News

By Hermione

By Hermione

Understanding the Coating Types of Color Coated Aluminum Coil

What Is Color Coated Aluminum Coil?

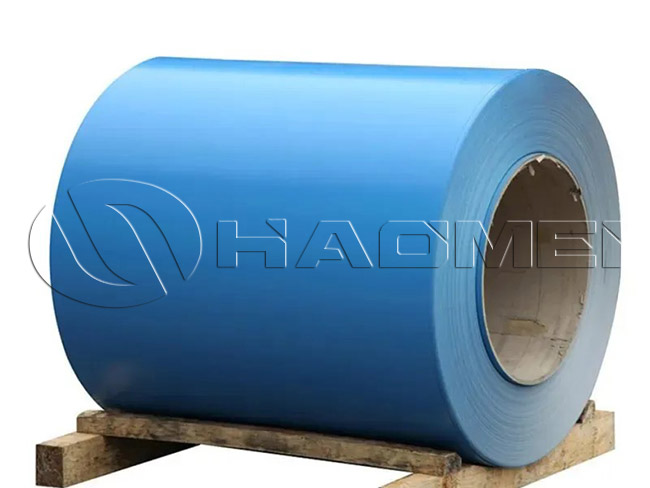

Color coated aluminum coil is produced by applying one or multiple layers of organic coating onto an aluminum alloy substrate through continuous roll-coating followed by high-temperature curing.

The coating is the core of the product-responsible for weather resistance, corrosion resistance, aesthetics and processability.

Structure of Color Coated Aluminum Coil

The coating system is not a single layer; it is a functional multilayer design. A typical three-layer or five-layer structure includes:

(1) Pretreatment Layer (Conversion Coating)

Function: Enhances adhesion between coating and aluminum substrate, passivates the surface, and improves corrosion resistance.

Common types: phosphate chemical film, chromate-free passivation film, chrome-free sealants.

(2) Primer / Tie Coat

Function: Improves adhesion, enhances corrosion resistance, and serves as a barrier protective layer.

(3) Intermediate Coat (optional)

Function: Increases film thickness, covers substrate defects, and improves impact resistance.

(4) Topcoat

Function: Provides color, gloss and decorative effects, along with UV resistance, chemical resistance, and durability.

This layer determines the aluminum coil’s appearance and lifespan.

(5) Clear Coat / Overcoat / Sealer (optional)

Function: Enhances abrasion resistance, stain resistance, self-cleaning capability, and scratch resistance; may also offer special effects such as anti-fingerprint or antibacterial performance.

Design Logic:

Each layer has its own purpose, and the combination of layers determines the final performance and cost of the color coated aluminum coil.

Common Coating Types

(1) Polyester (PE) Coated Aluminum Coil

Polyester-coated aluminum coils typically have a cost advantage, generally being cheaper than fluorocarbon-coated aluminum coils, providing a cost-effective option for budget-sensitive projects. PE-coated aluminum coils offer a wide range of colors, easily creating a vibrant and stylish visual effect. For interior decoration and the walls and roofs of ordinary industrial plants, polyester-coated aluminum coils create an aesthetically pleasing atmosphere without incurring high costs, making them popular among small and medium-sized enterprises.

(2) Polyvinylidene Fluoride (PVDF) Coated Aluminum Coil

Fluorocarbon-coated aluminum coils are considered the "king of durability," possessing superior weather resistance. They withstand prolonged exposure to ultraviolet radiation and resist acid and alkali corrosion, ensuring that the color will not fade for 30 years, maintaining a bright and vibrant appearance. PVDF-coated aluminum coils are mainly used in high-end buildings or buildings in harsh environments, especially suitable for industries such as chemical and metallurgy, as well as humid coastal areas, areas with high ultraviolet radiation, and areas with severe pollution and corrosion.

(3) High-Durability Polyester (HDP) Coating

It has excellent aging resistance and corrosion resistance, and its acid resistance is excellent, which is 5-6 times that of ordinary paint coatings. When the polyester resin is replaced with hydrophilic polyester resin with strong anti-fouling properties, the coating surface has extremely strong self-cleaning and anti-fouling properties, and its weather resistance exceeds 15 years, and its weather resistance is close to that of PVDF.

2. Coating Thickness Options

Single Coat (4-20 μm)

Thin and economical-ideal for temporary buildings, construction fences, and short-term exhibition panels.

Double Coat (25-28 μm)

The most common structure: primer + topcoat + backcoat.

Balances cost and performance.

Suited for residential walls, shopping mall façades, and general architectural applications.

Triple Coat (35-38 μm)

Mainly used for PVDF systems, offering superior weatherability and color depth.

Used in high-end office buildings, airport terminals, and large-scale projects where long-term durability is required.

3. Surface Patterns

Embossed

Creates textured surfaces such as orange-peel or sand patterns, improving scratch resistance and reducing glare.

Wood Grain

Realistic wood textures for landscaping structures, traditional-style architecture, and cultural buildings.

Stone Grain

Simulates marble or granite-ideal for hotels, luxury halls, and premium interiors.

Brick Pattern

Suitable for retro-themed building façades, old town renovation projects, and artistic neighborhoods.

Camouflage

Used for military facilities, outdoor base stations, and adventure camp structures.

Technical Specifications of Coated Aluminum Coil

| Common Alloys | 1050, 1100, 3003, 3004, 3105, 5005, 5052, 5754,8011,etc |

| Temper | H14, H16, H24, H26, H32, H42 |

| Thickness | 0.02-1.50 mm (up to 3.0 mm available) |

| Width | 20-2000 mm |

| Outer Diameter | 400-1500 mm |

| Inner Diameter | 150 / 405 / 505 mm |

| Surface Quality | free of oil stains, waves, dents, pinholes and color differences |

| Coatings | PE / HDPE / SMP / PVDF / PU / FEVE / Epoxy |

| Coating Thickness | Front 18-35 μm; Back 5-15 μm |

| Gloss | high gloss, semi-gloss, matte |

| Surface Effects | wood grain, stone grain, brushed, metallic, patterns |

| Weather Resistance | 5-30 years depending on coating type |

| Applications | façade panels, roofing sheets, appliances, signage, decoration panels, vehicles |

| MOQ | 1-3 tons |

Performance Features of Color Coated Aluminum Coil

Lightweight: Much lighter than color coated steel, reducing building load and transportation costs.

Rich Colors: Wide range of solid colors, metallic colors and pearlescent finishes.

Chemical Resistance: Excellent resistance to acid rain, salt spray and pollutants.

Climate Adaptability: Maintains integrity and color even under rain, snow and humidity.

Mechanical Durability: High impact resistance and good abrasion performance after long-term use.

Energy Efficiency: Reflective coatings improve insulation and reduce energy costs.

Excellent Workability: Suitable for bending, rolling, stamping, shearing and deep drawing without damaging the coating.

Long Service Life: Strong protective surface significantly prolongs lifespan even in harsh environments.

Eco-Friendly: Aluminum is highly recyclable with high residual value.

Applications of Pre-painted Aluminum Coil

Construction & Decoration:Building façades, roofing, wall panels, interior decoration.

Transportation:Vehicle interior panels, road signs, advertisement panels.

Appliances:Refrigerator panels, washing machines, air conditioners.

Furniture:Cabinet doors, storage systems.

Insulation Materials:Outer protective layers for insulation pipes.

Packaging:Food and pharmaceutical packaging.

Coating Methods

Roll Coating

The most widely used method-economical, efficient and produces uniform coatings.

Process includes pretreatment, primer, intermediate coat and topcoat, each followed by curing.

Spray Coating

Uses compressed air to spray paint onto the aluminum surface.

Advantages: rich color options, uniform thickness, detailed patterns.

Cost is higher due to more complex equipment and process control.

Powder Coating

Static-charged powder adheres firmly to the metal surface.

Fast, solvent-free and environmentally friendly.

However, color choices are limited and requires high-temperature curing.

How to Choose the Right Color Coated Aluminum Coil?

1. Based on the Usage Environment

Different applications require different types of color-coated aluminum coils, as the temperature, humidity, and cleanliness levels vary. Therefore, when selecting these materials, it's crucial to consider the specific application environment to ensure that the chosen material meets the requirements in all aspects. For example, fluorocarbon color-coated aluminum coils are suitable for outdoor environments, polyester color-coated aluminum coils for dry indoor environments, and fluorocarbon color-coated aluminum coils for coastal environments. Generally, fluorocarbon color-coated aluminum coils offer better weather resistance and are suitable for various harsh environments.

2. Based on the Application

Different uses require different strength and corrosion resistance levels.

Choose the alloy and coating system based on forming requirements and service conditions.

3. Based on Required Service Life

Each coating type offers different warranty periods:

PVDF: 15-25 years

SMP/HDP: 10-15 years

PE: Shorter outdoor warranty; indoor use up to 10 years

-

3003 H14 Color Coated Aluminum Coil for Roofing

3003 H14 color-coated aluminum coil uses PE/PVDF coating and features excellent formability, high corrosion resistance, and weldability.

2025-12-17

-

PVDF Coated Aluminum Coil For Industrial Roofing

PVDF coated aluminum coil for industrial roofing delivers long-term color stability, corrosion resistance and reliable coil coating quality for harsh climates.

2026-02-03

-

1100 Color-Coated Aluminum Coils for Automotive Interior Decoration

1100 PE / PVDF coated aluminum coils not only retain the physical properties of aluminum but also provide a wide range of color options, making them widely used in various automotive interior components.

2025-12-19