News

By Hermione

By Hermione

1000 Series Aluminum Coil Coating Process

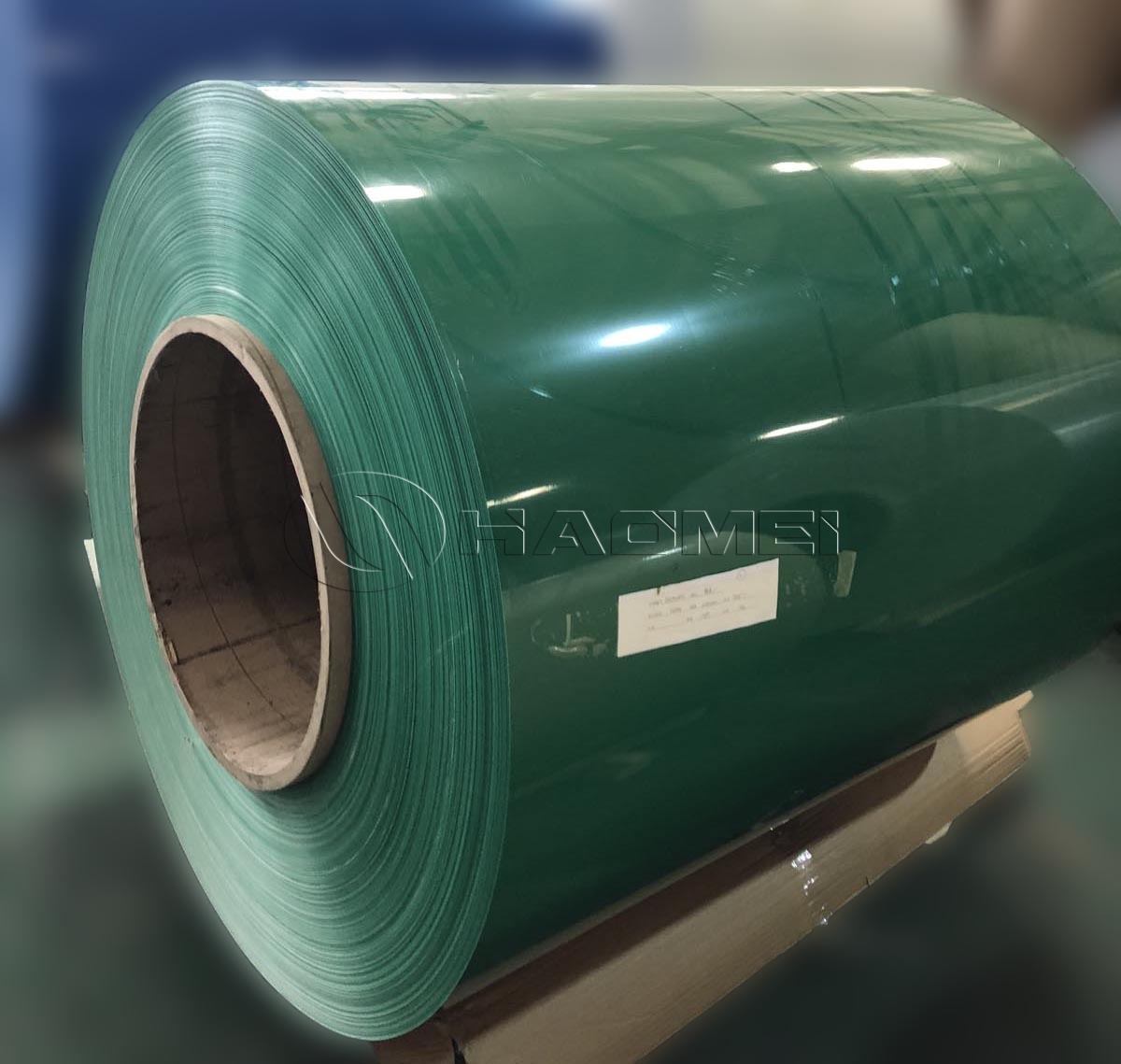

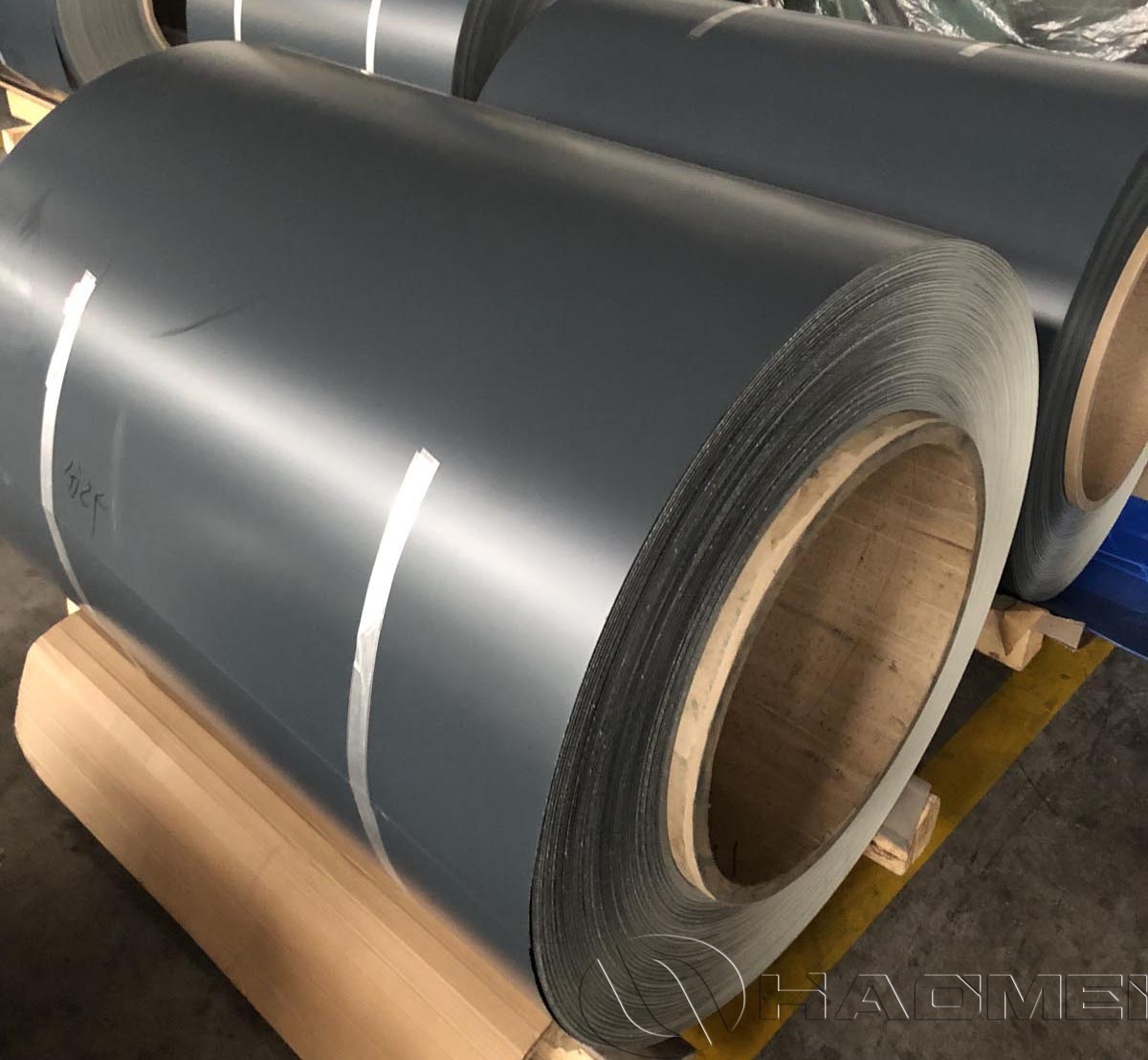

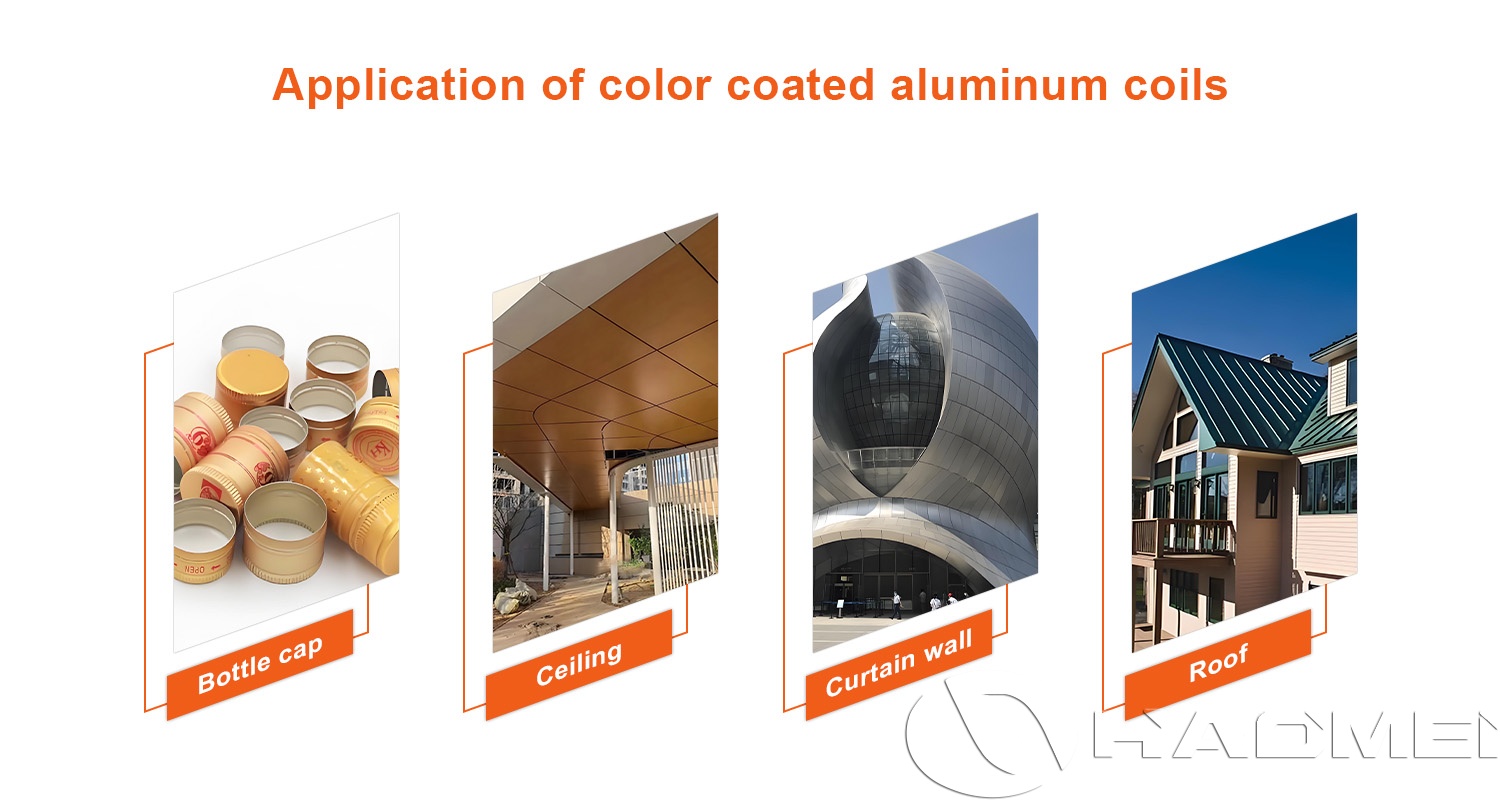

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating. It is widely used for building envelope components (ceilings, cladding trims, flashings), roll-formed profiles, insulation jacketing, signage, and decorative sheet/coil where deep forming, smooth surface, and consistent color are prioritized over high structural strength.

Why 1000 Series Works Well as a Coated Substrate

1000 series aluminum (typically 99.0% Al) has several traits that directly influence coating quality and downstream fabrication:

Excellent formability: Ideal for bending, hemming, beading, and light stamping; reduces risk of micro-cracks that can propagate through the paint film during forming.

High thermal conductivity: Supports uniform oven curing and stable line speed control in coil coating.

Naturally clean surface: With proper degreasing and conversion coating, it provides reliable adhesion for both PE coating and PVDF coating systems.

Lower strength than Mn/Mg alloys: Best matched to non-load-bearing panels, trim parts, and decorative components where stiffness comes from section geometry rather than base metal strength.

In practical selection, 1000 series coils are commonly paired with PE for interior and general-purpose applications, or with PVDF for outdoor exposure requiring higher UV/color stability.

1000 Series Aluminum Coil Coating Process (Coil-Coating Line)

A stable aluminum coil coating process is built around three pillars: surface preparation, controlled film build, and precise curing. Below is a typical process logic used for 1000 series substrates.

1) Incoming Coil Control and Surface Preparation

Incoming inspection: alloy temper, thickness tolerance, surface cleanliness, and edge condition.

Degreasing / alkaline cleaning: removes rolling oil and shop contaminants; critical for preventing fisheyes, craters, and adhesion loss.

Rinsing: multi-stage rinses to limit ionic residue.

2) Chemical Pretreatment (Conversion Coating)

Pretreatment is the bonding bridge between aluminum and paint:

Chromium-free conversion (common today) improves wet adhesion and corrosion resistance.

Film weight and uniformity are controlled to avoid powdering (too heavy) or weak corrosion protection (too light).

3) Primer Coating and Flash-Off

Primer is applied by roller coater, then flashed and cured.

Primer selection is matched to the topcoat system and end-use corrosion requirements.

For harsh outdoor environments, primer chemistry and dry film thickness are often adjusted as much as the topcoat.

4) Topcoat Application: PE vs PVDF

PE (polyester) topcoat: good appearance, cost-effective, suitable for interior panels, ceilings, appliance panels, and general architectural trims.

PVDF (fluorocarbon) topcoat: superior UV resistance, chalking resistance, and long-term color retention for faades, curtain wall accessories, and outdoor signage.

Products in this category are commonly supplied as PE Coated Aluminum Coil or PVDF Coated Aluminum Coil, depending on exposure class and durability targets.

5) Baking/Curing: TemperatureTimeMetal Temperature (PMT)

Coil coating quality depends on achieving the specified peak metal temperature:

Under-curing can reduce hardness, solvent resistance, and adhesion.

Over-baking can increase brittleness and accelerate gloss loss.

6) Cooling, Protective Film (Optional), and Recoiling

Controlled cooling stabilizes the film.

Protective film may be laminated for scratch-sensitive fabrication steps (roll forming, press brake, transport).

Recoiling includes tension control to prevent pressure marks.

7) Quality Verification (Typical)

Dry film thickness (DFT), gloss, color (E), pencil hardness, T-bend, impact, MEK rub, crosshatch adhesion

Corrosion tests (salt spray, humidity) based on coating system and specification

Common 1000 Series Alloys and Typical Uses

Within 1000 series, small differences in impurity control and conductivity-related properties influence use cases:

1050 (Al 99.5%): very good formability and surface finish; used for decorative trims, insulation jacketing, signage, coated sheet for light forming. Commonly supplied as 1050 Color Coated Aluminum Coil.

1060 (Al 99.6%): slightly higher purity; often chosen when excellent ductility and stable coating appearance are required for tight-radius bending. Commonly supplied as 1060 Color Coated Aluminum Coil.

1100 (Al 99.0%): widely used general-purpose commercial purity aluminum; good balance of cost, forming, and coating consistency; suitable for ceilings, cladding accessories, and nameplates.

1200: similar to 1100 for many coating applications; often selected for general decorative coil stock.

1350: higher electrical conductivity; more typical for electrical applications, but can be coated when insulation or identification color coding is needed.

Selection note: if the application needs higher dent resistance or panel stiffness, 3xxx/5xxx series may be more suitable; however, for complex forming and visual uniformity, 1000 series remains a reliable base.

Core Specifications for 1000 Series Color Coated Aluminum Coil

Table: Core Specifications 1000 Series Prepainted Aluminum Coil

| Item | Typical Range / Options |

|---|---|

| Base alloy | 1050 / 1060 / 1100 / 1200 / 1350 |

| Temper | O, H12, H14, H16, H18 (selected by forming & flatness needs) |

| Coil thickness (base metal) | 0.202.00 mm (common architectural range: 0.301.20 mm) |

| Coil width | 201600 mm (slit to requirement) |

| Coating system | PE (polyester), PVDF (fluorocarbon) |

| Coating structure | 2-coat-2-bake or 3-coat-3-bake (application dependent) |

| Typical dry film thickness (DFT) | Top: 1530 m (PE), 2030 m (PVDF); Back: 515 m |

| Surface finish | Gloss/matte, solid color, metallic, patterned (by request) |

| Pretreatment | Chromium-free conversion coating (standard), others by spec |

| Coil ID | 405 / 505 mm |

| Coil OD | Up to ~1600 mm (line & logistics dependent) |

| Protective film | Optional (forming/transport protection) |

| Key performance checks | Adhesion, T-bend, impact, hardness, E, salt spray/humidity |

Application Fit: Where 1000 Series Coated Coil Performs Best

Ceilings and interior panels: PE systems with stable gloss and easy fabrication.

Architectural trims, flashings, fascia accessories: good bendability; PVDF used for long-term outdoor exposure.

Insulation jacketing and cladding wraps: corrosion resistance plus clean appearance; often requires smooth finish and consistent coil-to-coil color.

Signage and display panels: uniform color, flatness control, and print/film compatibility (depending on topcoat).

Practical Process Considerations Specific to 1000 Series

Surface softness and pressure marking: commercial-purity aluminum is relatively soft; careful tension control, roll cleanliness, and packing design reduce roll marks.

Forming after coating: choose primer/topcoat flexibility to meet the target T-bend; tighter bends generally benefit from optimized resin and DFT control.

Color consistency: manage coil-to-coil E through batch control, curing window stability (PMT), and consistent film build.

Corrosion performance: pretreatment quality and primer choice are as critical as PVDF/PE selection, especially at cut edges and formed areas.

-

1200 Color Coated Aluminum Coil for Building Facade

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25

-

Pvdf Coated Aluminum Coil For Honeycomb Panels

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02

-

PVDF Coated Aluminum Coil Maintenance And Cleaning

Learn PVDF coated aluminum coil maintenance and cleaning with practical methods, coating system insights, and process factors affecting durability in architectural cladding.

2026-01-27