News

By Hermione

By Hermione

PVDF Coated Aluminum Coil Maintenance And Cleaning

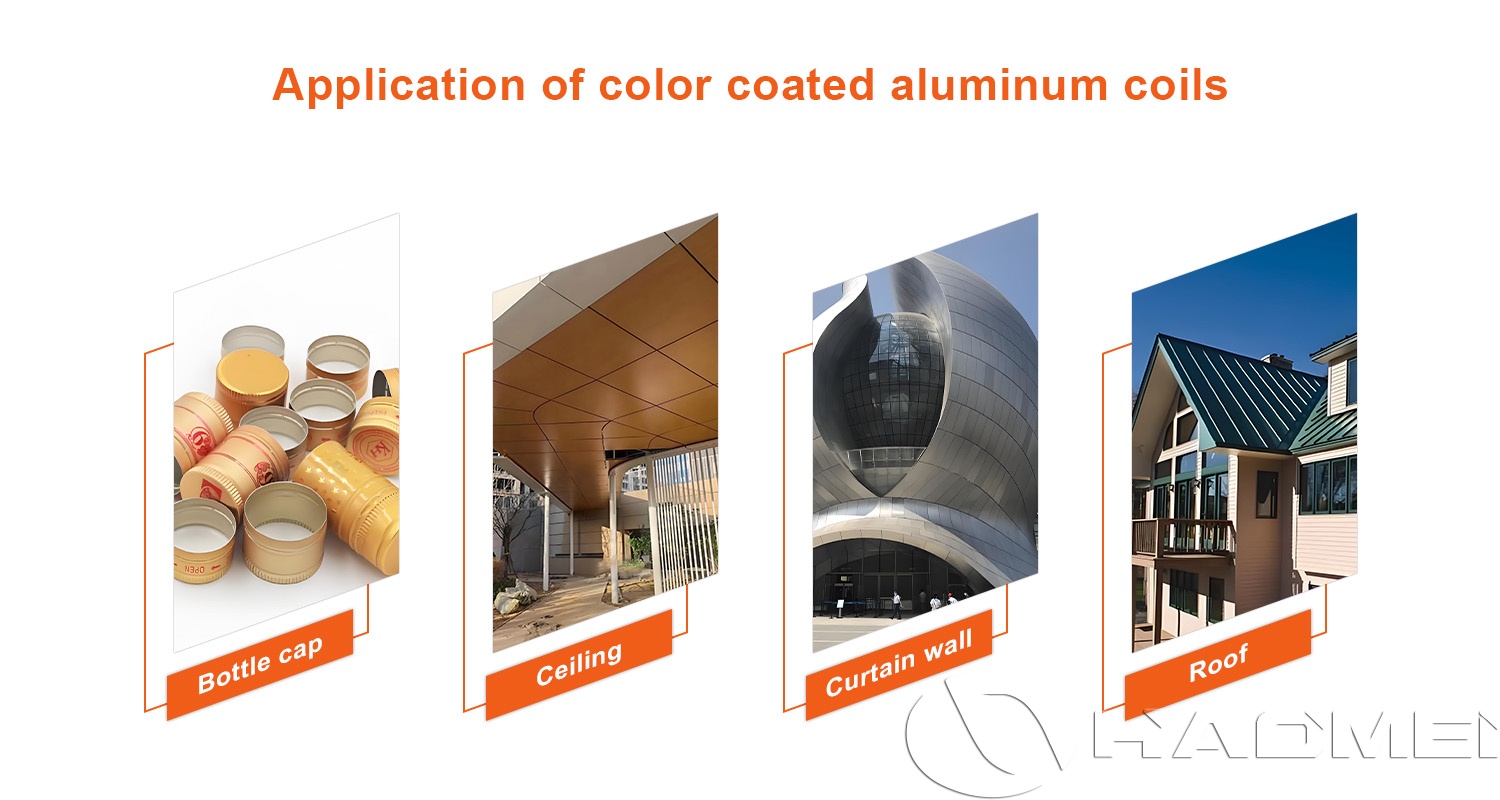

PVDF coated aluminum coil is positioned as a long-life, low-maintenance architectural and exterior-grade color-coated material, valued for durable color retention and weather resistance. It is widely used in curtain wall panels, facade cassettes, soffits, roof profiles, composite panel skins, and other building-envelope components where appearance stability and serviceability matter.

Why PVDF-Coated Aluminum Cleans Differently

A PVDF finish is a fluoropolymer coating engineered to reduce chalking and resist UV-driven degradation. That chemistry also influences how dirt bonds to the surface. In many environments, contaminants (road dust, soot, marine salts, industrial fallout) adhere more weakly than on standard polyester, so routine washing can restore appearance without aggressive chemicals.

At the same time, PVDF is not "scratch-proof." Most premature appearance issues come from cleaning methods that mechanically damage the coating (abrasive pads, gritty brushes) or chemically attack it (strong alkali, strong acid, oxidizing cleaners). Effective aluminum coil maintenance is therefore less about frequent washing and more about using the right method and intervals based on exposure.

Coating System Design: What You Are Cleaning

In a typical coil-coated construction, you are cleaning a layered system rather than bare metal:

Pretreatment conversion layer on aluminum (improves adhesion and corrosion resistance)

Primer (barrier and adhesion layer)

PVDF topcoat (the functional weathering layer)

Optional clear coat or special effect layers (for certain gloss, metallic, or pattern finishes)

This structure matters because the PVDF coating system achieves durability through controlled film build and crosslinking during bake. If cleaning products penetrate micro-defects or if aggressive solvents soften the topcoat, staining and gloss loss can accelerate, especially at edges, bends, and formed areas.

For product context, PVDF systems are typically selected for exterior longevity compared with PE Coated Aluminum Coil options used more often in interior or lower-UV applications. The underlying aluminum alloy and temper (common architectural grades include 3003/3105/5005, etc.) influence formability and dent resistance, but the cleaning "rules" are driven primarily by the topcoat chemistry and film integrity.

Coil Coating Process Factors That Affect Cleanability

In coil coating, small process variations can influence long-term cleaning behavior:

Surface preparation and pretreatment control: Poor cleaning or inconsistent conversion coating can lead to localized adhesion loss, which later appears as blistering or edge lifting after repeated wetting.

Primer/topcoat compatibility: Optimized intercoat adhesion helps prevent micro-delamination when panels cycle through heat and humidity.

Cure window (PMT and dwell time): Under-cure can reduce chemical resistance and make the surface more prone to staining; over-bake can impact gloss and flexibility. A correctly cured PVDF film generally releases dirt more easily and resists detergent attack.

Film thickness uniformity: Too thin reduces barrier performance; too thick can increase internal stress and cracking risk on tight radii. Both conditions can complicate cleaning PVDF aluminum by trapping contaminants in surface defects.

These factors are why maintenance performance should be discussed together with manufacturing discipline, not treated as an afterthought.

Core Specifications (Typical for PVDF Coil-Coated Aluminum)

| Item | Typical Range / Option | Notes |

|---|---|---|

| Aluminum alloy | 3003, 3105, 5005, 5052 | Selection depends on forming, strength, and corrosion environment |

| Aluminum thickness | 0.20-3.00 mm | Common architectural skin: 0.8–2.0 mm |

| Coil width | 600-1600 mm | Slitting available per panel line needs |

| Temper | H14, H16, H24, H26 (typical) | Matched to bending/forming requirements |

| Coating type | 70% PVDF (topcoat) | Fluoropolymer exterior-grade systems |

| Topcoat thickness | 20-30 μm (typical) | Higher build possible for specific specs |

| Primer thickness | 5-10 μm (typical) | Barrier and adhesion |

| Gloss | Matte to high gloss | Depends on resin, pigment, and additives |

| Finish options | Solid, metallic, mica, special effects | Some effect pigments need gentler cleaning |

| Service environment | Outdoor UV, humidity, pollution | Cleaning interval depends on exposure severity |

Practical Cleaning Methods for PVDF Coated Aluminum Coil Surfaces

Cleaning should be approached as controlled surface care. The aim is to remove deposits without altering the coating's gloss, texture, or film continuity.

1) Routine washing (most facades and soffits)

Use clean water rinse first to float off loose grit.

Wash with a pH-neutral or mild detergent solution.

Use a soft sponge or soft cloth; keep the surface wet to reduce friction.

Rinse thoroughly with clean water to prevent detergent residue.

Dry with a clean soft cloth where water spotting is a concern.

This method is generally sufficient for rain-shadow zones, horizontal ledges, and areas near HVAC exhaust where deposits concentrate.

2) Removal of stubborn deposits (oils, traffic film, light stains)

When mild detergent is insufficient:

Step up gradually to slightly stronger but still non-aggressive cleaners that are compatible with fluoropolymer coatings.

Use small-area testing first because metallic and special-effect finishes may show rub marks sooner than solid colors.

Avoid cleaners containing strong alkali (commonly associated with heavy-duty degreasers), strong acids, or oxidizers, as these can attack the resin matrix or pigments and cause irreversible gloss change.

3) Marine and industrial environments (salt and fallout control)

In coastal areas, airborne chlorides can accumulate in joints and edges; in industrial zones, acidic particulates can lodge in textured finishes.

Use more frequent fresh-water rinsing to prevent crystallized salt acting as an abrasive.

Pay attention to seams, fastener lines, and drip edges where deposits concentrate.

Ensure run-off does not dry in place on hot panels, which can increase spotting.

What to Avoid to Preserve Appearance and Warranty Conditions

Many PVDF appearance complaints trace back to cleaning tools rather than coating defects.

Abrasive pads, scouring powders, and stiff brushes: can create micro-scratches that trap dirt and dull gloss.

High-pressure washing too close to seams: can drive water into joints, accelerating edge-related issues.

Strong solvents or paint thinners: may soften or swell the coating depending on formulation.

Cleaning in direct high heat: rapid drying can leave detergent residue and water marks.

If the project requires documented maintenance procedures, align the cleaning chemistry and tools with the coating supplier's compatibility list and the building’s environmental exposure.

Maintenance Considerations for Formed Panels Made from PVDF Coil

PVDF coil is commonly roll-formed, brake-formed, or fabricated into cassettes. Formed zones deserve extra attention during maintenance because bending concentrates strain in the coating.

Tight radii and hems can develop micro-crazing if the alloy/temper and coating flexibility are mismatched.

Dirt accumulation at bends may appear as "staining," but it is often deposit trapped in geometric recesses.

Gentle, frequent cleaning in these zones outperforms infrequent aggressive scrubbing.

For more technical background on the base material and finish options used in building envelopes, PVDF-grade products are typically categorized under PVDF Coated Aluminum Coil selections.

How Proper Cleaning Extends Service Life

Well-executed aluminum coil maintenance preserves the PVDF topcoat's functional surface, keeping deposits from becoming chemically active (e.g., salts and industrial particulates) and minimizing the abrasion cycle that drives premature gloss loss. When cleaning is matched to the coating system design and the realities of the coil coating process, PVDF coated aluminum maintains stable color and appearance across long exterior service periods, particularly on facades, roofs, and visible architectural cladding.

-

5052 vs. 3003 Color-Coated Aluminum Coil: Which Material Is Right for You?

3003 and 5052 are the two most commonly used substrates, and they are often made into color-coated aluminum coils for use in building curtain walls, industrial plants and shipbuilding.

2025-12-12

-

1000 Series Aluminum Coil With PVDF Coating

1000 series PVDF coated aluminum coil delivers corrosion resistance, UV stability and smooth formability for cladding, roofing and signage using 1050/1060/1100 alloys.

2026-01-12

-

1200 Color Coated Aluminum Coil for Building Facade

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25