Description:

| Alloy: | 1060, 1100, 3003, 3004, 3105, 5052, 5005, 8011 |

| Temper: | H14, H16, H24, H26, etc. |

| Thickness Range: | 0.5mm - 6.0mm |

| Width Range: | 20mm - 1600mm |

| Weather Durability: | Over 20 years outdoor, color difference ΔE ≤ 2 |

| Alloy: | 1060, 1100, 3003, 3004, 3105, 5052, 5005, 8011 |

| Temper: | H14, H16, H24, H26, etc. |

| Thickness Range: | 0.5mm - 6.0mm |

| Width Range: | 20mm - 1600mm |

| Weather Durability: | Over 20 years outdoor, color difference ΔE ≤ 2 |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

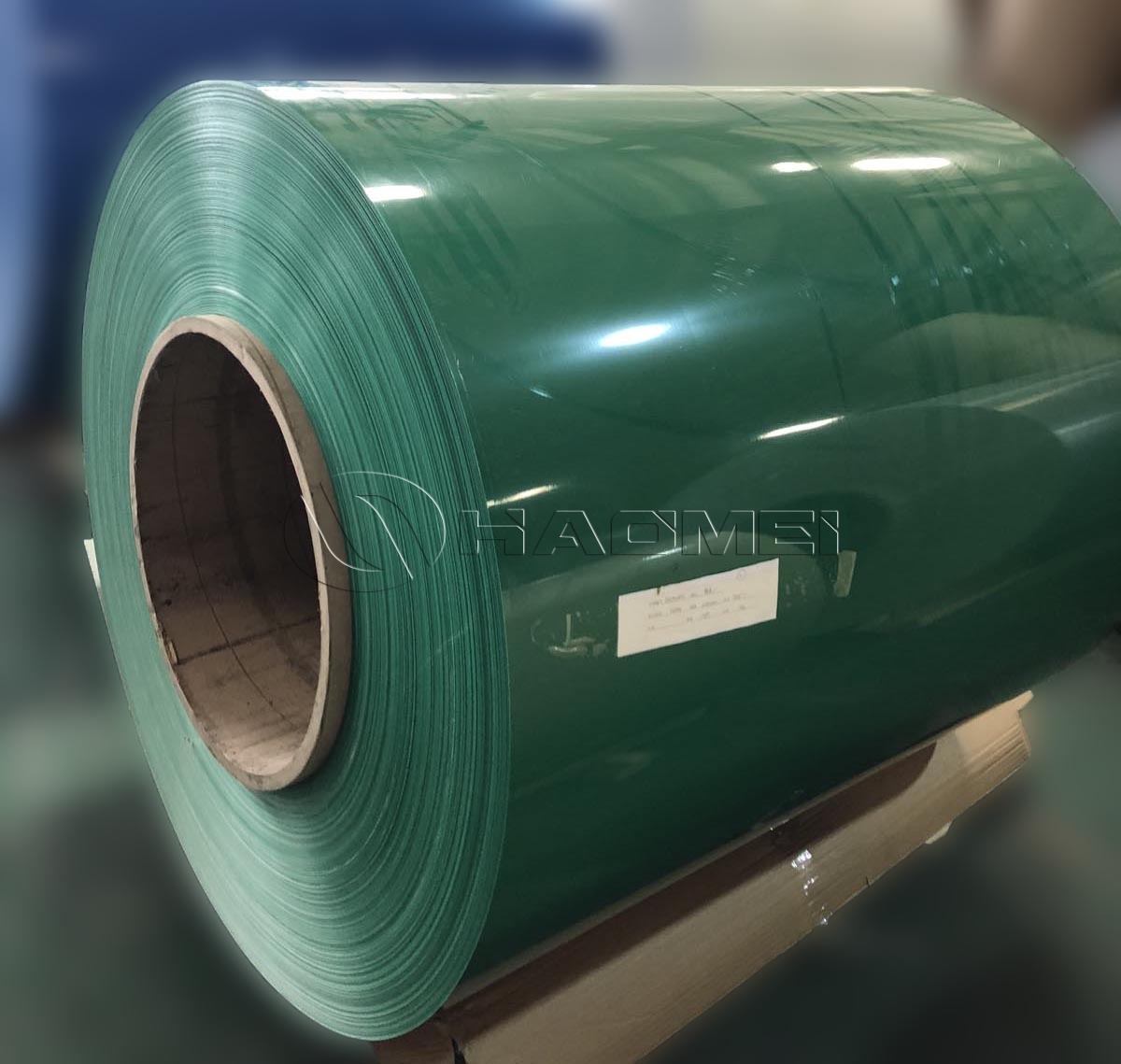

PVDF coated aluminum coil, also known as fluorocarbon coated aluminum coil, is a premium color-coated aluminum product. It is made from high-quality aluminum alloy as the base material, which undergoes degreasing and chemical treatment before being coated with polyvinylidene fluoride (PVDF) resin. The coil is then baked and cured at high temperatures to ensure a durable and uniform coating.

PVDF coated aluminum coils exhibit exceptional weather resistance, superior corrosion resistance, and excellent color stability. They can withstand harsh outdoor environments for more than 20 years without fading or chalking, making them ideal for architectural curtain walls, roof cladding, airport terminals, subway stations, bridge railings, and home appliance panels.

PVDF, short for polyvinylidene fluoride, has a unique chemical structure. The carbon–fluorine (C-F) bond in its molecular chain has very high bond energy (485 KJ/mol). Since ultraviolet photons in sunlight cannot easily break C-F bonds, fluoropolymers are almost unaffected by sunlight. Therefore, aluminum coated with PVDF paint demonstrates excellent weather durability, superb color retention, acid and alkali resistance, and remarkable gloss retention, even under extreme outdoor exposure.

1. Exceptional Weather Resistance

PVDF coatings contain highly stable fluorocarbon bonds that resist UV radiation, acid rain, pollution, and extreme temperatures. They can maintain color and gloss for over 20 years in outdoor conditions without fading or chalking.

2. Excellent Corrosion Resistance

The coating effectively resists acids, alkalis, and salt spray, making it particularly suitable for coastal and industrial environments with high corrosion potential.

3. Low Maintenance

PVDF coated aluminum coils require minimal maintenance, significantly reducing lifecycle costs compared to other materials. Their smooth surface and weather resistance make cleaning easy and prevent corrosion or staining of the substrate.

4. Long-Lasting Color Stability

Thanks to highly stable pigments, the coating maintains its original color saturation and gloss even under prolonged sunlight exposure.

5. High Strength and Light Weight

Aluminum combines high strength with low density, ensuring easy installation while meeting wind and seismic resistance requirements for modern architecture.

6. Excellent Formability

The material has good flexibility and can be bent, punched, or formed into various decorative panel shapes.

7. Environmentally Friendly

PVDF coatings are free from lead, chromium, and other toxic substances, complying with RoHS environmental standards. The aluminum substrate is 100% recyclable, in line with modern green building principles.

| Alloy | 1060, 1100, 3003, 3004, 3105, 5052, 5005, 8011 |

| Temper | H14, H16, H24, H26, etc. |

| Thickness Range | 0.2mm - 3.0mm |

| Width Range | 20mm - 1600mm |

| Coating Thickness | Front: 25-30μm / Back: 5-8μm |

| Coating Type | Single or Double Side |

| Gloss Level | High gloss / Semi-gloss / Matt |

| Surface Finish | PVDF Coating (Various Colors), Wood Grain, Stone Grain, Marble Finish |

| Paint Brands | PPG, Akzo Nobel, Nippon, Beckers |

| Weather Durability | Over 20 years outdoor, color difference ΔE ≤ 2 |

| Processing Performance | Bending ≥ 2T, no cracking or peeling |

| MOQ | 1-3 tons |

| Test Item | Standard Requirement | Result | Test Method |

| Color Difference | ΔE ≤ 2.0 | Better than standard | GB/T17748 |

| Gloss Deviation | ≤10 | Better than standard | GB/T17748 |

| Coating Thickness | ≥25μm (2-coat) / ≥30μm (3-coat) | Pass | GB/T17748 |

| Pencil Hardness | ≥HB | ≥HB | GB/T17748 |

| Flexibility | ≤2T | ≤2T | GB/T17748 |

| Adhesion | Circle Test: 1 / Grid Test: 0 | Pass | GB/T17748 |

| Impact Resistance | ≥50kg·cm | ≥50kg·cm | GB/T17748 |

| Boiling Water Resistance | 2h No Change | Pass | GB/T17748 |

| Solvent Resistance | ≥200 rubs | Pass | GB/T17748 |

| Acid Resistance (5% HCl, 24h) | No Change | Pass | GB/T17748 |

| Alkali Resistance (5% NaOH) | No Blistering, ΔE ≤ 2.0 | Pass | GB/T17748 |

| Nitric Acid Resistance | No Abnormalities, ΔE ≤ 5.0 | Pass | GB/T17748 |

| Oil Resistance (20# Engine Oil, 24h) | No Change | Pass | GB/T17748 |

| Salt Spray Resistance (4000h) | ≥ Grade 1 | Pass | GB/T17748 |

| Abrasion Resistance | ≥5L/μm | Better than standard | GB/T17748 |

| Stain Resistance | ≤5% | Better than standard | GB/T17748 |

| Artificial Aging (4000h) | ΔE ≤ 4.0 | ΔE ≤ 4.0 | GB/T17748 |

| Gloss Retention | ≤ Grade 2 | ≤ Grade 2 | GB/T17748 |

| Other Aging Performance | Grade 0 | Grade 0 | GB/T17748 |

Architectural Curtain Walls: Skyscrapers, landmark buildings, stadiums, airports, train stations, and public facilities.

Roof Systems: Ideal for metal roofing requiring high weather resistance and long service life.

Transportation Facilities: Subways, light rail systems, highway noise barriers, and tunnel linings.

Special Environments: Suitable for coastal areas, high-altitude regions, and acid rain zones.

Composite Panels: Ideal surface layer for aluminum composite panels and honeycomb panels.

| Series | Alloy | Temper | Thickness | Width | Length |

| 1000 Series | 1050, 1060, 1100, 1200, 1350 | H42,H44,H46,H48,etc | 0.25-3.0 mm | ≤1800 mm | Customizable |

| 3000 Series | 3003, 3004, 3105 | ||||

| 5000 Series | 5050, 5052, 5083, 5454, 5754 | ||||

| 8000 Series | 8011 |

| Comparison Item | PVDF Coated Aluminum Coil | HDPE Coated Aluminum Coil | PE Coated Aluminum Coil |

| Main Features | Excellent UV, anti-chalking, and weather resistance | High hardness, strong wear and corrosion resistance | Bright colors, good flexibility, low cost |

| Outdoor Service Life | 20+ years | 10-15 years | 8-10 years |

| UV Resistance | ★★★★★ (Excellent) | ★★★★☆ (Good) | ★★★☆☆ (Moderate) |

| Chemical Resistance | ★★★★★ (Strong) | ★★★★☆ (Good) | ★★★☆☆ (Average) |

| Surface Hardness | Medium-soft, good crack resistance | High hardness, scratch resistant | Soft, ideal for complex forming |

| Processability | Excellent (cutting, bending, punching) | Limited, for flat surfaces | Excellent for complex shapes |

| Self-Cleaning | Excellent (Lotus Effect) | Average | Average |

| Gloss Level | Mainly matte/semi-gloss | High gloss | Optional (high/semi/matte) |

| Cost | Higher | Moderate | Lower |

| Typical Applications | High-end facades, airports, subways, bridges, durable exteriors | Industrial roofs, warehouses, outdoor equipment | Indoor decoration, billboards, ceilings, appliance panels |

Q1: What's the main difference between PVDF coating and ordinary color coated aluminum?

A1: PVDF coating contains over 70% fluorocarbon resin, offering superior UV resistance, corrosion resistance, and self-cleaning ability. Regular PE coatings are mainly used indoors with lower weather resistance.

Q2: What is the expected service life of PVDF coated aluminum coil?

A2: Under normal conditions, PVDF coatings can last over 25 years without fading or chalking; in coastal or industrial areas, 15+ years is typical.

Q3: Can colors be customized for my brand or project?

A3: Yes. We can match RAL colors, gloss levels, and surface textures (e.g., wood grain, stone, brushed finishes) according to your sample or design.

Q4: Is PVDF coating resistant to high temperatures or acid-base environments?

A4: PVDF coatings withstand temperatures from -40°C to +120°C, and resist acid rain, salt spray, and industrial gases effectively.

Q5: What are the storage and transportation precautions?

A5: Keep the coils in a dry, ventilated area, away from sunlight and moisture. Use moisture-proof wooden pallets, and allow the material to acclimate at room temperature for 48 hours before use.

Q6: Do you provide samples or technical data sheets?

A6: Yes. A4-sized samples or detailed technical data sheets are available free of charge for customer testing and comparison.

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19