Description:

| Alloy: | 8079 |

| Temper: | 0.15mm – 1.5mm |

| Width: | 20mm – 1600mm |

| Coating Thickness: | PE: 15–25μm; PVDF: 25–30μm |

| MOQ: | 1-3 tons |

| Alloy: | 8079 |

| Temper: | 0.15mm – 1.5mm |

| Width: | 20mm – 1600mm |

| Coating Thickness: | PE: 15–25μm; PVDF: 25–30μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

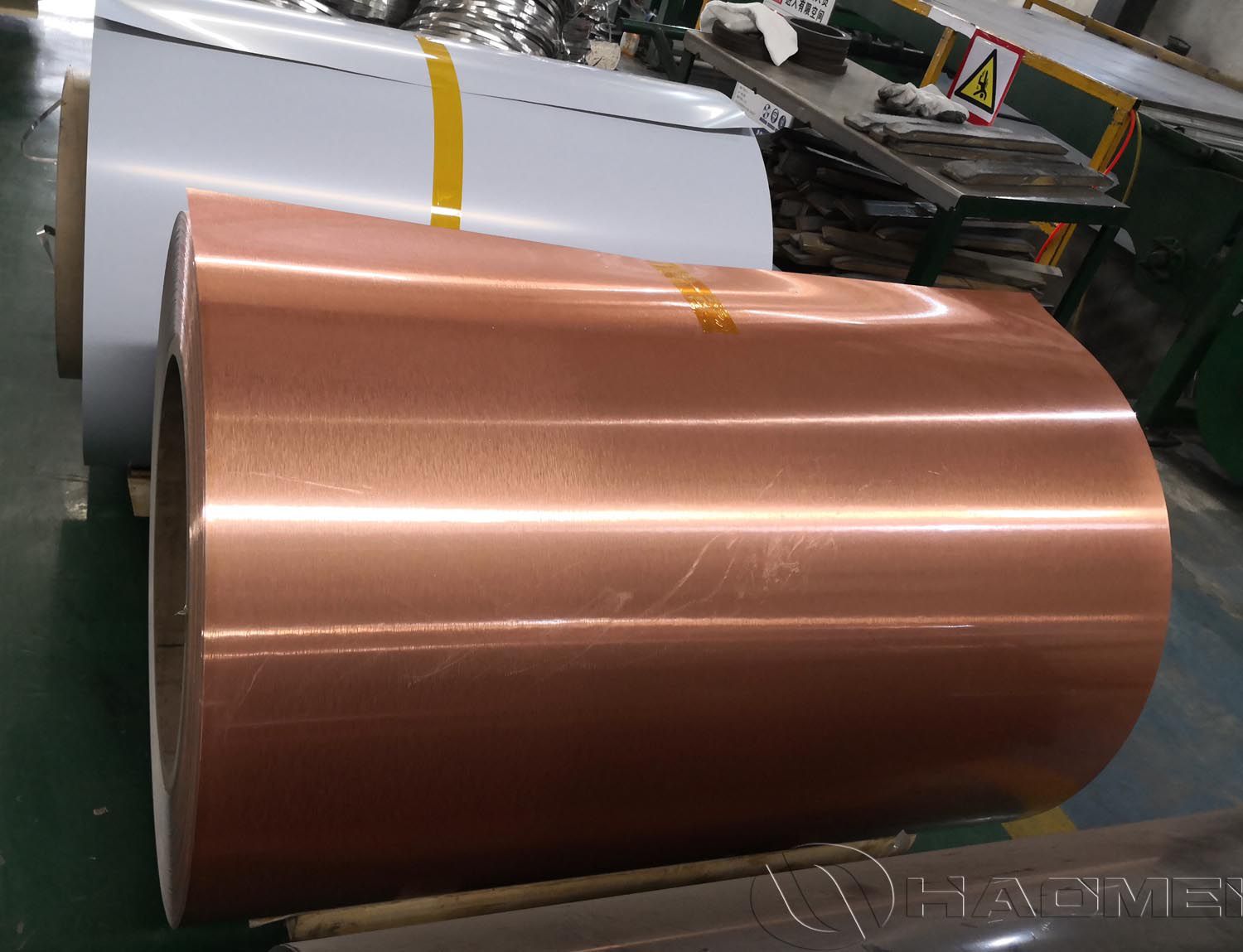

8079 color coated aluminum coil uses 8079 aluminum alloy as the base material. After surface pretreatment (such as cleaning and chromizing), organic coatings are applied onto the surface using a continuous roll coating process, followed by baking and curing to form a composite material.

8079 alloy is a commonly used anti-rust aluminum alloy similar to 8011, but its formulation provides superior durability, corrosion resistance, and heat insulation when rolled into ultra-thin foil. Therefore, it is widely used in pharmaceutical packaging, food containers, bottle cap sealing, home appliance panels, architectural decoration, and more.

| Alloy | 8079 |

| Temper | O, H14, H16, H18 |

| Thickness | 0.15mm - 1.5mm |

| Width | 20mm - 1600mm (customizable) |

| Coating Thickness | PE: 15-25μm; PVDF: 25-30μm |

| Coating Type | Single-side / double-side / dual-color |

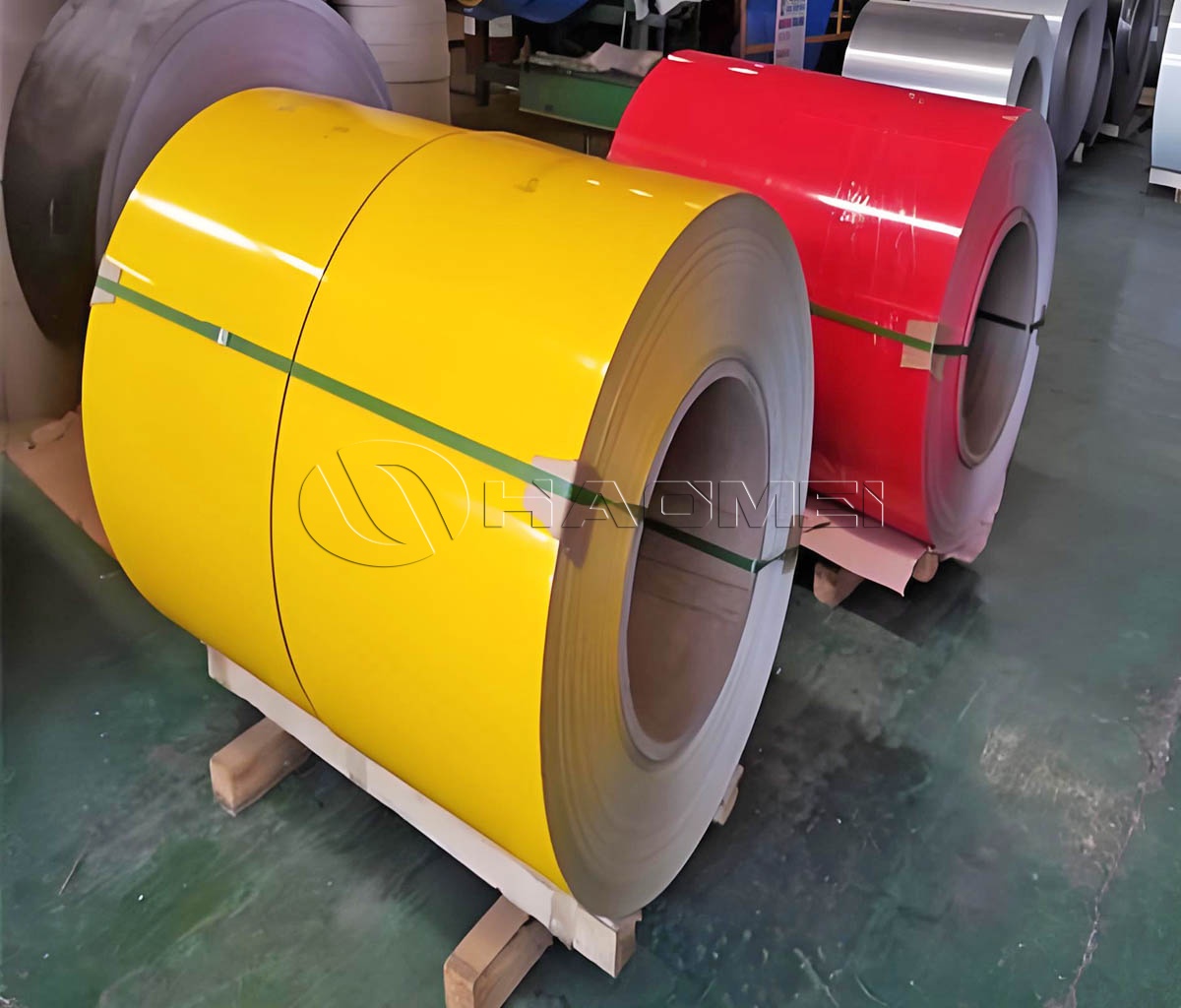

| Color | RAL colors, wood grain, stone grain, metallic finishes (customizable) |

| Gloss | High gloss, semi-gloss, matte |

| Surface Treatment | Brushed, matte, embossed, mirror, bright surface |

| Protective Film | Single or double-sided PE protective film (optional) |

| Origin | Zhengzhou, China |

| MOQ | 1-3 tons |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 8079 | 0.05-0.3 | 0.7-1.3 | 0.05 | - | - | - | 0.10 | - | 0.05 | 0.15 | remainder |

Mechanical Properties

| Property | Unit | H14 | O |

| Tensile strength (σb) | MPa | 125-165 | 95-130 |

| Yield strength (σ0.2) | MPa | 70-110 | 30-60 |

| Elongation (A50) | % | 2-5 | 10-18 |

| Elastic modulus | GPa | 69 | 69 |

| Hardness (HV) | HB | 35-45 | 25-35 |

Physical Properties

| Property | Unit | Typical Value |

| Density | g/cm³ | 2.71 |

| Melting point | ℃ | 660 |

| Thermal conductivity | W/m·K | 230 |

| Electrical conductivity | % IACS | 35 |

| Specific heat capacity | J/kg·K | 900 |

| Linear expansion coefficient | ×10⁻⁶/K | 23.8 |

| Oxidation resistance | - | Excellent |

| Reflectivity | % | ≥80 |

1. Excellent ductility and formability

8079 alloy has high elongation and does not easily crack during deep drawing, stretching, or stamping processes.

2. Strong coating adhesion

The coating is cured at high temperature and firmly bonded to the aluminum surface, ensuring no peeling or blistering.

3. Outstanding corrosion resistance

Even in humid, acidic, alkaline, or salt-spray environments, 8079 coated aluminum remains glossy and color-stable.

4. Superior decorative appearance

Available in diverse finishes: glossy, matte, wood grain, stone grain, brushed metal, etc.

5. Environmentally friendly

Free of harmful heavy metals and compliant with EU RoHS, suitable for food and pharmaceutical packaging.

Pharmaceutical packaging: blister packs, aluminum-plastic sealing lids

Food packaging: chocolate, milk powder, instant coffee, and other outer packaging

Bottle caps: anti-theft caps, easy-open caps, pharmaceutical aluminum caps

Architectural decoration: façade panels, roofing systems, ceiling panels, louvers

Home appliances: refrigerator panels, microwave oven shells, decorative panels

Transportation: interior trim panels, reflective panels, ship decoration components

PE (Polyester Coating): Cost-effective, vibrant colors, excellent flexibility.

PVDF (Polyvinylidene Fluoride): Ideal for outdoor applications with high weathering resistance.

Epoxy / Special primers: Used for food and pharmaceutical inner packaging requiring specific barrier performance.

Composition & Performance:

8011 coated aluminum coil usually has higher silicon content and may contain Mn and Mg, giving it higher strength and corrosion resistance.

8079 aluminum coil provides better elongation and puncture resistance.

Applications:

8011 aluminum is used widely in food packaging, pharma packaging, bottle caps, cable foil, etc.

8079 coil is preferred for pharmaceutical blister packs and lithium battery soft packaging due to its forming ability and barrier performance.

Direct supply from a source factory: Integrated production from aluminum ingot casting to rolling and color coating

Advanced equipment: Italian VALDARNO continuous coating line ensures uniform and stable coating

Strict quality control: Color difference testing, adhesion testing, T-bend testing, salt-spray corrosion testing

Strong customization capability: Custom colors, thickness, width, and coating types

Environmental compliance: Certified with ISO9001, ISO14001, SGS, RoHS

Rich export experience: Products exported to Europe, Southeast Asia, Middle East, Americas, etc.

Learn how PVDF coated aluminum coil supports fire rating standards such as EN 13501-1 and ASTM E84, covering coating systems, processes and test-critical details.

2026-01-30

5052 color-coated aluminum coils typically have coatings including polyester (PE) or fluorocarbon (PVDF), and are commonly used in building curtain walls, ceilings, and home appliance manufacturing.

2025-12-08

3003 and 5052 are the two most commonly used substrates, and they are often made into color-coated aluminum coils for use in building curtain walls, industrial plants and shipbuilding.

2025-12-12