News

By Hermione

By Hermione

PVDF Coated Aluminum Coil For Architectural Decoration

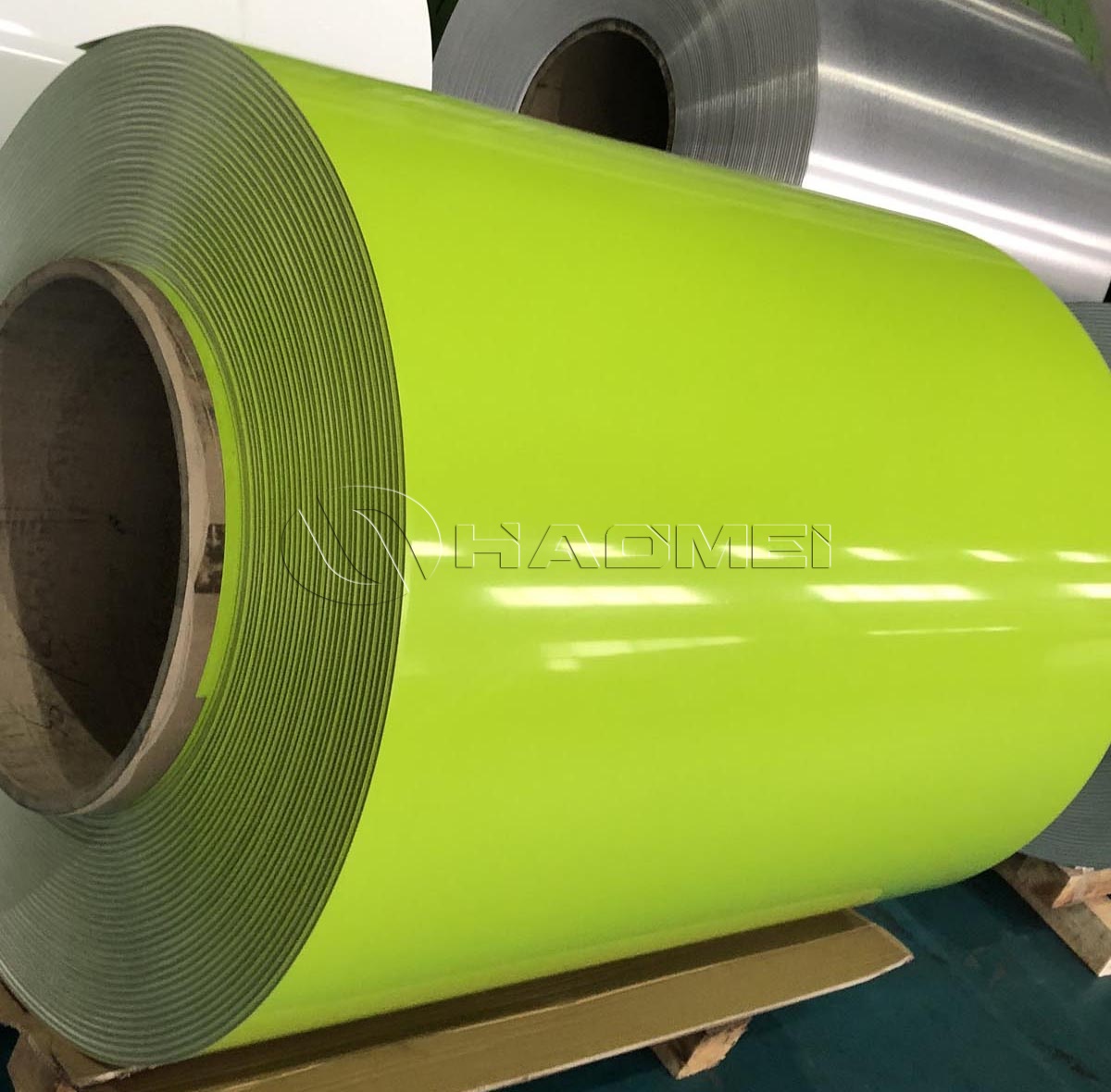

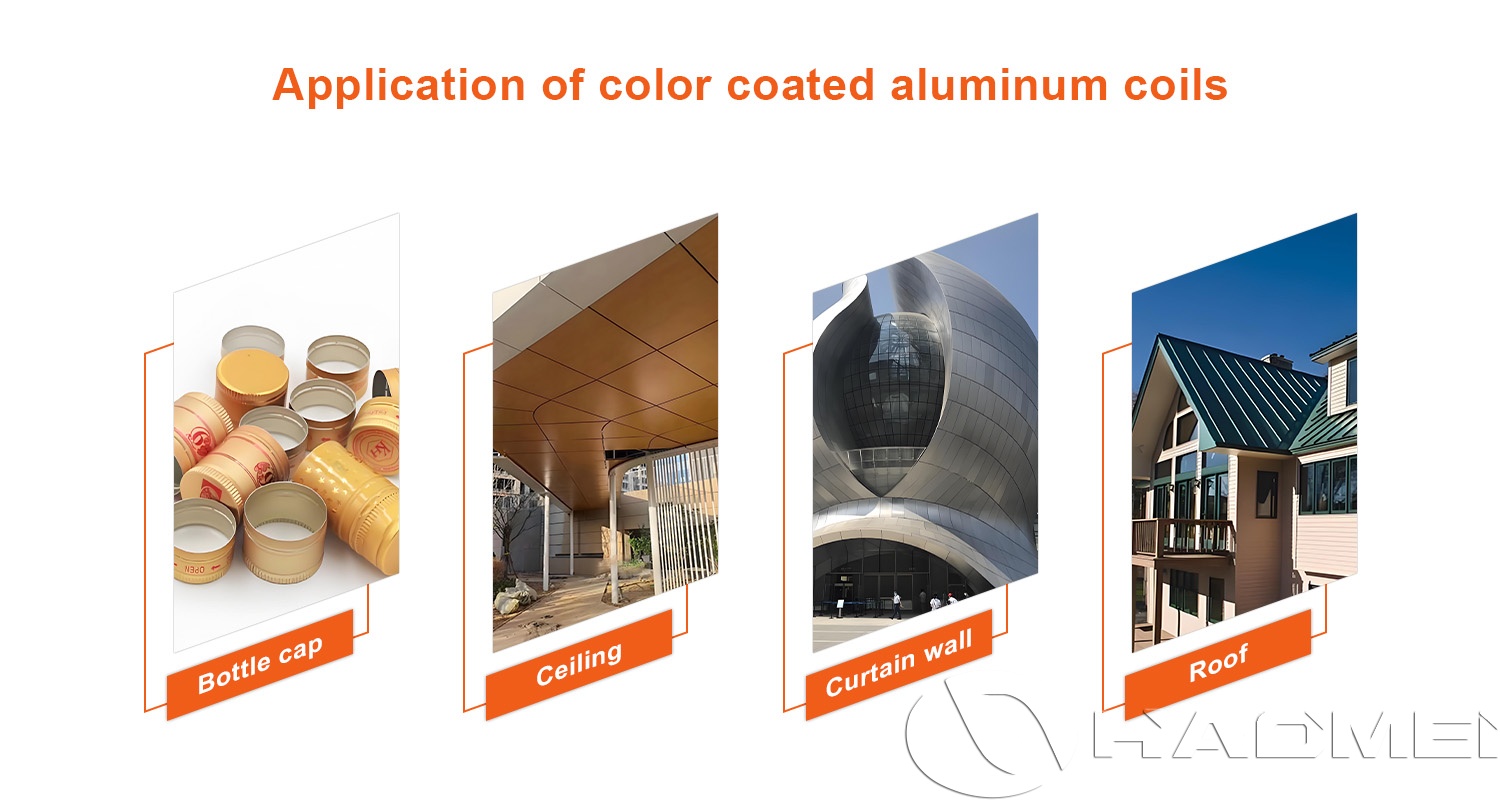

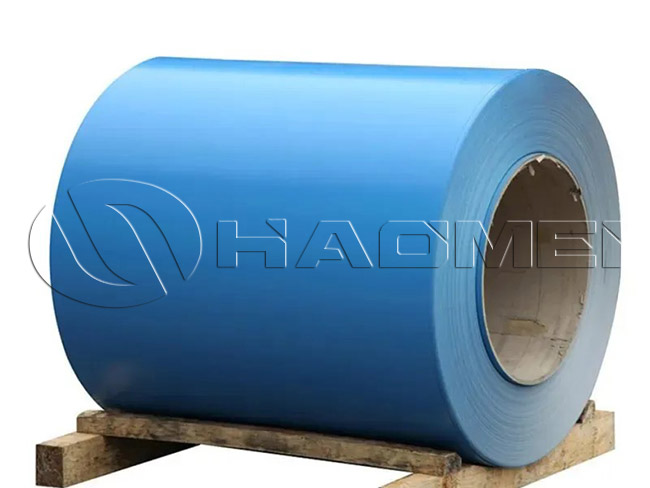

PVDF coated aluminum coil for architectural decoration is positioned as a premium, long-life prepainted metal for building envelopes where color stability and weatherability are critical. It is widely used for exterior facades, aluminum composite panels (ACP), curtain wall trims, soffits, canopies, roof edging, and other architectural elements that demand consistent appearance across large areas.

Why aluminum coil + PVDF is a reliable architectural material

Architectural decoration often combines three requirements that are difficult to balance: visual design freedom, long-term durability outdoors, and manufacturability into complex shapes. Aluminum coil provides the lightweight, corrosion-resistant substrate and formability needed for bending, roll-forming, and panel fabrication, while PVDF (fluorocarbon) coating protects the surface from UV radiation, humidity, salt spray, and airborne pollutants.

From a materials engineering perspective, the performance is not only determined by the paint brand or resin type, but by the interaction between alloy selection, pretreatment chemistry, primer/topcoat design, and curing control in the continuous coil coating line.

Substrate selection: strength, flatness, and corrosion margin

For architectural parts, coil is typically supplied in alloys that balance flatness, yield strength, and bending performance:

5005 (Al-Mg): favored for facade sheets and trims due to good anodic compatibility, surface uniformity, and corrosion resistance.

3003/3105 (Al-Mn): frequently used for general architectural panels and roll-formed profiles thanks to stable forming behavior.

5052 (Al-Mg): selected when higher strength or improved marine corrosion resistance is required.

Temper is chosen to match fabrication: H14/H24 for forming and profiling; H16/H18 where stiffness and dent resistance are prioritized. Proper coil leveling and low residual stress help reduce oil-canning risk in wide panels.

When project specifications require a dedicated PVDF system for exterior exposure, the material is typically supplied as PVDF Coated Aluminum Coil to ensure coating durability aligns with facade service-life expectations.

Coating system design: pretreatment to topcoat as one performance chain

A PVDF architectural system is engineered as a layered structure, each layer serving a distinct role:

Pretreatment (chemical conversion coating) builds the adhesion foundation and corrosion barrier. Chromium-free systems are widely adopted, provided line control (bath concentration, contact time, rinse quality) is stable.

Primer contributes to adhesion, flexibility, and corrosion resistance, especially at cut edges and formed radii.

PVDF topcoat delivers the primary outdoor durability: UV stability, chalk resistance, gloss retention, and color longevity.

Optional clear coat can be added for enhanced stain resistance or special gloss/texture control.

Typical architectural PVDF constructions are 2-coat-2-bake or 3-coat systems depending on performance targets. For metallic colors, pearlescent effects, or matte finishes, pigment selection and dispersion quality are critical because they directly influence long-term fading behavior and visual uniformity between coil lots.

Coil coating process: where durability is manufactured, not claimed

Continuous coil coating turns raw aluminum into a finished decorative material with repeatable quality. The core process logic is straightforward, but the engineering details determine whether the coating survives decades outdoors:

Surface preparation and cleaning remove rolling oil and contaminants to prevent adhesion loss and microblistering.

Pretreatment and rinsing control conversion weight and uniformity; poor rinse conductivity control can lead to premature corrosion under film.

Primer coating and curing establish a stable base; under-cure reduces solvent resistance and long-term adhesion, while over-cure can embrittle the film.

PVDF topcoat application (roller coating) targets uniform film build, minimizing edge build-up and roller marks.

Oven curing is managed by peak metal temperature (PMT), line speed, and airflow balance to achieve complete crosslinking without damaging gloss or pigment orientation.

Inspection and testing typically includes color difference (Delta E), gloss, film thickness, adhesion (T-bend/crosshatch), MEK rub, impact, and bend performance.

In practice, architectural projects benefit from tight controls on color matching and lot traceability, since facade panels are installed side-by-side and any shade drift becomes visible. Managing coil-to-coil consistency requires not only paint control, but also stable pretreatment chemistry and consistent PMT across production shifts.

Core specifications (typical for architectural PVDF coil)

Table: Core Specifications for PVDF Coated Aluminum Coil (Architectural Use)

| Item | Typical Range / Option | Notes |

|---|---|---|

| Alloy | 3003, 3105, 5005, 5052 | Selected by forming and corrosion environment |

| Temper | H14, H16, H18, H24 | H24 often used for balanced formability |

| Thickness | 0.20-3.00 mm | Facade/ACP skins commonly 0.30–1.50 mm |

| Width | 20-1600 mm | Subject to mill capability and slitting plan |

| Coating type | PVDF (fluorocarbon) | Exterior-grade weatherability |

| Coating structure | 2-coat / 3-coat | Primer + PVDF topcoat, optional clear coat |

| Topcoat dry film thickness | 20-30 μm (typical) | Project spec may vary |

| Primer dry film thickness | 5-10 μm (typical) | Improves adhesion and corrosion resistance |

| Finish | Gloss, matte, metallic, textured | Visual design and glare control |

| Color | RAL/Pantone/custom | Color matching controlled by Delta E targets |

| Protective film | Optional | Helps reduce handling scratches during fabrication |

| MOQ | 1-3 tons | |

Practical architectural applications and fabrication considerations

PVDF coated aluminum coil is commonly processed into:

Facade cladding and ACP skins: PVDF topcoats help maintain color consistency and resist chalking under strong sunlight.

Curtain wall covers, trims, flashings: good bend performance is essential; appropriate temper and primer flexibility reduce risk of microcracks at radii.

Soffits, ceilings, canopies: matte or low-gloss finishes control glare while maintaining cleanability.

Roll-formed profiles and roof edge systems: uniform coating thickness and curing prevent premature edge corrosion and film brittleness.

For fabrication, controlling the minimum bend radius (relative to thickness and temper) and protecting cut edges are key for long-term appearance. While aluminum does not rust like steel, aggressive coastal or industrial environments can drive filiform corrosion if pretreatment quality, primer selection, and edge design are not aligned.

Where interior or lower-UV applications prioritize cost efficiency over maximum weatherability, a complementary option is PE Coated Aluminum Coil, while PVDF remains the standard choice for exterior architectural decoration requiring long service life.

-

3003 H14 Color Coated Aluminum Coil for Roofing

3003 H14 color-coated aluminum coil uses PE/PVDF coating and features excellent formability, high corrosion resistance, and weldability.

2025-12-17

-

Pvdf Coated Aluminum Coil For Honeycomb Panels

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02

-

Pvdf Coated Aluminum Coil For Exterior Cladding

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29