News

By Hermione

By Hermione

How to Make Aluminum Coil Look Like Wood?

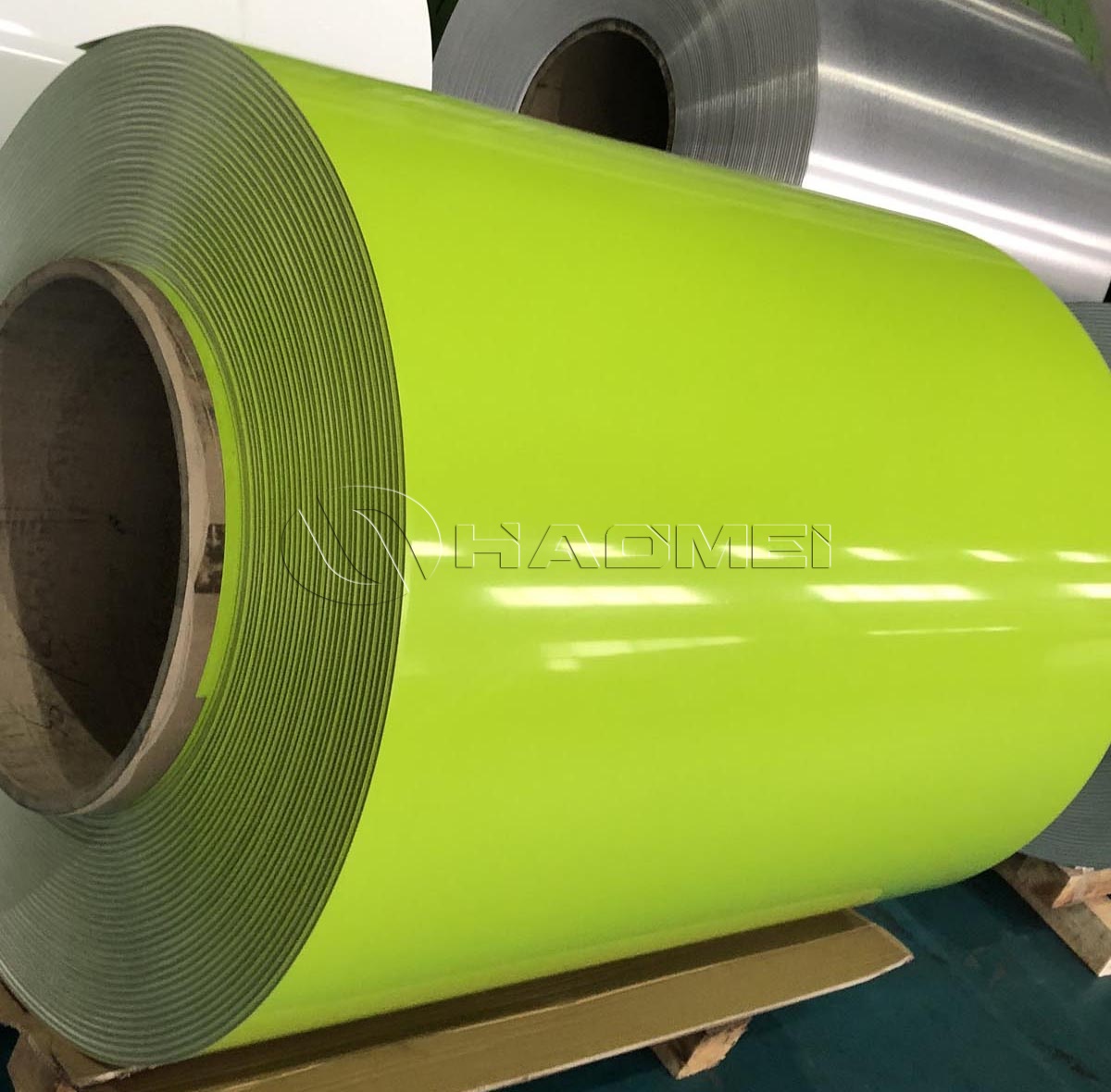

Color coated aluminum coil is a widely used and highly durable material, commonly applied in fields ranging from architectural decoration to automotive manufacturing. While its sleek and modern appearance is attractive, there are times when a more natural and organic look,such as wood is desired.

Wood Grain Coated Aluminum Coil produced by HAOMEI Aluminum uses aluminum alloy coils as the base material. Through advanced surface coating and transfer technologies, realistic wood grain textures are created on the aluminum surface, making it visually similar to natural wood while retaining the superior performance of aluminum.

Common aluminum alloy grades:

1050, 1100, 1200, 3003, 3105, 5005, 5052, etc.

How to Make Aluminum Coil Look Like Wood?

Achieving a realistic wood grain appearance on aluminum is a sophisticated process. Currently, there are two main methods used in the industry: thermal sublimation transfer and roller coating.

1. Thermal Sublimation Transfer Process (Vacuum Film)

This is the most widely used method for producing high-definition and highly realistic wood grain effects.

Base coating:

The aluminum coil is first thoroughly cleaned and then coated with a powder or liquid base coat, typically polyester or PVDF.Film wrapping:

A special plastic film printed with high-resolution wood grain patterns is tightly wrapped around the aluminum surface.Vacuum suction:

Air is removed to ensure perfect contact between the film and the coated surface.Oven curing:

The wrapped coil passes through a high-temperature oven. Through sublimation, the ink on the film turns into gas and penetrates into the coating layer.Cooling and peeling:

After cooling, the film is removed, leaving the wood grain pattern embedded within the coating rather than merely on the surface.

2. Roller Coating Method

This method is highly suitable for large-scale and high-speed production.

Pre-treatment:

The aluminum surface undergoes chemical cleaning and chromate treatment to ensure strong coating adhesion.Multi-layer coating:

Multiple rollers apply several layers of paint. First, a base color is applied, followed by a patterned roller to print the wood grain, and finally a clear topcoat for surface protection.High consistency:

This process ensures consistent patterns across aluminum coils that can extend thousands of meters in length.

Why Choose Wood Grain Coated Aluminum Coil?

Compared with traditional wood materials, wood grain aluminum offers numerous advantages.

1. Exceptional Durability and Weather Resistance

Unlike solid wood, aluminum does not warp, crack, or rot when exposed to moisture. Wood grain aluminum coils with PVDF coating can maintain color stability for over 20 years, even under strong UV exposure and extreme weather conditions.

2. Class A Fire Resistance

Aluminum is non-combustible and meets the highest national fire safety standards. It does not release toxic smoke at high temperatures, making it suitable for high-rise buildings and public spaces with strict fire protection requirements.

3. Lightweight and Easy Installation

Aluminum is significantly lighter than solid wood or wood-plastic composites (WPC), reducing structural load and increasing installation efficiency by up to 40%.

4. Environmentally Friendly and Sustainable

Aluminum is 100% recyclable. Using wood-look aluminum reduces demand for natural wood, helps protect forests, and promotes the use of a material that can be recycled indefinitely.

5. Decorative Appeal

Wood grain patterns give aluminum coils a natural, warm texture that blends seamlessly with both modern minimalist and traditional design styles, enhancing product aesthetics and perceived value.

6. Cost Efficiency

Compared with solid wood, wood grain coated aluminum coils are more cost-effective and better suited for large-scale production.

Wood Grain Aluminum Coil – Technical Specifications

| Alloy | 1100 / 1200 / 3003 / 3005 / 5005 / 5052 |

| Temper | H14 / H24 / H26 |

| Thickness | 0.3 - 3.0 mm |

| Width | 600 - 1600 mm |

| Coating Type | PE / PVDF |

| Coating Thickness | ≥ 25 μm (PVDF) |

| Wood Grain Process | Heat Transfer / Digital Printing |

| Surface Finish | Matte / Semi-gloss |

| Color Options | Oak, Walnut, Teak, Cherry, Custom |

| Application | Exterior / Interior Decoration |

| Standard | ASTM / EN / GB |

Common Wood Grain Patterns

Oak: Clean lines and light-to-medium tones, suitable for modern minimalist styles.

Walnut: Dark color with complex grain, ideal for high-end furniture and packaging.

Cedar: Light color with fine texture, commonly used for outdoor decoration.

Rubberwood: Neutral tone, eco-friendly, suitable for environmentally conscious products.

Main Applications of Wood Grain Aluminum Coil

Architectural façades and curtain wall systems

Interior ceilings and wall decoration

Aluminum ceilings and aluminum baffles

Doors, windows, and sunshade systems

Commercial spaces and public building decoration

Choosing the Right Coating: PE or PVDF?

In the production of wood grain coated aluminum coils, the choice of coating directly affects service life, weather resistance, and application suitability. The two most common options are PE (polyester) and PVDF (fluorocarbon) coatings.

1. PE Wood Grain Coated Aluminum Coil

PE coating is a polymer-based coating material. It is well known for its excellent color vibrancy and high gloss, making it ideal for replicating the "polished" appearance of indoor wooden furniture.

Best suited for:Interior wall cladding, ceilings, kitchen cabinets, and shop decoration.

Service life: Typically 5-10 years under normal indoor conditions

Advantages: More cost-effective, wider gloss range, and excellent flexibility for complex bending

2. PVDF Wood Grain Coated Aluminum Coil

Polyvinylidene fluoride (PVDF) is a fluorocarbon coating considered the "gold standard" for exterior architectural applications. With a fluorine content of at least 70%, it forms strong chemical bonds that resist environmental degradation.

Best suited for:Building façades, roofs, curtain walls, and outdoor signage in high-UV or coastal areas.

Service life: Over 20 years with no significant chalking or fading

Advantages: Outstanding resistance to UV radiation, acid rain, and industrial pollutants

TAG :

-

5052 vs. 3003 Color-Coated Aluminum Coil: Which Material Is Right for You?

3003 and 5052 are the two most commonly used substrates, and they are often made into color-coated aluminum coils for use in building curtain walls, industrial plants and shipbuilding.

2025-12-12

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31