Description:

| Alloy: | 5754 |

| Temper: | H111, H22, H32, H34, H112, H38, HO |

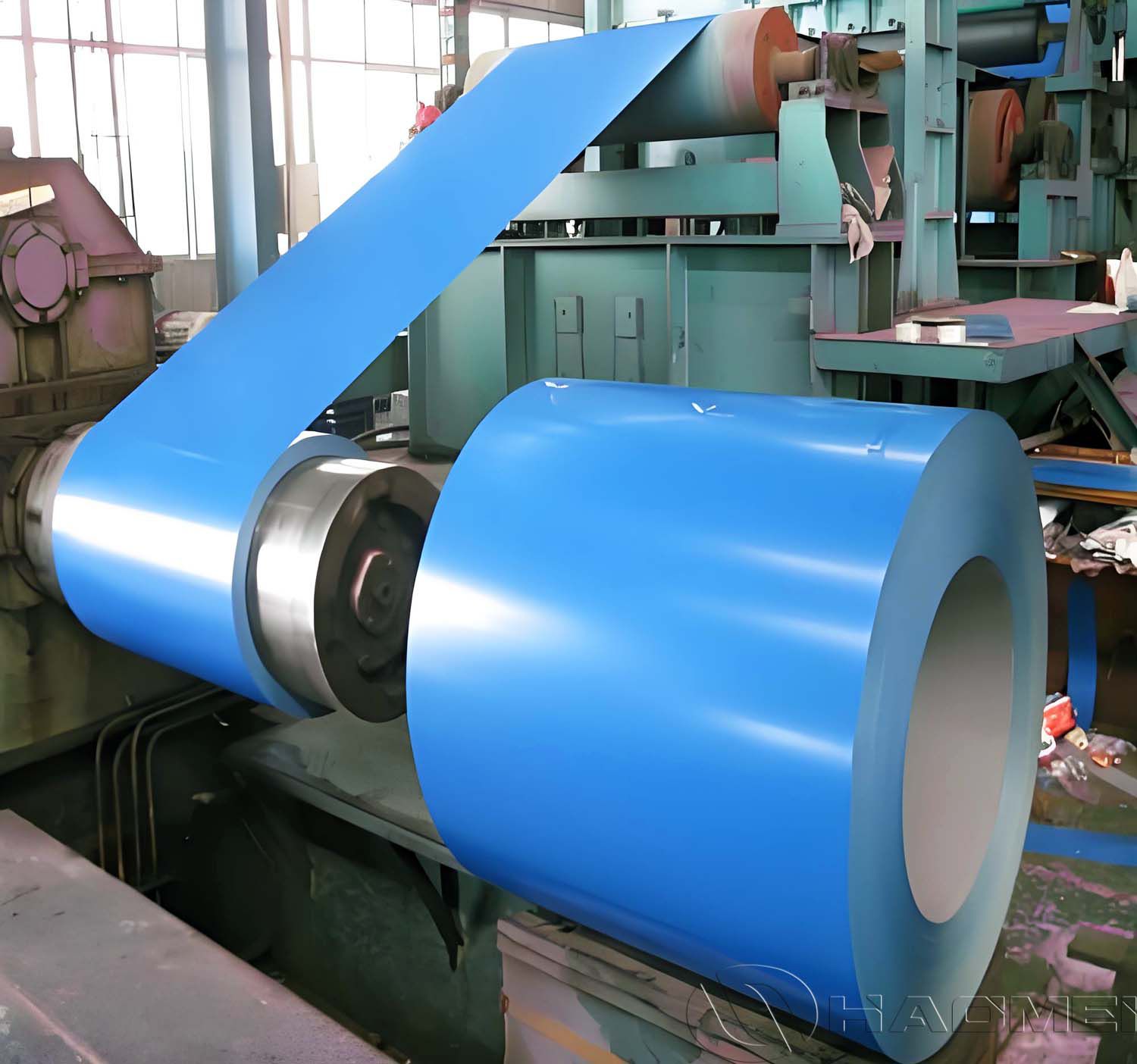

| Surface Treatment: | Color coating, multiple colors available |

| MOQ: | 1-3 tons |

| Alloy: | 5754 |

| Temper: | H111, H22, H32, H34, H112, H38, HO |

| Surface Treatment: | Color coating, multiple colors available |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

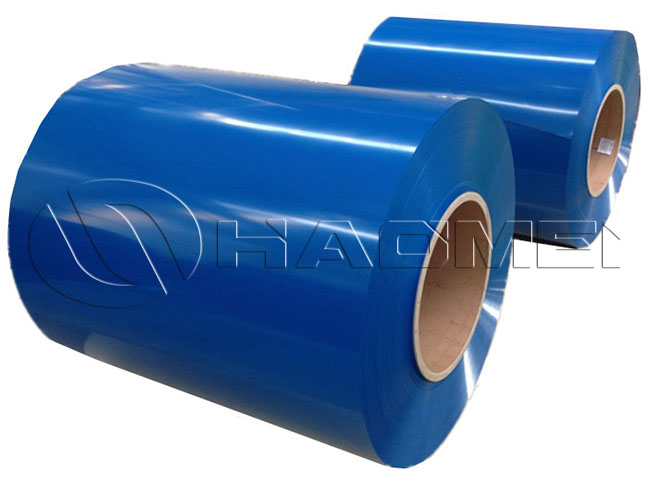

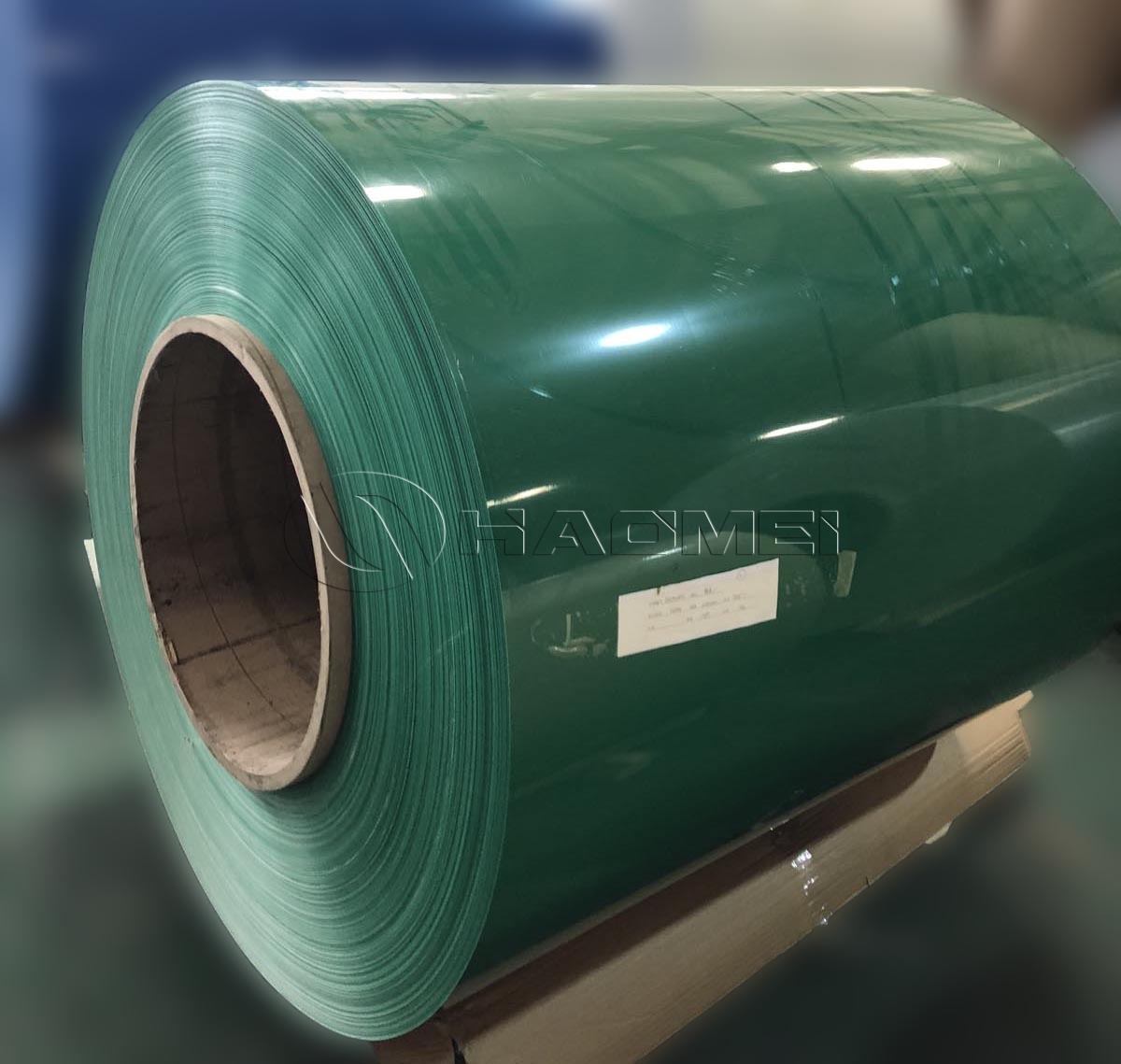

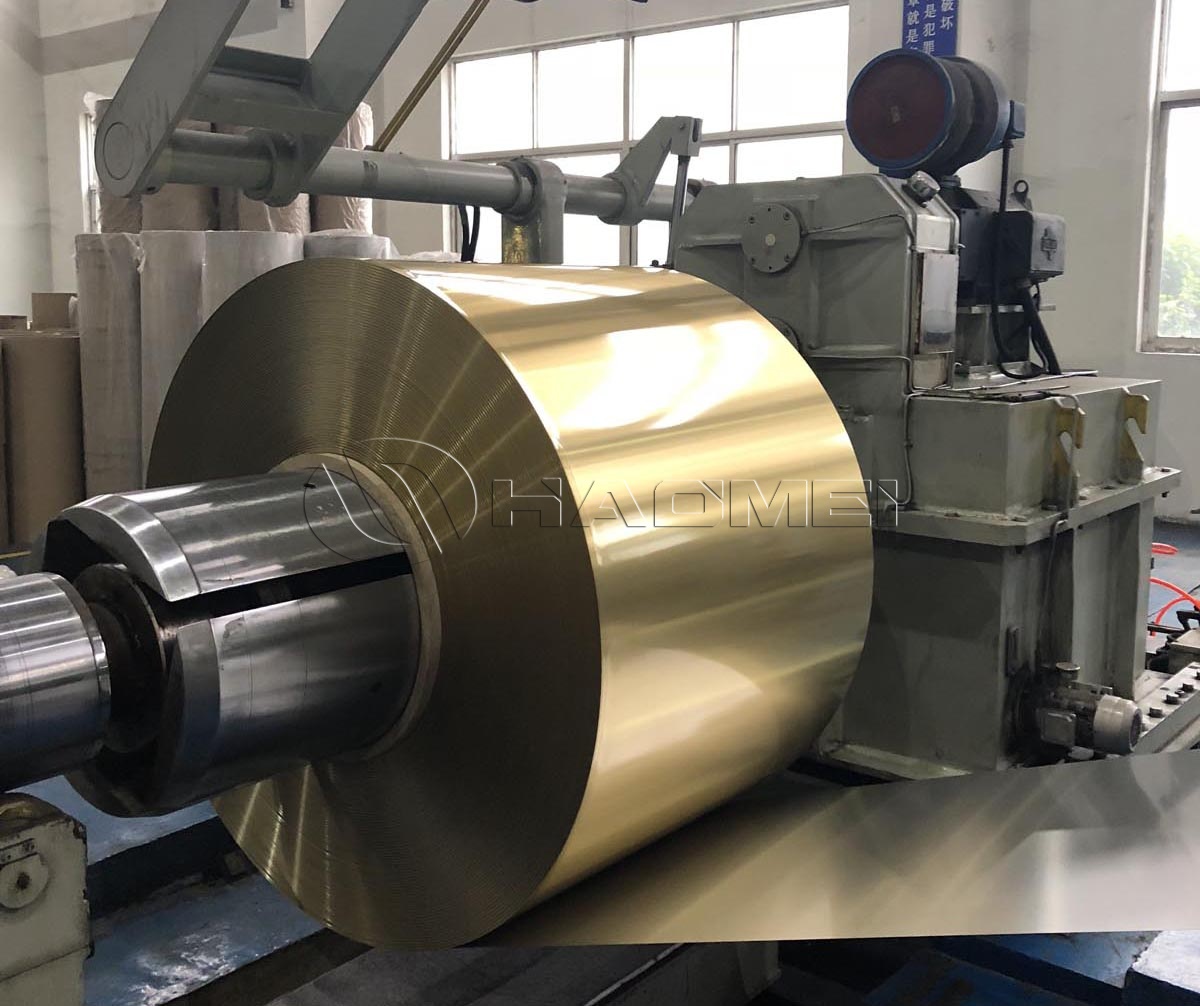

The 5754 color coated aluminum coil is a decorative metal coil made from 5754 aluminum-magnesium alloy sheets. After degreasing, chemical pre-treatment, roll coating, and baking, an organic coating is formed on the surface. This material combines the lightweight, high-strength, and corrosion-resistant properties of aluminum alloy with the aesthetic appeal and weather resistance of the color coating. It is a high-end material integrating both functionality and decoration and serves as an ideal alternative to traditional steel coils and color steel sheets.

The 5754 alloy belongs to the 5xxx Al-Mg series, with magnesium content ranging from 2.6% to 3.6%. It offers medium strength, excellent fatigue resistance, and outstanding seawater corrosion resistance. After color coating, it not only improves decorative appearance but also significantly enhances surface oxidation, acid/alkali resistance, and UV resistance.

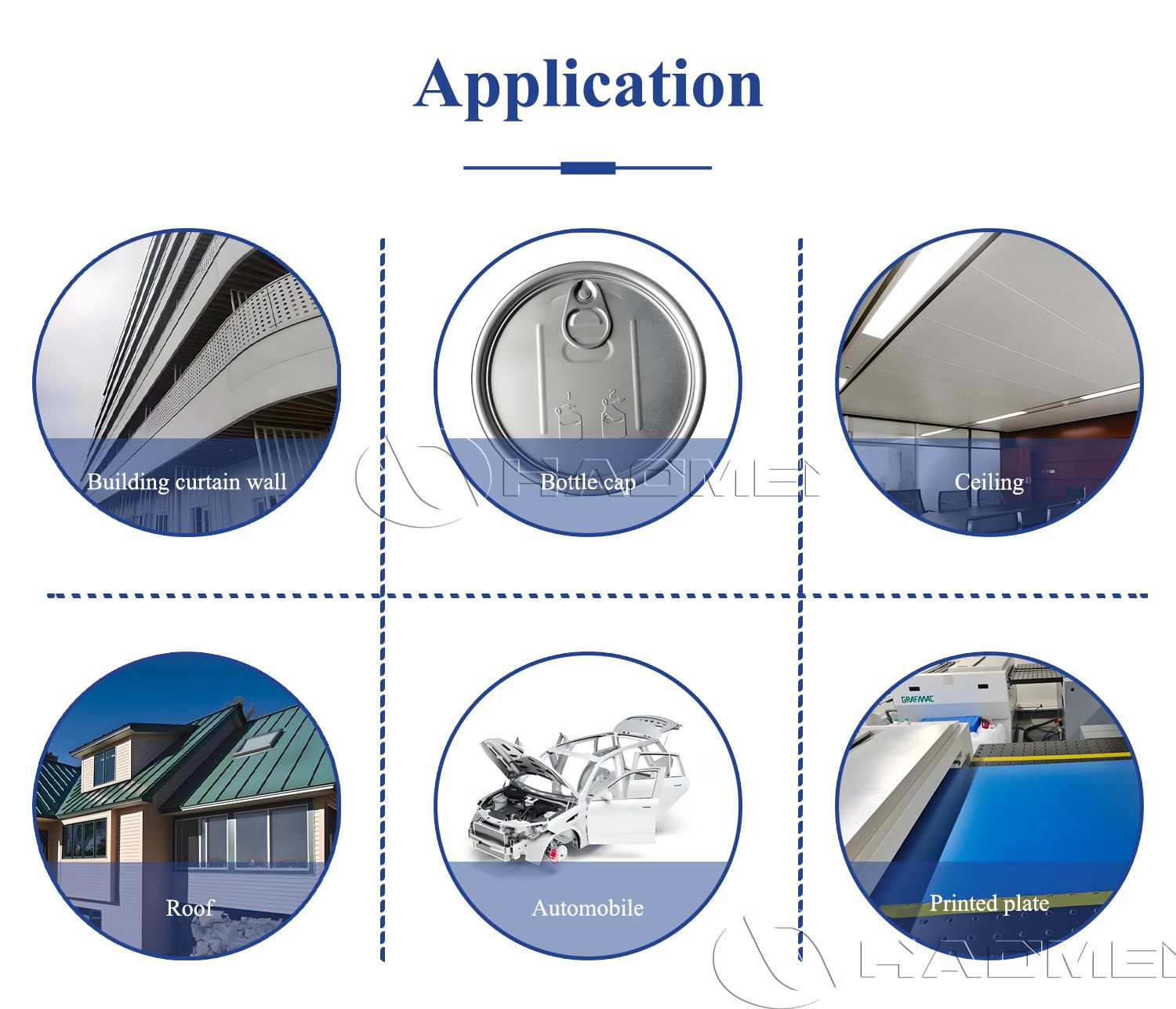

In applications such as architectural facades, ship hulls, automobile bodies, rail transport, storage tanks, and appliance panels, 5754 exhibits higher strength than 5052, making it particularly suitable for floors and curtain wall applications.

O (Annealed Soft): Suitable for deep drawing and stretching

H12 / H14: Semi-hard, moderate strength

H24 / H32: Medium strength, well-balanced performance

H111 / H112: Commonly used in marine and structural components, high toughness and ductility

Polyester Coating (PE): Flexible with a wide color range; suitable for indoor and general outdoor use; warranty up to 10 years.

Fluorocarbon Coating (PVDF): Extremely weather-resistant; suitable for harsh environments and high-end construction; warranty over 20 years.

| Alloy | 5754 |

| Temper | H111, H22, H32, H34, H112, H38, HO |

| Thickness | 0.5mm - 6.0mm |

| Width | 100mm - 2300mm |

| Length | 1000mm - 16000mm |

| Surface Treatment | Color coating, multiple colors available |

| Base Coil | DC coil |

| Weight per Pallet | Approx. 0.5-2.5 MT |

| Salt Spray Resistance | Superior to 3xxx series, meets high corrosion resistance standards |

| Packaging | Export-standard wooden pallet |

| Packing Method | Upright or flat stacking |

| Delivery Time | Within 30 days |

| Origin | Zhengzhou, China |

| MOQ | 1-3 tons |

Mechanical Properties

| roperty of alloy 5754 | O | H12/H32 | H14/H34 | H16/H36 | H18/H38 |

| Tensile Strength | 195-240MPa | 220-260 MPa | 245-285 MPa | 270-310 MPa | 295 -335 MPa |

| Yield Strength (0.2% offset) | 80-120 MPa | 165-200 MPa | 205-240 MPa | 230-270MPa | 260-300 MPa |

| Elongation at Break | 22-28% | 16-20% | 12-16% | 8-12% | 6-10% |

| Hardness (Rockwell B) | No work hardening | Low | Medium | High | Very high |

Physical Properties

| Property of alloy 5754 | Value |

| Density | 2.48 g/cm³ |

| Melting Point | 527–621°C |

| Thermal Conductivity | 190-225 W/m·K |

| Electrical Conductivity | 30-40% IACS |

| Thermal Expansion Coefficient | 13.1-13.3×10⁻⁶/°C (20–100°C) |

| Modulus of Elasticity | 69GPa |

| Poisson's Rate | 0.33 |

| Specific Heat Capacity | 0.22 BTU/(lb·°F) (920 J/(kg·°C)) |

| Shear Modulus | 26 GPa |

| Bulk Modulus | 69 GPa |

Chemical Composition of 5754 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | remainder |

Exceptional Corrosion Resistance: Excellent resistance to salt spray, seawater, and humid environments. Superior to 3xxx series alloys; ideal for coastal, marine, and heavy industrial areas.

Medium to High Strength: Higher strength than 3003 or 3105 color coated aluminum; good fatigue resistance ensures component stability and longevity.

Excellent Formability: Good cold workability and deep drawing performance; suitable for complex shaping, bending, and stamping.

Outstanding Weldability: Typical weldable alloy; welded joints maintain high strength, critical for shipbuilding and automotive applications.

Long-lasting Decorative Appearance: High-quality color coating provides rich colors and gloss; tightly bonded to the base material, preventing peeling and fading.

Environmentally Friendly & Recyclable: Free of heavy metals and VOCs; complies with RoHS and REACH standards; 100% recyclable.

Construction: Exterior wall curtain systems, roof tiles, ceiling panels, aluminum honeycomb panels, roller shutter doors; used in airports, exhibition centers, metro stations, and commercial complexes.

Transportation: Ship hulls, yacht decks, vehicle interior/exterior panels, RV exteriors, refrigerated truck bodies; vibration and fatigue resistant, lightweight, reduces energy consumption.

Home Appliances & Industrial Equipment: Refrigerator side panels, washing machine housings, air conditioner decorative panels, machine enclosures; industrial equipment covers, elevator panels, reflector plates for lighting.

Packaging & Storage Tanks: Food packaging, beverage cans, liquid storage tanks, chemical containers; acid/alkali resistant, ensures content safety.

Versus 3xxx Series: Higher magnesium content provides superior salt spray and seawater corrosion resistance; ideal for ship hulls, coastal buildings, and transport equipment.

Versus 3105 Alloy: Higher yield and tensile strength; suitable for structural applications while maintaining excellent formability and weldability.

Versus 5052 Alloy: Similar strength with better surface smoothness and coating adhesion; widely used in curtain wall decoration and appliance panels.

Overall: 5754 color coated aluminum coil balances strength, corrosion resistance, and formability, positioning it as a medium-high strength alloy ideal for demanding decorative and structural applications.

1100 / 3003 color-coated aluminum coils are lightweight, weather-resistant, and have good processability, making them suitable for billboards and traffic signs.

2025-12-23

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

This article introduces color coated aluminum coil engineered for roofing sheets, positioning it as a lightweight, corrosion-resistant, and formable substrate for roll-formed roof panels in industrial, commercial, and residential buildings.

2026-01-07