News

By Hermione

By Hermione

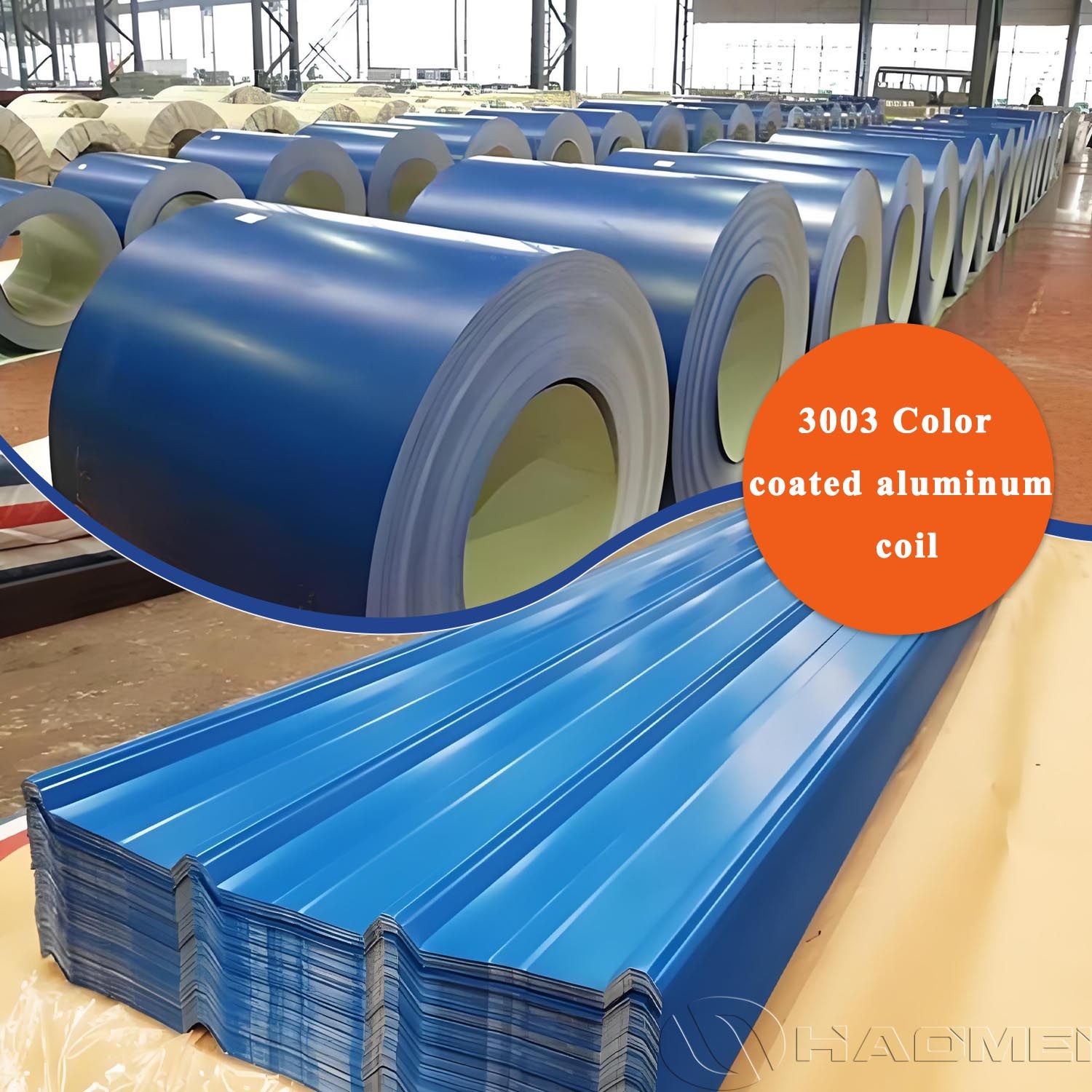

3003 H14 Color Coated Aluminum Coil for Roofing

In modern roofing systems, material durability, formability, and visual appearance directly determine the overall quality of a building. The 3003 H14 color coated aluminum coil has gradually replaced traditional color steel sheets and plastic-based roofing materials, becoming the preferred choice for high-end industrial plants, sports facilities, and residential roofing projects.

Material Overview: 3003 Aluminum Alloy & H14 Temper

The 3003 aluminum alloy, a representative alloy of the 3000 series aluminum-manganese anti-rust alloys, contains 1.0-1.5% manganese. Its performance lies between industrial pure aluminum and higher-strength aluminum alloys, making it especially suitable for applications requiring excellent formability, high corrosion resistance, and good weldability.

The H14 temper indicates that the material has undergone controlled cold working (strain hardening) to achieve a half-hard condition, offering a balanced combination of moderate strength and superior forming capability.

Color Coating Process and Coating Types

3003 color coated aluminum coil is produced through a continuous coil coating process, in which one or multiple organic coating layers are applied to the aluminum surface.

The most common coating systems include Polyester (PE) and Fluorocarbon (PVDF) coatings.

| Coating Type | Main Characteristics | Typical Applications |

| Polyester (PE) | Rich color options, cost-effective, good flexibility and adhesion | Industrial buildings, warehouses, and temporary roofing with moderate durability requirements |

| Fluorocarbon (PVDF) | Exceptional weather resistance, UV resistance, self-cleaning properties, long-lasting color | Public buildings (airports, stadiums), high-end commercial buildings, harsh climate regions |

In addition to coating type, coating structures may include single-layer, double-layer, and three-layer systems. Multi-layer coating systems typically apply primer, topcoat, and clear coat successively to the metal substrate, providing more comprehensive protection.

Furthermore, HAOMEI Aluminum offers customized surface finishes such as stone grain, wood grain, embossed, and camouflage patterns, meeting diverse customer requirements.

Product Specifications

| Alloy | 3003 |

| Temper | H14 |

| Thickness | 0.4-1.2 mm |

| Width | 600-2300 mm (customizable) |

| Length | 1000–16000 mm (customizable) |

| Coating Thickness | Front side: 15-25 μm Back side: 5-10 μ |

| Coating Type | PE / PVDF |

| Surface Finish | Glossy, matte, embossed (optional) |

| Color | Standard colors / customized colors |

| MOQ | 1-3 tons |

Key Advantages of 3003 H14 Color Coated Aluminum Coil for Roofing

1.xcellent Weather Resistance

Under long-term exposure to sunlight, rain, wind, and snow, the 3003 H14 color coated aluminum coil maintains stable mechanical properties and appearance.

2.Low Maintenance Cost

Compared with traditional roofing materials, it is resistant to rust and color fading, significantly reducing long-term maintenance and replacement costs.

3.Good Thermal Reflectivity

Light-colored or high-reflectivity coatings effectively reduce heat absorption, helping improve building energy efficiency.

4.Excellent Processing Performance

With good plasticity, the material performs well in standing seam systems, corrugated profiling, and antique tile designs, with minimal risk of cracking at bends.

5.Lightweight and Structural Safety

Aluminum has a density approximately one-third that of steel, significantly reducing roof load and structural stress while improving installation efficiency and safety.

6.High Construction Efficiency

The material's flexibility allows fast on-site forming and installation, shortening the construction cycle.

Application Areas

Industrial Facilities: Chemical plants and logistics warehouses requiring resistance to acid and alkali corrosion

Public Buildings: Metal roofing systems for airport terminals, high-speed railway stations, and stadiums

High-End Residential Projects: Villa roofing drainage systems, aluminum-magnesium-manganese roofing panels

Architectural Details: Eaves, gutters, fascia boards, and exterior wall decoration

Why Choose 3003 Color Coated Aluminum Coil for Roofing?

| Material | Advantages | Disadvantages |

| 3003 H14 Color Coated Aluminum Coil | Corrosion-resistant, lightweight, aesthetic, cost-effective | Lower strength than stainless steel |

| Stainless Steel Sheet | High strength, superior corrosion resistance | Heavy weight, high cost |

| Color Coated Steel Sheet | Lowest initial cost | Poor corrosion resistance, high maintenance cost |

| Pure Aluminum Sheet | Excellent formability | Lower strength, relatively weaker corrosion resistance |

-

Fireproof 1100 PE / PVDF Color Coated Aluminum Coil

Fireproof 1100 PE PVDF prepainted aluminum coil offers excellent flame resistance, durability and weather resistance, ideal for building facade and ceiling systems.

2025-12-22

-

Color coated Aluminum Coils for Roofing, Ceiling, and Wall Systems

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

-

5052 vs. 3003 Color-Coated Aluminum Coil: Which Material Is Right for You?

3003 and 5052 are the two most commonly used substrates, and they are often made into color-coated aluminum coils for use in building curtain walls, industrial plants and shipbuilding.

2025-12-12