Description:

| Alloy: | 1060 |

| Temper: | H42 (H22), H44 (H24), H46 (H26), H48 (H28) |

| Coating Type: | PE / PVDF |

| Coating Thickness: | Bottom: 16-18 μm; Top: up to 25 μm |

| MOQ: | 1-3 tons |

| Alloy: | 1060 |

| Temper: | H42 (H22), H44 (H24), H46 (H26), H48 (H28) |

| Coating Type: | PE / PVDF |

| Coating Thickness: | Bottom: 16-18 μm; Top: up to 25 μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

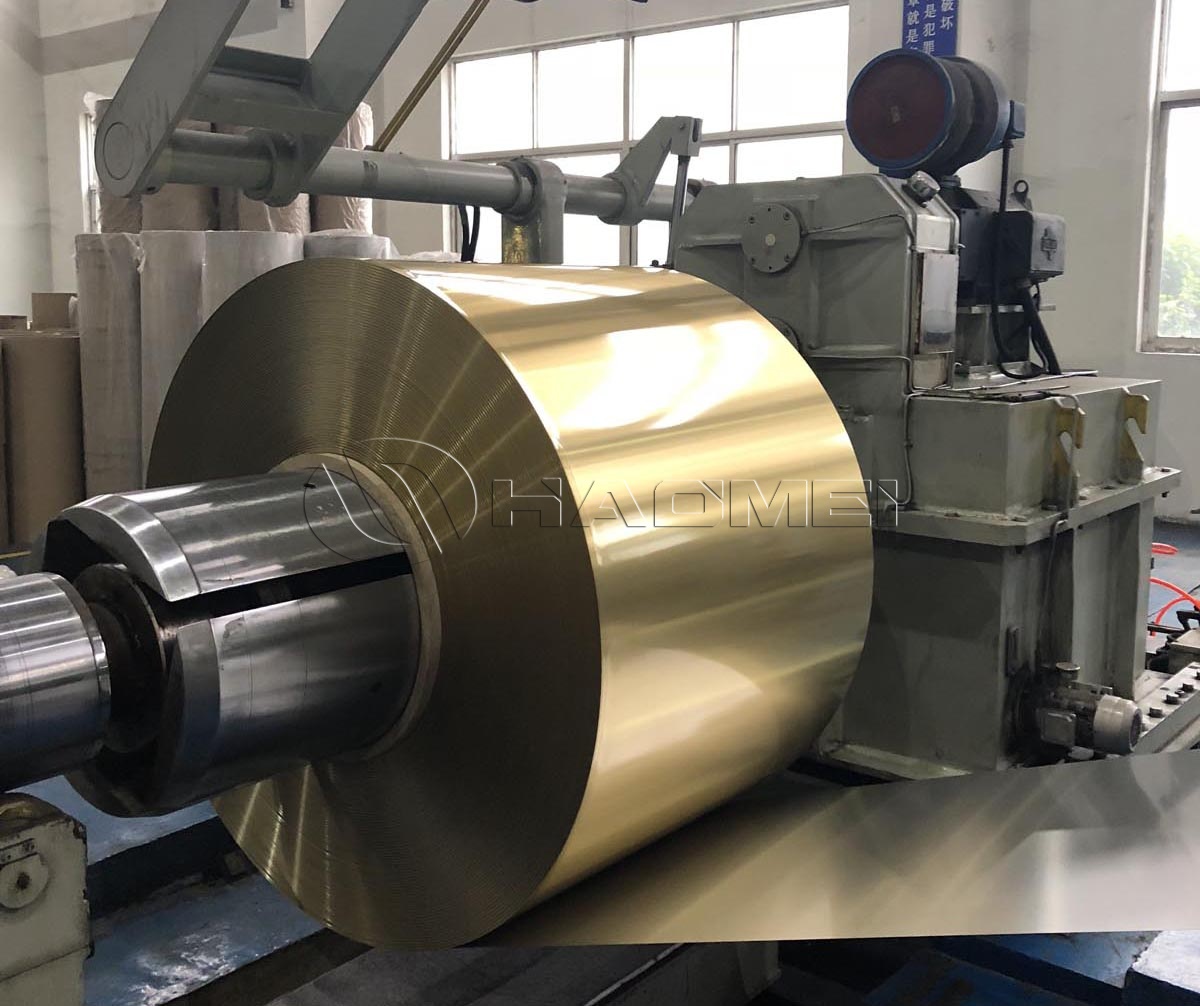

The 1000 series color coated aluminum coils are classified into 1050, 1060, 1070, 1100, and 1200 grades based on their aluminum purity. Among them, 1060 color coated aluminum has an aluminum purity of over 99.6%, making it one of the purest and most widely used alloys in various industries due to its excellent properties.

The 1060 color coated aluminum coil is produced through multiple sophisticated processes, including degreasing, chemical conversion, coating, and baking, resulting in a highly decorative and durable aluminum product.

Its surface is coated with high-performance organic paints such as Polyester (PE) or Polyvinylidene Fluoride (PVDF), offering not only diverse color choices and aesthetic appeal but also outstanding weather resistance, corrosion protection, and processability.

This makes it ideal for architectural decoration, signage, appliance panels, ceilings, and lighting applications.

As a pure aluminum series product, 1060 aluminum offers excellent ductility, corrosion resistance, and long service life with a lower cost, though its strength and stiffness are slightly inferior to those of the 3000 and 5000 series alloys. Its applications are largely similar to those of the 1050 color coated aluminum coil.

The 1060 color coating process mainly includes two types:

Polyester (PE) Coating:

A UV-resistant coating suitable for indoor decoration and advertising materials.

PVDF Coating:

Provides superior anti-fading and anti-UV performance, ideal for both indoor and outdoor architectural decoration in public spaces and harsh environments.

| Alloy | 1060 |

| Temper | H42 (H22), H44 (H24), H46 (H26), H48 (H28) |

| Thickness | 0.18-3.0 mm |

| Width | 100-1500 mm |

| Length | In coil or customized |

| Coating Type | PE (Polyester), PVDF (Polyvinylidene Fluoride), HDPE (High-Density Polyethylene) |

| Coating Thickness | Bottom: 16-18 μm; Top: up to 25 μm |

| Color | RAL color chart, wood grain, stone grain, or customized |

| Film | Protective film or customized |

| Production Process | Continuous roller coating |

| MOQ | 1-3 tons |

Chemical composition of 1060 coated aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.5 |

Chemical Composition and Mechanical Properties

| Tolerance & Mechanical Data | Specification |

| Main Alloy | A1060 (O) |

| Thickness (mm) | Tolerance (mm) |

| 0.2-0.4 | ±0.01 |

| 0.4-0.8 | ±0.015 |

| 0.9-1.1 | ±0.02 |

| 1.2-1.6 | ±0.025 |

| 1.8-2.0 | ±0.03 |

| Width (mm) | Tolerance (mm) |

| <100 | ±0.1 |

| 100-200 | ±0.2 |

| 201-500 | ±0.2 |

| 501-1250 | ±1 |

| >1250 | ±2 |

Burrs and Edge Collapse

| Aluminum Strip Width (mm) | Burr Height (mm) | Collapsed Edge Height (mm) |

| <0.2 | 0.01 | ≥0.05–0.1 |

| 0.2-1.0 | 0.015 | - |

| 1.1-1.5 | 0.02 | - |

| >1.6 | 0.03 | - |

Mechanical Properties

| Tensile Strength | 60-95 N/mm² |

| Elongation | ≥25% |

| Density at 20°C | 2.703 kg/dm³ |

| Maximum Resistivity at 20°C | ≤0.02825 Ω·mm²/m |

Lightweight yet Strong:

Only one-third the density of steel while maintaining good strength and rigidity.

Excellent Weather Resistance:

PVDF coating ensures over 20 years of outdoor durability without fading or chalking.

Outstanding Formability:

1060 pure aluminum provides excellent ductility and is easy to shear, punch, and bend.

Wide Color Options:

Available in RAL standard and customized colors for flexible design.

Green and Sustainable:

100% recyclable aluminum material; coatings are non-toxic and eco-friendly, meeting green building standards.

1. Architectural Decoration

The 1060 color coated aluminum coil is widely used for roof panels, exterior wall claddings, ceilings, and decorative partitions.

It provides both aesthetic appeal and functional protection for buildings, catering to various architectural styles from modern to classical.

It is commonly used in residential buildings, shopping malls, convention centers, and exhibition halls to create vibrant and durable surfaces.

2. Food Packaging

In the packaging industry, 1060 coated aluminum is used for producing food cans, lids, bottle caps, and sealing materials.

It is non-toxic, corrosion-resistant, moisture-proof, and sterilizable, making it an ideal material for food-grade packaging.

3. Electrical and Home Appliances

1060 color coated aluminum is applied in the production of air conditioner panels, washing machine panels, refrigerator doors, kitchen cabinet fronts, and electronic device housings.

Its high formability allows precise shaping to meet diverse design and functional requirements.

4. Transportation

In the transportation sector, it is used to manufacture truck bodies, vehicle side panels, train carriage panels, and trailer claddings.

The lightweight property helps reduce vehicle weight and improves fuel efficiency.

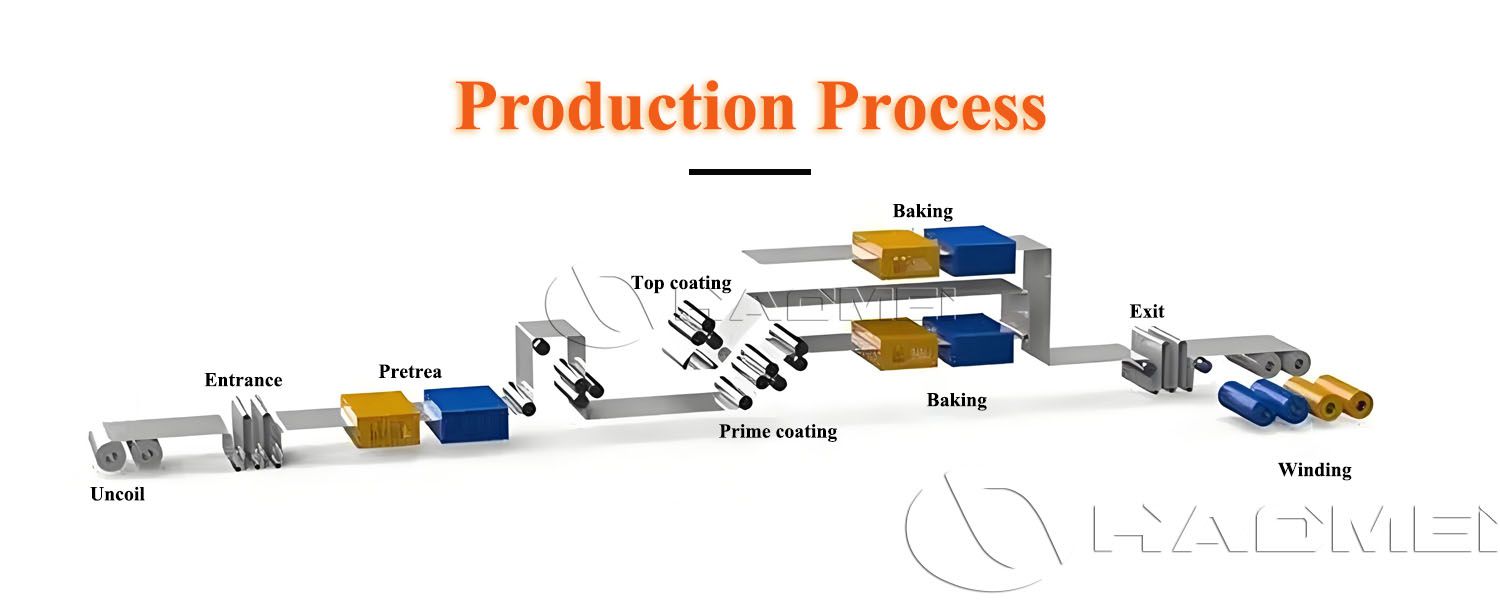

Uncoiling → Stitching → Entry Loop → Pretreatment → Primer Coating → Baking → Cooling → Finish Coating → Baking → Film Embossing → Exit Loop → Inspection → Cutting → Coiling

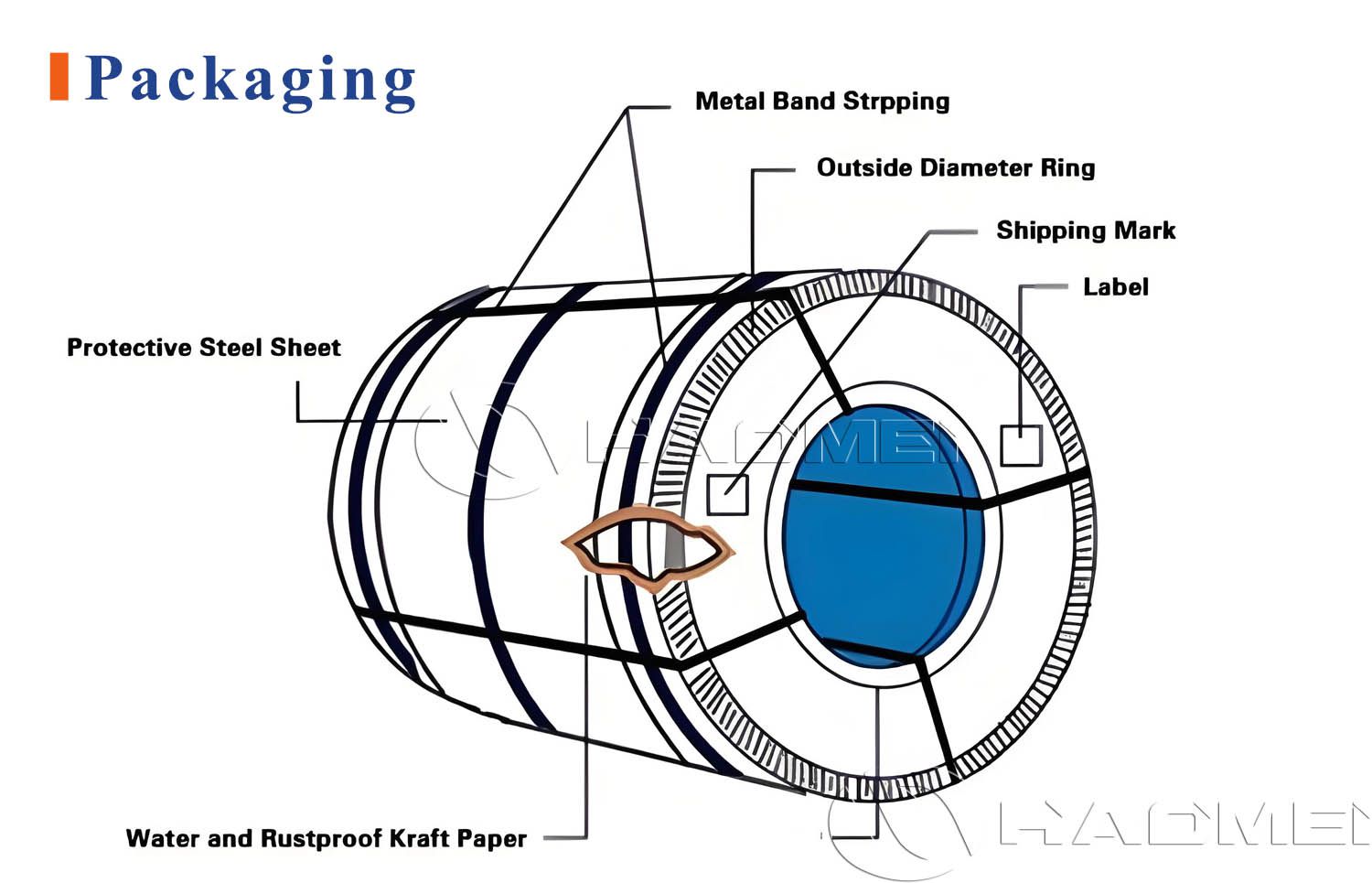

Packaging: Moisture-proof paper + plastic film + wooden pallet or iron box

Transportation: By sea, land, or air-ensuring the coils are delivered without scratches or dents

Minimum Order Quantity: 3 tons (sample orders are supported)

This article introduces color coated aluminum coil engineered for roofing sheets, positioning it as a lightweight, corrosion-resistant, and formable substrate for roll-formed roof panels in industrial, commercial, and residential buildings.

2026-01-07

Camouflage coatings not only have a decorative effect, but also enhance the weather resistance and corrosion resistance of aluminum, and are widely used in military vehicles, SUVs, off-road vehicles and customized vehicles.

2025-12-02

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29