Description:

| Alloy: | 5005 |

| Coating Type: | PVDF / PE / EPOXY / PU |

| Warranty: | PE 5-10 years, PVDF 15-20 years |

| Color: | Any RAL or custom request |

| MOQ: | 1-3 tons |

| Alloy: | 5005 |

| Coating Type: | PVDF / PE / EPOXY / PU |

| Warranty: | PE 5-10 years, PVDF 15-20 years |

| Color: | Any RAL or custom request |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

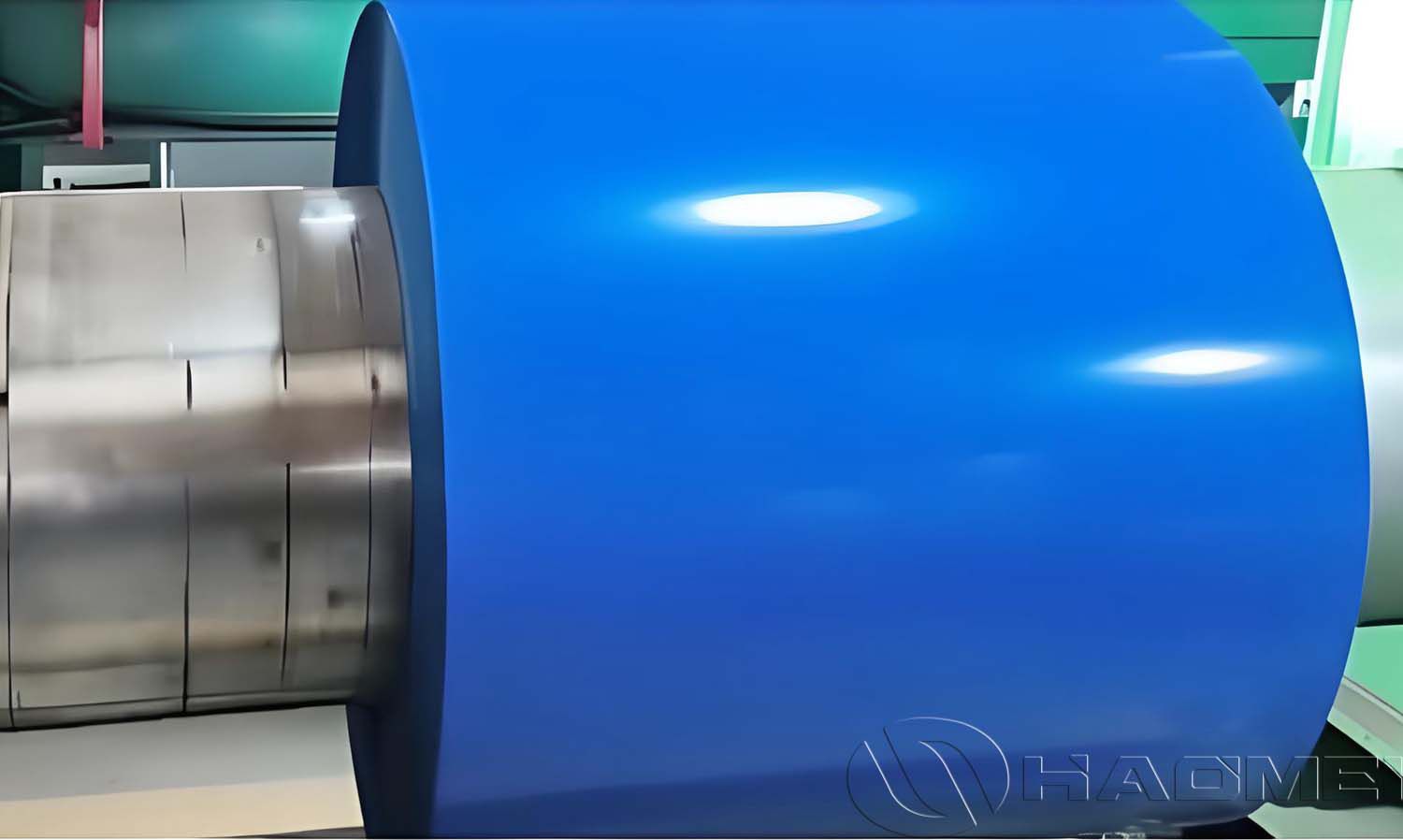

The 5005 color coated aluminum coil is a high-performance aluminum material made from 5005 aluminum-magnesium alloy as the substrate. Using advanced roll-coating technology, it is uniformly coated with high-performance paints such as PVDF and PE, followed by high-temperature baking and curing.

The 5005 alloy belongs to the Al-Mg corrosion-resistant aluminum series, offering medium strength, excellent corrosion resistance, and good weldability. After color coating, the surface forms a durable protective layer along with the colored coating, enhancing both the decorative appearance and weather resistance, extending the service life of the material.

5005 coated aluminum coils are commonly used in building exterior wall decoration, roofing systems, ceiling systems, traffic facilities, advertising signs, and other fields. They are an ideal material for high-end building decoration and industrial manufacturing.

Exceptional Durability: Especially with PVDF (Polyvinylidene Fluoride) coating, it offers up to 20+ years of long-term weather resistance, effectively protecting against UV radiation and acid rain.

Rich and Lasting Colors: Available in standard and custom colors with high color saturation and excellent color retention, ensuring outdoor applications remain vibrant without fading or chalking.

Perfect Gloss and Smoothness: Coating thickness is uniform, and the surface is smooth and fine, meeting high aesthetic standards.

Excellent Mechanical Performance: 5005 color coated aluminum exhibits excellent processing and forming properties. As a non-heat-treatable alloy, its strength can be enhanced via cold working.

Eco-friendly and Recyclable: Free of harmful substances such as chromium, lead, or mercury, and 100% recyclable, complying with green building and sustainability requirements.

| Temper | O, H18, H22, H44, etc. |

| Thickness | 0.2mm - 3.0mm |

| Width | 10mm - 2000mm |

| Length | 100mm - 16000mm |

| Inner Diameter | 405mm / 505mm |

| Coating Type | PVDF / PE / EPOXY / PU |

| Warranty | PE 5-10 years, PVDF 15-20 years |

| Coating Thickness | Single-side: 4-20 μm Double-side: 25-28 μm Triple-side: 35-38 μm |

| Color | Any RAL or custom request |

| Surface Finish | Glossy, matte, metallic, brushed, wood grain, stone texture |

| Delivery Forms | Coil, sheet, strip |

| Single Coil Weight | 3-8 MT |

| Coil Inner Diameter | 508mm or 405mm |

| Protective Film | Single or double-sided PE |

| Applications | Roof systems and ceiling decorations for airports, train stations, exhibition halls, factories, and stadiums |

| Origin | Zhengzhou, China |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | State | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

| 5005 | O | >0.2-0.5 | 100-145 | ≥35 | ≥15 | 33-43 |

| >0.5-1.0 | ≥20 | |||||

| >1.0-4.0 | ≥25 | |||||

| H22 | >0.2-0.5 | 125-165 | ≥80 | ≥12 | 30-53 | |

| >0.5-1.0 | ≥15 | |||||

| >1.0-4.0 | ≥18 | |||||

| H24 | >0.2-0.5 | 145-185 | ≥110 | ≥8 | 40-60 | |

| >0.5-1.0 | ≥10 | |||||

| >1.0-4.0 | ≥10 | |||||

| H26 | >0.2-0.5 | 165-205 | ≥135 | ≥3 | 50-68 | |

| >0.5-1.0 | ≥4 | |||||

| >1.0-4.0 | ≥6 | |||||

| H28 | >0.2-0.5 | ≥185 | ≥165 | ≥2 | 57-68 | |

| >0.5-1.0 | ≥2 | |||||

| >1.0-4.0 | ≥3 |

Chemical Composition of 5005 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5-1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | remainder |

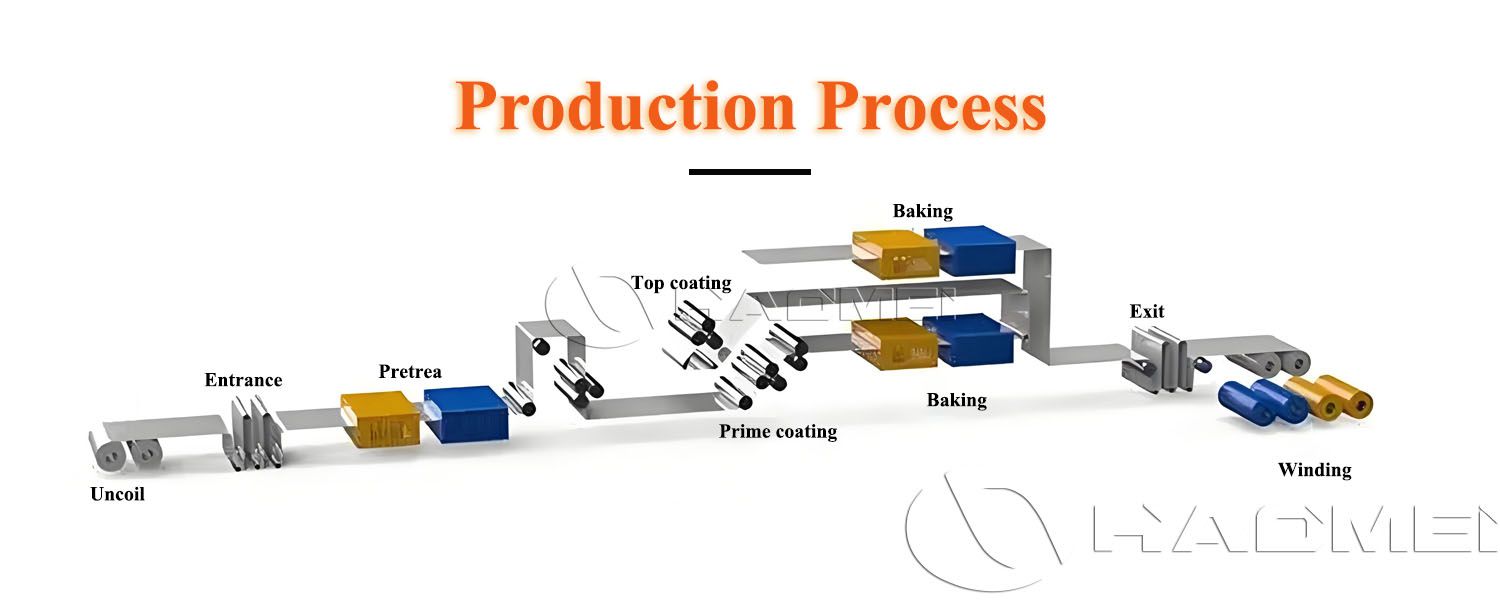

The production of 5005 color coated aluminum uses pre-roll coating technology on continuous production lines. The main steps include:

In the pretreatment stage, the aluminum coil undergoes chemical pretreatment to form a conversion film. This process improves the product's corrosion resistance and increases coating adhesion.

In the coating stage, roller coating technology is used, employing single-bake single-coat, double-bake double-coat, or triple-bake triple-coat processes depending on requirements.

The coatings for color-coated aluminum coils are mainly divided into two categories: polyester-coated aluminum coils (PE) and fluorocarbon-coated aluminum coils (PVDF).

The PVDF coating system for fluorocarbon-coated aluminum coils is divided into pre-roll coating and ordinary spray coating. Pre-roll coating uses paint with a PVDF base content as high as 70%, produced using a horizontal automated two-coat two-bake or three-coat three-bake roller coating process.

In the curing stage, the aluminum strip passes through a curing oven and is baked at a set temperature to ensure that all volatile organic compounds on the aluminum strip are eliminated and the coating is completely cured.

1. Architectural Decoration: Curtain walls, roofing panels, canopies, ceiling panels, window and door trims.

2. Home Appliances & Furniture: Lamp housings, refrigerator panels, appliance cladding, decorative furniture panels.

3. Advertising & Signage: Billboards, signboards, display racks, exterior wall decoration panels.

4. Transportation & Industrial: Vehicle panels, subway station decorations, warehouse doors, equipment enclosures, protective covers.

5. Marine & Coastal Buildings: Suitable for humid or salt-spray environments due to corrosion resistance.

6. Printing Industry: Manufacturing PS, CTP, and UV-CTP printing plates.

The 5052 H32 aluminum coil uses a color coating process that involves continuously rolling a polyester (PE), fluorocarbon (PVDF), or other coatings onto the aluminum coil substrate and then baking and curing it.

2025-12-05

PVDF coated aluminum coil for facades delivers long-lasting color, corrosion resistance, and formability for architectural cladding, panels, and profiles.

2026-01-08

Learn PVDF coated aluminum coil maintenance and cleaning with practical methods, coating system insights, and process factors affecting durability in architectural cladding.

2026-01-27