Description:

| Alloy: | 1050 |

| Thickness: | 0.2mm - 1.5mm |

| Coating Type: | Polyester (PE), PVDF, Epoxy |

| Coating Thickness: | Single side: 5-25μm / Double side: 5-35μm |

| Color Options: | RAL Standard Colors / Customized Colors |

| Alloy: | 1050 |

| Thickness: | 0.2mm - 1.5mm |

| Coating Type: | Polyester (PE), PVDF, Epoxy |

| Coating Thickness: | Single side: 5-25μm / Double side: 5-35μm |

| Color Options: | RAL Standard Colors / Customized Colors |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

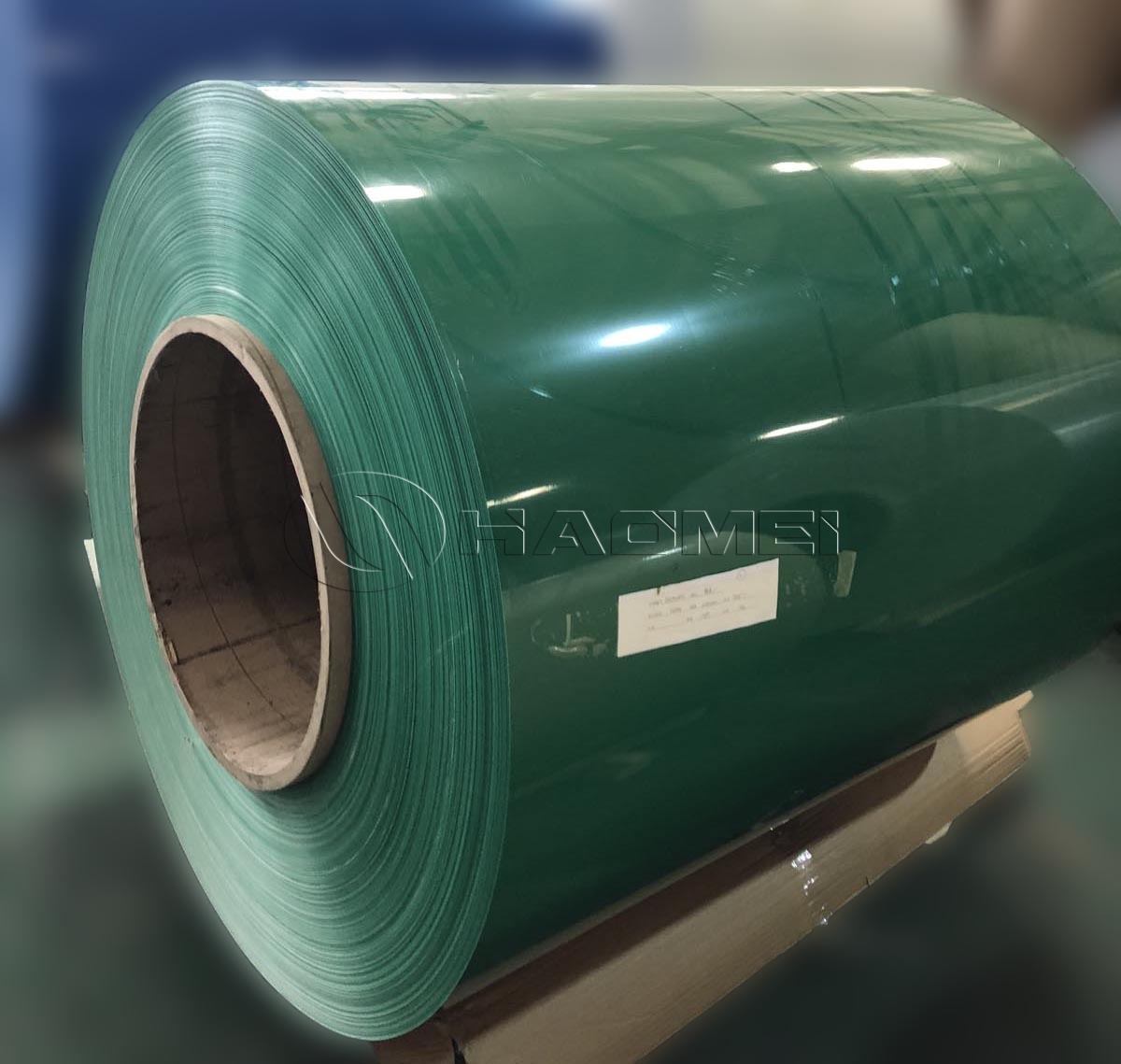

The 1050 color coated aluminum coil is a decorative coated product made from high-purity 1050 aluminum as the base material. It is produced through a series of precision processes including degreasing, chemical conversion, roller coating, and high-temperature baking.

This product is known for its excellent formability, stable chemical properties, and vivid color performance, making it an ideal material for architectural decoration, advertising signage, home appliances, and transportation.

As a representative of the 1000 series pure aluminum, 1050 alloy contains more than 99.5% aluminum, offering excellent conductivity, thermal conductivity, and corrosion resistance. Combined with high-performance coatings such as PE or PVDF, it provides multiple advantages including lightweight structure, aesthetic appearance, weather resistance, and environmental sustainability.

Excellent Formability:

The 1050 aluminum substrate has high plasticity, making it easy to perform complex forming processes without cracking.

Cost-Effective:

Compared with some alloy grades, 1050 offers a more economical solution while maintaining good performance.

Lightweight and Energy-Saving:

With a lower density than color-coated steel, it reduces structural load and improves installation efficiency.

Strong Coating Adhesion:

The advanced surface treatment and roller coating process ensure a firm bond between the coating and substrate, preventing peeling or delamination.

Outstanding Weather Resistance:

The coated surface withstands UV radiation, wind, rain, and freezing conditions. PE coatings provide up to 10 years of durability, while PVDF coatings last over 20 years.

Environmentally Friendly and Recyclable:

1050 aluminum contains no heavy metals or harmful substances and is 100% recyclable, aligning with sustainable development standards.

| Alloy | 1050 |

| Temper | O, H14, H16, H18, H24, etc. |

| Thickness | 0.2mm - 1.5mm |

| Width | 20mm - 1600mm |

| Length | 1000mm - 16000mm |

| Coating Type | Polyester (PE), PVDF, Epoxy |

| Coating Thickness | Single side: 5-25μm / Double side: 5-35μm |

| Color Options | RAL Standard Colors / Customized Colors |

| Surface Finish | Glossy, Matte, Brushed, Embossed, Wood Grain, Stone Grain, Mirror, etc. |

| Inner Diameter | 150mm / 405mm / 505mm |

| Outer Diameter | 76mm / 152mm |

| Coating Process | Two-Coat Two-Bake / Three-Coat Three-Bake |

| Packaging | Standard Wooden Pallet |

| MOQ | 1-3 tons |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.5 |

| Alloy | 1050 O |

| Tensile Strength | 60-95 MPa |

| Yield Strength (0.2% Offset) | 20-40 MPa |

| Elongation | 25-35% |

| Hardness (HRB) | 20-30 |

| Density | 2.7 g/cm³ |

| Melting Point | 643-657°C |

| Thermal Conductivity | 205 W/m·K |

| Electrical Conductivity | 61% IACS |

| Thermal Expansion Coefficient | 23.1×10⁻⁶/°C (20–100°C) |

Home Appliances:

Refrigerator inner panels and back panels, air conditioner guide plates, washing machine side panels, oven liners.

Interior Decoration:

Ceiling panels, lighting reflectors, wall partitions, interior wall cladding.

Packaging Materials:

Easy-open can lids, food packaging, and pharmaceutical foil packaging.

Transportation:

Automotive interior panels, fuel tank covers, and pipe cladding.

Electronics:

Heat sinks, electronic casings, and small enclosures.

Compared to 3003 or 5052 color coated aluminum coils, the 1050 coil has lower tensile strength but higher purity.

1050 is ideal for decorative, reflective, and lightweight applications, while 5052 and 3003 are preferred for structural and load-bearing uses.

To meet different customer needs, GNEE supplies both alloy base coils and 1050 color coated aluminum coils.

Equipped with advanced continuous roller coating production lines ensuring precise color consistency;

Over 20 years of export experience, serving clients across Southeast Asia, the Middle East, South America, and Europe;

OEM/ODM customization for color, width, thickness, and coil diameter;

100% inspection before shipment to guarantee product quality;

One-stop procurement service-from raw base material to finished coated coil, reducing total sourcing cost.

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31