Description:

| Alloy: | 3004 |

| Coating Type: | PVDF, Polyester |

| Colors: | Solid colors, metallic colors, wood-grain, marble patterns |

| Production Process: | Hot rolling & cast rolling |

| MOQ: | 1-3 tons |

| Alloy: | 3004 |

| Coating Type: | PVDF, Polyester |

| Colors: | Solid colors, metallic colors, wood-grain, marble patterns |

| Production Process: | Hot rolling & cast rolling |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

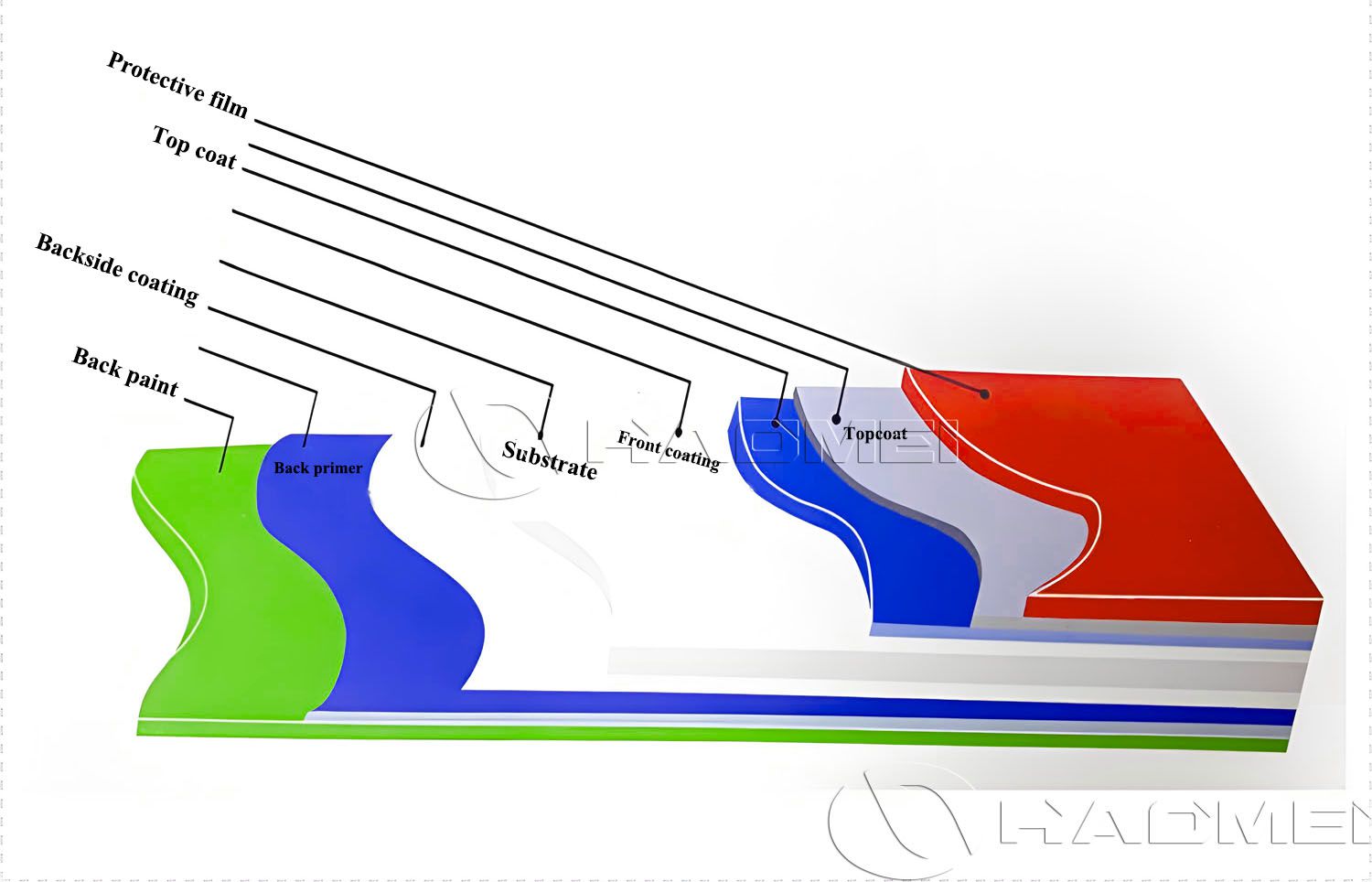

3004 color coated aluminum coil is a new type of metal material produced using 3004 aluminum alloy as the base metal. After cleaning, chromizing, roller coating, and high-temperature baking, its surface is coated with various paint layers such as PE and PVDF.

3004 aluminum alloy belongs to the Al-Mn series. As a commonly used anti-rust aluminum sheet, it contains a small amount of magnesium, making it part of the aluminum-magnesium-manganese family.

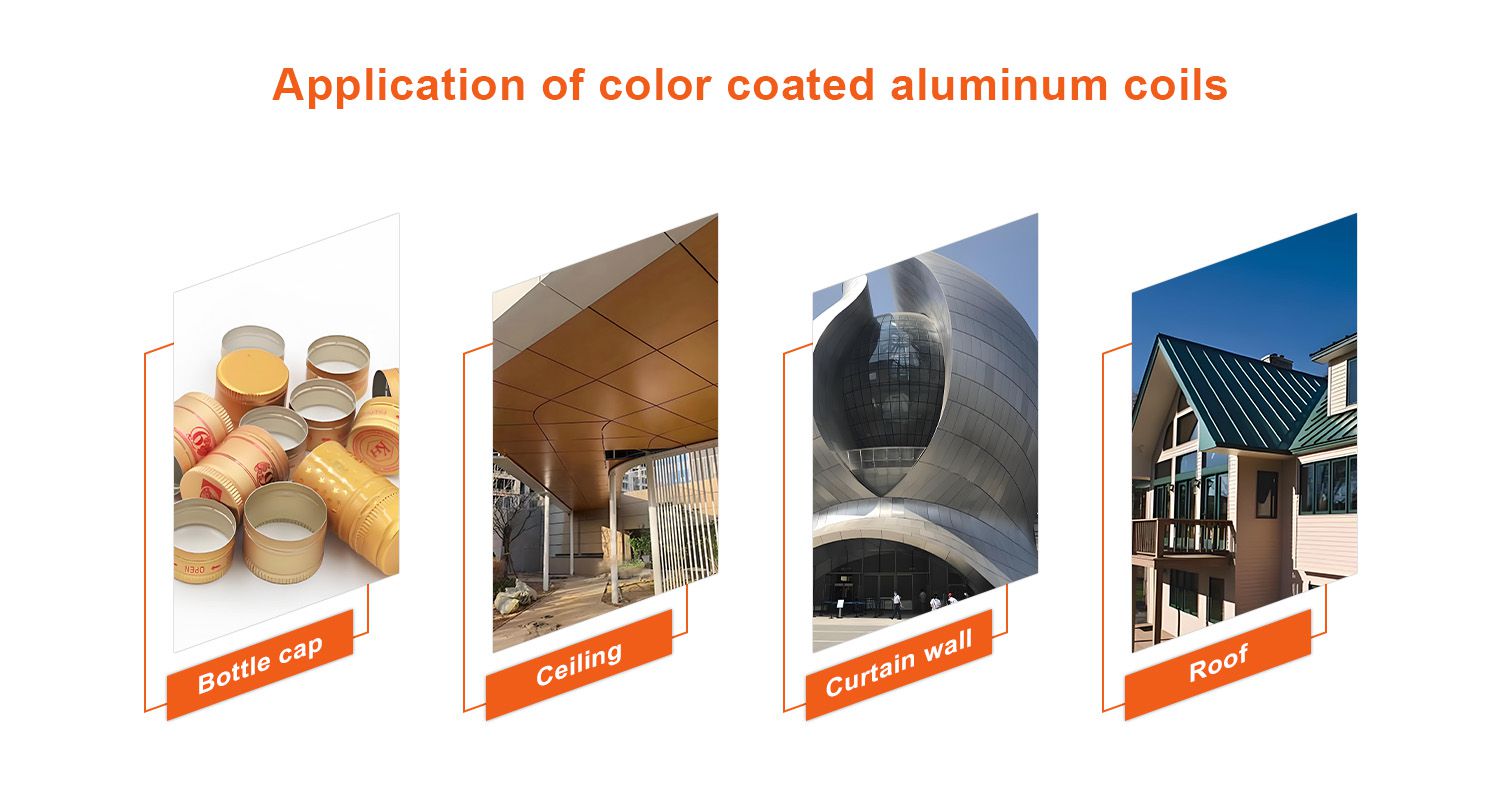

3004 coated aluminum coil not only maintains the lightweight characteristics of aluminum but also offers slightly higher strength than 3003 color coated aluminum coil. With surface coating treatment, it has excellent weather resistance and decorative effects. It is widely used in building curtain walls, roofing systems, home appliance shells, food packaging, ceilings, roller shutter doors, and more.

H14: Semi-hard, suitable for stamping and bending parts.

H16: Higher strength, suitable for stretching and roll forming.

H18: Full hard temper, used for applications requiring high rigidity.

O: Annealed soft temper, ideal for deep drawing and stretching.

| Material | 3004 aluminum alloy |

| Temper | O, H14, H16, H18 |

| Thickness | 0.2mm-4.0mm |

| Width | 20mm-2500mm |

| Length | 1000mm-1600mm |

| Coating Type | PVDF (fluorocarbon), Polyester (PE) |

| Coating Thickness | Single coating: 4-20 μm Double coating: 25-28 μm Triple coating: 35-38 μm |

| Gloss | 10-90%; coating hardness: >2H |

| Colors | Solid colors, metallic colors, wood-grain, marble patterns |

| Surface Protection | Protective film available |

| Production Process | Hot rolling & cast rolling |

| Applications | Automotive, machinery, ACP, aluminum panels, ceilings, interior decoration, etc. |

| Packaging | Standard export package with wooden pallet |

| MOQ | 1-3 tons |

Mechanical Properties

| Property | Value |

| Tensile Strength (MPa) | 190-240 |

| Yield Strength (MPa) | ≥130 |

| Elongation (%) | ≥50 |

| Elastic Modulus (GPa) | 70 |

| Density (g/cm³) | 2.73 |

| Thermal Conductivity (W/m·K) | 160 |

| Melting Point (℃) | 635 |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Zn | Mn | Mg | Other |

| 3004 | 0.30 | 0.70 | 0.25 | 0.25 | 1.00-1.50 | 0.80-1.30 | 0.05 |

1. High Toughness & Anti-Deformation Base Metal

With a manganese content of 1.0-1.5%, it provides outstanding tensile strength, elongation, impact resistance, and bending resistance. Suitable for large-span roofing and complex forming environments without cracking.

2. Excellent Corrosion Resistance

3004 alloy itself has good rust resistance. Combined with a high-performance coating, it can resist more than 4,000 hours of salt spray, ultraviolet aging, acid and alkali corrosion, and is not easy to fade or powder in coastal, high temperature and high humidity environments.

3. High Strength and Commutation

Compared to pure aluminum, 3004 alloy boasts higher strength while retaining excellent deep-drawing and forming properties, making it easy to process by shearing, stamping, and bending.

4. Excellent Decorative Properties

The coating offers a rich variety of colors, providing over 80 standard colors, including RAL color charts and swatches. Gloss levels are selectable, and it can mimic various textures (such as wood grain and stone grain) to meet diverse architectural aesthetic needs.

5. Lightweight and Energy-Saving

Aluminum has a low density and is lightweight, which helps reduce the structural load on buildings and lower transportation costs.

6.Environmentally Friendly and Weather-Resistant

The coating has excellent weather resistance, is not prone to fading, and the aluminum is 100% recyclable, meeting green building material standards.

3004 color-coated aluminum coils can be coated with different types of coating systems depending on the application. The most common types are as follows:

1. PE (Polyester) Coated Aluminum Coil

PE coatings, based on weather-resistant polyester, offer advantages such as good adhesion, high gloss, and a variety of colors, making them widely used in interior ceilings, roller shutters, advertising boards, and appliance back panels.

Lifespan: 5-10 years

Features: Low cost, strong decorative effect, moderate weather resistance.

2. PVDF (Fluorocarbon) Coated Aluminum Coil

PVDF coatings are made of fluorocarbon resin (Kynar 500 or Hylar 5000), offering excellent resistance to UV rays, corrosion, and aging, making them suitable for long-term outdoor use.

Service life: 20-30 years

Features: Long-lasting color, resistant to acid and alkali corrosion, and excellent self-cleaning properties.

Applications: Building exterior walls, roofing systems, curtain wall panels, marine components, etc.

3. Epoxy Coating

It is mainly used for special purposes such as food packaging, beverage cans, and the inner walls of cosmetic containers. It has excellent adhesion and chemical stability and meets food contact safety standards.

| Item | Polyester | PVDF |

| Coating Thickness | ≥18 µm | ≥25 µm |

| Gloss Deviation | ≤10% (<70 gloss) | ≤10% (<70 gloss) |

| ≤5% (≥70 gloss) | ≤5% (≥70 gloss) | |

| Pencil Hardness | ≥3H | ≥3H |

| Adhesion | ≥ Class 1 | ≥ Class 1 |

| Flexibility | ≤2T | ≤2T |

| Boiling Water Resistance | No change (2h) | No change (2h) |

| Color Difference | ΔE ≤ 2.0 | ΔE ≤ 2.0 |

| MEK Resistance | ≥100 times | ≥150 times |

1. Building Decoration

Roofing systems: Suitable for large public buildings like airports, stations, stadiums

Curtain wall panels: For ACP, honeycomb panels, and solid aluminum panels

Interior decoration: Ceilings, partition walls, and interior cladding

2. Industrial Manufacturing

Home appliances: Refrigerator side panels, air-conditioner panels, washing machine bodies

Transportation: Car and train interior panels, insulation panels

Other uses: Grain silos, storage tanks, packaging containers

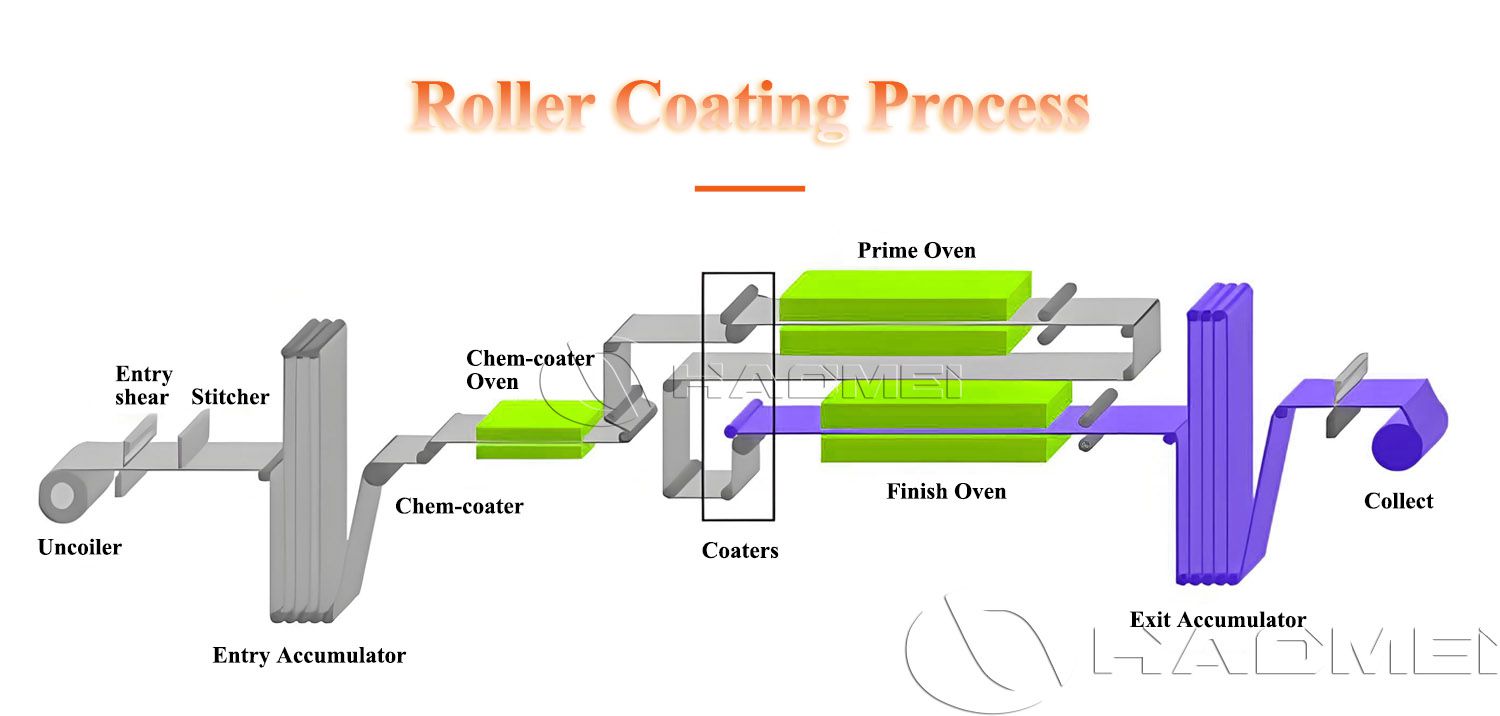

The production process of 3004 color-coated aluminum coils includes:

Base aluminum coil selection

Alkali cleaning and degreasing

Chemical pretreatment (chromium / non-chromium)

Coating application (primer + topcoat)

Baking and curing

Cooling and recoiling

Final inspection

After these processing steps, the surface of the aluminum coil is coated with paint of various colors, which can be categorized into single-coat, double-coat, or even triple-coat processes depending on the application requirements.

Coating thickness:

Single coat: 4μm-20μm;

Double coat: 25μm-28μm;

Triple coat: 35μm-38μm.

In architectural decoration, home appliance housings, advertising signage, and industrial decoration, cold rolled color-coated aluminum coils are gradually replacing traditional steel materials due to their attractive appearance, excellent processability,

2025-12-30

The 5052 H32 aluminum coil uses a color coating process that involves continuously rolling a polyester (PE), fluorocarbon (PVDF), or other coatings onto the aluminum coil substrate and then baking and curing it.

2025-12-05

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02