Description:

| Alloy : | 1100, 3003, 3005, 3105, 5005, 8011 |

| Front Side: | PVDF coating or PE coating |

| Back Side: | PE coating |

| Coating Thickness: | PVDF series ≥ 25μm; PE series ≥ 18μm |

| MOQ: | 1-3 tons |

| Alloy : | 1100, 3003, 3005, 3105, 5005, 8011 |

| Front Side: | PVDF coating or PE coating |

| Back Side: | PE coating |

| Coating Thickness: | PVDF series ≥ 25μm; PE series ≥ 18μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

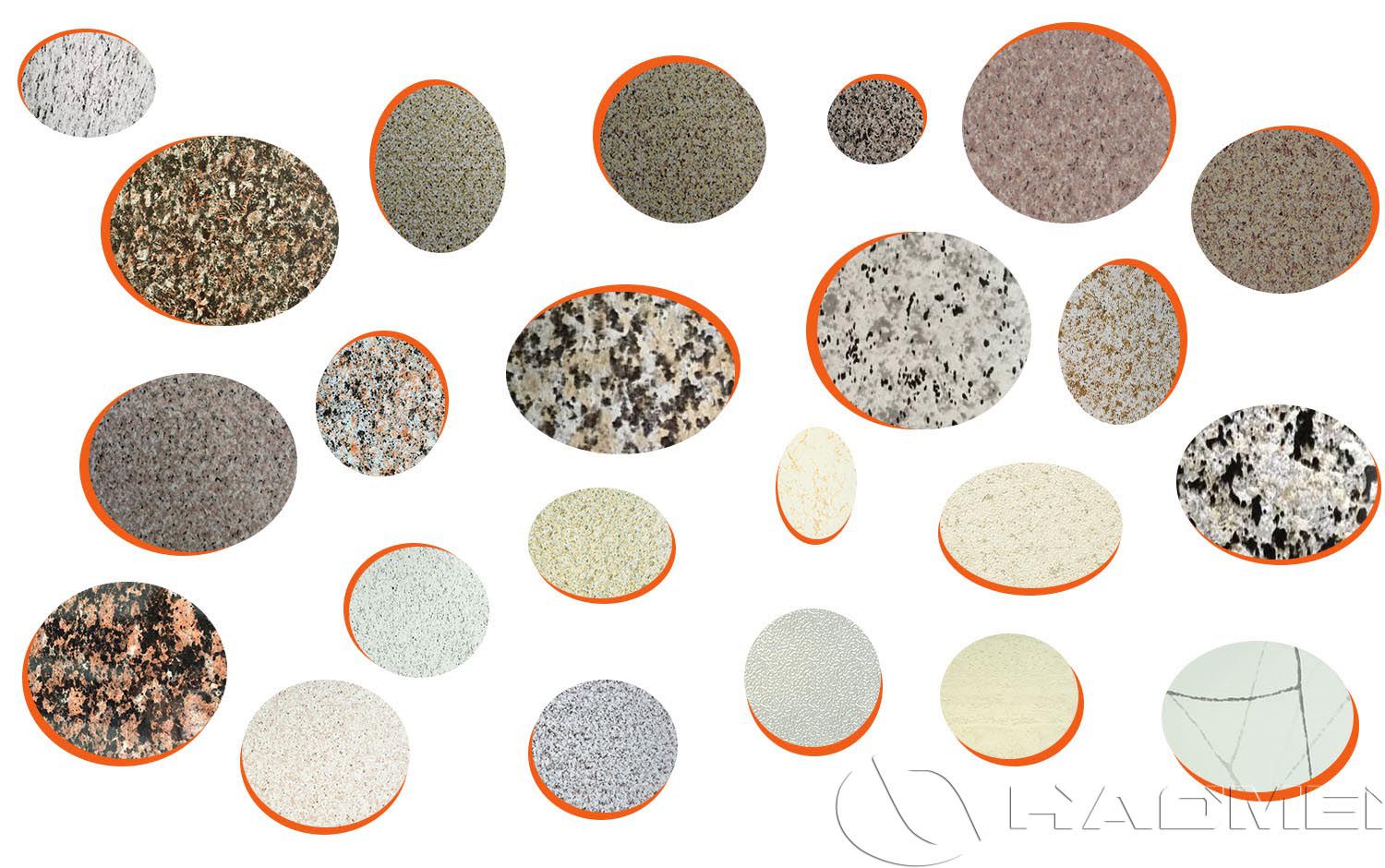

HAOMEI Aluminum develops and produces pre-painted decorative aluminum panels with brick patterns, wood grains, stone grains, camouflage, and other special textures. These products feature realistic patterns, excellent formability, corrosion resistance, energy efficiency, easy installation, and high safety-making them an ideal alternative to traditional stone and glass materials.

HAOMEI Aluminum uses advanced printing and coating technology to create realistic marble textures on the surface of aluminum coils. The multi-layer coatings are baked at high temperature, forming a strong bond with the metal substrate. The durable coating not only enhances aesthetic appeal but also provides practical advantages such as scratch resistance, easy maintenance, and UV protection-making it suitable for both interior and exterior use.

Common substrates include 1050, 1060, 3003, 5005, 5052, and 5083 aluminum alloys, ensuring both metallic strength and premium stone-like appearance. Compared with natural stone, marble pattern aluminum coils are lightweight, easy to install, highly weather-resistant, and environmentally friendly. They are widely used in building facades, interior decoration, furniture manufacturing, and ship interior outfitting.

In construction, they upgrade the visual quality of facades, cladding, and decorative wall panels, combining natural aesthetics with industrial durability.

In furniture and cabinetry, wood grain designs add warmth, while marble textures create a luxurious look for countertops and bathroom surfaces.

Camouflage finishes are used in outdoor equipment and automotive accessories, offering both stylish appearance and strong performance.

| Alloy | 1100, 3003, 3005, 3105, 5005, 8011 series |

| Temper | H18, H16, H14, H24, etc. |

| Thickness | 0.18mm-1.20mm |

| Width | 100mm-1600mm |

| Inner Diameter | 405mm / 505mm |

| Front Side | PVDF coating or PE coating |

| Back Side | PE coating |

| Gloss | customizable |

| Coating Thickness | PVDF series ≥ 25μm PE series ≥ 18μm |

| Coating Hardness | ≥ 2H (pencil hardness) |

| Adhesion | not lower than Grade 1 |

| Impact Resistance | no cracking or peeling (50KG/CM, ASTM D-2794:1993) |

| Flexibility | 2T |

| MEK Resistance | ≥ 100 |

| Scrub Resistance | ≥ 10,000 cycles with no change |

| Coil Weight | 0.5T–3T |

| Packaging | export-grade wooden pallet |

| Manufacturer | Zhengzhou, China |

| MOQ | 1-3 tons |

1. Realistic Marble Texture

High-definition printing and multi-layer coatings create vivid, layered patterns comparable to natural stone-with even greater design versatility.

2. Superior Weather Resistance

PVDF or FEVE fluorocarbon coatings provide exceptional UV, salt-spray, and pollution resistance. Outdoor service life can exceed 25 years with long-lasting color stability.

3. Lightweight yet Strong

Aluminum weighs only one-third of natural stone, helping reduce building loads and simplifying transport and installation.

4. Outstanding Corrosion Resistance

The aluminum alloy substrate combined with fluorocarbon coatings protects against acid rain, humidity, and salt corrosion, ideal for coastal and high-humidity environments.

5. Excellent Workability

Suitable for cutting, punching, bending, and roll-forming with no cracking or color loss perfect for various decorative shapes.

6. Eco-friendly and Energy Saving

Fully recyclable metal coil avoids environmental damage from stone quarrying and aligns with green building standards.

7. Easy Installation & High Safety

Unlike brittle stone, aluminum will not crack or fall. It ensures safe handling, reduced construction cycles, and improved safety.

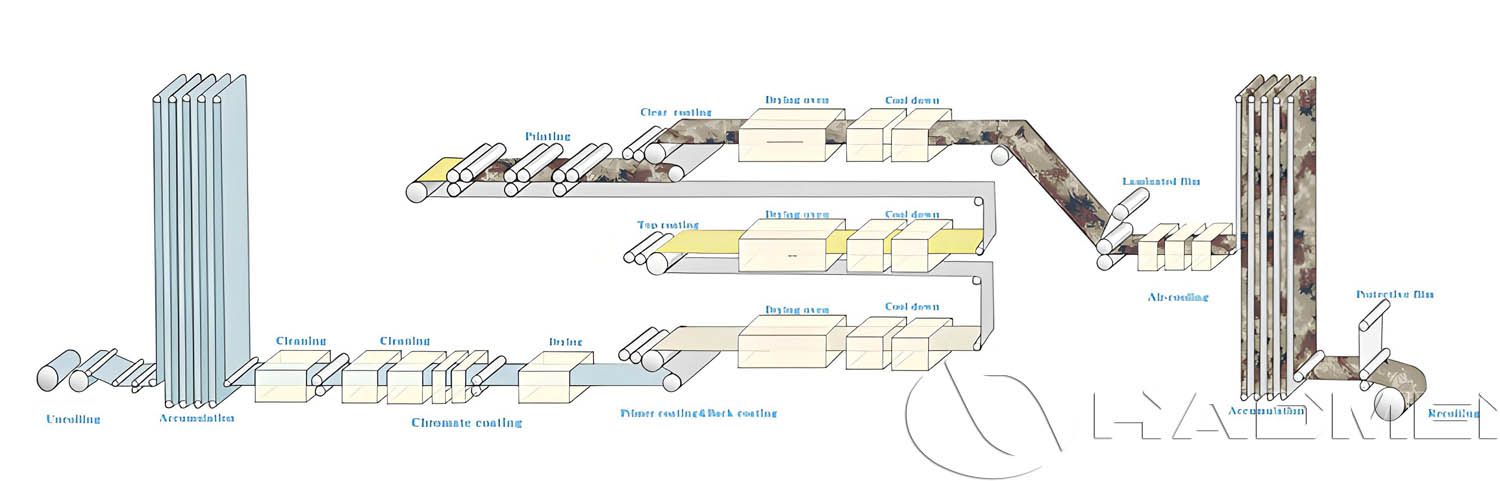

This is the core technology that differentiates marble pattern aluminum from other decorative aluminum materials. The realistic texture is achieved through three main processes:

1. Roll-Coating Printing

Engraved printing rollers transfer multi-color marble patterns onto the primed aluminum sheet.

Advantages: clear patterns, high efficiency, excellent consistency

Applications: large façade panels, ceilings, cladding systems

2. Heat Transfer Printing

A digitally printed heat-transfer film containing marble images is pressed onto the coated aluminum under high temperature, causing the pigment to sublimate and penetrate the coating.

Advantages: strong layering and customizable design

Applications: furniture panels, interior wall panels, doors

3. Specialty Spraying / Effect Coatings

Special pigments, particles, or texture-enhancing components are sprayed onto the surface to replicate stone-like granularity and tactile effects.

Advantages: produces a 3D textured feel and high realism

Applications: topcoat or clear-coat effect layers

1. PE (Polyester) Coated Aluminum

Cost-effective with rich color options. Ideal for interior decoration and industrial buildings. Affordable and visually appealing-popular among medium and small projects.

2. PVDF (Fluorocarbon) Coated Aluminum

Known as the "Durability King", offering extreme UV and chemical resistance. Ideal for iconic landmarks, coastal buildings, and long-term outdoor applications with 15-20+ years durability.

3. Epoxy Roll-Coated Aluminum

Features exceptional adhesion and chemical resistance-suitable for specialized environments such as chemical plants or food processing areas.

Single-coat

Thin and economical, used for temporary construction fences, event displays, and short-term decorative panels.

Double-coat

The most widely used, balancing cost and performance. Ideal for residential façades and shopping center exteriors.

Triple-coat

Thicker and more protective-used for high-end façades of office towers, airports, and major public buildings.

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems.

2026-01-19