News

By Hermione

By Hermione

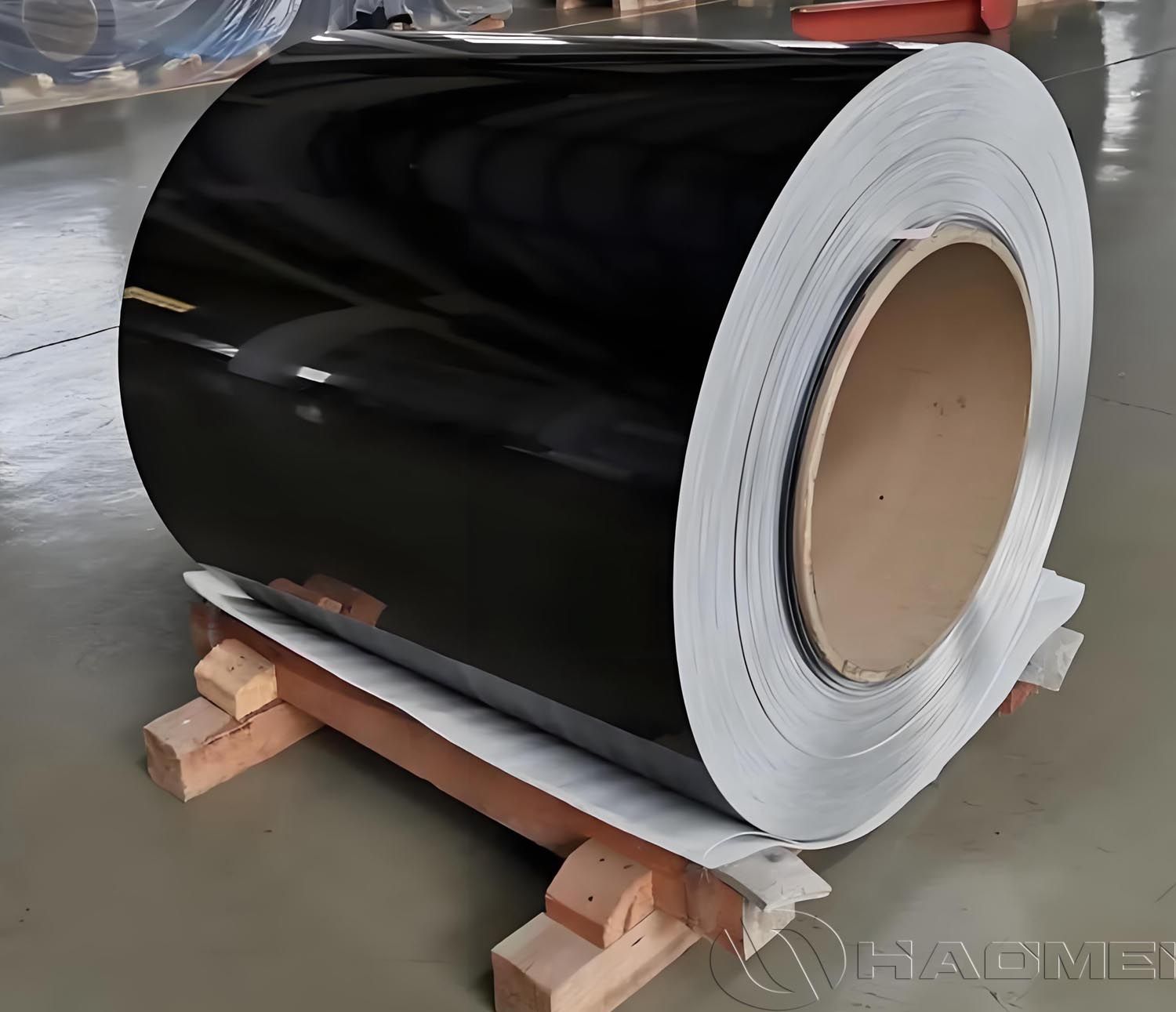

Black Color Coated Aluminum Coil 5052

Black color coated aluminum coil is produced from a 5052 aluminum alloy base and manufactured through surface chemical pretreatment + high-quality coating (PE or PVDF) + oven curing. The final surface shows a deep black or matte black finish. It is widely used in architectural decoration, home appliance panels, transportation equipment, and marine engineering.

The main alloying element of 5052 aluminum is magnesium (2.2%-2.8%), which gives it significantly higher fatigue strength than the 3003 aluminum series. It offers excellent vibration resistance and stress resistance, making it ideal for moving components or installations exposed to windy environments.

5052 Color coated aluminum coil also has excellent formability. In the annealed state, it enables deep drawing, bending, and complex forming, making it an ideal base material for color-coated aluminum coil.

Common Temper States

O Temper

Fully annealed, the softest state. Excellent elongation and superb formability. Best for deep drawing and stretching.

H32 Temper

Work-hardened and stabilized. Offers the best balance of strength and formability. It is the most widely used temper for 5052 color coated aluminum coils.

H34 Temper

Higher strength and hardness with improved wear resistance. Lower elongation compared to H32, requiring larger bending radius during fabrication.

H24 Temper

Moderately work-hardened. Higher hardness than H22/H32 and slightly lower elongation but still maintains good processing performance.

Technical Specifications of 5052 Black Color Coated Aluminum

| Alloy | 5052 |

| Temper | H32 / H34 / H24 / O |

| Colors | Gloss black, matte black, textured black, brushed black, customized black |

| Coating Type | PE / PVDF / Epoxy |

| Thickness | 0.2 mm - 1.2 mm |

| Width | 20 mm - 1600 mm |

| Length | 1000 mm - 16000 mm |

| Coating Thickness | Front: 15-30 μm / Back: 5-10 μm |

| Gloss Level | 10%-90% optional |

| Protective Film | Single side / double side |

| Inner Diameter | 505 mm / 405 mm |

| MOQ | 1-3 tons |

Mechanical Properties

| Temper | Tensile Strength | Yield Strength | Elongation |

| O (Annealed) | 170-210 MPa | 65-100 MPa | ≥ 20% |

| H32 | 230-260 MPa | 130-150 MPa | ≥ 12-15% |

| H34 | 260-290 MPa | 145-190 MPa | ≥ 10-12% |

| H24 | 225-260 MPa | 120-150 MPa | ≥ 10-13% |

Applications of Black Coated Aluminum Coil

1. Architectural Facades

Matte or ultra-matte black aluminum panels are widely used in high-end office buildings, museums, and boutique hotels. They absorb ambient light, enhancing the clarity of the building silhouette and delivering a sculptural, high-end visual effect.

2. Outdoor Electronic Equipment Enclosures

Thanks to 5052's corrosion resistance and shielding properties, black coated aluminum coils are used for 5G base station covers, outdoor advertising equipment frames, and intelligent traffic system housings.

3. New Energy Charging Stations & Energy Storage Cabinets

Black surfaces resist dirt and present a stable, sleek appearance-perfect for outdoor charging piles and residential energy storage units.

4. Premium Home Appliance Panels

An excellent alternative to stainless steel or plastic, offering a lighter and more metallic texture for refrigerator doors, range hoods, and integrated stove panels.

5. Other Uses

Rolling shutter doors, honeycomb panels, insulation panels, louvers, downpipes, and nearly all architectural components. Black not only enhances aesthetic value but also improves functional performance.

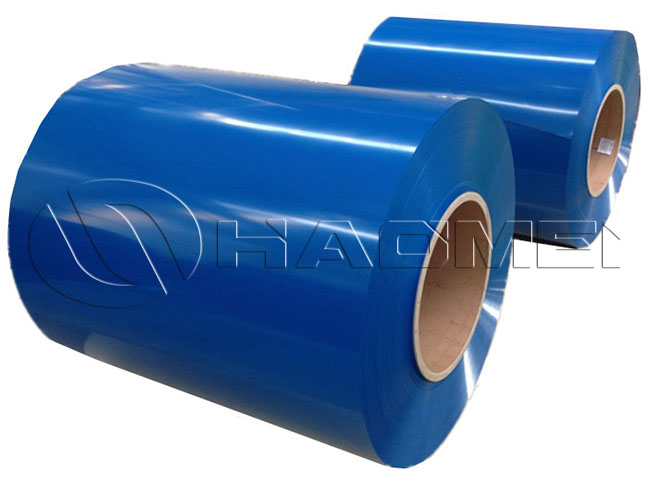

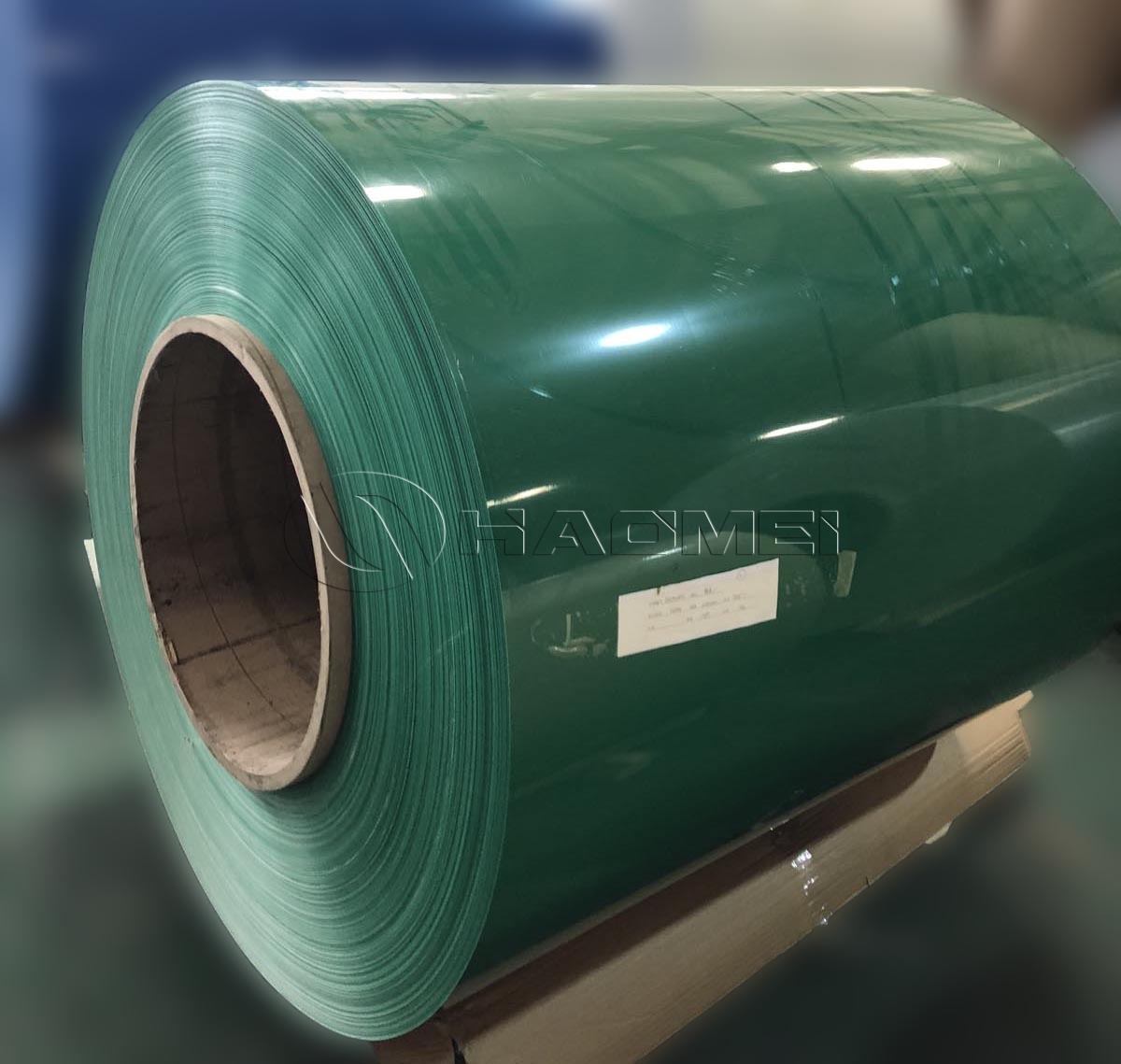

Coating Types

The performance of black color coated aluminum coil depends on both the aluminum substrate and the coating system.Currently, there are two main types of coatings on the market: polyester paint and fluorocarbon paint, each with its own characteristics and applicable scenarios.

Polyester paint coatings offer good weather resistance and a wide range of colors, typically with a warranty period of around 10 years. They are relatively inexpensive and suitable for most conventional building applications, such as interior decoration, curtain walls, and roofing.

Fluorocarbon paint coatings, on the other hand, provide an even higher level of weather resistance and durability, with a warranty period exceeding 20 years. Fluorocarbon paints resist various environmental erosions, including ultraviolet radiation, acid rain, and salt spray, maintaining their color for a long time.

FAQ

Q1: What advantages does 5052 alloy have over the common 3003 alloy?

A1:

5052 (Al-Mg series): Medium-to-high strength, excellent corrosion resistance, especially against seawater and humid environments. Ideal for facades, roofing, and high-demand outdoor applications.

3003 (Al-Mn series): 3003 aluminum coilsoffer advantages such as economic price and excellent formability. They are primarily used for general interior components or economical exterior components where corrosion resistance requirements are relatively low.

For long-lasting, high-corrosion-resistance black applications, 5052 is the superior choice.

Q2: Is the coating process environmentally friendly?

A2: Yes. The production uses chromium-free pretreatment, and coatings comply with ROHS and REACH standards. SGS environmental test reports are available.

Q3: Will black 5052 color coated aluminum fade over time?

A3:No, especially with PVDF coating. Outdoor color stability can reach 20-30 years, even in regions with strong sunlight.

Q4: What delivery forms are available?

A4:Parent coil, slit coil, small coils, embossed finishes, and OEM/export packaging options.

Q5: What customization options are supported?

A5:HAOMEI Aluminum offers a variety of customization options, such as color, size, coating type, and shipping packaging, to meet diverse customer needs.

Q6: Any special care needed for black color coated aluminum?

A6:

Clean at least 1-2 times per year using water and mild non-abrasive cleaners

Avoid strong acids, alkalis, or abrasive detergents

Use matching repair paint for minor scratches to maintain a uniform appearance

-

Matte Finish 1000 Series Color Coated Aluminum

Matte finish 1000 series color coated aluminum coil with PE/PVDF options, clean forming, and stable color for trim, ceilings, and lightweight panels.

2026-01-20

-

1100 / 3003 Color Coated Aluminum Coil for Signboards and Advertising Boards

1100 / 3003 color-coated aluminum coils are lightweight, weather-resistant, and have good processability, making them suitable for billboards and traffic signs.

2025-12-23

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19