News

By Hermione

By Hermione

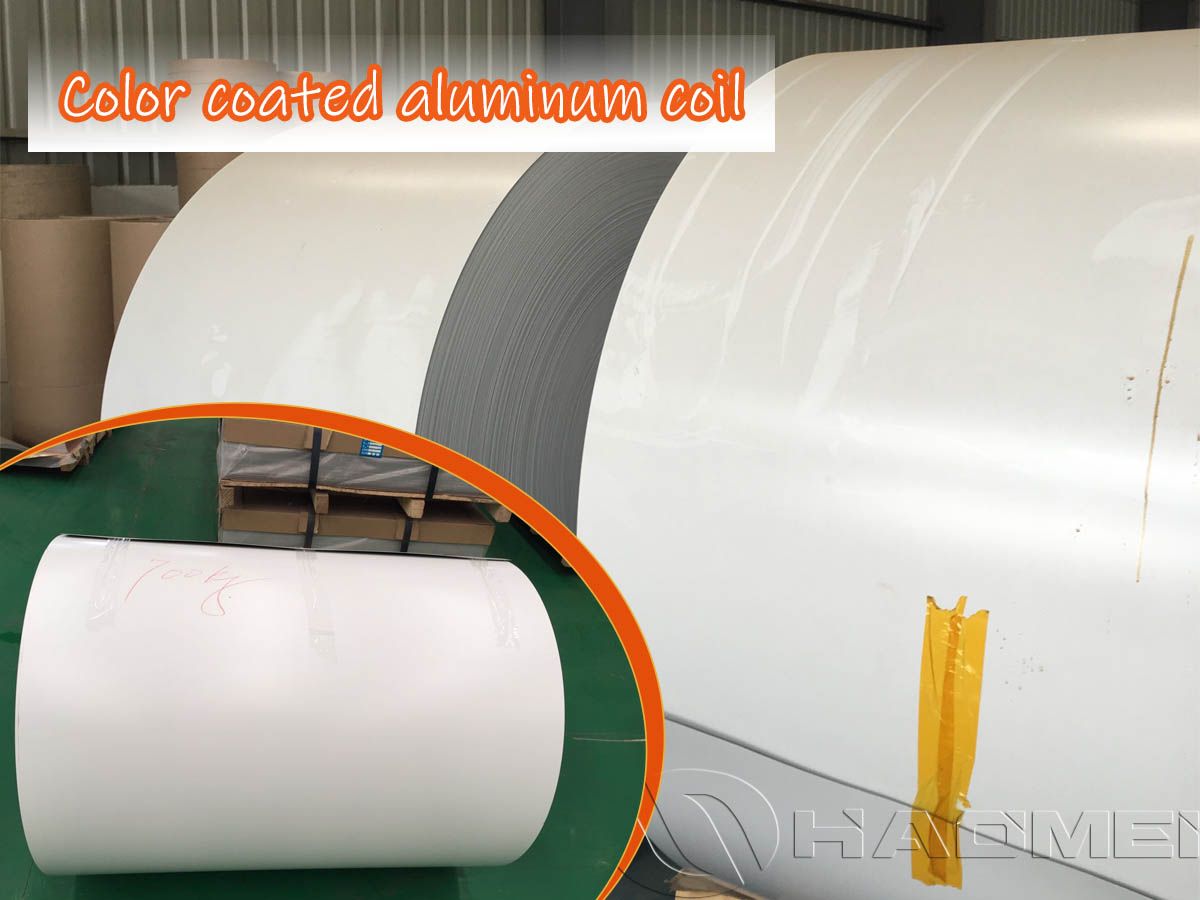

1100 / 3003 Color Coated Aluminum Coil for Signboards and Advertising Boards

On neon-lit city streets, whether it is traffic signs guiding the way or large billboards showcasing brand appeal, the vivid colors and smooth surfaces behind them are inseparable from a core material-color coated aluminum coil.

HAOMEI Aluminum has newly launched 1100 and 3003 color coated aluminum coils, featuring lightweight properties, excellent weather resistance, and outstanding processability, fully meeting the material requirements of various signboards and advertising boards.

1100 Color Coated Aluminum Coil

1100 aluminum contains up to 99% aluminum and is a representative industrial pure aluminum.

1100 color coated aluminum coil offers excellent formability and ductility, making it ideal for signboards that require complex bending or stamping. It is widely used in advertising boards and indoor/outdoor signage with high requirements for processing performance and surface appearance.

3003 Color Coated Aluminum Coil

3003 belongs to the Al-Mn alloy series. While maintaining good formability, it provides significantly higher mechanical strength than 1100 and excellent corrosion resistance.

Even in humid or mildly corrosive outdoor environments, it maintains stable structural performance. For long-term outdoor use or projects with higher requirements for structural stability, 3003 color coated aluminum coil is the preferred choice.

Color Coating Process

(1) Coating Types

PE (Polyester) Coating

Strong adhesion and high color saturation, mainly used for indoor displays or short- to medium-term outdoor advertising.PVDF (Fluorocarbon) Coating

Contains a high proportion of fluorocarbon resin, offering outstanding weather resistance, UV resistance, and self-cleaning properties. Even under intense sunlight or acid rain exposure, it can maintain color stability for up to 20 years, making it an ideal choice for high-end traffic signs.

(2) Surface Finishes

RAL standard colors or customized colors

High gloss, matte, semi-matte

Metallic, wood grain, stone grain decorative effects

Smooth surface with no indentation, no color difference, and no waviness

Why Do Advertising and Signage Manufacturers Prefer Color Coated Aluminum Coil?

Lightweight

Aluminum has only one-third the density of steel, reducing transportation costs and minimizing the load on supporting structures for high-altitude billboards.Excellent Processability

Easy cutting, grooving, bending, curving, and riveting. The coating does not crack or peel during forming.Outstanding Weather Resistance

Protected by PE or PVDF coatings, aluminum coils can withstand strong sunlight, rain, humidity, and temperature fluctuations, with a service life of 20–30 years, significantly reducing maintenance costs.Superior Decorative Performance

High surface flatness and minimal color variation make it suitable for high-quality printing and lamination, greatly enhancing visual impact.Low Maintenance Cost

Compared with steel sheets or painted panels, color coated aluminum coils are corrosion-resistant and rust-free, offering a much longer service life.Wide Temperature Resistance

Stable performance from -50°C to 120°C, without cracking or blistering.Eco-Friendly and Recyclable

Aluminum is infinitely recyclable. Even after decommissioning, the base material retains high recycling value.

Technical Parameters of Color Coated Aluminum Coil

| Alloy | 1100 / 3003 |

| Temper | H14 / H24 / H16 (customizable) |

| Thickness | 0.3 - 2.0 mm |

| Width | 500 - 1600 mm |

| Length | 1000 - 16000 mm |

| Inner Diameter | 76 / 152 mm |

| Coating Type | PE (Polyester) / PVDF (Fluorocarbon) |

| Coating Thickness | Front: 15-25 μm / Back: 5-10 μm |

| Surface Finish | High gloss / Matte / Semi-matte |

| Color | RAL standard colors or customized |

| Surface Treatment | Color coating, film laminated (optional) |

| Processing | Screen printing, spraying, laminating, punching |

| Applications | Advertising boards, signboards, guide signs, light boxes |

| MOQ | 1-3 tons |

Applications of Prepainted Aluminum Coil

Outdoor traffic signs and guide boards

Commercial billboards and light box panels

Shop signs and storefront signage

Public facility wayfinding systems

Indoor and outdoor display and promotional boards

As a professional color coated aluminum coil manufacturer, HAOMEI Aluminum supplies aluminum alloys from 1xxx, 3xxx, 5xxx, and 8xxx series, offering diversified coating customization services, including high gloss, matte, metallic colors, and brushed finishes.

Our products are exported to more than 40 countries worldwide, with competitive pricing, sample availability, and comprehensive after-sales service.

TAG :

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

-

Double-Sided Color Coated Aluminum Coil

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06

-

Pe Coated Aluminum Coil Vs Pvdf

Compare PE coated aluminum coil and PVDF coated aluminum coil by resin chemistry, coil coating process, durability, color retention, and end uses.

2026-01-27