Description:

| Alloy: | 1100 |

| Temper: | HO, H12, H14, H16, H18, H22, H24, H26 |

| Thickness: | 0.2 mm - 6.0 mm |

| Color: | RAL colors, wood grain, stone grain, or custom |

| Coating Type: | PE,PVDF,HDPE,etc |

| MOQ: | 1-3 tons |

| Alloy: | 1100 |

| Temper: | HO, H12, H14, H16, H18, H22, H24, H26 |

| Thickness: | 0.2 mm - 6.0 mm |

| Color: | RAL colors, wood grain, stone grain, or custom |

| Coating Type: | PE,PVDF,HDPE,etc |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

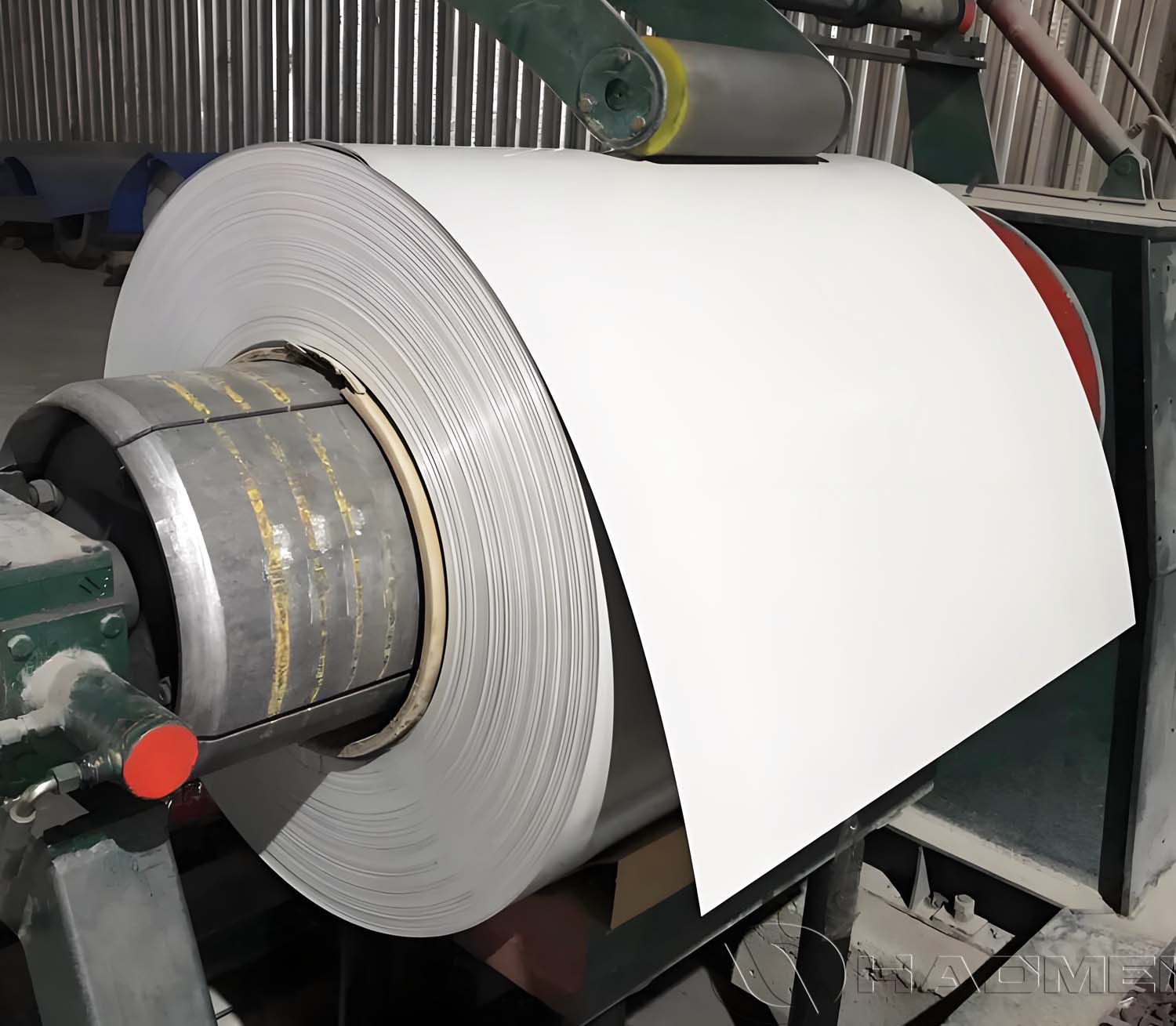

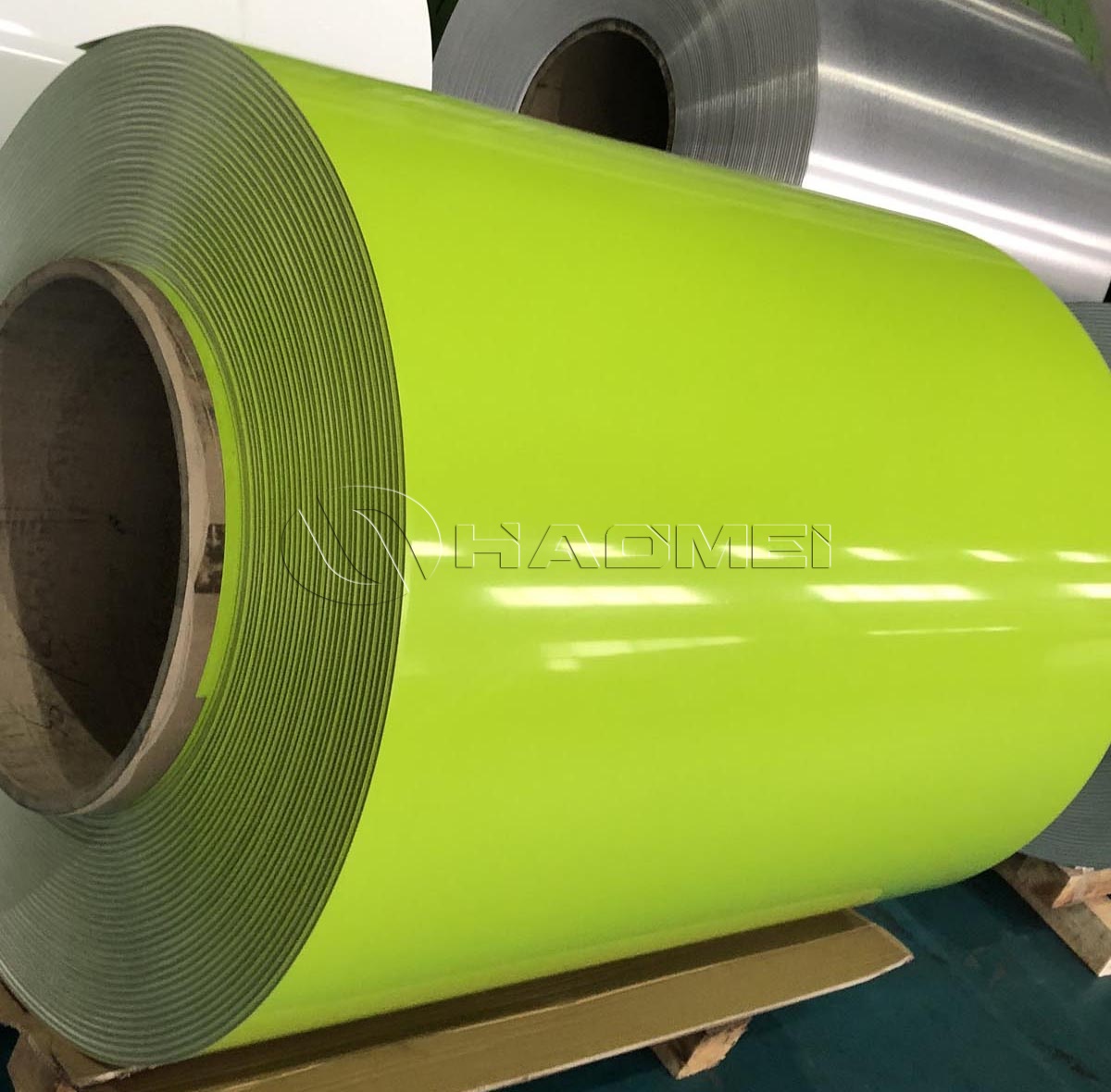

The 1100 color coated aluminum coil is a high-purity aluminum product made from 1100 alloy as the base material. It is processed through multiple precise steps including degreasing, chemical conversion, coating, and baking, to form a decorative and protective color coating on the surface.

The coating can be applied by roller coating or spray coating production lines, using different types of paints such as PE, PVDF, HDPE, FEVE, or custom coatings.

With an aluminum content of 99.0% or higher, 1100 aluminum has excellent corrosion resistance, formability, and surface processing performance.

After applying the color coating, the coil not only gains an attractive appearance but also demonstrates outstanding weather resistance, UV aging resistance, and anti-corrosion properties.

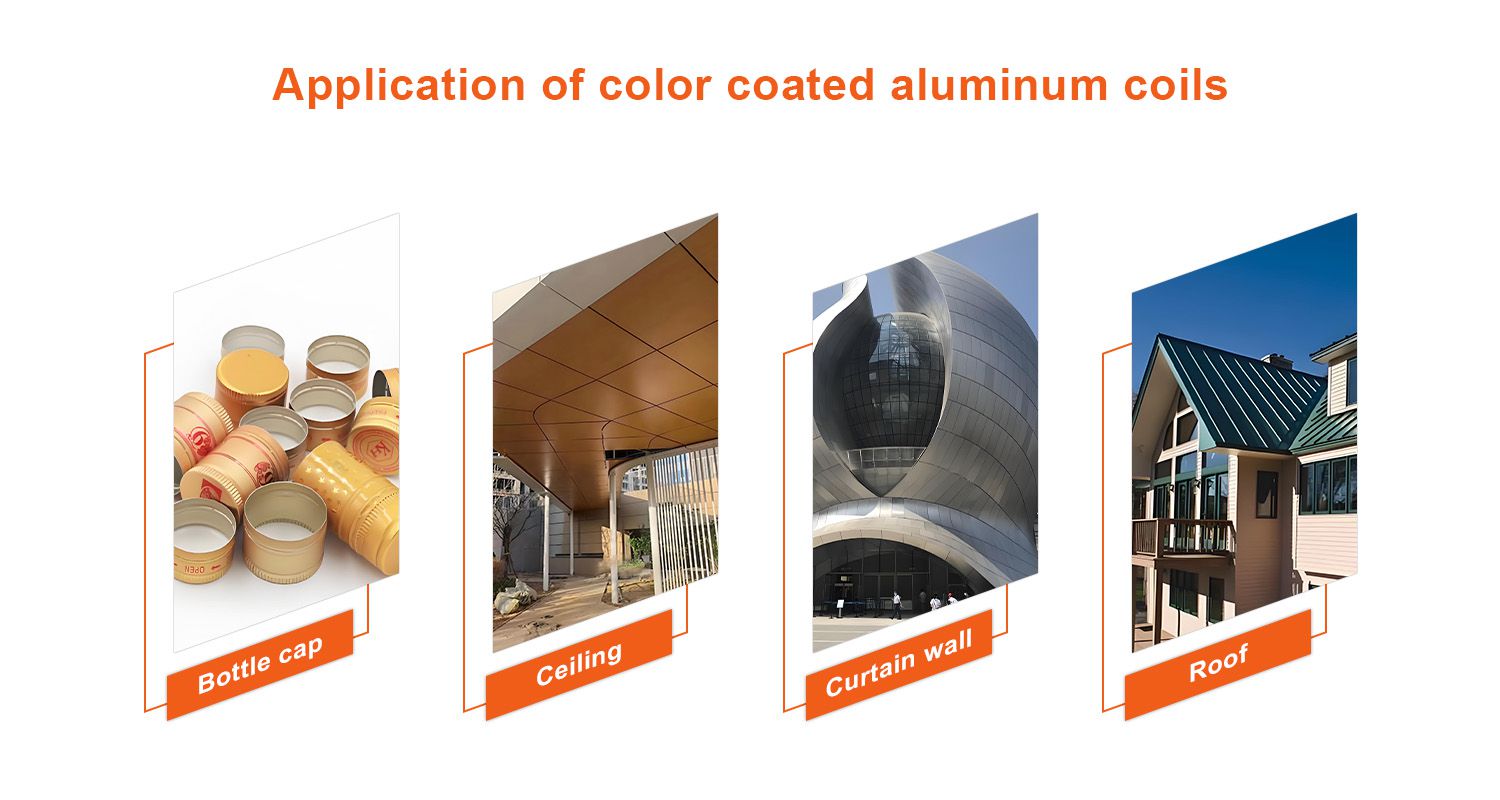

It is widely used in architectural decoration, home appliance panels, ceilings, curtain walls, roofing sheets, and transportation applications.

| Alloy | 1100 |

| Temper | HO, H12, H14, H16, H18, H22, H24, H26 |

| Thickness | 0.2 mm - 6.0 mm |

| Width | 80 mm - 2300 mm |

| Length | 100 mm - 16000 mm |

| Coil Type | DC or CC (Direct Cast or Continuous Cast) |

| Inner Diameter | 76 mm, 152 mm, 408 mm, 508 mm |

| Color | RAL colors, wood grain, stone grain, or custom |

| Coating Type | PE (Polyester), PVDF (Polyvinylidene Fluoride), HDPE (High-Density Polyethylene) |

| Coating Thickness | Single coat: 3-25 μm; Double coat: 25-35 μm; Triple coat: ≥35 μm |

| Production Method | Roller coating |

| Packaging | Export standard, wooden pallet |

| Packaging Type | Top-hanging or side-hanging |

| Delivery Time | Within 30 days |

| Place of Origin | Zhengzhou, China |

| MOQ | 1-3 tons |

Mechanical Properties of 1100 Color Coated Aluminum Coil

| Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 0.2-0.3 | 110-145 | 95 | 1 |

| 0.301-0.5 | 110-145 | 95 | 2 |

| 0.51-1.5 | 110-145 | 95 | 3 |

| 1.51-4.0 | 110-145 | 95 | 4 |

Chemical composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1100 | 0.95 | 0.05-0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99 | |

1. Lightweight and Highly Ductile

Low material density and strong ductility allow easy stamping, bending, drawing, and laminating, making it suitable for various shapes and structures.

2. Surface Flatness

Smooth surface without composite high-temperature impressions; no residual stress after shearing and no deformation.

3. Aesthetic Appeal

Available in wood grain, stone grain, and other realistic textures that simulate natural materials.

Patterns can be customized, offering customers a wide range of design options.

4.. Weather resistance

The painted patterns, applied by joint coating and high-temperature baking, maintain high gloss, have good color stability, and minimal color difference. Polyester paint has a 10-year warranty, and fluorocarbon paint has a warranty of over 20 years.

5. Mechanical Strength

Produced using premium aluminum, adhesives, and composite techniques, ensuring sufficient bending and flexural strength to withstand seasonal temperature, wind pressure, and humidity changes without deformation or expansion.

6. Environmental Protection

Resistant to salt, alkali, and acid rain corrosion; non-toxic and free from bacteria growth.

Does not release harmful gases or cause rusting of structures.

Meets national fire resistance standard B1 level.

To meet different environmental and decorative requirements, the 1100 color coated aluminum coil can be provided with various coating systems:

1. PE (Polyester Coating)

Features: Bright colors, high gloss, good formability.

Applications: Interior decoration, ceiling panels, advertising boards, and interior wall panels.

Service Life: 8-10 years (indoor use).

2. PVDF (Fluorocarbon Coating)

Features: Excellent weather and UV resistance, acid and alkali corrosion resistance, long-lasting color stability.

Applications: Exterior walls, roofing systems, curtain walls, and marine environments.

Service Life: 20-25 years (outdoor use).

3. Epoxy Coating

Features: Strong adhesion, high wear resistance, and good impact strength.

Applications: Appliance shells, electronic products, packaging, and protective linings.

Service Life: 10-15 years.

4. Nano Coating

Features: Self-cleaning, anti-fouling, and oil-resistant properties with strong surface protection.

Applications: High-end building exteriors, transportation facilities, clean rooms, hospitals.

Advantages: Easy to clean, long-lasting gloss, and low maintenance cost.

5. PU (Polyurethane Coating)

Features: High flexibility, excellent impact and abrasion resistance.

Applications: Industrial plants, warehouse roofing panels, metal doors, and facades.

Architectural Decoration: Curtain walls, ceilings, roofing panels, shutters, rolling doors, awnings, and decorative wall panels.

Home Appliances & Furniture: Refrigerator panels, lighting housings, decorative panels, appliance shells.

Advertising Industry: Billboards, signboards, display stands, building facades.

Transportation: Vehicle interiors, ship cabin panels, subway tunnel linings.

Industrial Applications: Rolling doors, storage tank shells, machine room covers, equipment housings.

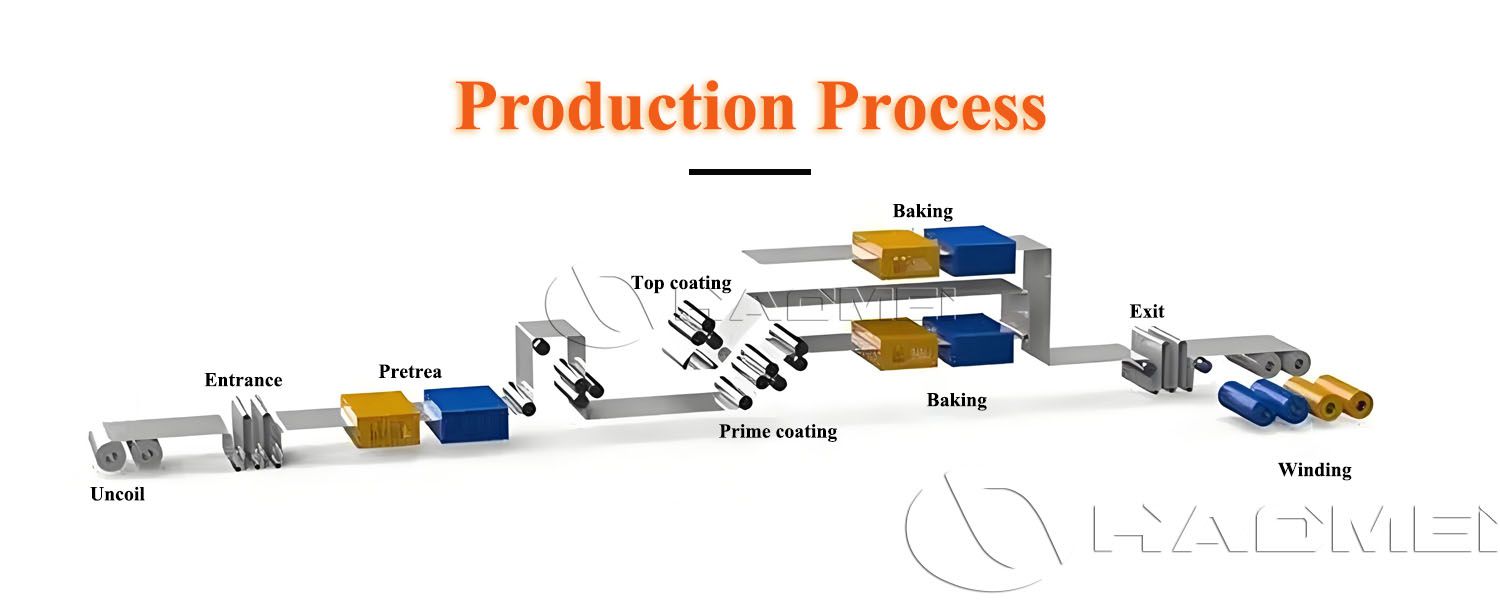

The production of color coated aluminum coils requires high precision and strict quality control, involving the following steps:

Uncoiling → Degreasing and Cleaning → Roller Coating → Drying → Inspection → Recoiling → Packaging

Depending on the coating system, single-coat, double-coat, or triple-coat baking processes can be applied.

During pretreatment, continuous spraying and cleaning enhance corrosion resistance and coating adhesion.

A conversion film is chemically formed on the aluminum surface for improved paint bonding.

The coating process includes two stages - primer coating and top coating.

After primer application, the aluminum coil is dried, and the surface is roller-coated with the top paint layer.

During curing, the coil passes through an oven with controlled temperature (200-300°C) to ensure complete polymerization and elimination of volatile compounds.

HAOMEI Aluminum Industry, a professional manufacturer of color-coated aluminum coils, produces color-coated aluminum coils and roll-coated aluminum coils. We offer PVDF and PE color-coated aluminum coils, and can also cut to length as semi-finished products. We also process aluminum coils into orange peel finish, color-coated profiled aluminum sheets, and color-coated embossed aluminum sheets. Our products are of high quality, with a complete range of models. We offer direct sales from the factory at competitive prices and export to many countries and regions overseas.

3003 H14 color-coated aluminum coil uses PE/PVDF coating and features excellent formability, high corrosion resistance, and weldability.

2025-12-17

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

5052 black color-coated aluminum coils are widely used in building decoration, home appliance housings, transportation and marine engineering.

2025-12-04