News

By Hermione

By Hermione

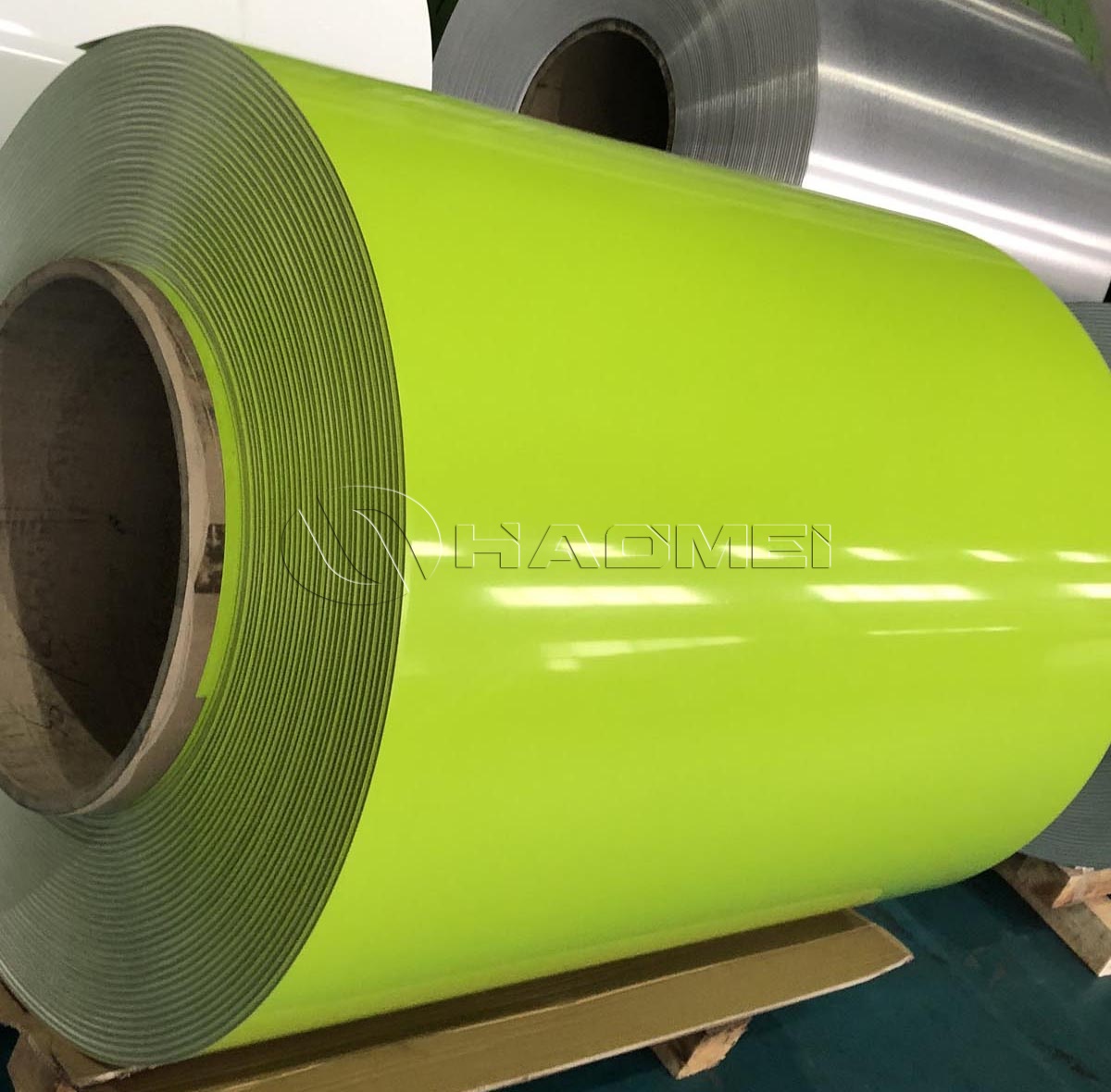

Double-Sided Color Coated Aluminum Coil

What Is a Double-Sided Color Coated Aluminum Coil?

A double-sided color coated aluminum coil is a high-performance composite material in which both sides of the aluminum substrate are precisely coated. It uses high-quality aluminum coil as the base material and applies multiple functional coating layers to the front and back surfaces through professional pretreatment and coating processes.

Compared with single-sided color coated aluminum coils, the key advantage of double-sided color coated aluminum coils lies in their design flexibility: the front and back sides can adopt different colors or different coating systems, enabling differentiated functional and aesthetic requirements to be met simultaneously.

Raw Material Selection

During production, we select aluminum alloy substrates according to specific application requirements. Common options include:

| Alloy series | Alloy | Advantage |

| 1000 Series Aluminum | 1050, 1060, 1100 | High purity and excellent ductility, suitable for decorative and light industrial applications. |

| 3000 Series Aluminum | 3003, 3004, 3005 | Balanced strength and formability, widely used in construction and industrial fields. |

| 5000 Series Aluminum | 5052, 5005 | Outstanding corrosion resistance, ideal for high-humidity or coastal environments. |

All substrates undergo strict surface treatment and performance inspection before coating to ensure strong coating adhesion and consistent finished quality.

Core Production Process of Double-Sided Color Coating

Double-sided color coated aluminum coils place higher demands on production line stability and process control. As a manufacturer, we focus on the following key steps:

1.Surface Pretreatment

Degreasing, chemical conversion, or passivation processes are applied to ensure clean and uniform surfaces on both sides, providing a stable base for coating adhesion.

2.Synchronized Front and Back Coating Control

Using precision coating systems, primer and topcoat are applied separately to each side, ensuring consistent coating thickness and controllable color deviation.

3.Customizable Coating Systems

PE, PVDF, and other coating systems can be selected based on the application environment, balancing decorative appearance and weather resistance.

4.Precise Baking and Curing

Strict control of oven temperature profiles ensures full curing of the coating, preventing defects such as blistering, pinholes, or insufficient adhesion.

Performance Advantages of Double-Sided Color Coated Aluminum Coil

Corrosion Resistance:

Even in humid environments or regions with large temperature fluctuations, double-sided coatings protect both sides of the aluminum substrate, extending service life by 30%-50%.Excellent Processability:

Coatings remain intact during bending, stamping, and roll forming processes.Scratch Resistance:

Coating hardness reaches 3H, effectively resisting wear during daily use.Decorative Appeal:

Same-color or dual-color designs on both sides deliver a 360-degree aesthetic effect, eliminating the need for secondary finishing.Environmentally Friendly & Recyclable:

Aluminum is 100% recyclable, supporting green building certifications such as LEED.

Coating Types

| Coating Type | Key Advantages | Recommended Applications |

| PE (Polyester) | Bright colors, high cost-effectiveness, excellent indoor stability | Interior ceilings, signage, commercial partitions |

| PVDF (Fluorocarbon) | Superior weather resistance, UV resistance, anti-aging (20+ years) | High-end exterior walls, coastal buildings, public facilities |

| HDPE (High-Durability Polyester) | Balanced performance and cost between PE and PVDF | Industrial plants, warehouse roofing |

Color Options

We offer up to 160,000 standard colors and custom color matching services, including:

Metallic colors: silver gray, champagne gold, pearl white, etc.

Solid colors: bright red, vivid blue, matte black, etc.

Wood grain / stone patterns: meeting high-end decorative requirements.

Application Scenarios of Color Coated Aluminum Coil

Interior and exterior architectural panels, ceilings, curtain wall systems

Appliance housings, back panels, and structural components

Aluminum louvers, roller shutters, and sunshade systems

Transportation and equipment exterior panels

Industrial equipment and modular housing panels

Quality Assurance: Strict Quality Control

As a source manufacturer, we adhere to the following standards for every double-sided color coated aluminum coil delivered:

T-Bend Test:

Ensures no coating peeling or cracking at extreme bends of 0T-2T.

MEK Rub Test:

Rigorously verifies coating curing and crosslinking to guarantee solvent resistance.

Color Difference Control:

Monitored with spectrophotometers to ensure ΔE < 0.5 within the same batch.

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

-

1100 H14 Prepainted Aluminum Coil Price

Learn what shapes 1100 H14 prepainted aluminum coil price: alloy and temper basics, PE/PVDF coating processes, key specifications, and typical applications.

2026-01-13

-

Pvdf Coated Aluminum Coil For Exterior Cladding

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29