News

By Hermione

By Hermione

Color Coated Aluminum Coil For Roofing Sheets

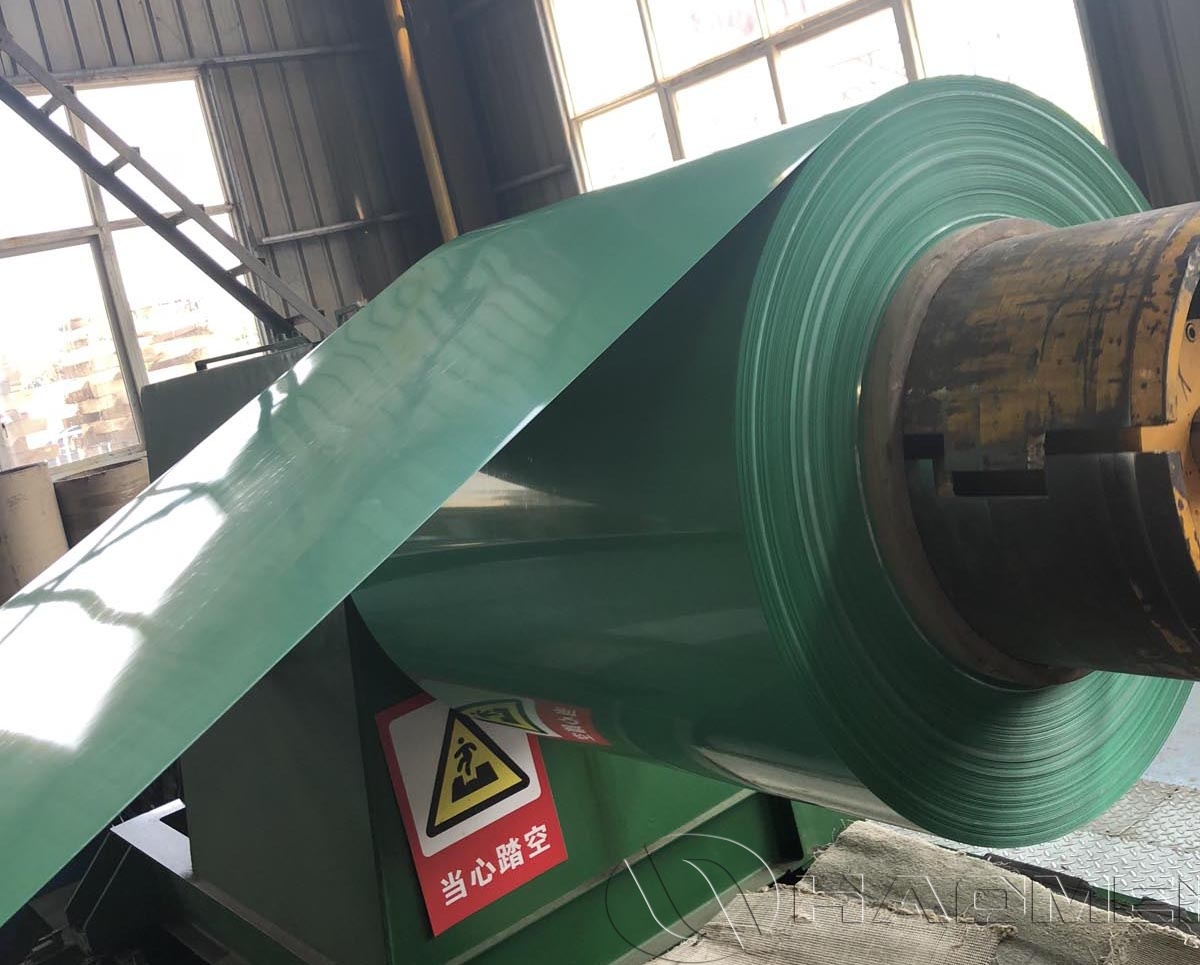

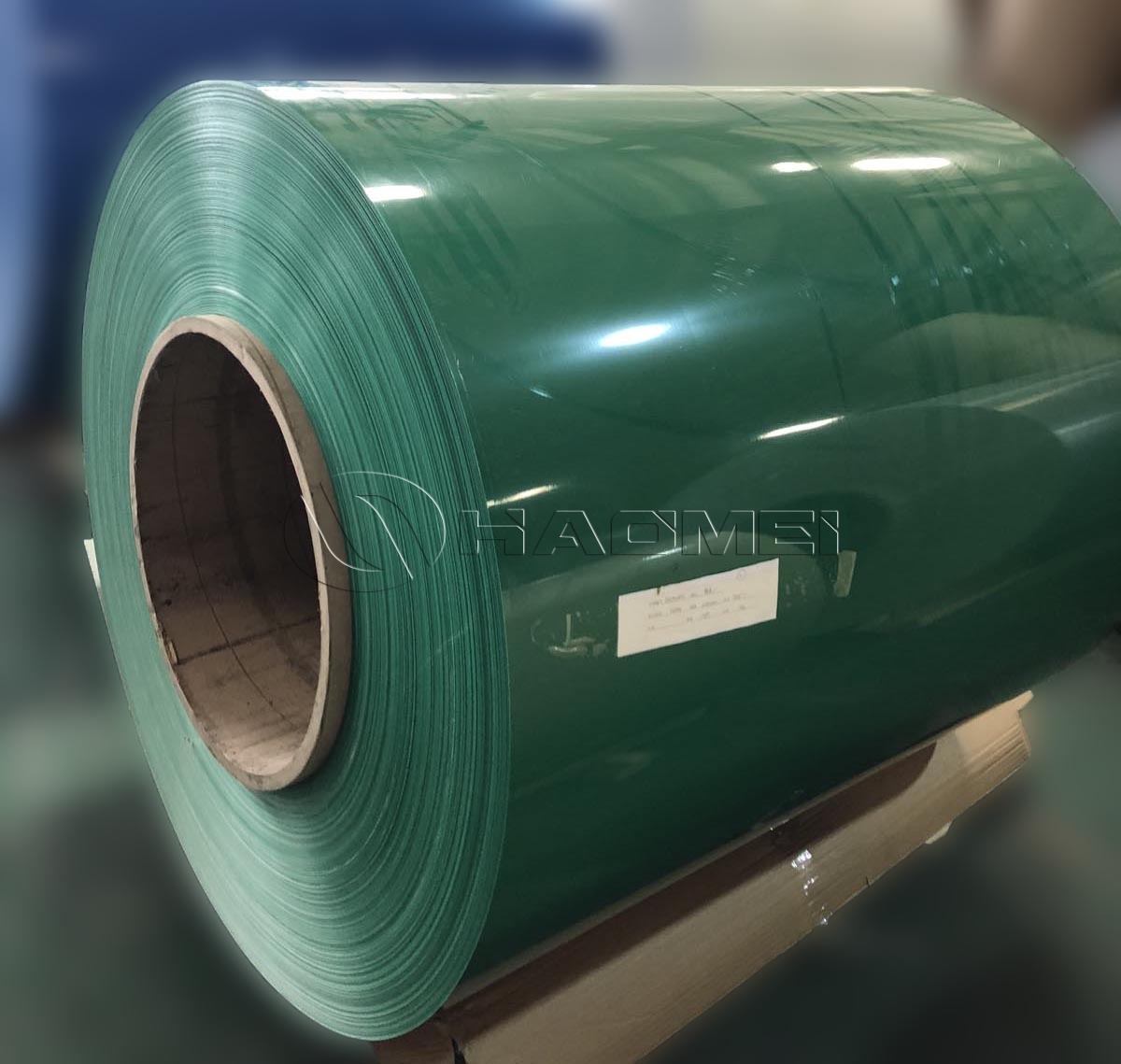

Color coated aluminum coil for roofing sheets is positioned as a premium pre-finished metal substrate designed for roll-formed and press-formed roof panels where long service life, low maintenance, and stable appearance are required. It is widely used in industrial plants, warehouses, logistics centers, commercial roofing, residential villas, and renovation projectsespecially in coastal, high-UV, and high-humidity environments.

Material Characteristics: Built for Outdoor Roofing Performance

Color coated aluminum coil combines an aluminum alloy core with a high-performance organic coating system. Compared with many traditional roofing materials, aluminum offers an excellent strength-to-weight ratio, natural corrosion resistance, and easy fabrication for long-length roofing sheets.

Key material advantages for roofing sheets include:

Lightweight and high formability: Suitable for roll forming into trapezoidal, corrugated, or standing-seam profiles without cracking.

Corrosion resistance: The aluminum substrate plus conversion layer and coating system improves resistance to rainwater, industrial atmospheres, and salt-laden air.

Weatherability and color retention: Coating selection (PE or PVDF) determines UV resistance and long-term gloss stability.

Thermal reflectivity options: Light colors and reflective pigments can reduce heat absorption, supporting energy-efficient roofing design.

Clean appearance and design flexibility: A wide range of colors, gloss levels, and finishes can match architectural requirements.

For demanding outdoor roofing and faade environments, many projects specify a fluorocarbon system; see our dedicated page for PVDF Coated Aluminum Coil.

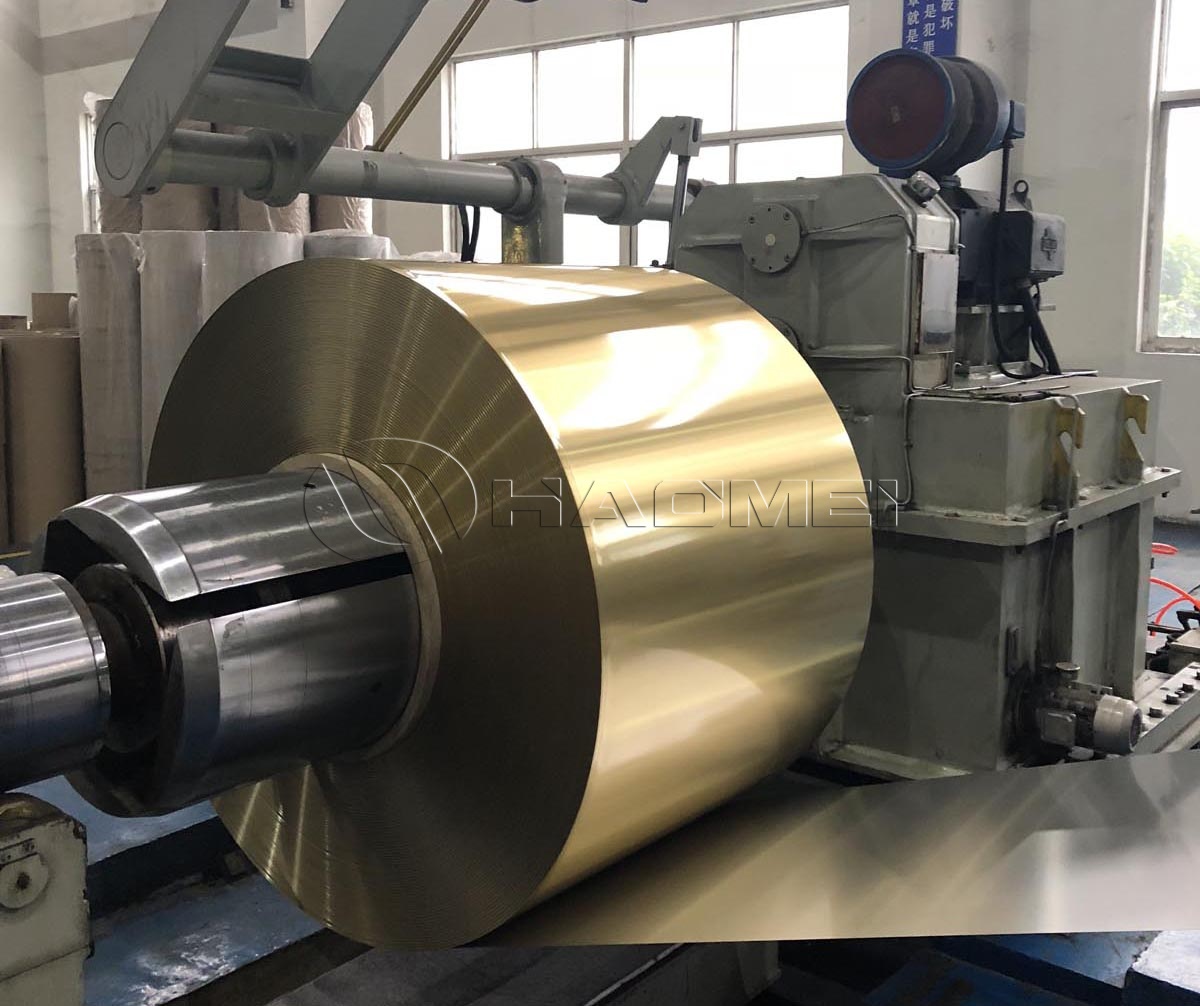

Manufacturing Process: Coil Coating for Consistency and Durability

Color coated aluminum coil for roofing sheets is produced via a continuous coil coating line to ensure stable film build and uniform curing. A typical process flow includes:

Incoming coil inspection: Substrate thickness, flatness, surface quality, and alloy/temper verification.

Cleaning and degreasing: Removes rolling oils and contaminants to ensure coating adhesion.

Chemical pretreatment (conversion coating): Forms a stable interface layer to enhance corrosion resistance and bonding.

Primer coating and curing: Provides adhesion, flexibility, and corrosion protection.

Topcoat coating and baking: Delivers color, weather resistance, and surface performance (gloss, hardness, stain resistance).

Cooling, rewinding, and protective film (optional): Protects the coated surface during transport and roll forming.

Final inspection and packing: Verifies appearance and key performance indicators before shipment.

Application Matching: Selecting the Right Coil for Roofing Sheets

Roofing sheets place simultaneous demands on formability (profile forming), outdoor durability (UV, moisture, pollutants), and installation robustness (fastener zones, edges, cut surfaces). Matching the correct substrate and coating system is therefore critical:

Alloy selection: Common roofing alloys such as 3xxx series balance strength and forming performance for long-span panels and roll-formed profiles.

Coating system selection:

PE: Cost-effective for standard environments and shorter maintenance cycles.

PVDF: Superior UV stability and color retention for long-life roofing, coastal areas, and high-sunlight regions.

Coating thickness and primer system: Influences corrosion resistance, scratch tolerance, and durability at cut edges.

Gloss and texture: Matte or low-gloss finishes can reduce glare on large roof surfaces; smooth finishes may improve cleanability.

Technical Parameters of Color-Coated Aluminum Coils

| Item | Typical Range / Requirement | Test Reference (Typical) |

|---|---|---|

| Aluminum alloy | 1xxx / 3xxx / 5xxx series (project-dependent) | EN/ASTM equivalent |

| Temper | H14 / H16 / H24 (common for roofing forming) | EN/ASTM equivalent |

| Coil thickness | 0.201.20 mm | Micrometer / thickness gauge |

| Coil width | 6001,250 mm (customizable) | Steel rule / width gauge |

| Coating system | PE / PVDF (single or double coat) | Supplier spec + process control |

| Coating structure | 2/1, 2/2 (top/back as required) | Process record |

| Topcoat dry film thickness | PE: 1520 m; PVDF: 2025 m | Coating thickness gauge |

| Primer dry film thickness | 58 m | Coating thickness gauge |

| Back coat thickness | 510 m (as required) | Coating thickness gauge |

| Gloss (60) | 1080 (by color/finish) | ASTM D523 |

| Pencil hardness | HB (typical) | ASTM D3363 |

| Adhesion (cross hatch) | 01 grade | ASTM D3359 |

| T-bend (flexibility) | 0T2T (by alloy/temper/coating) | ASTM D4145 |

| Impact resistance | 50 kgcm (typical) | ASTM D2794 |

| Salt spray resistance | 5002,000 h (system-dependent) | ASTM B117 |

| Color difference (E) | 1.01.5 (batch control target) | Spectrophotometer |

Quality Control and Batch Stability: Key Production Controls

To ensure stable roofing-sheet performance at scale, our process focuses on repeatability from substrate to final packing:

Substrate control: Verified alloy chemistry, mechanical properties, thickness tolerance, and surface cleanliness.

Pretreatment management: Strict control of bath concentration, pH, conductivity, temperature, and dwell time to stabilize conversion coating quality.

Coating application control: Real-time monitoring of roller pressure, line speed, viscosity, and wet film thickness to maintain consistent film build.

Oven curing verification: Continuous tracking of PMT (peak metal temperature) and cure window to prevent under-cure (poor adhesion) or over-bake (brittleness, color shift).

Color management: Spectrophotometer-based matching, standard light source checks, and batch E targets to maintain uniformity.

In-line and final inspection: Gloss, thickness, adhesion, flexibility (T-bend), and appearance checks; defect traceability by coil ID.

Packaging protection: Edge guards, moisture protection, and optional surface protection film to minimize transport and handling damage.

Customization: Adapting to Different Roofing Projects

We support project-specific customization to match different climates, roof profiles, and installation methods:

Alloy and temper selection based on forming radius, profile depth, and required strength.

Coating system options including PE for standard conditions and PVDF for high-UV/coastal durability targets.

Color and gloss: RAL or customer samples, controlled E targets, matte/low-gloss or high-gloss finishes.

Coating structure: Top/back coat thickness and primer type tailored to corrosion category and roof design.

Dimensions and processing compatibility: Coil thickness/width, inner diameter, coil weight, and surface protection film to suit customer roll-forming lines.

Performance validation support: Recommendations aligned with service environment (UV exposure, salt air, rainfall), plus agreed incoming inspection items for stable production.

For roofing sheets that require long-term outdoor reliability and consistent aesthetics, color coated aluminum coil provides an efficient, scalable, and design-flexible solution.

-

Is the Coating of 5052 Color-Coated Aluminum Coil PVDF or PE?

5052 color-coated aluminum coils typically have coatings including polyester (PE) or fluorocarbon (PVDF), and are commonly used in building curtain walls, ceilings, and home appliance manufacturing.

2025-12-08

-

Color coated Aluminum Coils for Roofing, Ceiling, and Wall Systems

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19