Description:

| Alloy: | 5052 |

| Temper: | H32 / H34 / H36 |

| Thickness: | 0.3mm - 2.0mm |

| Width: | 1000mm - 1500mm |

| MOQ: | 1-3 tons |

| Alloy: | 5052 |

| Temper: | H32 / H34 / H36 |

| Thickness: | 0.3mm - 2.0mm |

| Width: | 1000mm - 1500mm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

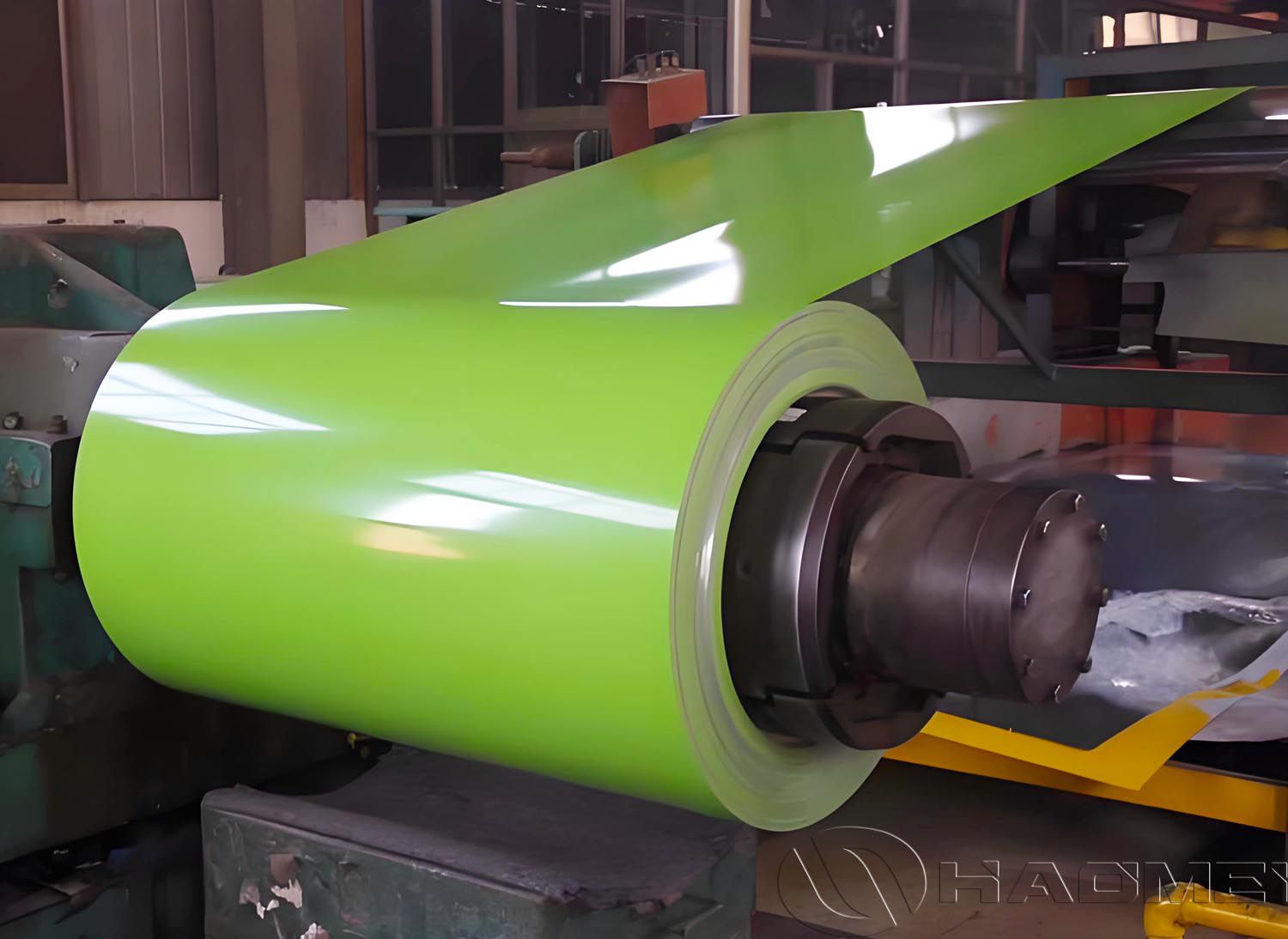

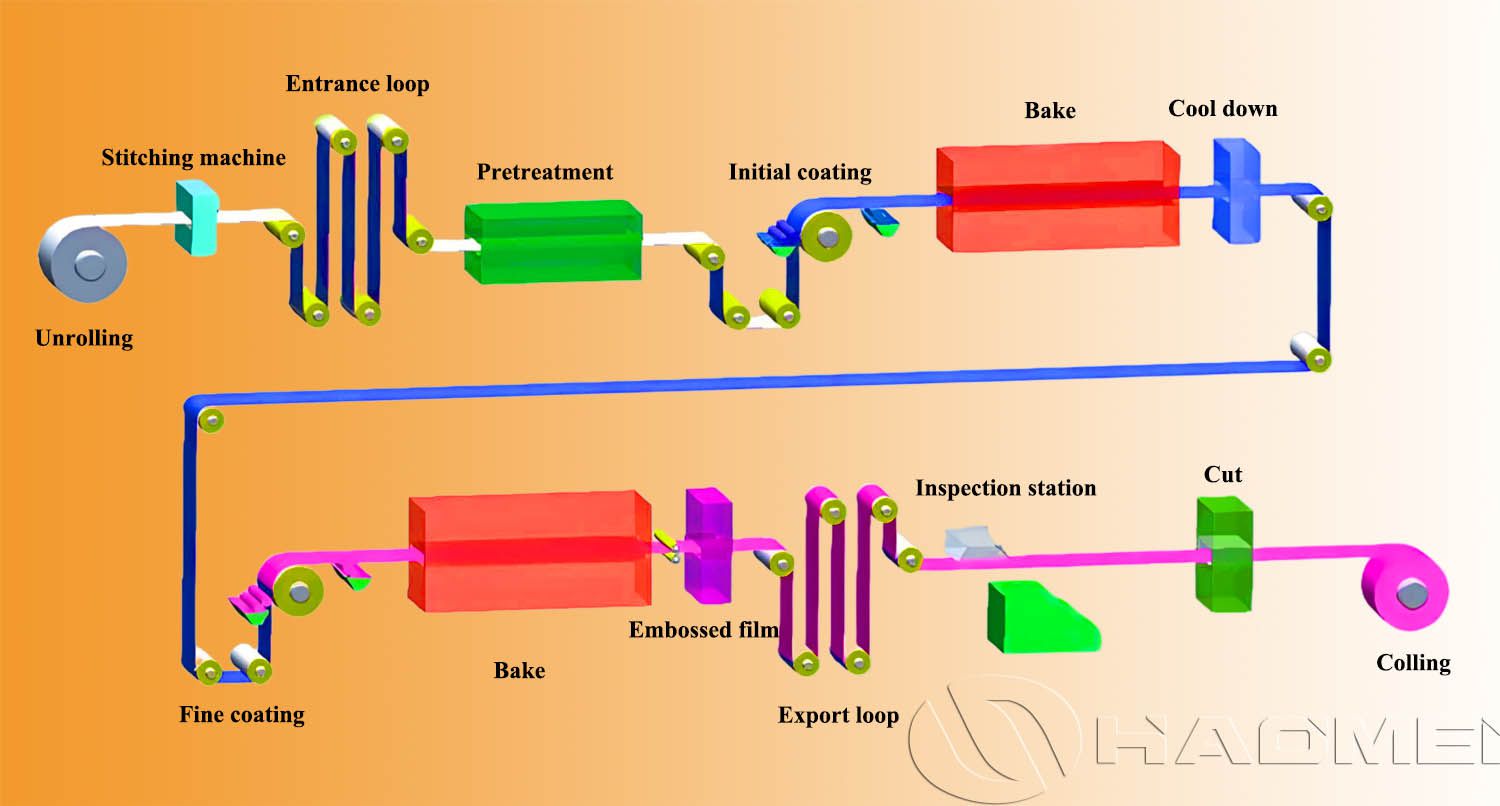

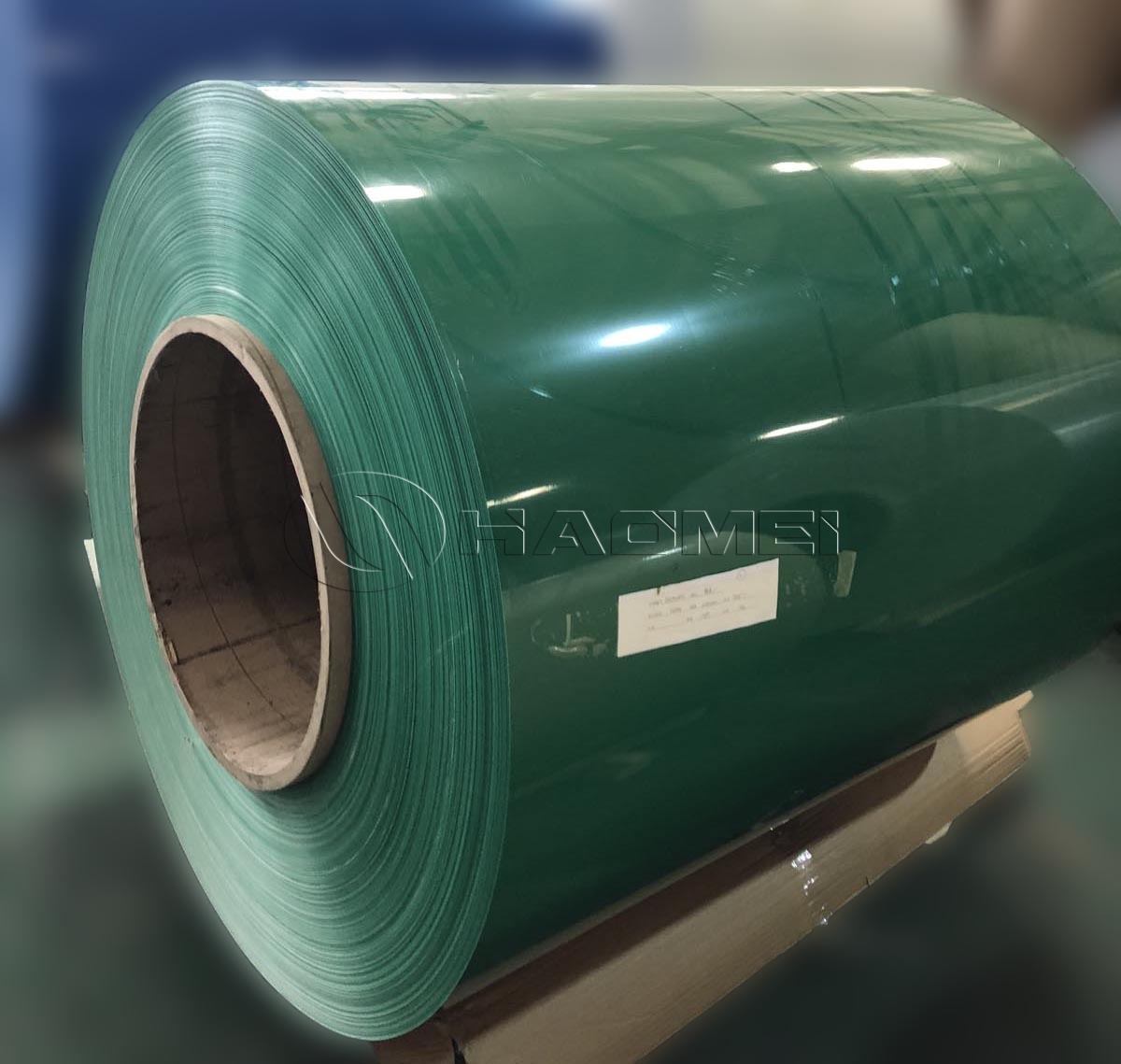

The 5052 color coated aluminum coil is a new decorative and functional material made from high-quality 5052 aluminum alloy sheets. Through pre-treatment, continuous coating, and baking/curing processes, the product combines the excellent mechanical properties and corrosion resistance of 5052 alloy with the superior decorative appearance and weather resistance of high-performance coatings. It is widely used in construction, transportation, electronics, and many other industries.

| Alloy | 5052 |

| Temper | H32 / H34 / H36 |

| Thickness | 0.3mm - 2.0mm (customizable) |

| Width | 1000mm - 1500mm (customizable) |

| Length | 1000mm - 16000mm (customizable) |

| Surface Treatment | Color Polyester Coating (PE), Fluorocarbon Coating (PVDF), Wood Grain Transfer |

| Coating Thickness | 15 - 35 μm |

| Base Material Properties | High strength, good ductility, corrosion-resistant, anti-oxidation |

| Color | Any RAL color, special effects can be customized |

| Delivery Form | Sheet, coil, strip |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | Temper | Thickness/mm | Tensile Strength Rm/MPa | Tensile Strength/MPa | Elongation% |

| 5052 | H36, H46 | >0.220-0.300 | 255~305 | ≥200 | ≥2 |

| >0.300 -0.500 | ≥3 | ||||

| H18, H38, H48 | >0.220-0.300 | ≥270 | ≥210 | ≥2 | |

| >0.300 -0.500 | ≥3 | ||||

| H19, H39,H49 | >0.220-0.300 | ≥290 | ≥220 | ≥2 | |

| >0.300 -0.500 | ≥3 |

Chemical Composition of 5052 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

Excellent Weather Resistance: PVDF coated aluminum coil offers a warranty of over 20 years; PE coated aluminum up to 10 years. Both resist UV radiation, temperature fluctuations, and corrosive environments for long-term durability.

Superior Decoration: Wood grain, stone patterns, and other effects provide a realistic texture, giving buildings a natural, lively aesthetic.

Good Mechanical Performance: Strong bending and flexural resistance, ensuring the material does not warp or deform under seasonal climate changes such as wind pressure, temperature, or humidity.

Eco-Friendly & Safe: Resistant to salt, alkali, and acid rain corrosion; non-toxic, does not release harmful gases, compliant with modern green building standards.

Lightweight & High Strength: Aluminum has low density, reducing building load and structural costs.

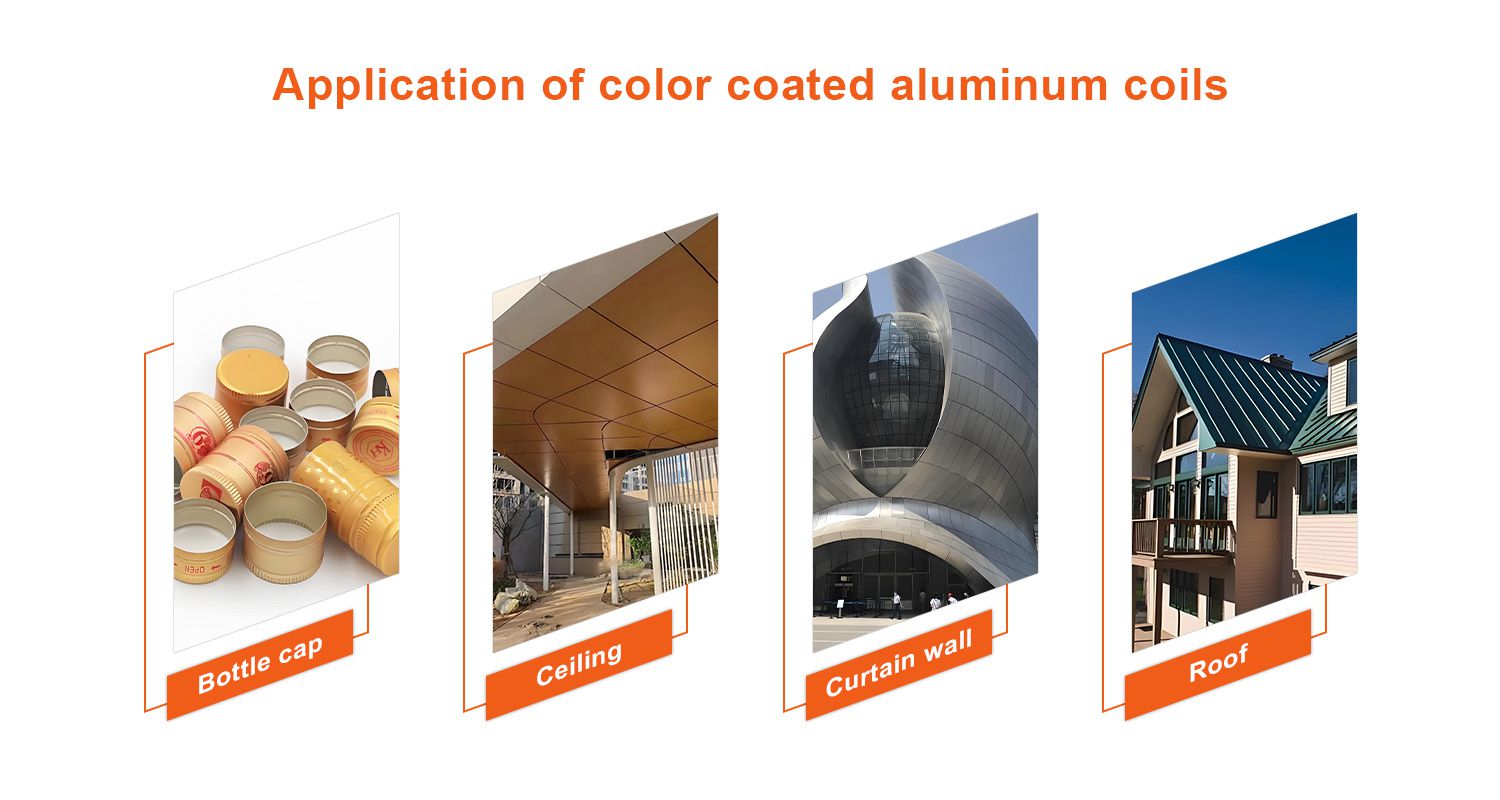

Architectural Facades & Roofing: Exterior walls of high-rise buildings, metal roofing, partition panels.

Transportation: Interior and exterior decorative parts for cars, ships, light rail car panels.

Electronics & Electrical Appliances: Appliance housings, control panels, switch cabinets.

Home Appliances: Panels for refrigerators, air conditioners, washing machines, and other appliances.

Signage & Advertising: Outdoor long-term use signage and directional signs.

Polyester Coating (PE): Most common and cost-effective coating. Offers good adhesion, rich color options, and excellent formability. Suitable for indoor decoration, ordinary signage, and outdoor applications with moderate durability requirements (5-10 years).

Fluorocarbon Coating (PVDF): High-end outdoor coating made with PVDF resin. Offers excellent weather resistance, UV resistance, anti-chalking, and self-cleaning properties, retaining color and gloss for over 15 years. Ideal for high-rise building facades, coastal areas, and industrial pollution zones.

Wood Grain / Stone Grain Transfer: Uses special inks and heat transfer techniques to create realistic wood or marble textures on the coated surface. Combines metal durability with natural beauty, used for high-decorative interior and exterior walls and ceilings.

Brushed Finish: Mechanical friction creates uniform linear patterns on the aluminum surface, highlighting metallic texture and modern aesthetics. Commonly used for appliance panels, electronic housings, and premium decorative panels.

Packaging: Usually includes moisture-proof inner layers (plastic film or anti-moisture paper), protective materials (foam or non-woven fabric), and outer fumigated wooden boxes or pallets reinforced with metal straps. Cardboard or metal edge protectors are added on both sides, with waterproof materials covering the exterior to prevent moisture during transit.

Labeling: Product specifications, weight, and manufacturer information are marked on the package. Customized labeling is available to ensure safe storage and transportation.

5052 black color-coated aluminum coils are widely used in building decoration, home appliance housings, transportation and marine engineering.

2025-12-04

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

Learn PVDF coated aluminum coil coating lifespan, fluorocarbon coating systems, coil coating process, and weather resistance performance for façades and roofing.

2026-01-28