Description:

| Alloy: | 1050, 1060, 3003, 3004, 3005, 3105, 5005, 5052, 5454, etc. |

| Thickness: | 0.15 mm - 0.7 mm |

| Patterns: | Wood grain, grass, marble, brick, camouflage, floral, traffic markings, etc. |

| Coating: | PE / SMP / HDP / PVDF |

| MOQ: | 1-3 tons |

| Alloy: | 1050, 1060, 3003, 3004, 3005, 3105, 5005, 5052, 5454, etc. |

| Thickness: | 0.15 mm - 0.7 mm |

| Patterns: | Wood grain, grass, marble, brick, camouflage, floral, traffic markings, etc. |

| Coating: | PE / SMP / HDP / PVDF |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

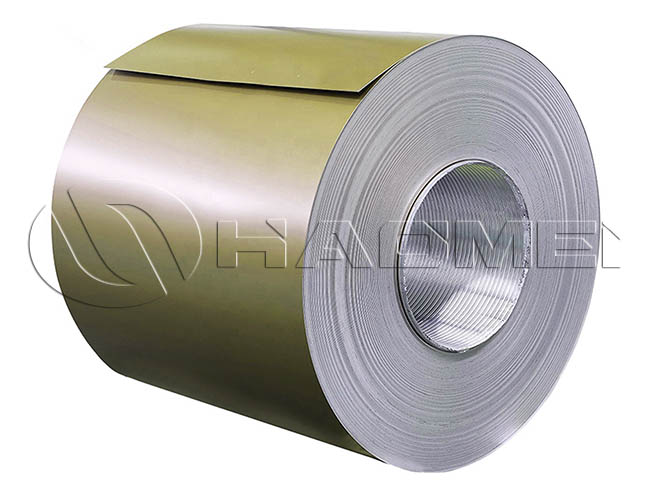

HAOMEI Aluminum offers imitation wood-grain color-coated aluminum sheets & coils in a wide variety of colors and patterns, featuring excellent wood-grain texture and a refreshing natural aesthetic. With outstanding decorative performance, the coated surface is smooth, and the color is uniform and bright. The coils have excellent weather resistance, color retention, gloss retention, and long-lasting durability. We provide strip-processing services and can produce wood-grain aluminum coils with widths from 600 mm to 1500 mm.

Wooden grain color-coated aluminum coil, also known as "imitation wood-grain aluminum coil," is a premium decorative metal material created using advanced coating and printing technologies to form realistic wood patterns on the aluminum surface. It perfectly combines the durability of metal with the natural beauty of wood while overcoming the weaknesses of natural wood such as susceptibility to corrosion, flammability, deformation, and high maintenance costs. It is a modern, eco-friendly green building material.

Wood grain coated aluminum coils are typically made from AA1070, AA1100, AA3003, AA3105, AA5052, or AA8011 series aluminum, offering high chemical stability and good formability suitable for continuous coil coating production. Through heat transfer printing or roller printing, realistic wood textures can be created, such as walnut, cherry, oak, nanmu, rosewood, and more.

Wood-grain coated aluminum coils are widely used for interior and exterior decoration, especially as architectural decorative materials.

PVDF Coating

PVDF-coated aluminum coil offers exceptional durability and weather resistance, along with enhanced acid and alkali resistance. When used for exterior wall cladding, it maintains color for more than 15 years.

PE Coating

Available in matte and glossy finishes. Its compact molecular structure ensures a smooth surface with high gloss, providing excellent coating appearance. Weather resistance: 8-10 years. Ideal for indoor decoration and signage manufacturing.

Excellent formability; acid, alkali, and salt resistance; strong decorative appeal

Durable, high strength, and easy to process

Realistic appearance, rich colors, excellent decorative effect

High surface gloss; wear-resistant, oil-resistant, easy to clean

Lightweight for easy handling and multiple installation methods

Simple maintenance, low cost

Eco-friendly, safe, and non-toxic

Class A fire-resistant, non-combustible, non-deforming

| Alloy | 1050, 1060, 3003, 3004, 3005, 3105, 5005, 5052, 5454, etc. |

| Temper | H16, H24, H26, H42, etc. |

| Thickness | 0.15 mm - 0.7 mm |

| Width | 600 mm - 1250 mm |

| Length | Customized |

| Patterns | Wood grain, grass, marble, brick, camouflage, floral, traffic markings, etc. |

| Coating | PE / SMP / HDP / PVDF |

| Primer | Epoxy primer / Polyester primer / Water-based acrylic primer / Polyurethane primer |

| Coating Thickness | Topcoat: 10-30 μm / Back coat: 5-25 μm |

| Processing Services | Bending, decoiling, welding, punching, cutting |

| Paint Adhesion | Grade ≥1 (GB/T 9286) |

| Bending Performance | ≤2T, no cracks |

| Impact Resistance | No cracks, no peeling |

| Gloss Level | 15-80% (matte or high gloss available) |

| Applications | Architectural exterior walls, interior decoration |

1. Building Facades & Cladding

Used on villas, commercial buildings, and high-rise residential exterior walls and balcony edges, providing a high-end, natural appearance.

2. Interior Ceilings & Wall Panels

Ideal for airports, subway stations, office buildings, hotels, and other public-space ceilings and wall decoration, bringing warmth and modern aesthetics.

3. Door & Window Systems

Perfect for producing wood-grain aluminum door and window profiles that combine wooden appearance with superior metal durability.

4. Furniture & Home Appliances

Used for outdoor furniture, cabinet doors, home appliance panels, enhancing product appearance and design value.

5. Transportation

Applicable for decorative elements in rail transit, ships, and automotive interiors.

1000 Series: Over 99% aluminum, excellent conductivity/thermal conductivity, corrosion resistance

2000 Series: 3-5% copper, high strength, heat treatable

3000 Series: Al-Mn alloy, strong anti-rust performance, good workability

5000 Series: Al-Mg alloy, low density, good weldability

6000 Series: Al-Mg-Si alloy, excellent comprehensive performance, heat treatable

7000 Series: Al-Zn-Mg-Cu alloy, ultra-high strength (σb ≥ 500 MPa)

8000 Series: Al-Li alloy, lighter and stiffer

Wood-grain color-coated aluminum offers customizable colors and textures, including:

Light Wood Series: Maple, white oak, light cherry

Dark Wood Series: Walnut, red sandalwood, teak

Special Textures: Bamboo, rustic coarse wood, fine embossed wood

Surface Gloss: Matte, semi-matte, high gloss, metallic

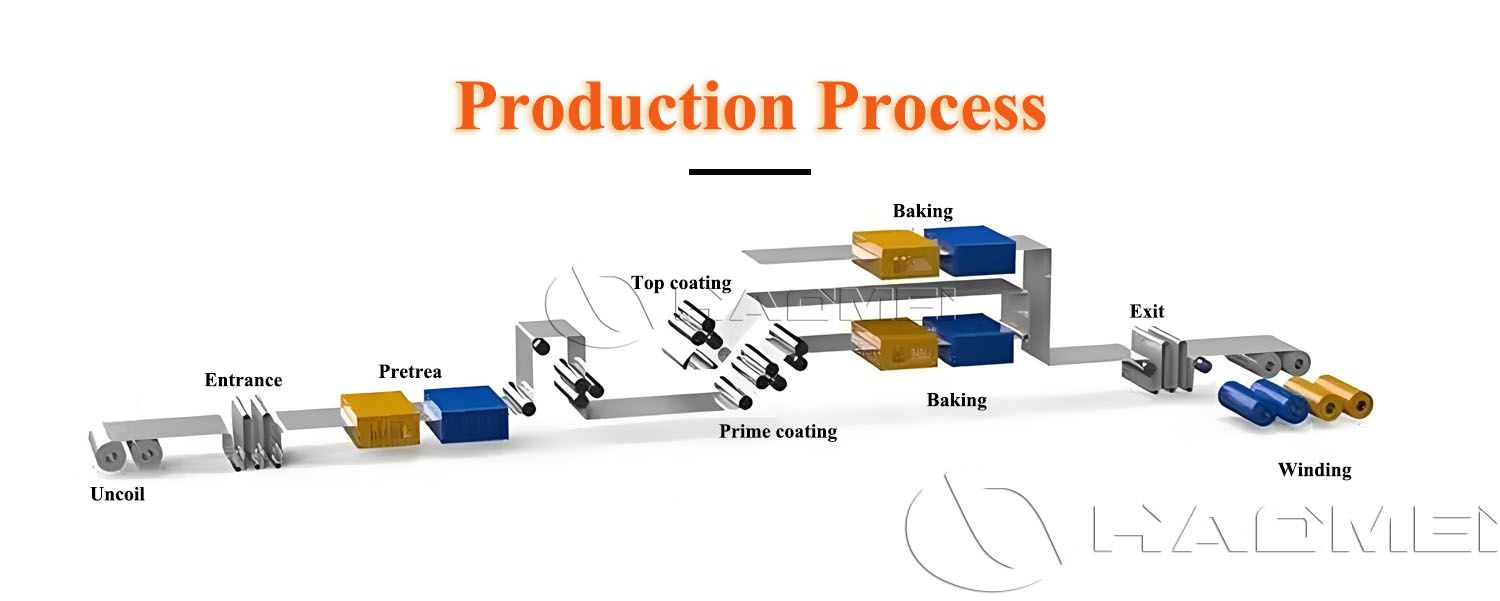

Surface Treatment: Cleaning and pre-treatment to ensure strong coating adhesion

Primer Coating: Applying primer to enhance adhesion and durability

Wood-Grain Printing: Using specialized printing to simulate various wood textures such as oak, walnut, and rosewood

Protective Coating: Applying a transparent protective topcoat to seal the pattern and provide environmental resistance

Curing: Baking and curing in ovens to ensure proper adhesion and coating durability

Inner moisture-proof paper, outer waterproof film

Secured with wooden crates or steel straps to ensure safe transport

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25

1050, 1100, 1200, 3003, and 3004 color coated aluminum coils are widely used in roofing panels, wall panels, corrugated roofing sheets, and architectural façade decoration.

2025-12-29

Fireproof 1100 PE PVDF prepainted aluminum coil offers excellent flame resistance, durability and weather resistance, ideal for building facade and ceiling systems.

2025-12-22