Description:

| Alloy: | 8011 |

| Thickness: | 0.15 mm - 1.5 mm |

| Production process: | CC / DC |

| Coating thickness: | PE: 15-25 μm; PVDF: 25-30 μm |

| MOQ: | 1-3 tons |

| Alloy: | 8011 |

| Thickness: | 0.15 mm - 1.5 mm |

| Production process: | CC / DC |

| Coating thickness: | PE: 15-25 μm; PVDF: 25-30 μm |

| MOQ: | 1-3 tons |

+86-18703635966

+86-18703635966

sales@alummc.com

sales@alummc.com

8011 color coated aluminum coil uses 8011 aluminum alloy coil as the base material. Through multiple processes such as degreasing, chemical conversion, coating, baking, and curing, it becomes a composite aluminum material that integrates decorative and protective functions.

Because 8011 aluminum contains higher amounts of Fe and Si, it offers excellent strength, ductility, corrosion resistance, and superior coating adhesion. For this reason, 8011 color-coated aluminum coil is widely used in the construction and manufacturing industries. HAOMEI Aluminum can also produce PE-coated and PVDF-coated aluminum coils.

Corrosion Resistance:

The coating acts as an effective barrier that prevents water, oxygen, and chemicals from contacting the aluminum substrate, significantly extending service life.

Lightweight:

8011 aluminum has a density of approximately 2.71 g/cm³, helping reduce structural loads in both construction and industrial applications.

Excellent Workability:

The coating is flexible. During bending, rolling, or forming, the coating does not crack or peel.

High Decorative Value:

Available in a wide range of colors, including solid colors, metallic finishes, wood grain, stone grain, and more to support customized designs.

Superior Weather Resistance:

Especially with PVDF coatings, the coil exhibits long-term resistance to UV, acid rain, and pollution, maintaining durable color stability.

Safety:

8011 aluminum is FDA-approved, non-toxic, and suitable for food-contact packaging.

Environmental Protection:

Many modern coatings are eco-friendly and meet green building standards.

| Alloy | 8011 |

| Temper | O, H14, H16, H18 |

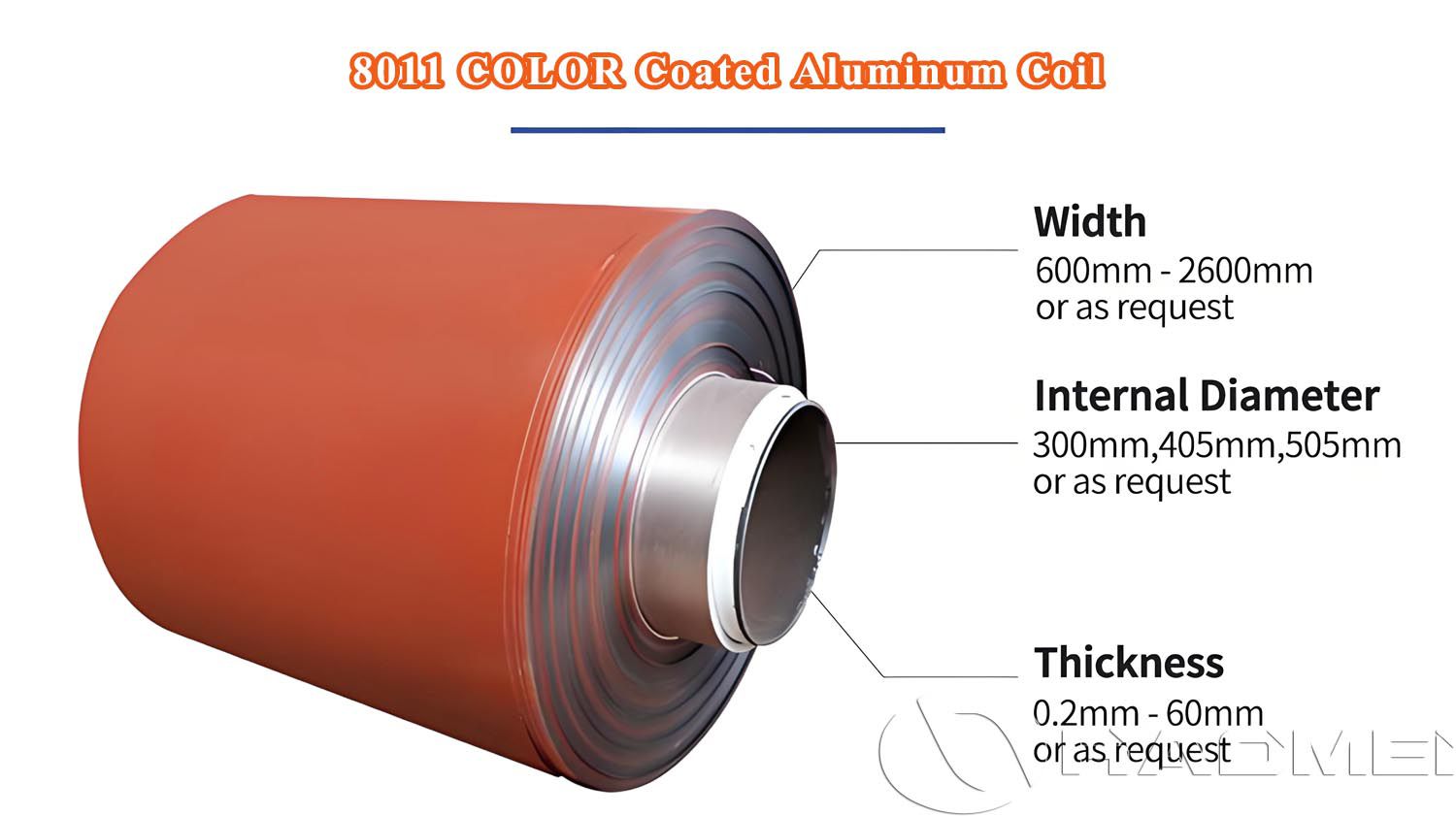

| Thickness | 0.15 mm - 1.5 mm |

| Width | 20 mm - 1600 mm (customizable) |

| Length | 100 mm - 6000 mm (customizable) |

| Production process | CC / DC |

| Coating thickness | PE: 15-25 μm; PVDF: 25-30 μm |

| Protective film | Optional single/double-sided PE film |

| Coating method | Single-sided coating, double-sided coating, front/back dual color |

| Color | RAL standard colors, wood grain, stone grain, etc. (customizable) |

| Surface finish | Mirror, matte, brushed, embossed |

| Inner diameter | 76 mm, 152 mm, 408 mm, 508 mm |

| Export packaging | Standard export wooden pallet (customizable) |

| Samples | Available |

| MOQ | 1-3 tons |

Mechanical Properties

| roperty of alloy 8011 | Temper: O | Temper: H12 | Temper: H14 | Temper: H16 | Temper: H18 |

| Tensile Strength | 90-130 MPa | 110-150 MPa | 130-170 MPa | 150-190 MPa | ≥170 MPa |

| Yield Strength (0.2% offset) | 35-65 MPa | 65-105 MPa | 95-135 MPa | 125-165 MPa | ≥150 MPa |

| Elongation at Break | 18-25% | 8-14% | 6-12% | 4-10% | 3-8% |

| Hardness (Rockwell B) | 25-40 | 40-55 | 50-70 | 60-80 | 70-90 |

Physical Properties

| Property | Value |

| Density | 2.7 g/cm³ |

| Melting Point | 643-657°C |

| Thermal Conductivity | 209 W/m·K |

| Electrical Conductivity | 61% IACS |

| Thermal Expansion Coefficient | 23.1×10⁻⁶/°C (20-100°C) |

Chemical Composition of 8011 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | 0.05 | 0.15 | remainder |

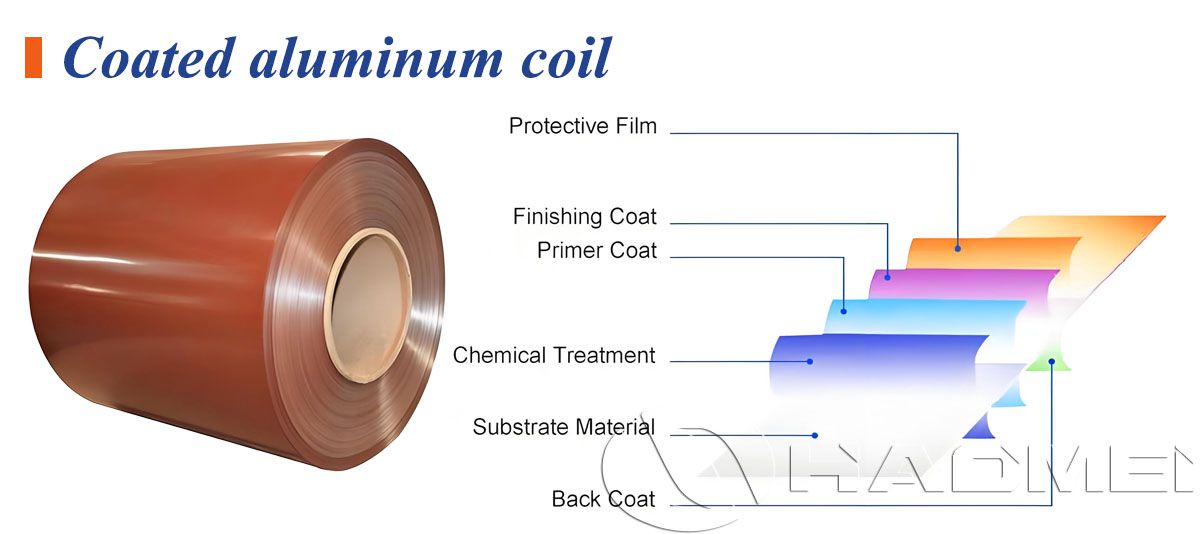

Base layer: 8011 aluminum alloy with good strength and workability

Conversion coating: Enhances adhesion and prevents oxidation

Primer layer: Improves total corrosion resistance and provides a base for the topcoat

Topcoat layer: Determines color, gloss, and weather resistance

Protective film (optional): Prevents scratches during transport and processing; removable before use

| Coating Type | Main Component | Features | Service Life |

| PE (Polyester) | Polyester resin | Bright colors, high gloss, affordable, easy to process | 10-15 years |

| PVDF | Polyvinylidene fluoride | Excellent weather & UV resistance, strong corrosion resistance | 20-25 years |

| Epoxy | Epoxy resin | Strong adhesion, good chemical resistance | Common for bottle caps & packaging |

| Polyurethane (PU) | PU resin | Good flexibility, scratch resistance, aesthetic finish | 15-20 years |

| Feature | 8011 Color-Coated | 3003 Color-Coated | 5052 Color-Coated |

| Alloy Series | 8000 | 3000 | 5000 |

| Strength | High | Medium | High |

| Ductility | Good | Excellent | Very good |

| Corrosion Resistance | Strong | Strong | Very strong |

| Cost | Medium | Lower | Higher |

| Applications | Packaging, appliances, construction | Ceilings, decoration, signage | Marine, outdoor structures |

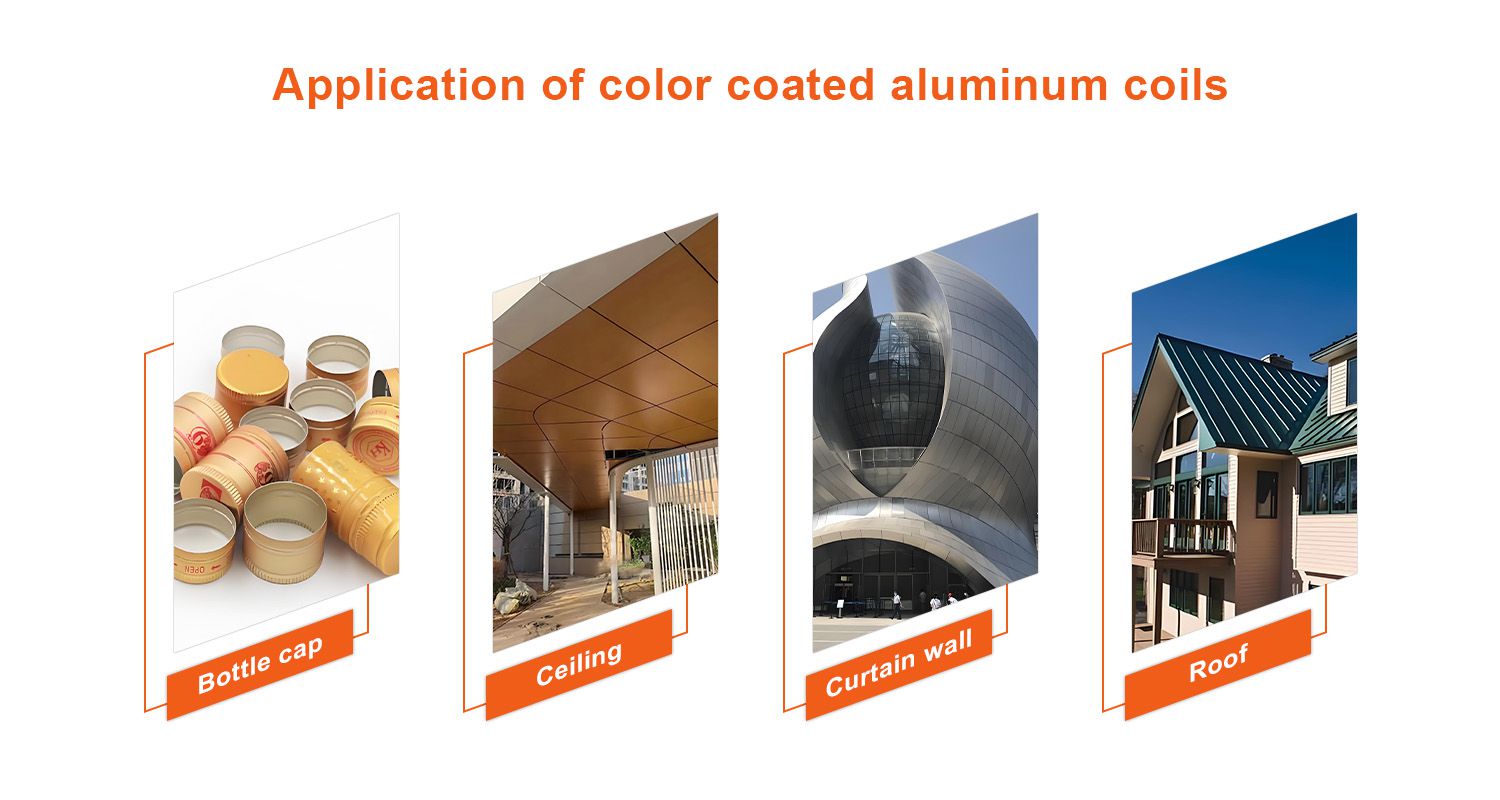

1. Construction & Decoration

Used for roofing, facades, ceilings, panels, and decorative cladding in industrial buildings, stations, airports, stadiums, commercial and residential buildings.

2. Food Packaging & Containers

Safe for direct food contact-used for food container lids, lunch boxes, and packaging materials. The coated surface supports high-quality printing.

3. Home Appliances & Electronics

Applied in panels and components for ovens, microwave shells, and internal device parts to improve aesthetics and corrosion resistance.

4. Other Industrial Uses

Including transformer strips, cable wrap, aluminum adhesive tape, filters, and automobile parts such as heat exchangers.

Q1. Can 8011 color-coated aluminum coils be customized in color and surface texture?

A1:Yes. We can customize according to RAL color cards or customer samples and offer wood grain, stone grain, mirror, brushed, matte, and more.

Q2. What is the difference between PE and PVDF coatings?

A2:PE: Affordable, ideal for indoor or mild environments

PVDF: Superior UV and weather resistance, best for long-term outdoor use

Q3. How should color-coated aluminum coils be stored and transported?

A3:Avoid rain and humid environments; store in a dry and well-ventilated place; lay flat during transportation to avoid collisions and scratches.

Q4. Do you provide samples and customization service?

A4:Yes. Free samples available. Custom thickness, color, width, and coating options. OEM/ODM and export packaging supported.

Q5. What is the service life of 8011 color-coated aluminum coil?

A5:Under normal conditions, the lifespan of a PE coating is 10-15 years, while that of a PVDF coating can reach 20-25 years, depending on the usage environment and maintenance methods.

Q6. Is it suitable for food packaging or bottle cap applications?

A6:Yes. 8011 alloy features excellent ductility and sealing properties. Epoxy or non-toxic PE coatings meet food-grade standards, suitable for pharmaceuticals, beverages, and food packaging.

1000 series PVDF coated aluminum coil delivers corrosion resistance, UV stability and smooth formability for cladding, roofing and signage using 1050/1060/1100 alloys.

2026-01-12

This article introduces color coated aluminum coil engineered for roofing sheets, positioning it as a lightweight, corrosion-resistant, and formable substrate for roll-formed roof panels in industrial, commercial, and residential buildings.

2026-01-07

Compare PE coated aluminum coil and PVDF coated aluminum coil by resin chemistry, coil coating process, durability, color retention, and end uses.

2026-01-27