News

By Hermione

By Hermione

1100 H14 Prepainted Aluminum Coil Price

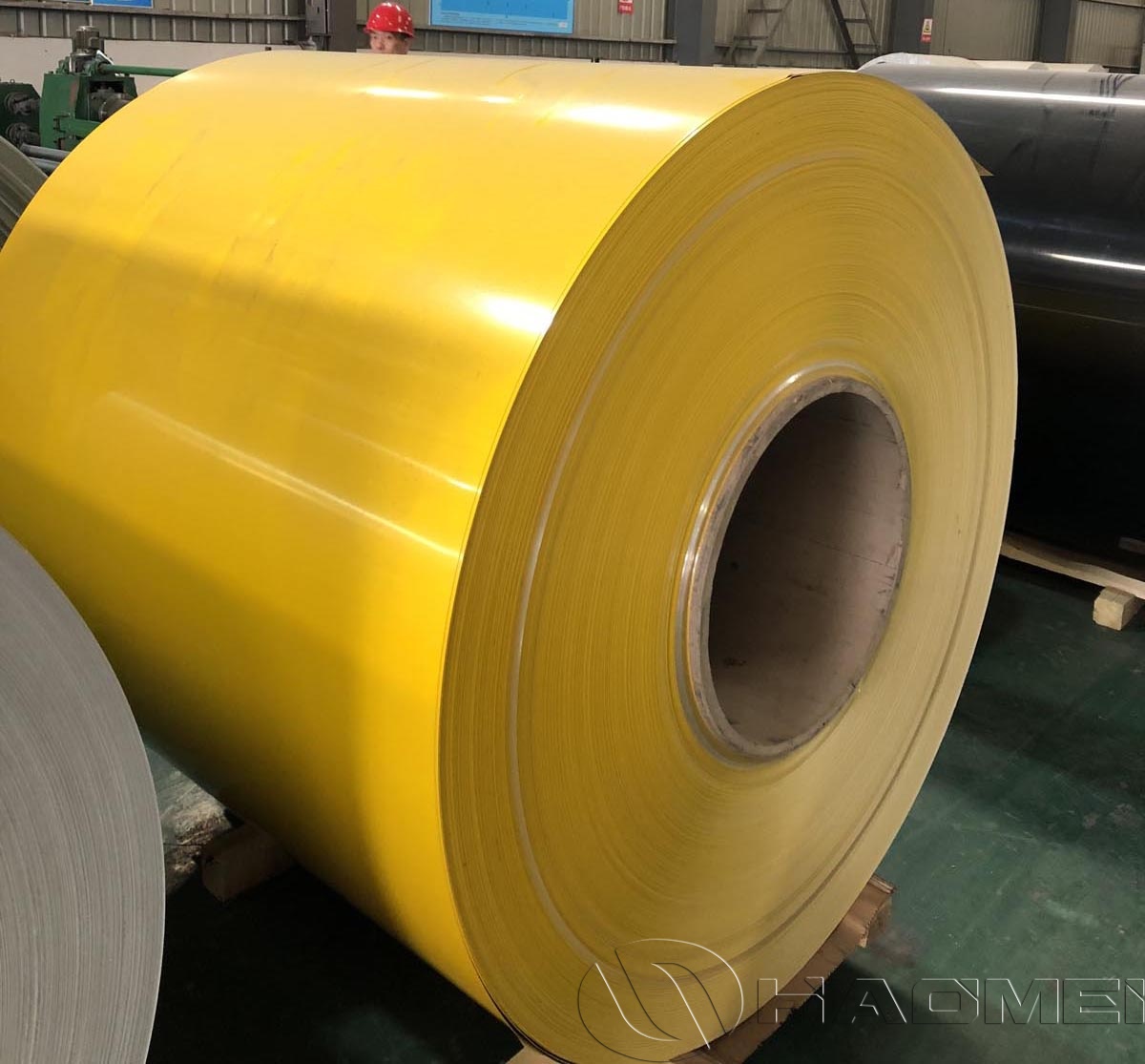

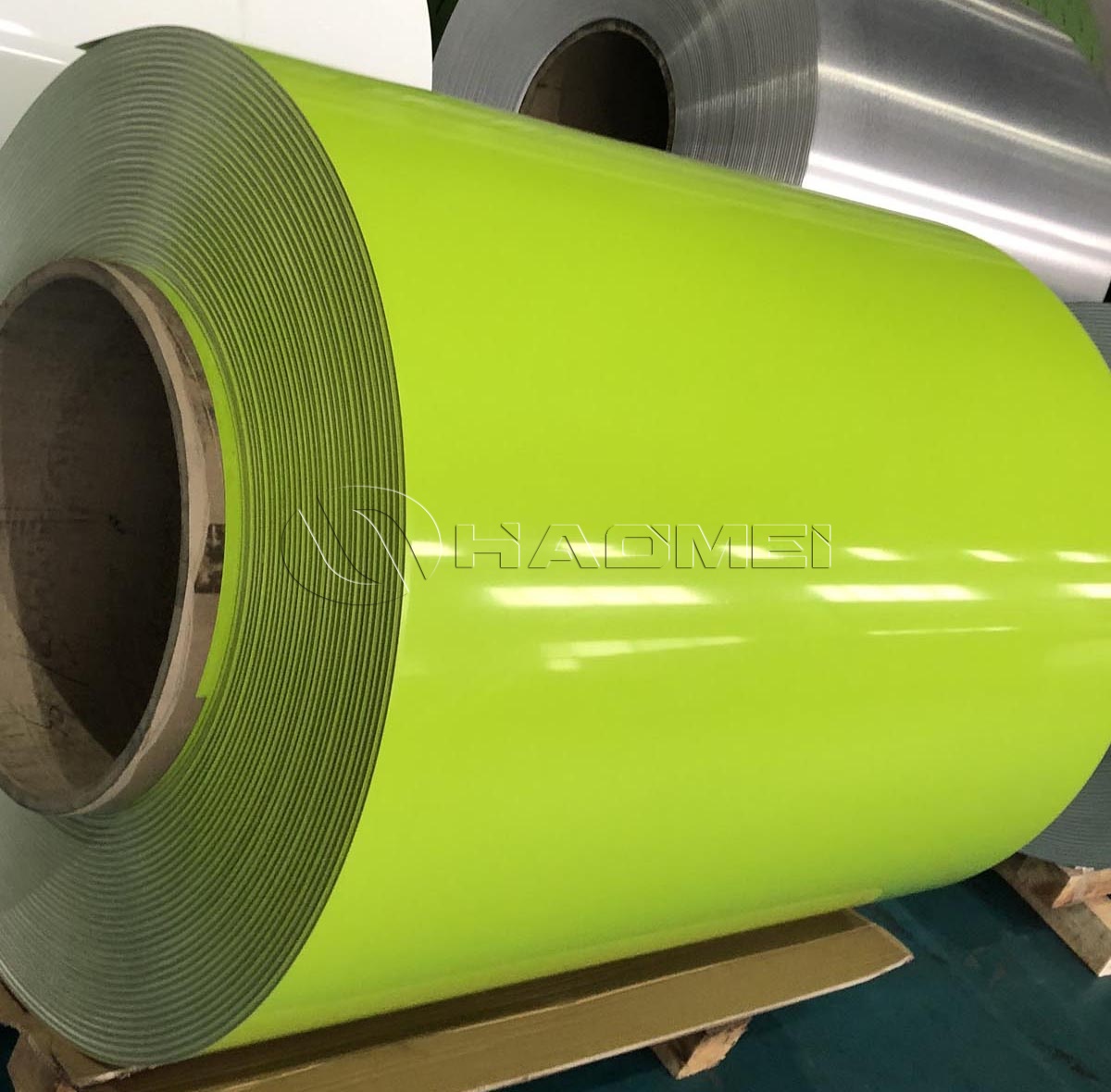

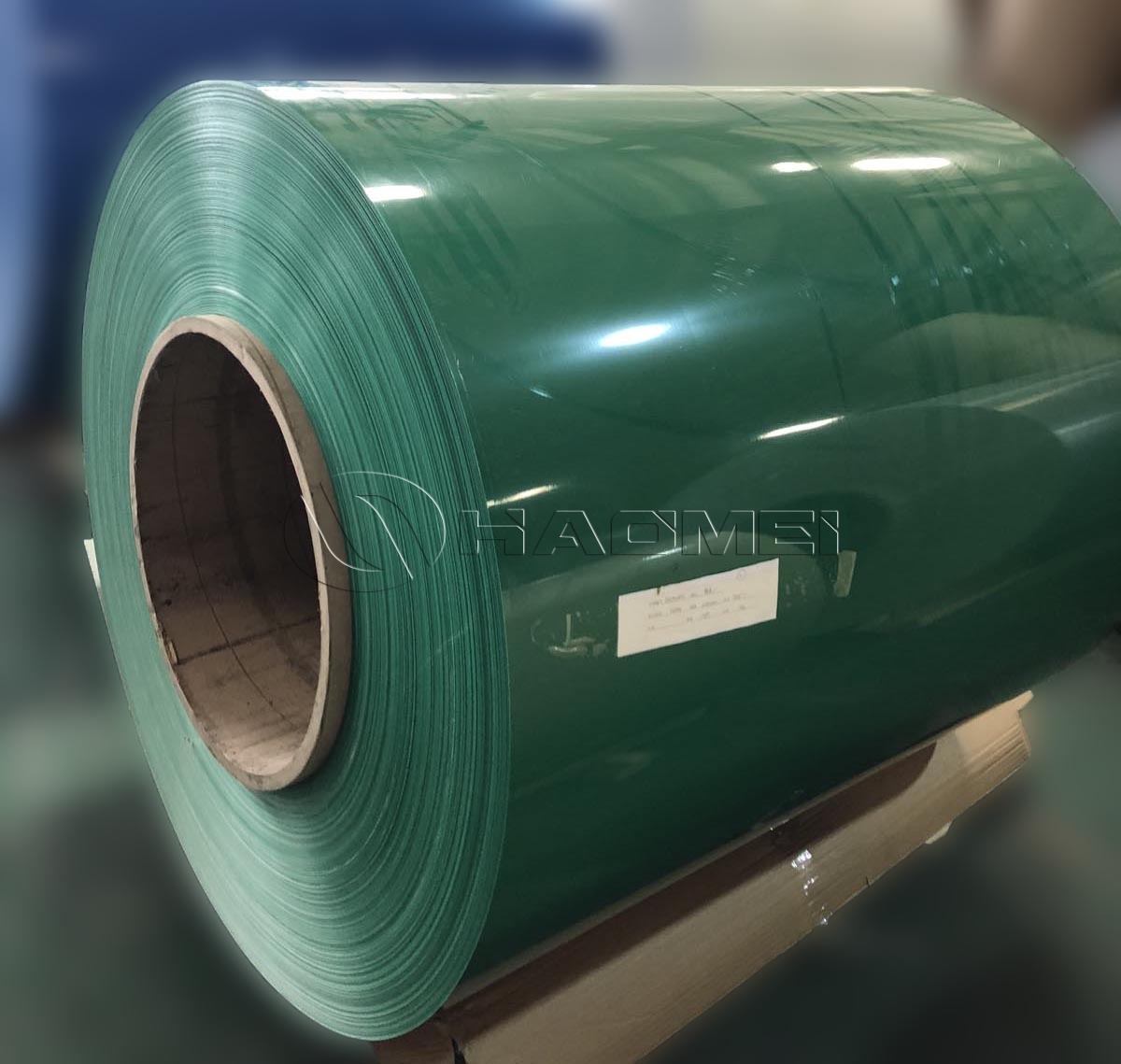

In the color coated aluminum coil market, 1100 H14 prepainted aluminum coil is positioned as a cost-effective, formable, and highly corrosion-resistant solution for decorative and light-duty engineered components. It is commonly selected for architectural trim, interior ceiling systems, cladding accessories, signage, appliance panels, and general fabrication where reliable appearance and stable coating performance are critical.

Understanding 1100 H14 and why it matters to price

Alloy 1100 belongs to the 1xxx series (commercially pure aluminum, typically 99.0% Al). Its value comes from excellent corrosion resistance, high reflectivity, strong coating adhesion, and easy forming.

H14 temper indicates the base metal has been strain-hardened to a half-hard level (H1x family), then stabilized to reach a consistent strength/ductility balance. Compared with O temper, H14 offers improved stiffness and dent resistanceoften preferred for flat panels, trims, and formed profiles.

From a pricing perspective, the 1100 + H14 combination influences:

Base coil cost (linked to aluminum ingot price and conversion premiums)

Yield and processing efficiency (H14 usually runs smoothly in roll-forming/slitting, reducing scrap risk when parameters are set correctly)

Fitness for thin-gauge coated products (supports stable flatness when coating and slitting are well controlled)

What drives 1100 H14 prepainted aluminum coil price

Although market fluctuations change daily, the underlying cost structure is relatively stable. For 1100 H14 prepainted aluminum coil price, the most common drivers are:

Aluminum LME price and regional premiums: the largest component of cost is the underlying aluminum value.

Coating system selection (PE vs PVDF): resin type, pigment package, and performance targets (UV, chemical resistance) strongly affect coating cost.

Coating thickness and layers: typical architecture-grade systems include primer + topcoat; some projects add enhanced primers or thicker topcoats for durability.

Color and effect complexity: standard solid colors are usually more economical than metallics, special effect pigments, or tight color-delta requirements.

Coil width, gauge, and tolerances: wider coils, tighter gauge tolerances, and strict flatness requirements can increase processing cost.

Surface preparation and pretreatment: chromate-free or enhanced conversion coatings improve adhesion/corrosion performance but add process control and material cost.

Order volume, slitting pattern, packaging, and delivery: multiple slit widths, small lots, and reinforced export packaging can raise conversion cost.

Manufacturing process: from mill coil to prepainted coil

A stable prepainted coil depends on controlled upstream metallurgy and a consistent coating line.

1) Substrate preparation

1100 H14 mill finish coil is typically cleaned and degreased, then receives a conversion coating pretreatment (commonly chrome-free). This step is essential to achieve strong paint adhesion and corrosion resistance, especially at cut edges.

2) Coil coating (continuous roll coating)

Paint is applied by precision rollers in controlled film thickness:

Primer coat supports adhesion, flexibility, and corrosion protection

Topcoat delivers color, gloss, UV resistance, and stain resistance

3) Baking/curing

Coils pass through an oven to cure the resin system. Proper cure balance is critical: under-cure can reduce chemical resistance; over-bake can reduce flexibility and impact performance.

4) Cooling, inspection, and finishing

Key checks often include gloss, color difference (E), dry film thickness, pencil hardness, T-bend, impact resistance, solvent rub, and surface defects control. Coils are then recoiled, protected (film/paper), and slit to customer sizes.

PE vs PVDF coatings: practical selection for real projects

Two mainstream coating options dominate project specifications:

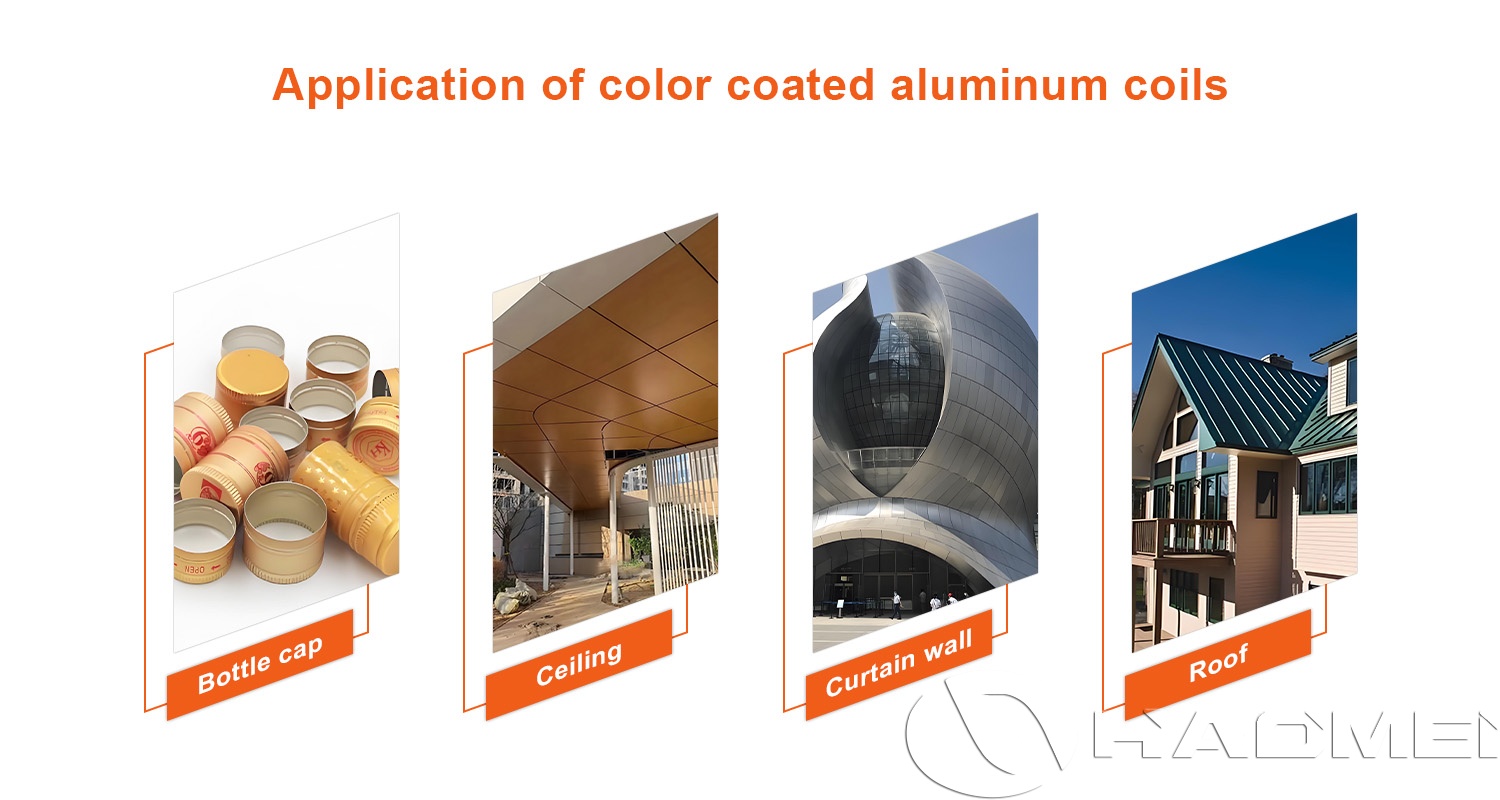

PE coating (polyester): widely used for interior decoration, ceilings, appliance panels, and general-purpose cladding accessories where cost efficiency and good formability are priorities. It offers solid appearance retention in typical environments.

PVDF coating (polyvinylidene fluoride): often specified for exterior architectural exposure and harsh UV conditions due to superior weathering and color retention. It is frequently selected for faades, long-life signage, and premium building envelopes.

Common alloys and where they are typically used

Choosing an alloy is not only about strengthit affects formability, corrosion behavior, and how the coating performs after bending.

1050 / 1060 / 1100 (1xxx series): high purity aluminum for excellent corrosion resistance and forming. Common in interior panels, trims, signage, and general coated products where high strength is not the primary requirement.

3003 / 3004 / 3105 (3xxx series, Al-Mn): higher strength than 1xxx with good formability. Often used for roofing, siding, curtain wall accessories, and housings requiring improved rigidity.

5005 / 5052 / 5754 (5xxx series, Al-Mg): stronger and more corrosion resistant in many environments; preferred for marine-influenced areas, transportation components, and applications needing better fatigue/strength performance. Coating systems must match forming severity to avoid micro-cracking on tight bends.

8011 (8xxx series): commonly selected for caps/closures and specific packaging/industrial uses where forming and barrier requirements are important.

For projects prioritizing surface appearance, forming reliability, and stable supply, 1100 H14 prepainted aluminum coil remains a frequent baseline choiceespecially when the structure is not load-bearing and the coating system is doing the environmental heavy lifting.

1100 H14 Corlor coated Aluminum Coil Specifications

| Item | Typical Range / Options |

|---|---|

| Alloy / Temper | 1100 H14 |

| Substrate thickness | 0.202.00 mm (common architectural: 0.301.20 mm) |

| Coil width | 201600 mm (subject to line capability) |

| Coating type | PE coating / PVDF coating |

| Coating structure | Topcoat + primer (single or double-sided as required) |

| Topcoat thickness (typical) | PE: ~1525 m; PVDF: ~2030 m |

| Primer thickness (typical) | ~510 m |

| Surface finish | Gloss/matte; solid colors; metallic (availability depends on system) |

| Surface protection | PE film / interleaving paper (optional) |

| Coil ID | 405 / 505 mm (common) |

| Standards (typical) | EN / ASTM / JIS (as specified) |

Practical application notes for 1100 H14 prepainted coil

Bending and roll forming: 1100 H14 provides improved stiffness vs O temper while still offering good bendability. Coating choice and cure profile affect T-bend performance.

Cut-edge behavior: as with all coated aluminum, edges are uncoated after shearing. Good pretreatment and primer selection help manage edge corrosion in demanding environments.

Exterior durability: when used outdoors, resin selection (often PVDF) and proper film build are key factors influencing color retention and chalking resistance.

Typical scenarios where price-performance is favorable

Because it balances appearance, corrosion resistance, and fabrication efficiency, 1100 H14 prepainted aluminum coil is commonly used for:

Ceiling and wall panel systems (interior)

Decorative trims, flashings, fascia, and cladding accessories

Signage and display panels

Appliance and light industrial paneling

General coated sheet-metal fabrication where forming is moderate and weight reduction is valued

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

-

Cold Rolled 1050 1060 1070 1100 1200 Color-Coated Decorative Aluminum Coils

In architectural decoration, home appliance housings, advertising signage, and industrial decoration, cold rolled color-coated aluminum coils are gradually replacing traditional steel materials due to their attractive appearance, excellent processability,

2025-12-30

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19