Description:

| Alloy: | 3003 |

| Thickness: | 0.18-3.0 mm |

| Coatings: | Polyester (PE), fluorocarbon (PVDF), epoxy resin |

| Colors: | Solid colors, metallic colors, wood-grain, marble finish |

| Alloy: | 3003 |

| Thickness: | 0.18-3.0 mm |

| Coatings: | Polyester (PE), fluorocarbon (PVDF), epoxy resin |

| Colors: | Solid colors, metallic colors, wood-grain, marble finish |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

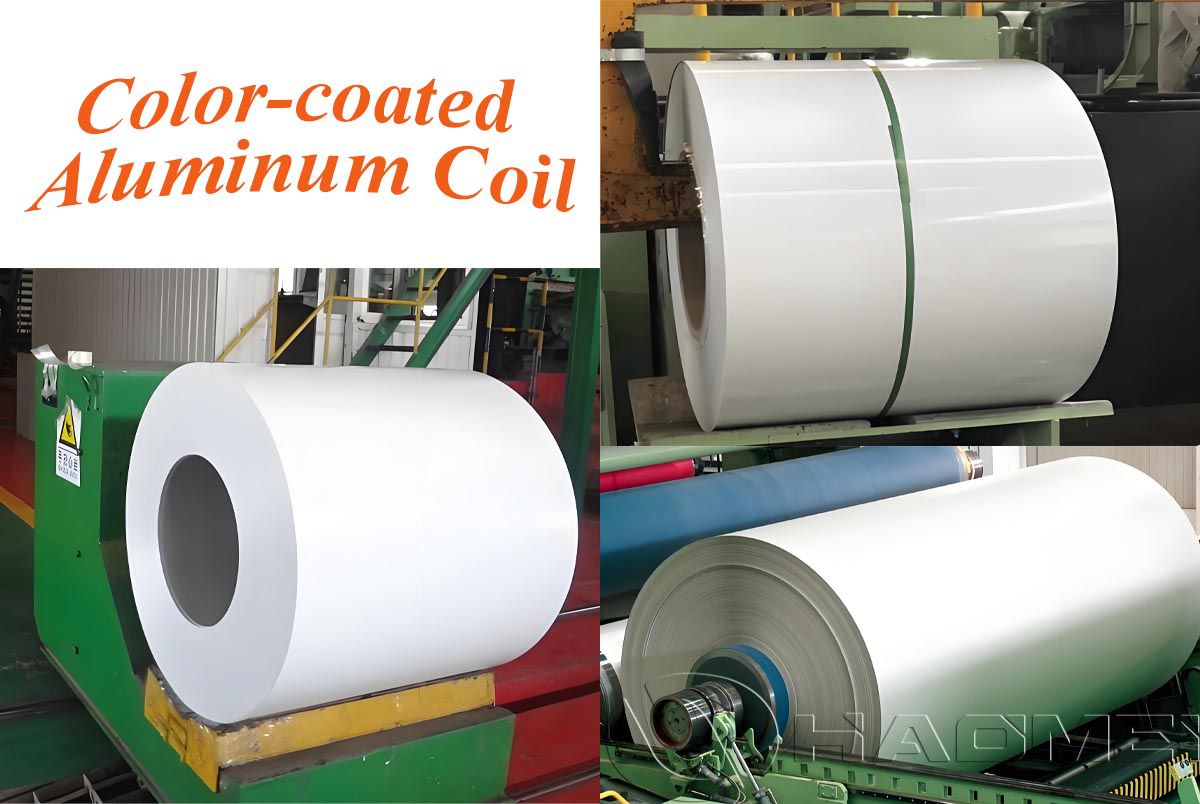

Haomei Aluminum, as a professional manufacturer of color-coated aluminum coils, adopts an advanced roller-coating process. Compared with spray-coating, roller coating ensures zero color difference, excellent flatness, minimal loss, smoother surfaces, strong adhesion, better wear resistance, smaller film-thickness deviation and lower processing cost. We currently offer polyester color-coated coils (PE), anodized aluminum sheets, and fluorocarbon color-coated coils (PVDF), which are widely used in building decoration, electronics, lighting, furniture, and other industries.

3003 color coated aluminum coil belongs to the aluminum–manganese alloy series and is also known as a rust-proof aluminum alloy. It offers good strength and excellent formability, making it suitable for applications requiring moderate strength, good corrosion resistance, and easy processing.

With the addition of a coating layer, 3003 color-coated aluminum coils are used extensively across architectural facades, appliance panels, advertising signage, automotive interior parts, and more.

Compared with 3105 color-coated aluminum coils, 3003 is more cost-effective. Its price is similar to alloys such as 1100, 1060, and 1070, but it provides moderate strength, good atmospheric corrosion resistance, and excellent weldability and cold formability. Its mechanical performance-especially at elevated temperatures-is superior to that of 1000-series alloys.

| Alloy | 3003 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H28 |

| Thickness | 0.18-3.0 mm |

| Width | 100-1500 mm |

| Length | Customizable |

| Coatings | Polyester (PE), fluorocarbon (PVDF), epoxy resin |

| Coating thickness | Single-layer: 4-20 μm Double-layer: 25-28 μm Triple-layer: 35-38 μm |

| Colors | Solid colors, metallic colors, wood-grain, marble finish |

| Film coating | Available |

| Production process | Hot-rolled and cast-rolled |

| Applications | Automotive, machinery, ACP panels, aluminum ceiling panels, interior decoration, etc. |

| Packaging | Export standard packaging, wooden pallets |

| MOQ | 1-3 tons |

Mechanical Properties

| Property of alloy 3003 | O | H12 | H14 | H16 | H18 |

| Tensile Strength | 90-140 MPa | 140-185 Mpa | 165-205Mpa | 185-225Mpa | ≥215Mpa |

| Yield Strength (0.2% offset) | ≤55 MPa | 110-145 MPa | 135-170 MPa | 160-195 MPa | ≥185Mpa |

| Elongation at Break | 20-25% | 8-12% | 6-10% | 4-8% | 3-6% |

| Hardness (Rockwell B) | 35-45HB | 35-45HB | 45-65HB | 55-75HB | 65-85HB |

Physical Properties

| Property | Value |

| Density | 2.7 g/cm³ |

| Melting Point | 643-657°C |

| Thermal Conductivity | 209 W/m·K |

| Electrical Conductivity | 61% IACS |

| Thermal Expansion Coefficient | 23.1×10⁻⁶/°C (20–100°C) |

Heat resistance

Weather resistance

Washable surface

Sound insulation

Acid and alkali resistance

Fire resistance

Lightweight, easy to install

Bright and vivid colors

Excellent formability, corrosion resistance

Eco-friendly and recyclable

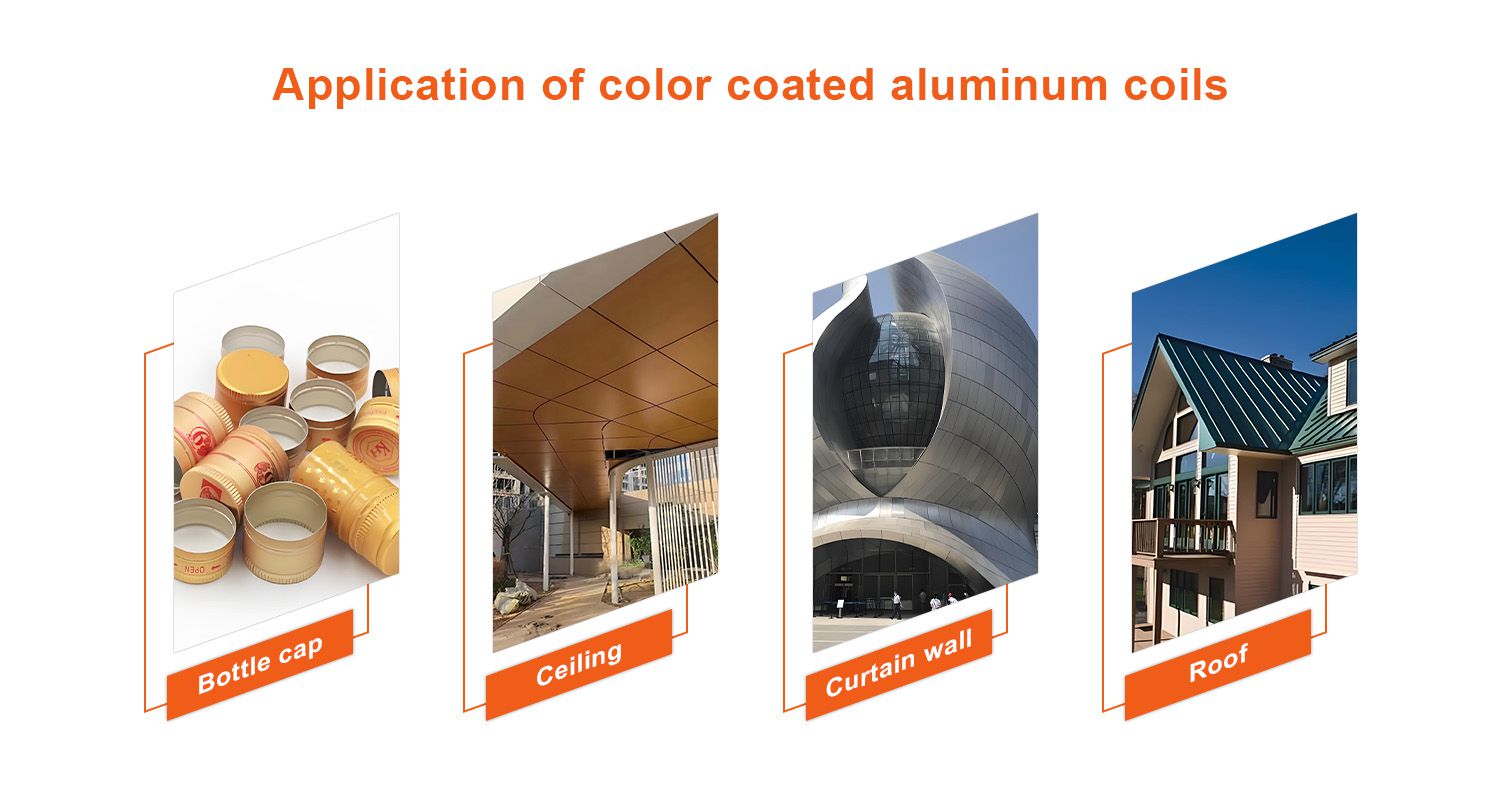

1. Building Decoration

Used in curtain wall panels, aluminum composite panel cores, roofing sheets, fireproof decorative panels, etc.

Capable of withstanding strong wind loads and outdoor weathering, with a service life of 20-25 years.

2. Home Appliances

Used in shells of household appliances such as range hoods, gas stoves, sterilizers, etc.

3003 coated aluminum resists oil fumes and moisture, withstands daily impacts, and remains easy to clean.

3. Transportation

Applied in subway and high-speed rail interiors, including wall panels and luggage rack panels.

It provides adequate strength for passenger impact and meets cleanliness standards.

4. Electronics and Packaging

Suitable for air-conditioning ducts, computer cases, electric appliance panels, food cans, and can lids (both pressurized and non-pressurized).

(1) Polyester (PE) Coating

PE coating is composed of high-molecular polymers and additives, cured at high temperature to form a strong protective film.

Key Advantages: PE coatings are moderately priced, possess excellent adhesion and high flexibility, making them ideal for complex bending and deep processing. They offer a wide range of colors and gloss levels, enabling the creation of various stunning effects.

Applications: Due to its moderate weather resistance, PE coatings are more suitable for interior decoration, appliance casings, and temporary structures or non-coastal outdoor environments where weather resistance requirements are not high.

(2) Fluorocarbon (PVDF) Coating - Superior Durability

PVDF coating uses polyvinylidene fluoride resin as the primary film-forming material, offering extremely strong chemical bonds and the best weather resistance among all coating systems.

Key Advantages: PVDF coatings resist strong UV radiation, acid rain, air pollution, and extreme temperature changes. They ensure that the coating will not fade, chalk, or peel for over ten or even twenty years.

Applications: It is the preferred coating for outdoor building facades, metal roofs, tunnels, high-rise buildings, and coastal areas, effectively extending the lifespan of buildings and maintaining their appearance.

| POLYESTER | PVDF | ||

| Item | Technical requirements | Item | Technical requirements |

| Thickness of coating film | ≥ 18 µm | Thickness of coating film | ≥ 25µm |

| Gloss deviation | gloss<70, tolerance≤10% | Gloss deviation | gloss<70, tolerance≤10% |

| gloss≥70, tolerance≤5% | gloss≥70, tolerance≤5% | ||

| Hardness of pencil | ≥3H | Hardness of pencil | ≥3H |

| Adhesion | no lower than class 1 | Adhesion | no lower than class 1 |

| Flexibility | ≤2T | Flexibility | ≤2T |

| Boiling water resistance | no change (2h) | Boiling water resistance | no change (2h) |

| Color difference | ΔE≤2.0 | Color difference | ΔE≤2.0 |

| MEK | ≥100 times | MEK | ≥150 times |

Color-coated aluminum coils are usually shipped using wooden rack packaging, which meets storage and transportation requirements. The wooden frame consists of two wooden beams on both the top and bottom.

The bottom beams are sufficiently high to accommodate forklift operation. The upper beams are shaped into an arc that matches the coil radius. The beams are secured with bolts, and the bolt ends remain below the arc surface to avoid scratching the coil.

1100 / 3003 color-coated aluminum coils are lightweight, weather-resistant, and have good processability, making them suitable for billboards and traffic signs.

2025-12-23

Learn what shapes 1100 H14 prepainted aluminum coil price: alloy and temper basics, PE/PVDF coating processes, key specifications, and typical applications.

2026-01-13

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04