News

By Hermione

By Hermione

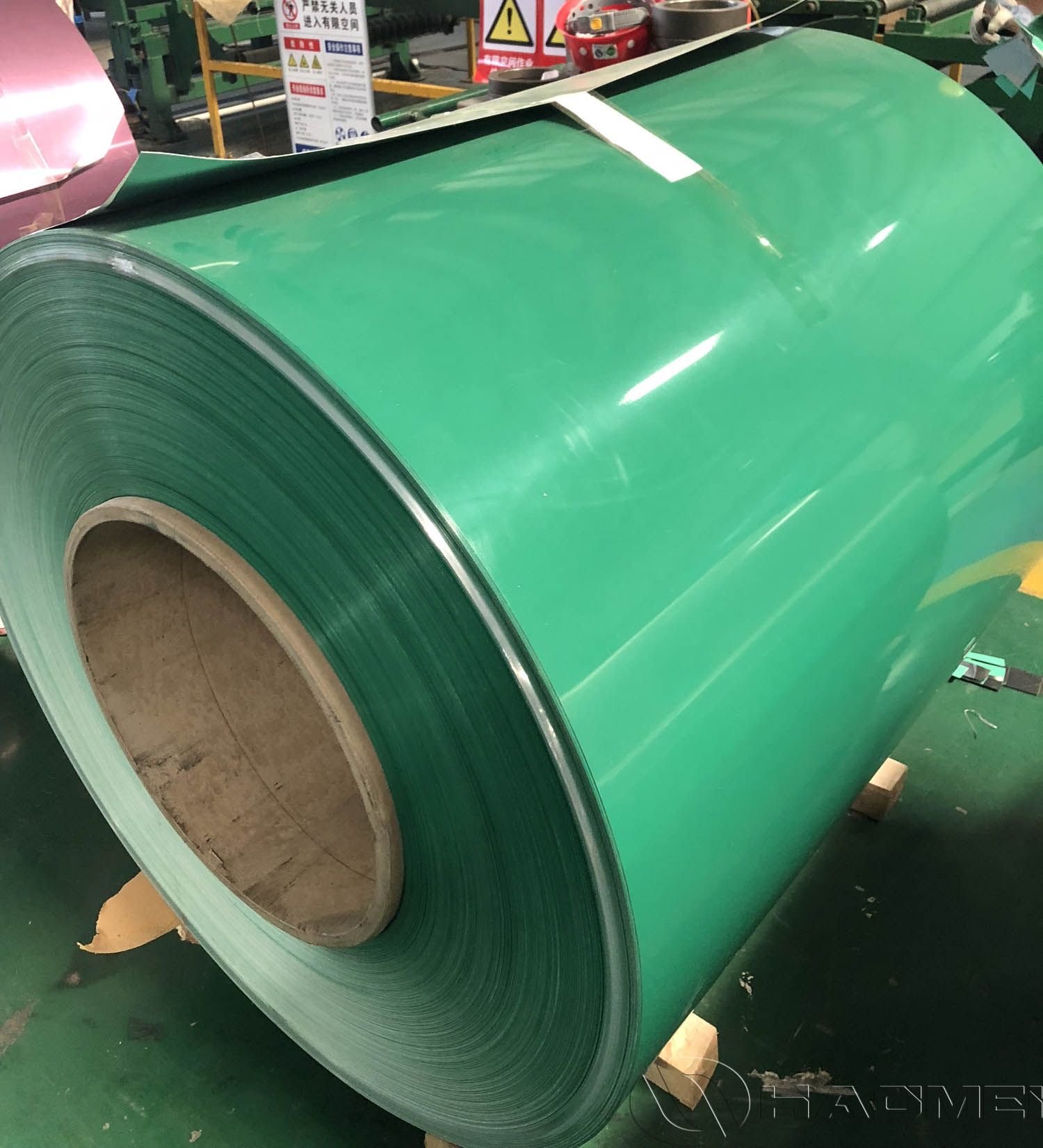

5052 H32 Color Coated Aluminum Coil for Sale

The 5052 H32 color coated aluminum coil is an upgraded aluminum-magnesium alloy material that combines medium strength, excellent corrosion resistance, and superior formability. The primary alloying element is magnesium (Mg 2.2-2.8%), with a small amount of chromium (Cr), which enhances corrosion resistance and improves mechanical stability.

The temper H32 means the material is first strain-hardened (cold-rolled) and then stabilized through low-temperature heat treatment. This condition offers ¼ hardness, creating an ideal balance between strength and formability, making it suitable for bending, stamping, and continuous roll forming.

The color-coating process (PE, PVDF, FEVE) applies multiple layers of high-performance coil coatings onto the aluminum substrate, followed by baking and curing. This process adds both decorative appeal and long-term protection. The brushed / scratch-resistant finish enhances the metallic texture while reducing the visibility of micro-scratches.

Technical Specifications of Color Coated 5052 H32 Aluminum Coil

| Alloy | 5052 |

| Temper | H32 |

| Thickness | 0.3-3.0 mm |

| Width | 20-1600 mm |

| Length | 1000-16000 mm |

| Coil Weight | 2-5 tons/coil |

| Coating Type | PVDF / PE / FEVE |

| Surface Finish | Brushed / Scratch-Resistant |

| Coating Thickness | Single coat: 5-12 μm; Double coat: 20-28 μm |

| Tensile Strength | 220-260 MPa |

| Yield Strength | ≥130 MPa |

| Elongation | ≥5% |

| Salt Spray Resistance | ≥1000 hours |

| Colors | RAL chart, metallic colors, matte, glossy, wood grain, stone grain, etc. |

Advantages of 5052 Color Coated Aluminum Coil

1. Corrosion Resistance: As an aluminum-magnesium alloy, 5052 exhibits excellent corrosion resistance in marine climates and humid environments. This makes it an ideal choice for shipbuilding, coastal construction, and transportation vehicle components.

2. Formability: Its good plasticity makes it suitable for forming complex shapes through stamping, deep drawing, and bending, meeting diverse design requirements.

3. Weldability: It can be welded using conventional arc welding methods, and the weld performance is reliable.

4. Medium-to-High Strength: 5052 possesses high tensile and yield strength, effectively resisting wind loads and structural stresses, making it an ideal material for the exterior walls of high-rise buildings.

5. Weather Resistance: Especially the PVDF coating, which has extremely strong weather resistance and UV resistance, ensuring that the color remains bright and long-lasting even after years of outdoor use.

6. Environmental Sustainability: The aluminum itself is 100% recyclable, and the pre-coating technology uses environmentally friendly processes, reducing pollution at the construction site.

7. Aesthetics: It offers highly customizable colors, with few surface scratches and a stable aesthetic effect.

Main Applications of 5052 Color Coated Aluminum Coil

Building Exterior Walls and Roofs: Metal curtain walls, roof panels, and aluminum ceiling panels for high-rise buildings.

Transportation: Interior decorative panels for high-speed rail, subway, and light rail; ship cabin decoration.

Home Appliance Manufacturing: Outer panels for home appliances requiring high strength, such as refrigerators and air conditioners.

Electronic Products: Outer casings for electronic devices requiring high surface texture, strength, and color.

Marine Equipment: Equipment and structures near ports or seawater that need to resist salt spray corrosion.

How Much Does 5052 Color Coated Aluminum Coil Cost per Ton?

HAOMEI Aluminum, a professional manufacturer of color-coated aluminum coils, prices its 5052 coated aluminum coils around $3300. The exact price depends on the aluminum ingot price, processing fees, and shipping costs on the day of purchase.

We promise to provide the best price of the day based on transparent cost accounting. To ensure an accurate quote, please provide the following details:

Required thickness: (e.g., 1.5 mm)

Required width: (e.g., 1250 mm)

Coating type: (PE scratch-resistant or PVDF scratch-resistant)

Color/gloss: (Provide RAL color code or specify high gloss/matte)

Quantity: (tons or square meters)

Delivery location: (affects logistics costs)

The final price will be determined by the sales manager.

FAQ

Q1: What is brushed or scratch-resistant color coated aluminum coil?

A1: It is a coil produced with a special surface coating that forms fine metallic textures, minimizing visible scratches and enhancing surface durability.

Q2: Can 5052 H32 coated aluminum coil be used for exterior building façades?

A2: Yes. PVDF or FEVE coatings are strongly recommended, offering 20-30 years of weather resistance.

Q3: Is it easy to process?

A3: Yes. H32 temper provides the right balance of hardness and ductility. It can be bent, stamped, rolled, and stretched without coating cracking or peeling.

Q4: Can I customize color and texture?

A4: We support personalized customization including RAL color chart colors, matte/gloss finishes, wood grain, stone grain, and brushed metal.

Q5: What is the minimum order quantity (MOQ)?

A5: Regular colors can be ordered from 1 ton; customized colors are generally 3-5 tons.

-

Understanding the Coating Types of Color Coated Aluminum Coil

What Is Color Coated Aluminum Coil?Color coated aluminum coil is produced by applying one or multiple layers of organic coating onto an aluminum alloy substrate through continuous roll-coating followed by high-temperature curing.The coating is the core of

2025-12-01

-

Pvdf Coated Aluminum Coil For Exterior Cladding

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29

-

1000 Series Aluminum Coil With PVDF Coating

1000 series PVDF coated aluminum coil delivers corrosion resistance, UV stability and smooth formability for cladding, roofing and signage using 1050/1060/1100 alloys.

2026-01-12