News

By Hermione

By Hermione

Pvdf Coated Aluminum Coil For Honeycomb Panels

PVDF coated aluminum coil for honeycomb panels is positioned as a high-durability, color-stable face material used to build lightweight aluminum honeycomb panels for exterior architectural envelopes. It is widely specified for curtain walls, rainscreens, soffits, canopies, and other façade zones where UV exposure, weathering, and long service life are critical.

Why PVDF-coated coil is the preferred skin for honeycomb panels

An aluminum honeycomb panel relies on two thin aluminum skins bonded to a honeycomb core to achieve high stiffness-to-weight ratio. The skin material must therefore do more than "look good": it needs consistent temper, predictable forming behavior, and a coating system that survives decades of sunlight, humidity, temperature cycling, and airborne contaminants.

PVDF (fluorocarbon) coatings are commonly selected because the C–F bond chemistry provides superior resistance to chalking and fading compared with standard polyester systems. When engineered for coil coating, PVDF systems maintain gloss and color consistency across long production runs, which is essential for façade batch uniformity (especially when panels are produced over multiple lots).

In practice, PVDF coated aluminum coil helps honeycomb panel fabricators control three key outcomes:

Surface durability during fabrication (cutting, routing, folding, and lamination)

Long-term corrosion resistance at edges, fastener zones, and joints

Stable aesthetics on vertical and inclined exposures where UV and rain-wash patterns vary

Substrate selection: balancing formability, flatness, and corrosion performance

The coating is only as reliable as the substrate beneath it. For honeycomb panel skins, alloy selection is driven by forming requirements (cassette returns, edge folds), panel flatness, and the environmental category.

Common choices include:

3000 series : such as 3003/3105, for good formability and cost efficiency

5000 series : such as 5005/5052, for higher strength and improved corrosion resistance, often favored for coastal or industrial atmospheres

Temper is typically selected to balance bending performance and surface stability after lamination. Skins that are too hard can crack at tight bend radii, while overly soft tempers can be more prone to handling marks and local waviness if process control is not tight.

Coating system design: from pretreatment to PVDF topcoat

A robust PVDF coil coating system for honeycomb panel skins is a layered structure designed to protect the metal and hold color under exposure.

1) Pretreatment and conversion layer : Good pretreatment is fundamental to adhesion and corrosion resistance, particularly near panel edges and routed areas. Modern lines typically use chrome-free conversion coatings (or equivalent high-performance conversion chemistries) to support adhesion and underfilm corrosion control.

2) Primer : The primer improves adhesion to the aluminum and provides additional barrier performance. Primer selection is also important for bonding compatibility with honeycomb panel adhesives (PU, epoxy, or other structural systems). A properly matched primer helps reduce the risk of delamination at elevated temperature and humidity.

3) PVDF topcoat (and optional clear coat) : The PVDF topcoat delivers weathering resistance, color stability, and stain resistance. For certain colors (metallics, micas) or high-gloss requirements, an additional clear coat may be used to optimize depth and cleanability.

Back-side coatings are often specified based on the bonding process and panel design. A functional back coat can improve adhesive wetting and provide handling protection without overbuilding film thickness.

How coil coating process control translates into panel reliability

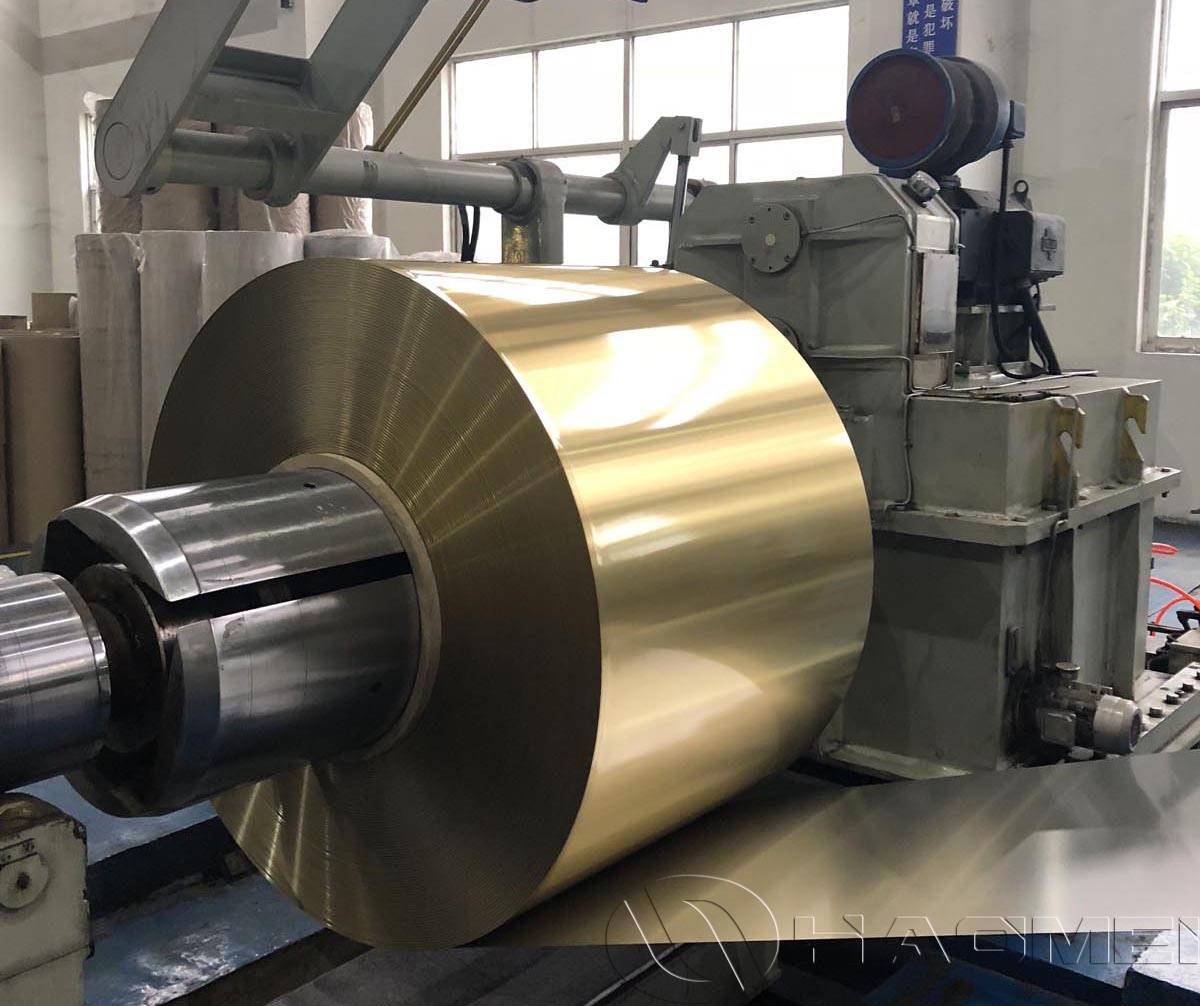

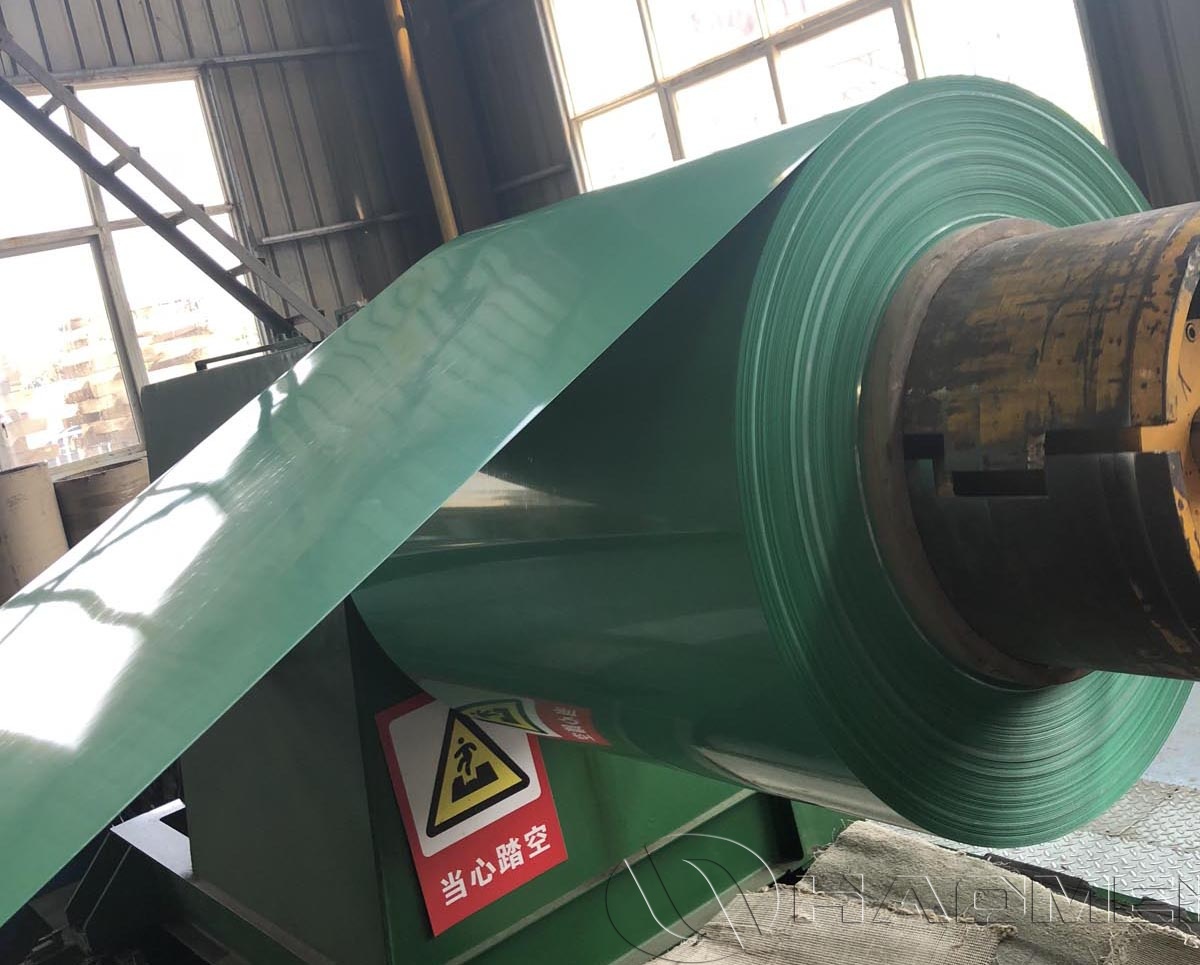

PVDF coated aluminum coil is produced via a continuous coil coating process, where consistency is achieved by controlling surface preparation, coating application, curing, and inspection.

Key manufacturing controls that matter specifically for honeycomb panel fabrication include:

Cleaning effectiveness and conversion coating uniformity, which directly affect adhesion and corrosion resistance

Wet film control and final dry film thickness (DFT) stability across width and length, reducing shade variation and improving forming robustness

Oven cure window (metal temperature and dwell), ensuring full crosslinking without overbake that can reduce flexibility

Coil tension and flatness management, helping panel fabricators maintain skin flatness during lamination and avoid telegraphing

Quality verification commonly includes color and gloss measurement, MEK rubs (cure check), adhesion testing (cross-hatch), bend tests, impact resistance, and corrosion screening such as salt spray and humidity exposure. These controls are not academic; they map directly to real panel failure modes: edge creep, microcracking at bends, and early color shift on the building elevation.

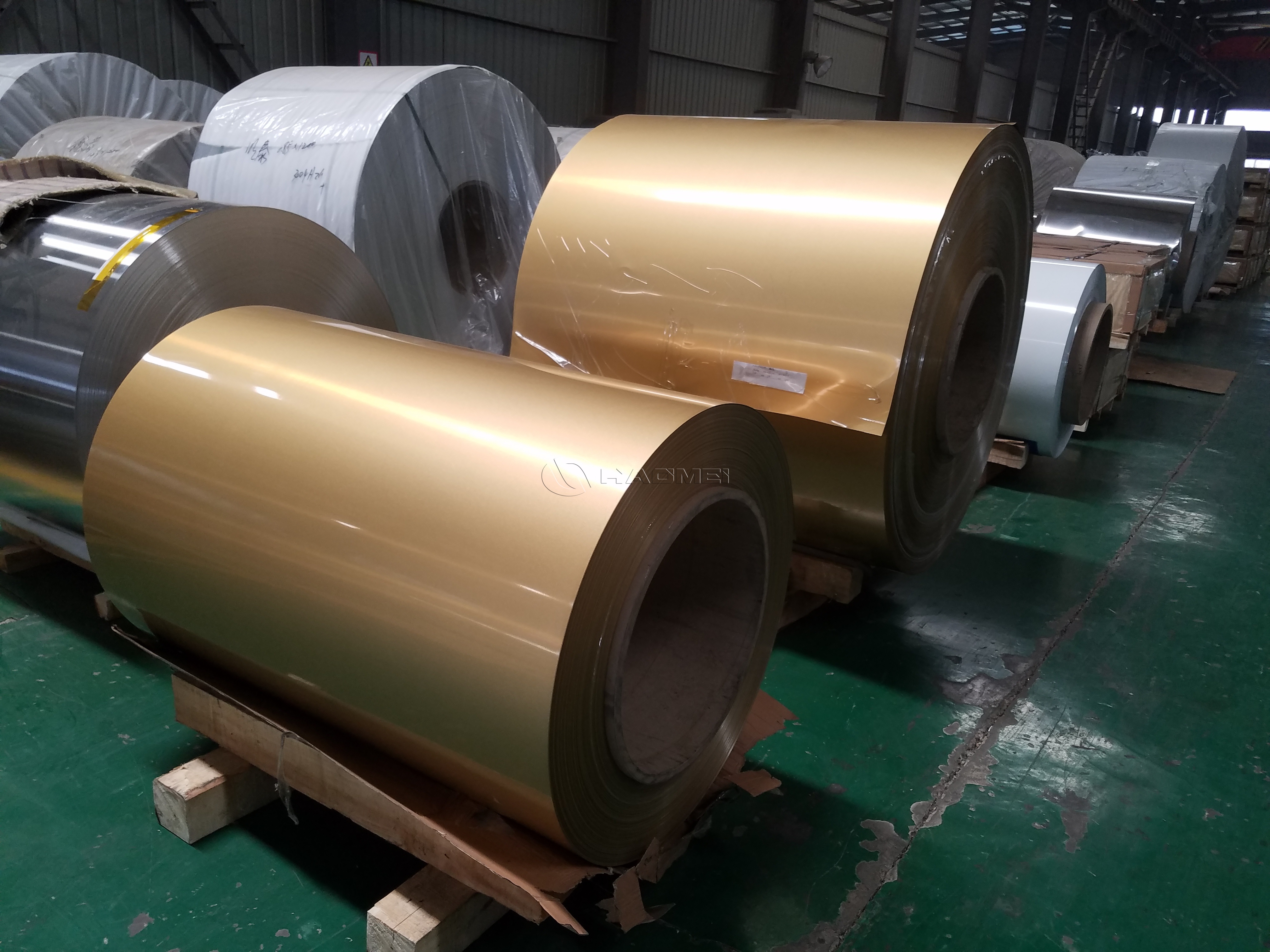

Core specifications for PVDF coated aluminum coil used in honeycomb panels

Table: Core Specifications (Typical Range)

| Item | Typical Range / Options | Notes for Honeycomb Panel Skins |

|---|---|---|

| Alloy | 3003, 3105, 5005, 5052,etc | 5000 series often preferred for harsher environments |

| Temper | H14, H24, H16 ,etc | Selected based on bend radius and skin rigidity needs |

| Thickness | 0.60-1.50 mm | Common skins: 0.8/1.0 mm; thicker for higher wind load |

| Coil width | 600-1600 mm | Matched to panel module and cutting optimization |

| Coating type | PVDF (fluorocarbon) | High weathering resistance for exterior façades |

| Topcoat DFT | 20-30 μm | Higher build for enhanced durability where specified |

| Primer DFT | 5-10 μm | Supports adhesion and barrier properties |

| Back coat DFT | 5-10 μm | Can be bonding-optimized for lamination |

| Gloss | Matte to high gloss | Chosen for aesthetics and maintenance strategy |

| Color | Solid, metallic, special effect | Batch control is critical for elevation uniformity |

| Protective film | Optional | Helps reduce handling scratches during fabrication |

Practical application: designing for edges, bends, and bonding interfaces

Honeycomb panels concentrate risk at the details: edges, returns, cutouts, and fastening zones. PVDF coated aluminum coil supports robust detailing when the skin is engineered for fabrication.

Bend and fold performance: Coil must tolerate forming without microcracking, especially at cassette returns. Proper cure and resin balance (and suitable temper) help preserve flexibility.

Edge durability: Routed edges and cut faces expose bare aluminum. Panel designs that seal edges effectively and manage water paths reduce corrosion risk. Pretreatment quality and primer integrity help mitigate underfilm creep near cut zones.

Bonding compatibility: Lamination performance depends on the back-side coating, surface energy, and cleanliness. A stable back coat and controlled surface condition improve adhesive wetting and long-term peel strength.

Color consistency on large façades: Coil-to-coil color management and lot traceability help maintain visual uniformity when panels are manufactured in phases.

Where PVDF honeycomb panel skins perform best

PVDF coated aluminum coil is typically specified for:

Exterior curtain wall and rainscreen architectural facade cladding

Airport, station, and commercial complexes where maintenance cycles are long

Coastal or high-UV regions where chalking and fading risks are elevated

Feature panels requiring metallic or special-effect colors with stable appearance

For interior-only honeycomb applications or short design life, polyester options may be considered, but PVDF remains the benchmark for exterior performance consistency; related alternatives are often categorized under PE Coated Aluminum Coil depending on durability requirements.

-

PVDF Coated Aluminum Coil For Industrial Roofing

PVDF coated aluminum coil for industrial roofing delivers long-term color stability, corrosion resistance and reliable coil coating quality for harsh climates.

2026-02-03

-

Pvdf Coated Aluminum Coil For Exterior Cladding

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29

-

5052 Color Coated Aluminum Coil for Exterior Walls and Roofing

5052 PVDF-coated aluminum coil features an exceptionally stable fluorocarbon chemical structure, giving it outstanding weather resistance, UV resistance, and color-retention performance, making it especially suitable for architectural applications that re

2025-12-09