News

By Hermione

By Hermione

Pvdf Coated Aluminum Coil For Facades

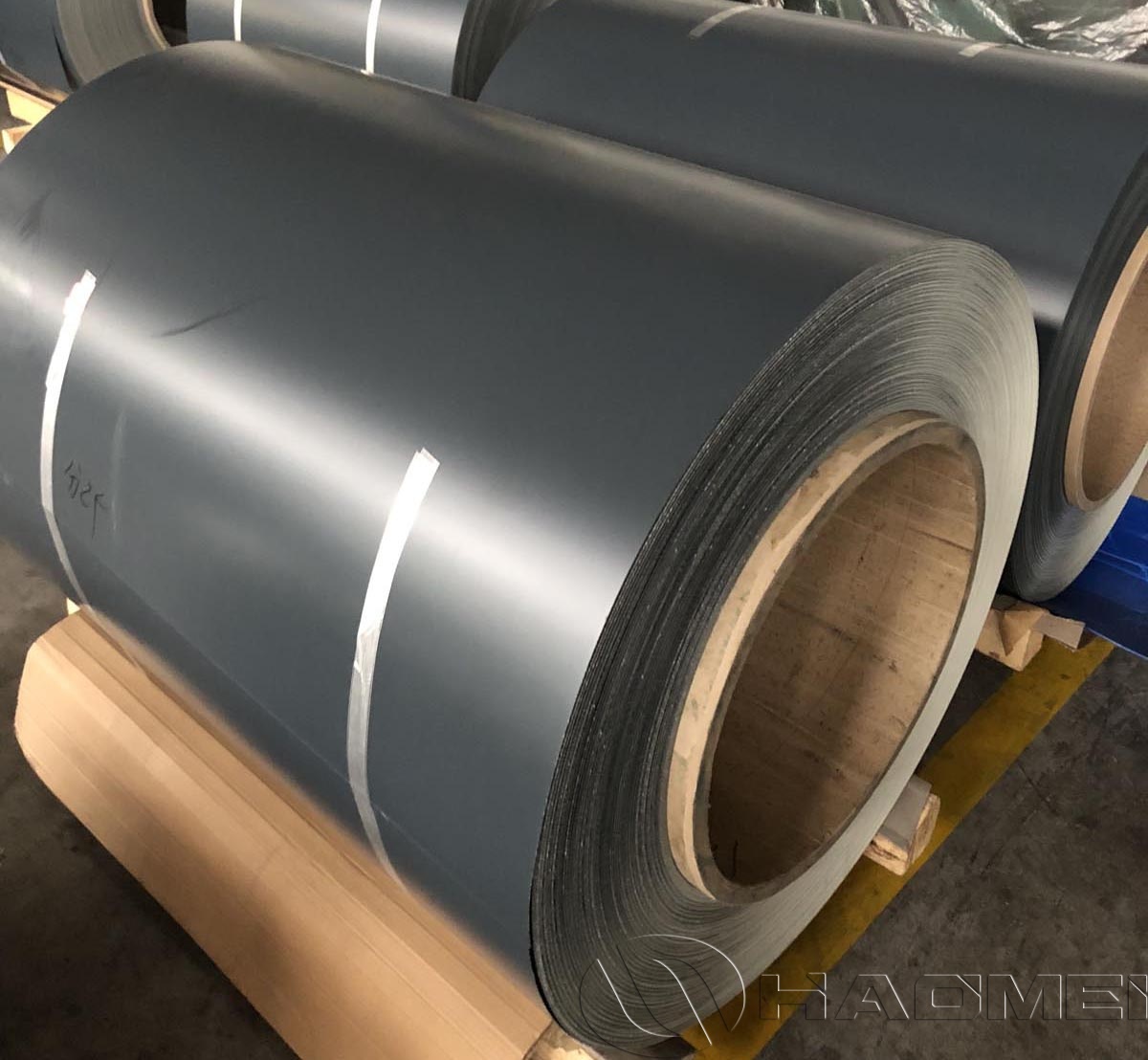

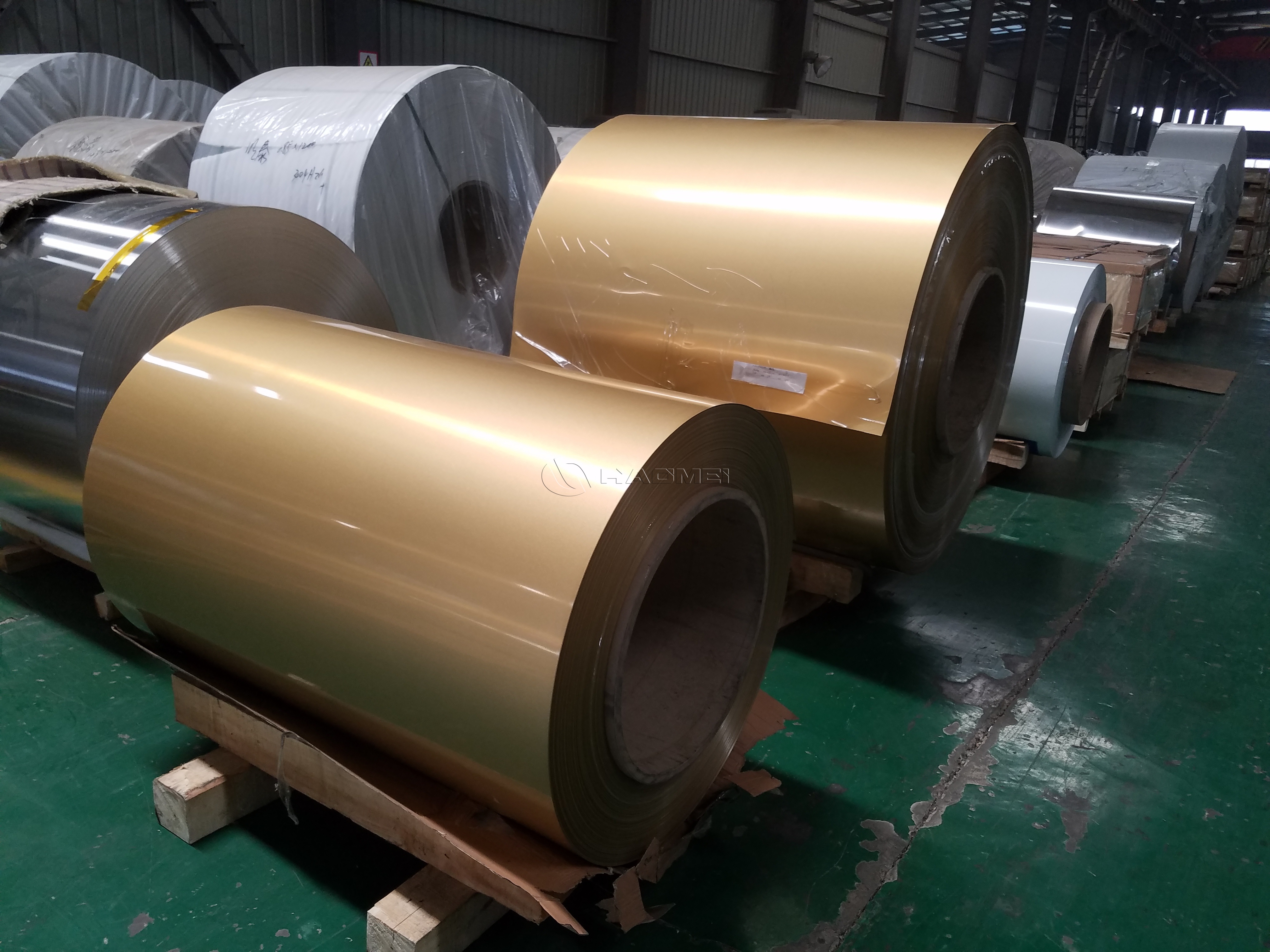

PVDF coated aluminum coil for facades is positioned as a premium architectural cladding material designed for long-term outdoor exposure. It is widely specified for exterior wall panels, rainscreen systems, curtain wall components, soffits, fascia, and formed profiles where UV resistance, color stability, and low maintenance are essential.

Why PVDF Coating Is the Preferred Choice for Exterior Facades

PVDF (polyvinylidene fluoride) fluorocarbon coating is engineered to withstand harsh environmentssunlight, humidity, salt spray, and temperature cyclingbetter than conventional coatings. For facade applications, the key value is performance retention over time: the surface resists chalking, fading, and corrosion, helping buildings maintain their intended appearance with minimal upkeep.

Typical facade-facing benefits include:

Strong resistance to UV exposure and weathering

Excellent corrosion protection when combined with proper pretreatment

High surface hardness and good scratch resistance for handling and installation

Good formability for bending, roll-forming, and panel fabrication

Material System: Aluminum Substrate + Pretreatment + PVDF Topcoat

A reliable facade coil is not only about the topcoat. Real-world durability depends on the full coating system:

Aluminum substrate: selected for strength, formability, and corrosion behavior.

Chemical pretreatment: typically chrome-free conversion coating to improve adhesion and corrosion resistance.

Primer layer: supports flexibility and barrier protection.

PVDF topcoat (and optional clear coat): provides the exterior-facing weathering performance and gloss/color retention.

This layered structure is why PVDF coated aluminum coil is commonly used in coastal cities, high-UV regions, and demanding commercial architecture.

Manufacturing Process Overview (Coil Coating)

PVDF coated aluminum coil is produced by continuous coil-coating lines, allowing consistent film thickness, color control, and curing across large volumes.

A typical process sequence includes:

Coil cleaning and degreasing

Surface pretreatment (conversion coating)

Primer coating and oven curing

PVDF topcoat application and high-temperature curing

Cooling, protective film lamination (as required), and recoiling

This controlled process supports tight appearance consistencycritical for facade projects where panels are installed side-by-side and color variation is unacceptable.

Common Aluminum Alloys for Facade Applications (and How to Choose)

Alloy selection affects strength, flatness, fabrication behavior, and long-term performance. Below are commonly specified alloys for architectural cladding:

3003 (Al-Mn): A general-purpose alloy with good formability and corrosion resistance. Commonly used for facade panels, soffits, and trim requiring reliable bending performance.

3105 (Al-Mn): Similar to 3003, often selected for building cladding coils and roll-formed profiles where consistent mechanical properties are required.

5005 (Al-Mg): Preferred when higher surface quality and anodizing compatibility are needed; also used for architectural applications requiring good corrosion resistance.

5052 (Al-Mg): Higher strength than 3003/3105, suitable for more demanding forming or where improved strength is beneficial (e.g., larger panels, high-wind zones, complex profiles).

1100 / 1050 (commercially pure aluminum): Excellent ductility and corrosion resistance, often used where deep forming is needed and strength demand is lower; also common in general finishing applications.

Practical guidance:

Choose 3003/3105 for balanced cost, formability, and broad facade suitability.

Choose 5005/5052 when strength, corrosion margin, or premium architectural requirements justify it.

Choose 1050/1100 when maximum ductility is the priority.

Core Specifications for PVDF Coated Aluminum Coil (Facade Grade)

| Item | Typical Range / Option |

|---|---|

| Coating Type | PVDF fluorocarbon coating (topcoat + primer) |

| Aluminum Alloy | 1050, 1060, 1100, 3003, 3105, 5005, 5052 (customizable) |

| Temper | H14, H16, H18, H24 (per forming needs) |

| Thickness | 0.203.00 mm |

| Width | 1001600 mm |

| Coil ID | 405 / 505 mm |

| Coating Thickness (Typical) | Topcoat 2030 m; Primer 510 m |

| Surface Finish | Solid colors, metallic, matte/gloss options (project-matched) |

| Protective Film | Available (recommended for panel fabrication and transport) |

| Application | Facade panels, cladding, curtain wall components, soffits, fascia |

Practical Facade Applications and Performance Considerations

PVDF coated aluminum coil is commonly processed into:

ACP/solid aluminum panels for exterior wall cladding

Rainscreen and cassette panels requiring stable aesthetics

Roll-formed profiles (fascia, coping, trims)

Perforated or formed architectural features

To maximize service life, it is recommended to align coil specifications with the fabrication route:

For tight bending or complex forming, specify an alloy/temper with adequate elongation and confirm bend radius requirements.

For coastal or high-pollution areas, prioritize robust pretreatment and appropriate coating build.

Use protective film during fabrication to reduce handling marks and maintain appearance uniformity.

PVDF vs. PE Coating for Facades

For exterior facades, PVDF is typically selected when long-term weathering resistance is the primary objective. PE coatings can be cost-effective for interior or short-to-medium outdoor exposure, but PVDF generally offers better gloss retention and anti-chalking performance under continuous UV and climate stress.

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

-

PVDF Coated Aluminum Coil For Industrial Roofing

PVDF coated aluminum coil for industrial roofing delivers long-term color stability, corrosion resistance and reliable coil coating quality for harsh climates.

2026-02-03

-

Pvdf Coated Aluminum Coil For Facades

PVDF coated aluminum coil for facades delivers long-lasting color, corrosion resistance, and formability for architectural cladding, panels, and profiles.

2026-01-08