Description:

| Alloy: | 1200 |

| Surface treatment: | Color coating (PE / FEVE / PVDF), embossed matte, brushed, wood-grain transfer |

| Coating thickness: | 15 - 25 μm |

| Color: | Any RAL color, customizable special effects |

| Alloy: | 1200 |

| Surface treatment: | Color coating (PE / FEVE / PVDF), embossed matte, brushed, wood-grain transfer |

| Coating thickness: | 15 - 25 μm |

| Color: | Any RAL color, customizable special effects |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

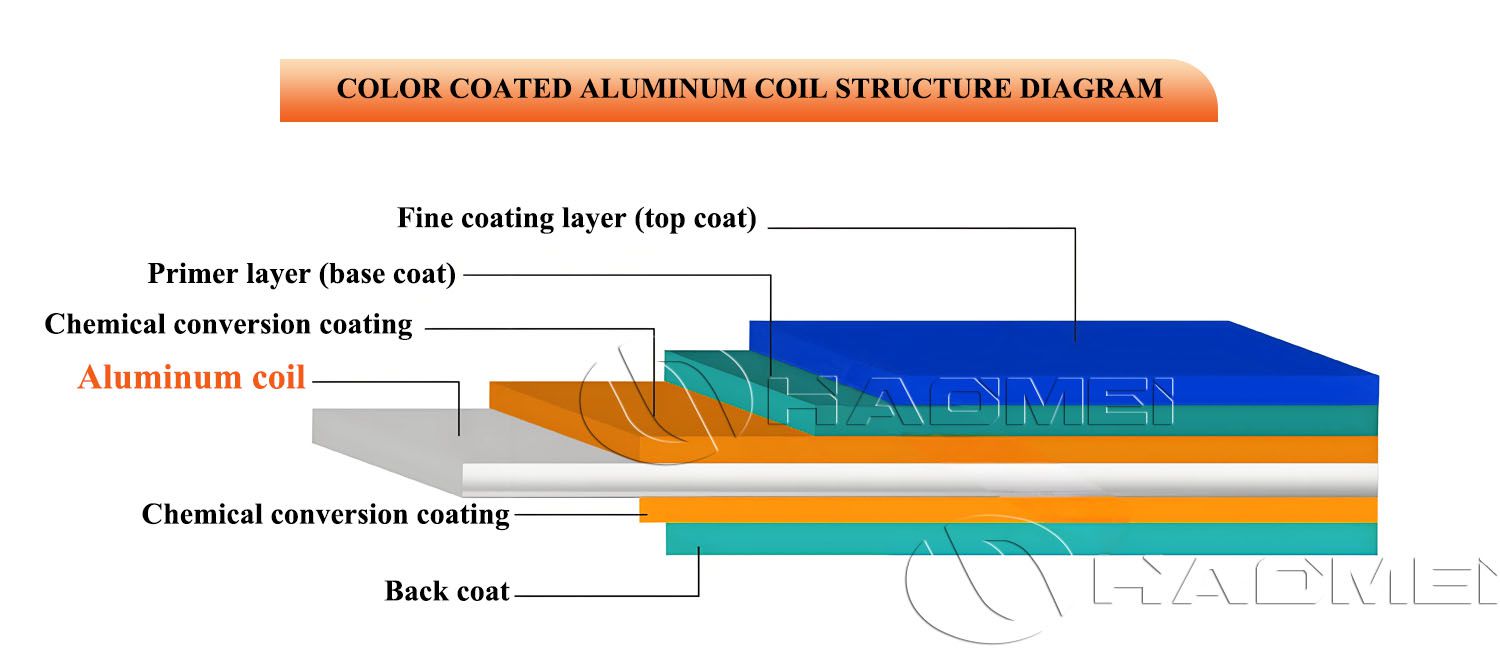

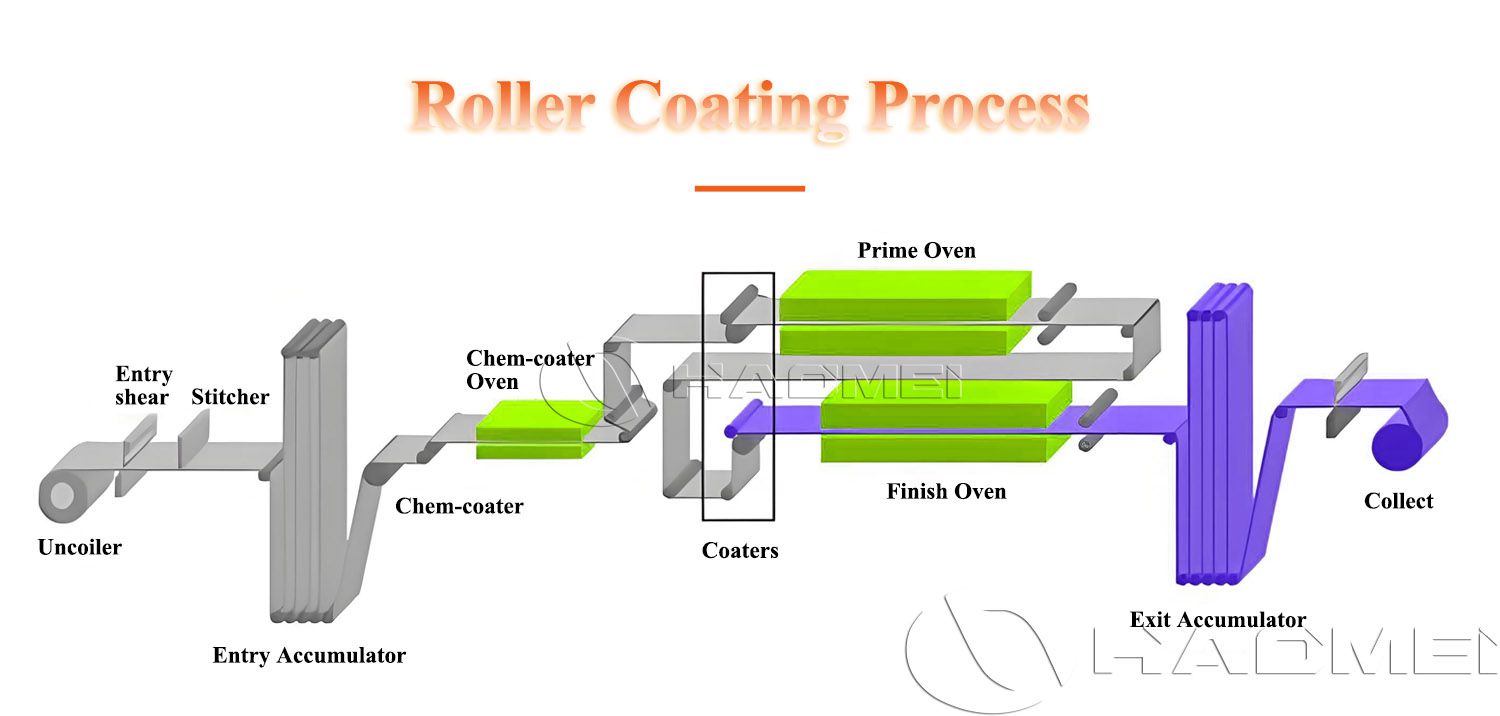

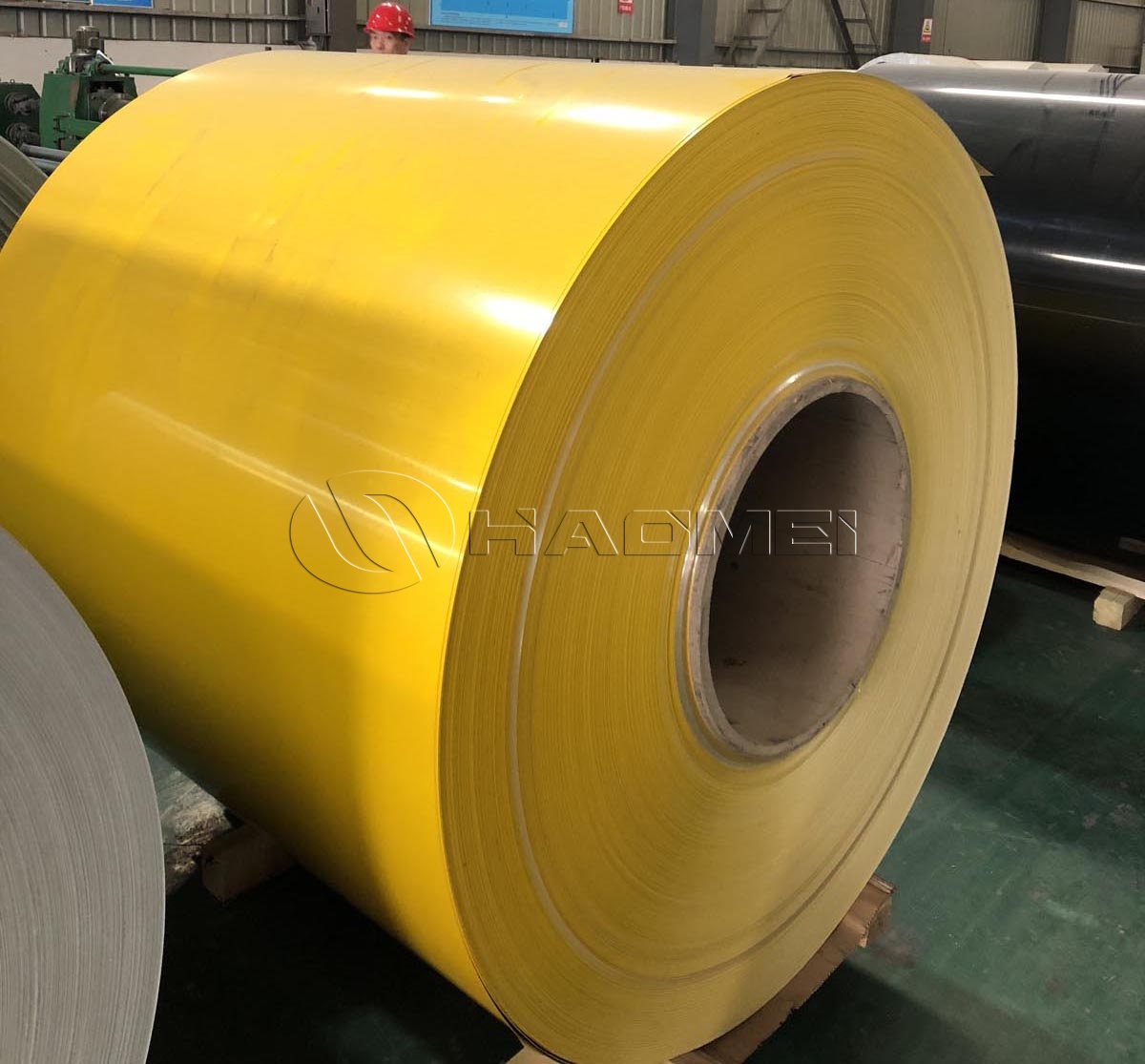

1200 color coated aluminum coil uses high-purity 1200 series industrial pure aluminum as the base material. Through advanced coating technology, multiple layers of coating are evenly applied onto the surface of the 1200 aluminum coil. These coatings not only enhance the decorative appearance but also provide superior protection. Compared with traditional plain aluminum sheets, color coated aluminum coils offer significantly better corrosion resistance, which effectively extends service life.

HAOMEI Aluminum supplies a wide range of colors and coating types, including polyester (PE) and fluorocarbon (PVDF) coatings, to meet different application environments and aesthetic requirements. Compared with traditional single-color aluminum coils, color coated coil products are better suited for modern architectural and industrial design needs.

Primer: Usually epoxy resin or polyurethane, providing excellent adhesion and anti-corrosion protection.

Topcoat: Options include Polyester (PE), Silicone-Modified Polyester (SMP), and Fluorocarbon (PVDF). The topcoat determines final appearance and weather resistance.

Back coat: Optional epoxy, polyester, or polyurethane coating for additional protection.

| Material | 1200 |

| Temper | H14 / H18 |

| Aluminum purity | ≥ 99.0% |

| Thickness | 0.2mm - 2.5mm (customizable) |

| Width | 600mm - 1600mm (customizable) |

| Surface treatment | Color coating (PE / FEVE / PVDF), embossed matte, brushed, wood-grain transfer |

| Coating thickness | 15 - 25 μm |

| Color | Any RAL color, customizable special effects |

| Coil weight | 2 - 8 tons (customizable) |

| Delivery form | Sheet, coil, strip |

| Base material properties | Excellent ductility, corrosion resistance, oxidation resistance, suitable for deep drawing |

| Packaging | Sea-worthy wooden pallets |

| Origin | Henan, China |

| MOQ | 1-3 tons |

Mechanical Properties

| Temper | Thickness Range | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| H14 (Half Hard) | 0.2-0.5mm | 90-110 | 40-60 | 10-15 |

| 0.5-1.0mm | 95-115 | 50-65 | 10-14 | |

| 1.0-2.5mm | 100-120 | 55-70 | 8-12 | |

| H18 (Full Hard) | 0.2-0.5mm | 110-130 | 60-70 | 6-10 |

| 0.5-1.0mm | 115-135 | 65-80 | 5-9 | |

| 1.0-2.5mm | 120-140 | 70-85 | 4-8 |

Chemical Composition of 1200 Alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Other | Al |

| 1200 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 99.0 |

Outstanding Corrosion Resistance

The high purity (≥99%) of 1200 aluminum provides natural oxidation resistance and excellent corrosion protection.

Lightweight with Good Strength

Much lighter than steel (approx. 1/3 weight) while maintaining adequate strength for many applications.

Excellent Workability

Suitable for bending, deep drawing, stretching, and forming into complex shapes.

Rich Colors & Decorative Effects

Multiple coating types and surface treatments satisfy architectural and industrial decorative requirements.

Eco-Friendly & Durable

Non-toxic coatings, UV-resistant, weather-resistant, non-fading, and non-cracking even under harsh conditions.

Cost-Effective

Compared with alloy aluminum, 1200 pure aluminum offers a more economical solution for applications where ultra-high strength is not required.

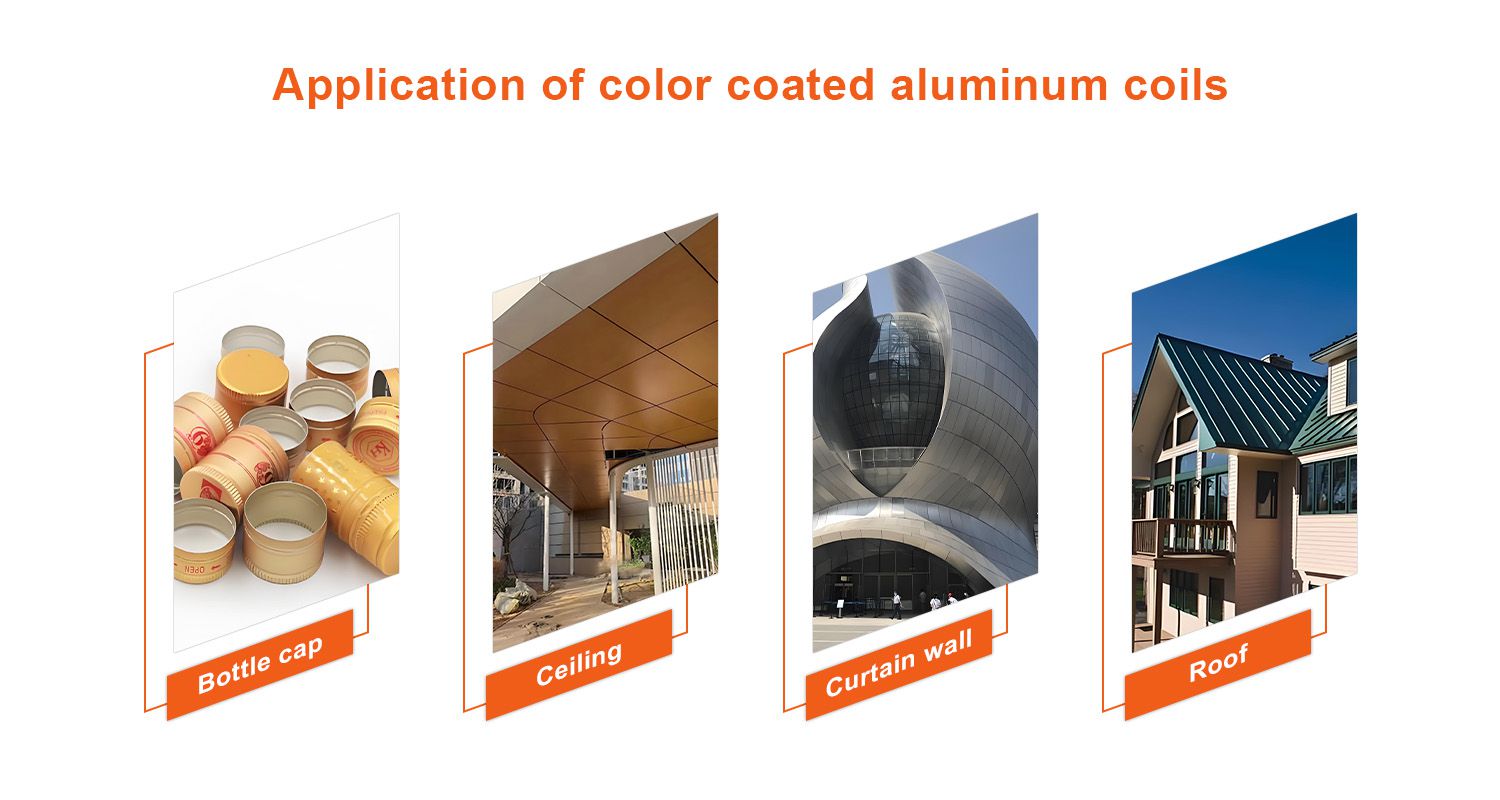

Architectural decoration: Ceilings, interior wall panels, partitions, edge trims

Insulation & ventilation: HVAC duct coverings, pipe insulation cladding (suitable for low-strength applications)

Electronics & lighting: Lamp reflectors, electronic housing components

Packaging & containers: Lightweight industrial containers and packaging materials

1. Polyester (PE) Coating

Offers excellent flexibility, adhesion, and economy. Bright colors. Ideal for indoor or standard outdoor environments.

2. Fluorocarbon (PVDF) Coating

Designed for extreme weather conditions such as coastal and industrial zones. Superior UV resistance, anti-fading, and long-term durability.

3. Diversified Surface Effects

Wood grain, stone grain, brushed metallic textures, and other decorative effects are available to enhance design possibilities.

Strong Customization Capability: Thickness, width, colors, and coating types can all be customized.

Stable Supply: Large inventory ensures on-time delivery.

Technical Support: Professional guidance for processing and installation.

High Cost Performance: Factory-direct pricing, transparent and competitive.

1050, 1100, 1200, 3003, and 3004 color coated aluminum coils are widely used in roofing panels, wall panels, corrugated roofing sheets, and architectural façade decoration.

2025-12-29

1100 / 3003 color-coated aluminum coils are lightweight, weather-resistant, and have good processability, making them suitable for billboards and traffic signs.

2025-12-23

5052 color coated aluminum coil for marine use delivers salt spray resistance and durability with PVDF/PE systems, controlled coil coating process, and stable H32 properties.

2026-01-23