Description:

| Alloy: | AA1100, AA1050, AA3003, AA3004, AA3005, AA3105, AA5005, AA5182, AA5052, AA5754, AA5454, AA8011 |

| Temper: | O / H42 / H44 / H46 / H48 |

| Coating Type: | Polyester (PE) |

| Coating thickness: | ≥ 16 µm |

| Alloy: | AA1100, AA1050, AA3003, AA3004, AA3005, AA3105, AA5005, AA5182, AA5052, AA5754, AA5454, AA8011 |

| Temper: | O / H42 / H44 / H46 / H48 |

| Coating Type: | Polyester (PE) |

| Coating thickness: | ≥ 16 µm |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

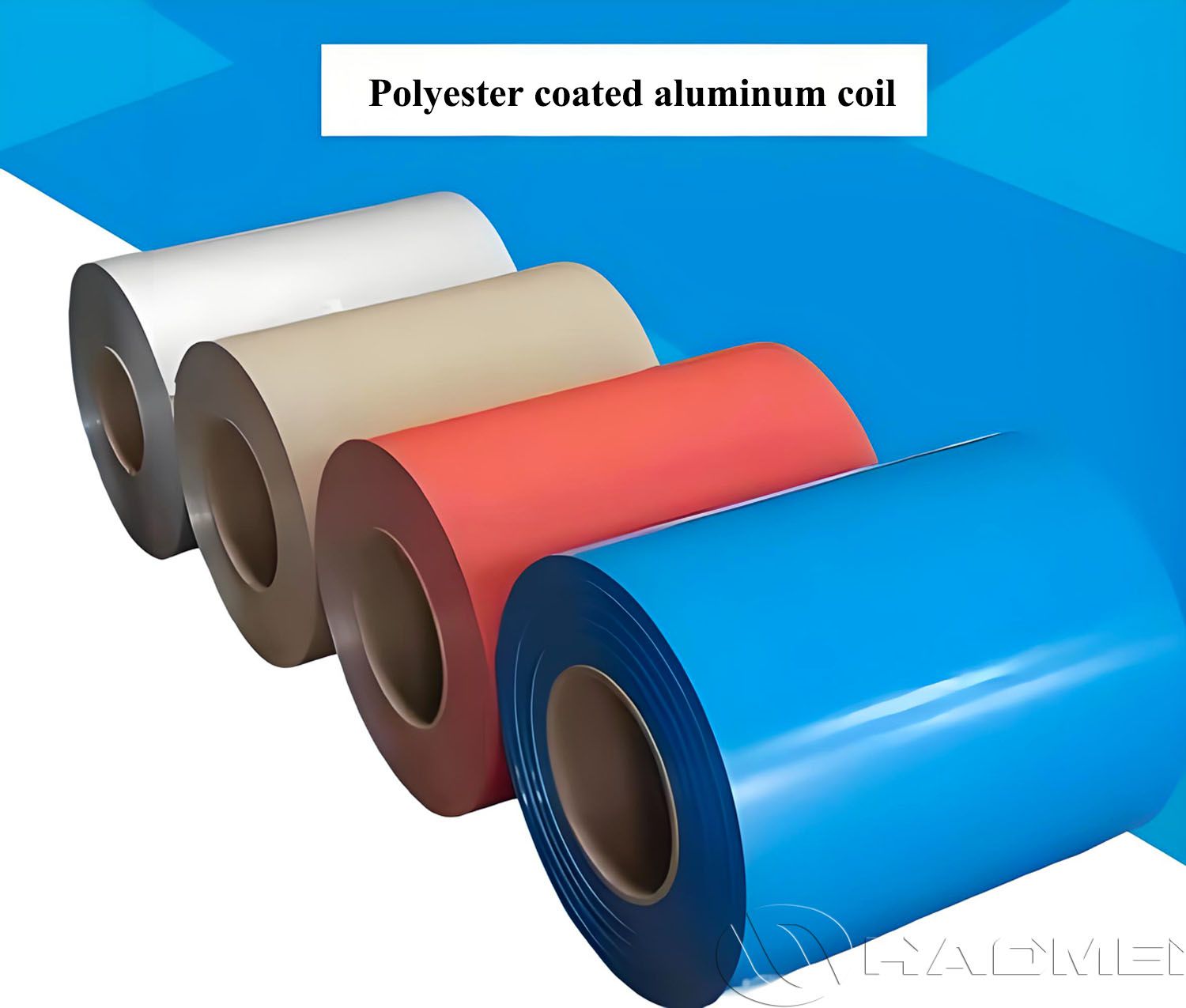

Coated aluminum refers to the process of applying a layer of colored coating onto the surface of aluminum sheet or coil.

HAOMEI Aluminum produces coated aluminum coils in various grades such as 1050, 1100, 3003, 3105, 5052, 5754, and 8011.

All color-coated aluminum coils are ISO9001 certified and available in all RAL colors. Surface finishes include polyester (PE), PVDF, and PE coatings, with customizable thickness, width, and length according to customer requirements.

These products are widely used in aluminum façade panels, honeycomb panels, aluminum ceilings, roofing systems, and tank manufacturing.

PE coated aluminum coil, also known as polyester coated aluminum coil, is made by coating the surface of an aluminum alloy substrate with multiple layers of polyester organic paint, followed by high-temperature baking and curing to form a composite material.

This UV-resistant coating uses high-molecular polymers as monomers and adds alkyd resin. It is available in matte or glossy finishes to suit your needs. The tight molecular structure gives the coating a smooth, glossy surface, ensuring excellent printability. This coating is specifically designed for interior aluminum decorative and signage substrates and comes with a 7-year warranty.

| Alloy | AA1100, AA1050, AA3003, AA3004, AA3005, AA3105, AA5005, AA5182, AA5052, AA5754, AA5454, AA8011 |

| Temper | O / H42 / H44 / H46 / H48 |

| Thickness | 0.02 mm - 3.0 mm |

| Width | 100 mm - 1800 mm |

| Length | 100 mm - 8000 mm |

| Coating Type | Polyester (PE), coating thickness ≥ 16 µm |

| Available Colors | Solid, metallic, marble, wood grain, anti-static, anti-scratch, etc. (customizable) |

| Impact Resistance | No cracks or peeling |

| MEK Resistance | Over 100 times |

| Subsequent Processing | Embossing, cutting into solid sheets, slitting into strips, etc. |

| Boiling Water Resistance | No deformation or color change after 2 hours at 99 ± 1°C |

| Corrosion Resistance | No visible changes after 48 hours immersion in 5% HCl and 5% NaCl (surface) or 2% HCl and 2% NaCl (internal) solutions |

| Place of origin | Place of origin: Zhengzhou, China |

| MOQ | 1-3 tons |

| Item | Technical requirement | Item | Technical requirement | Specification |

| Thickness of coating film | ≥16μm | Boiling water resistance | Make no difference within 2 hours | 0.10×1240-0.60×1240 |

| Glossiness deviation | When glossiness <70, the tolerance ≤10 When glossiness ≥70, the tolerance ≤ 5 | Color difference | △E≤3.0 | |

| Pencil hardness | ≥HB | |||

| Adhesive force | ≥ grade 1 | |||

| Flexibility (T) | ≤3 |

TOP COATING:

| TEST | METHOD | RESULTS | |

| Coating nature | PVDF | Standard PE | |

| Thickness | ECCA T1 | Color:20±2um Primer:5+2um or according spec. | Color:18-2±2um, or according spec. |

| Specular Gloss | ECCA T2 | Standard ±5% | Standard ±5% |

| Color difference | ECCA T3 | ⊿E<1(Non-metallics colors) | ⊿E<1(Non-metallics colors) |

| Polimerization | ILA-06 | >100 DF | >100 DF |

| Pencil Hardness | ECCA T4 | ≥F | ≥F |

| Impact | ECCA T5 | 100% | 100% |

| Adhesion (Cross cutting+Erichsen) | ECCA T6 | >75% | >75% |

| Bending | ECCA T7 | ≤2T | ≤2T |

| Resistant to salt acetic acid spray test | ECCA T8 | 1000h/class 3 (According to EN1396/C 6.5)(Depends on specification) | 1000h/Class 1(According to EN 1396/C.6.5) |

| Water immersion resistance | ECCA T9 | 1000h-B2S2 | - |

| Resistance to QUVB test | ECCA T10 | 10 00 h Gloss Retention ≥90% ⊿E≤2 | 500h Gloss Retention ≥30% ⊿E≤5 |

| Florida test | Class 3 (According to EU1396/C 6.3) | Class 3 (According to EU1396/C 6.3) | |

BACK COATING:

| TEST | METHOD | RESULT |

| Thickness coating | ECAA T1 | 5±2um |

| Bending | ECAA T7 | ≤2T |

| Polimerization | ILA 06 | >100 double roubs |

| Adhesion after cross cutting | ECAA T6 | OK |

| Adhesion after Erichsen | ECAA T6 | OK |

| Resistance to Salt Spray | ECAA T8 | 1000 hours |

Weather and Corrosion Resistance

Polyester coatings have excellent resistance to UV rays, acid rain, and corrosion. They can be used outdoors for long periods without fading or chalking, ensuring lasting beauty and durability for buildings or decorative applications.

Lightweight and Easy to Install

Aluminum has a low density-only one-third that of steel-making construction lighter and faster while reducing the load on building structures.

Economical and Practical

Due to its low density and ease of installation, aluminum provides an economical and efficient solution for various architectural and industrial applications.

Rich Color Options

The pigment system of PE coatings is mature and stable, offering strong color expression. A wide range of gloss levels and saturation can be easily achieved to meet designers' diverse aesthetic needs.

Excellent Workability

PE coated aluminum can be deeply drawn, bent, stretched, rolled, folded, and cut, making it suitable for different industrial and architectural processing requirements.

Environmentally Friendly and Recyclable

Aluminum is a fully recyclable material, aligning with modern environmental protection and sustainability trends.

AA1100, AA1050, AA3003, AA3004, AA3005, AA3105, AA5005, AA5083, AA5052, AA5754, AA5454, and AA8011.

Customers can specify their required alloy, thickness, and temper to achieve optimal performance.

Standard Color Coated Aluminum Coil

Includes common colors such as white, gray, blue, red, and yellow. These can be customized according to the RAL color chart to meet general application needs.

Special Color Coated Aluminum Coil

Custom colors available upon request - including metallic, pearlescent, marble, brick, and wood grain finishes - suitable for projects with specific aesthetic requirements.

Architectural Interior Decoration: Ceiling panels, interior wall panels, and partitions.

Composite Panels: As surface material for Aluminum Composite Panels (ACP) used in mid- to low-rise building façades and shop signs.

Home Appliances: Outer shells for refrigerators, air conditioners, and washing machines.

Advertising and Signage: Billboards, display boards, and exhibition stands.

Transportation: Interior panels for vehicles and ships.

Printing Industry: Used in manufacturing PS, CTP, and UV-CTP printing plates.

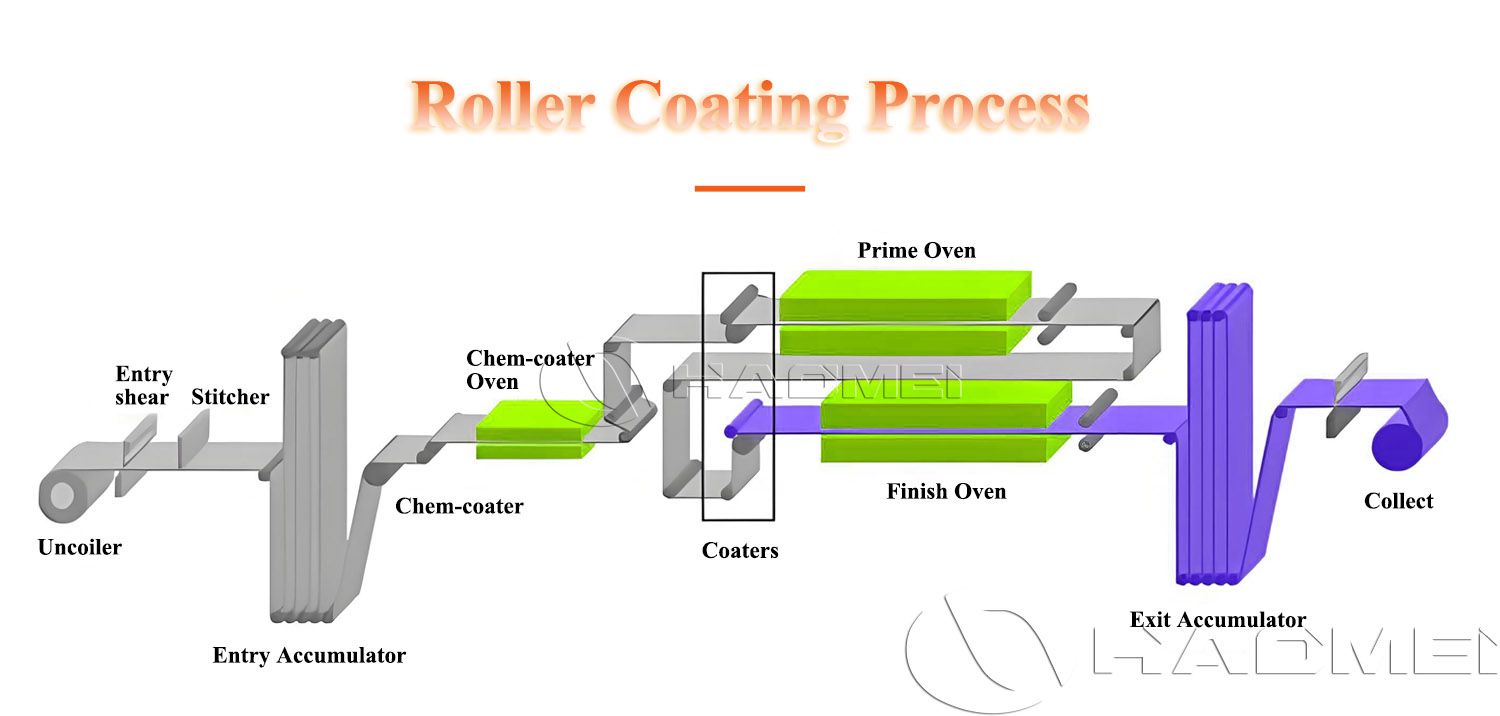

HAOMEI Aluminum adopts an advanced pre-roller coating process, which ensures color consistency, perfect flatness, and minimal material loss compared to spray coating methods.

Production Steps:

Uncoiling - Degreasing & Cleaning - Primer Coating & Baking - PE Top Coating - Baking & Curing - Protective Film Lamination & Slitting - Inspection - Rewinding - Packaging

Advanced processes such as double baking and double coating or triple baking and triple coating can also be used. The coating thickness is usually greater than 18 micrometers, the coating hardness is greater than 2H, and the adhesion is no less than Grade 1.

PE coated aluminum coils are packaged with moisture-proof paper, plastic film, and strong wooden pallets, ensuring product integrity during transportation.

Each coil is securely fastened and clearly labeled for easy identification.

HAOMEI Aluminum guarantees safe, fast, and reliable delivery to meet customer timelines worldwide.

1050, 1100, 1200, 3003, and 3004 color coated aluminum coils are widely used in roofing panels, wall panels, corrugated roofing sheets, and architectural façade decoration.

2025-12-29

1100 H16 color coated aluminum coil is a highly formable, corrosion-resistant color-coated aluminum coil suitable for architectural decorative strips, ceilings, exterior wall panels, etc.

2026-01-15

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04