properties

| Property of alloy 5083 | Value |

| Density | 2.66 g/cm³ |

| Melting Range | 577-610°C |

| Thermal Conductivity | 118 W/m·K |

| Electrical Conductivity | 35% IACS |

| Thermal Expansion Coefficient | 13.1–14.0×10⁻⁶/°C (20–100°C) |

| Modulus of Elasticity | 69 GPa |

| Poisson's Rate | 0.33 |

| Specific Heat Capacity | 0.215 cal/g·°C |

| Corrosion Resistance | Excellent in atmospheric, seawater, and chemical environments. |

| Machinability | Moderate |

| Weldability | Good |

1. Marine & Offshore Engineering

Widely used in shipbuilding and offshore structures, including hull structures, decks, bulkheads, and offshore platform components.

For this industry, H116 and H321 tempers are commonly used for optimal salt-spray corrosion resistance.

2. Transportation Industry

In new-energy vehicles, 5083-O battery shell side plates have become a key application, offering tensile strength above 280 MPa plus excellent forming and corrosion resistance.

Color-coated aluminum coils are also used in truck bodies, oil tankers, coal transport vehicles, and other commercial vehicles-balancing durability with lightweight design.

3. Construction & Decoration

Used for roofing, wall cladding systems, and decorative components of large public buildings, offering long-lasting protection and durability.

4. Special Industrial Applications

Applied in pressure vessels, LNG storage tanks, TV towers, and specialized industrial equipment, as well as electrical enclosures and high-voltage switchgear.

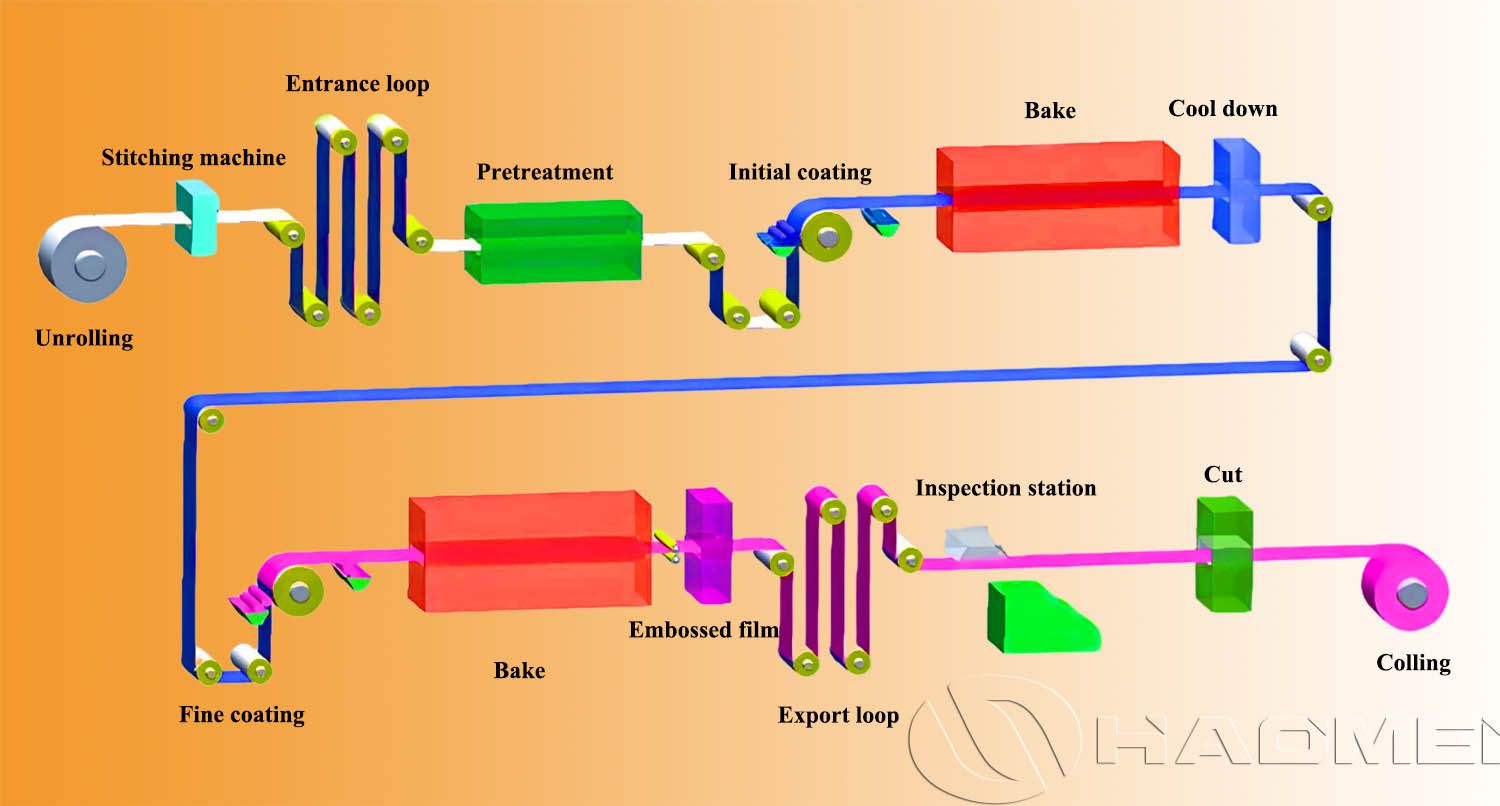

Substrate preparation: Use hot-rolled 5083 aluminum coil, then anneal and level.

Surface pretreatment: Degreasing, water washing, and chemical conversion coating to enhance adhesion.

Coating application: Precision roller-coating to ensure uniform paint thickness and gloss.

High-temperature curing: Cured at around 200°C to form a dense protective film; embossing, printing, or film-lamination can be added as needed.

Cooling and coiling: After cooling, leveling, and coiling, the finished color-coated aluminum coil is produced.

3003 H14 color-coated aluminum coil uses PE/PVDF coating and features excellent formability, high corrosion resistance, and weldability.

2025-12-17

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems.

2026-01-19

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02