News

By Hermione

By Hermione

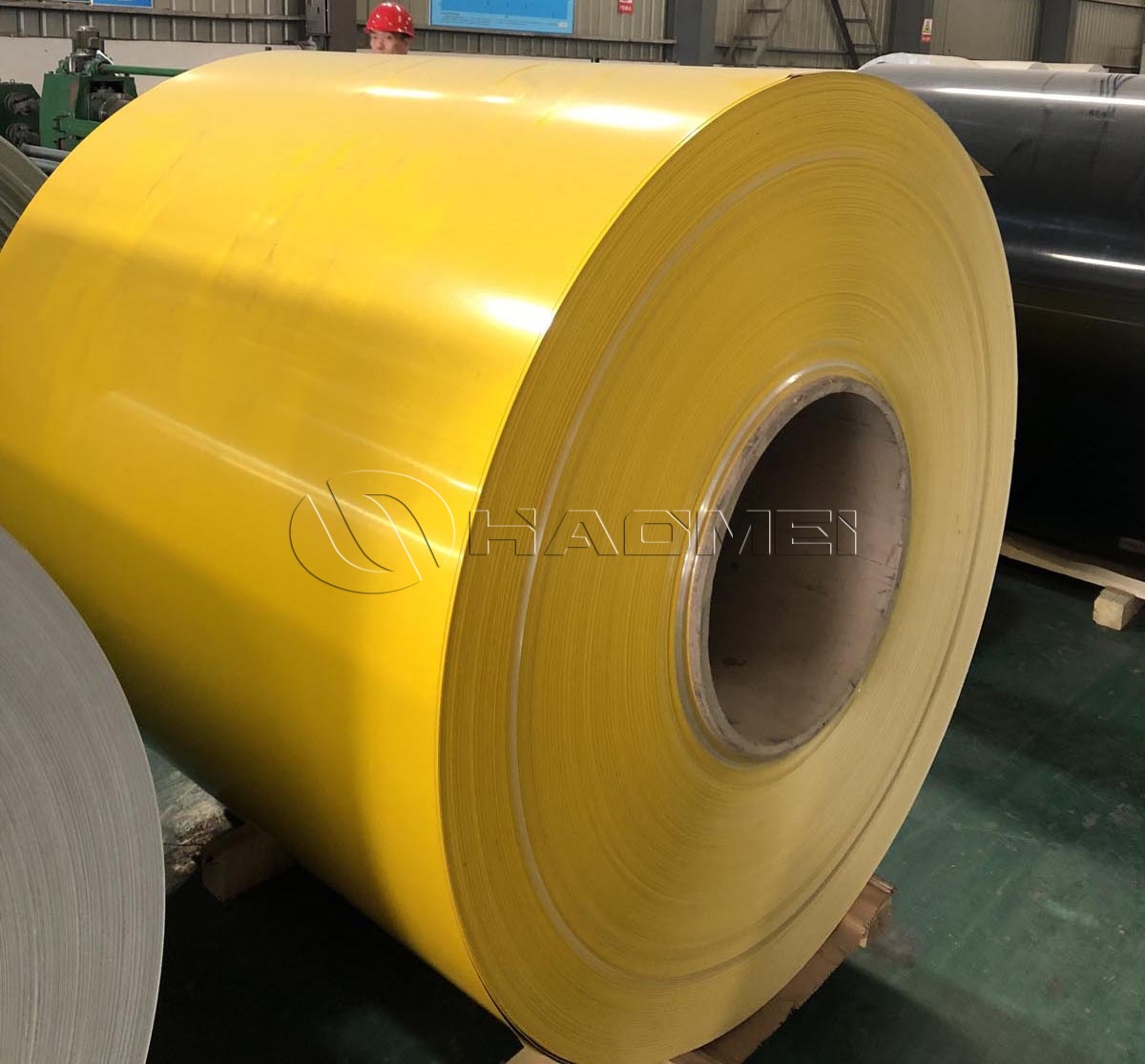

1000 Series Color Coated Aluminum Coil For Roofing

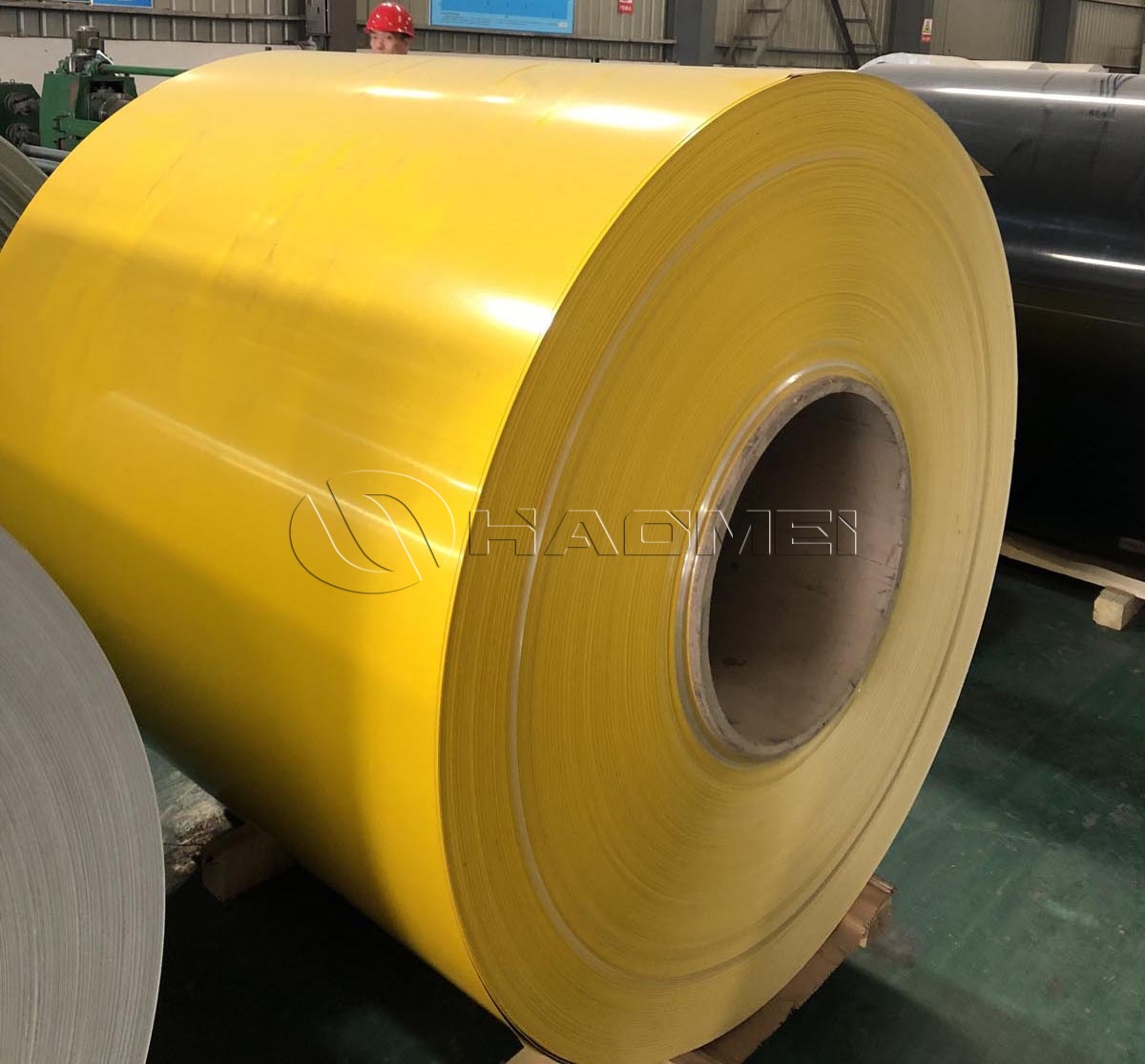

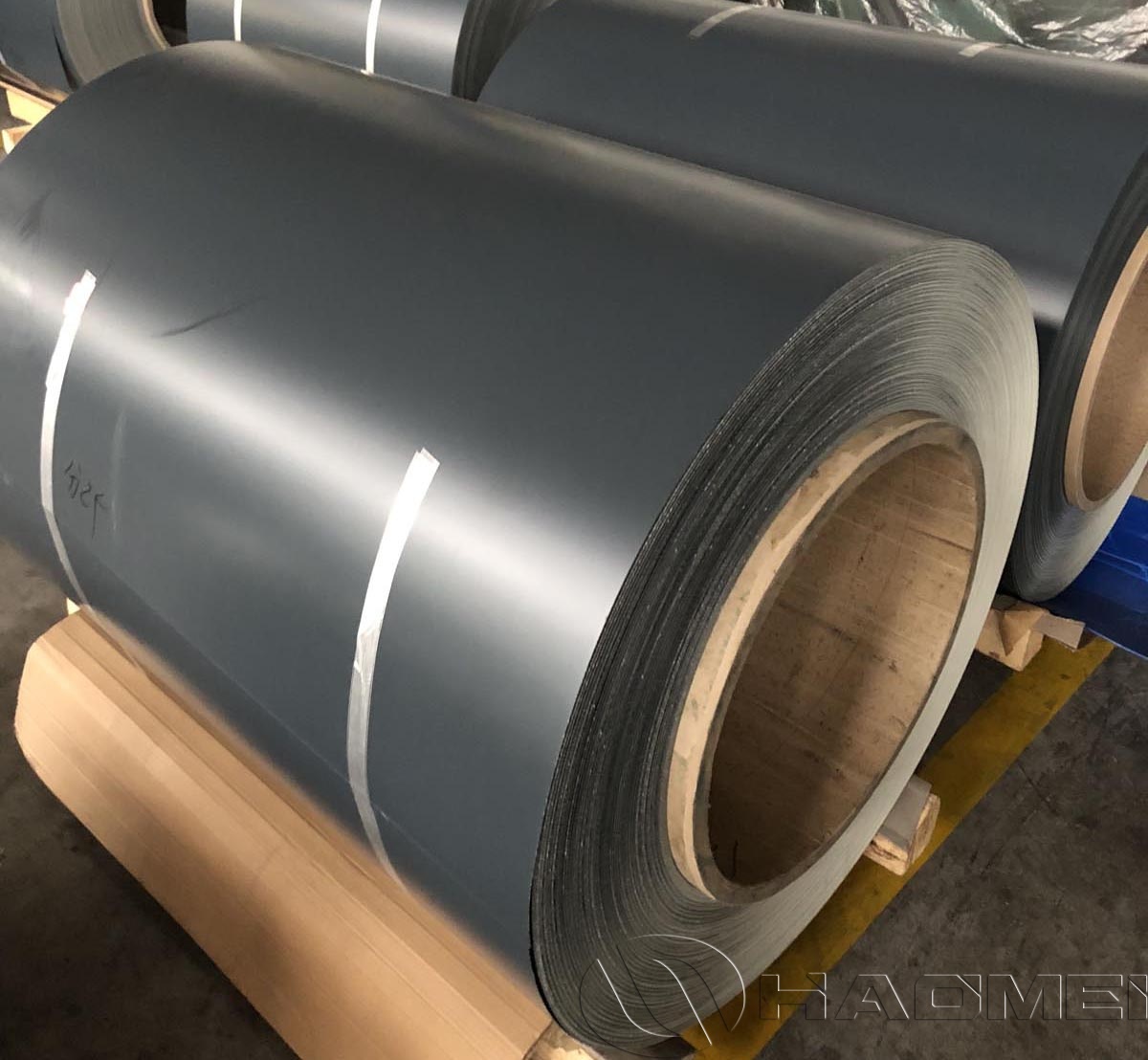

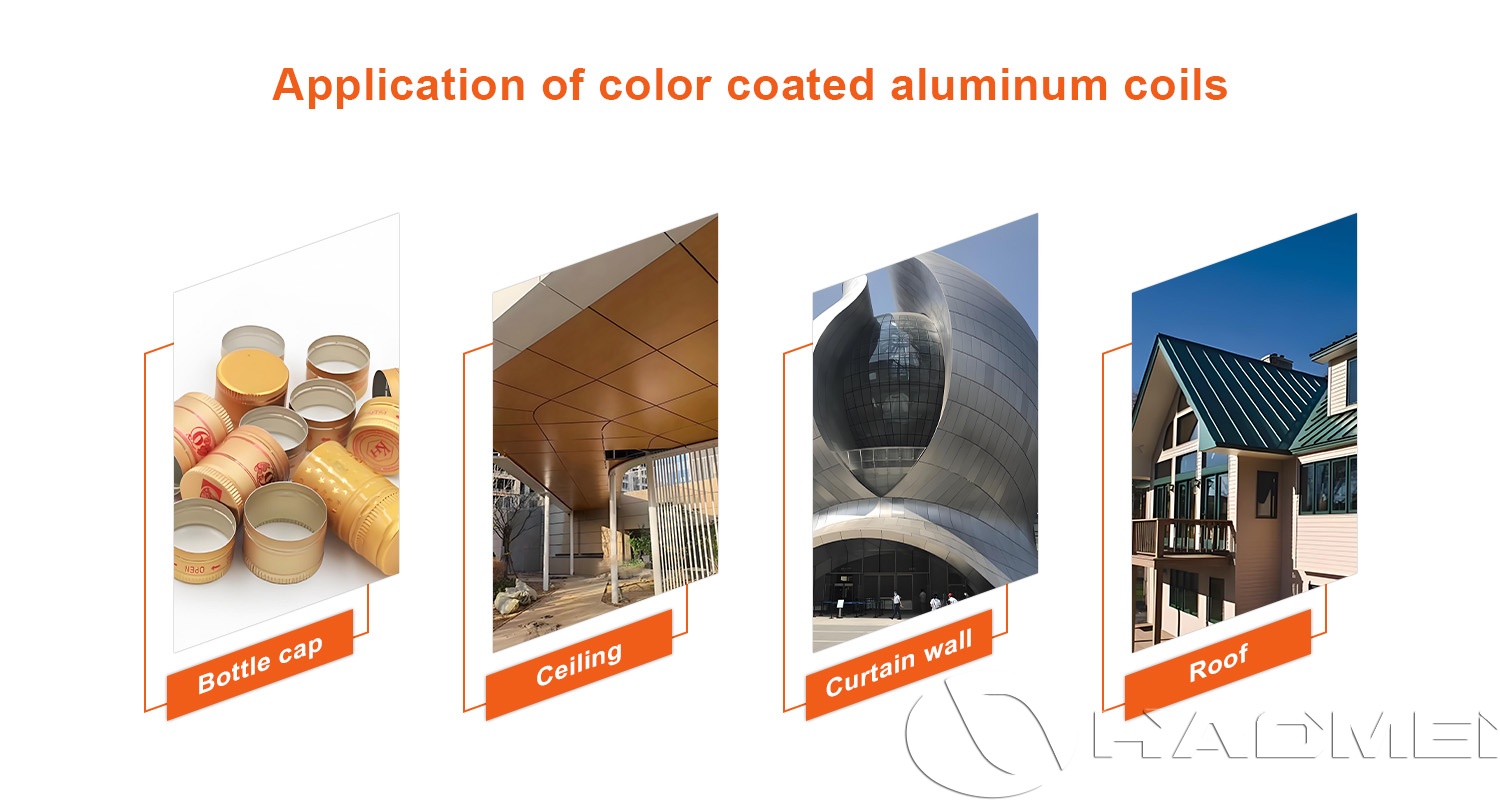

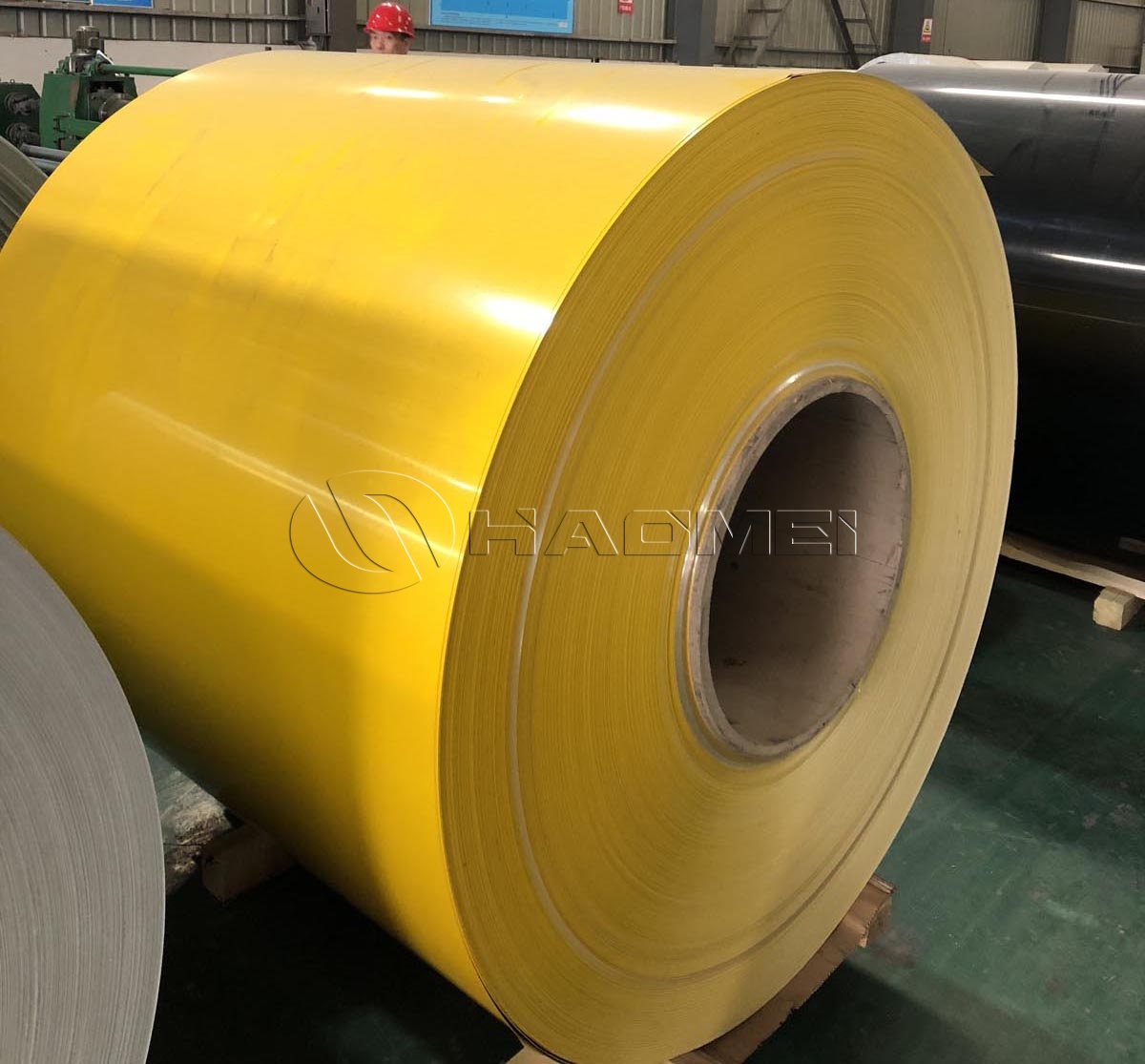

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems. It is widely used in residential roofing, light industrial buildings, modular housing, and renovation projects where stable appearance, easy forming, and long service life are required.

Why 1000 Series Works Well for Roofing

1000 series aluminum (commercially pure aluminum) typically provides excellent corrosion resistance and high formabilitytwo properties that directly support roofing manufacturing and on-site durability:

Corrosion resistance: High aluminum purity supports natural oxide film formation, helping resist general atmospheric corrosionimportant for roofs exposed to rain, condensation, and temperature cycling.

Formability: 1000 series coils are well suited for roll forming, bending, hemming, and seaming. This is beneficial for corrugated profiles, standing seam panels, and accessory trims.

Low density: Aluminums low weight reduces roof dead load, which can simplify structural requirements and handling.

Thermal performance: Aluminum reflects solar radiation effectively; paired with appropriate coating colors/finishes, it can help manage roof surface temperature.

In most roofing designs, the coating systemnot only the substratedefines long-term color stability, chalking resistance, and chemical durability.

Coating Systems for Outdoor Roof Environments

Color coated aluminum coil is typically supplied as a factory pre-painted product (coil coating) to ensure uniform film thickness, adhesion, and appearance consistency.

PVDF (fluorocarbon) coating: Preferred for demanding exterior roofs due to strong UV resistance, color retention, and chalking resistance.

PE (polyester) coating: Often selected for cost-sensitive roofing or less aggressive environments. PE Coated Aluminum Coil provides good appearance and processing performance, and is frequently used for trims, soffits, and general roofing panels where ultra-long UV stability is not the primary driver .

How 1000 Series Pre-Painted Aluminum Coil Is Manufactured

A stable roofing coil is the result of controlling both metallurgy and coating process windows. Typical production involves:

Substrate preparation: Degreasing/alkaline cleaning removes rolling oil; water rinse follows.

Chemical pretreatment: Chromate-free (or specified) conversion coating improves corrosion resistance and paint adhesion.

Primer coating: Applied by roller coater, then oven-cured to lock in adhesion and corrosion protection.

Topcoat coating: PVDF or PE topcoat applied and cured; gloss and color are controlled to project requirements.

Back coat (service coat): Applied on the reverse side to balance performance and protect against underside corrosion/abrasion.

Inspection and slitting: Includes color difference control, film thickness checks, T-bend/impact tests, and final slitting to roofing line widths.

This coil-coating approach supports consistent forming behavior during roll forming and helps reduce on-site painting variability.

Core Specifications (1000 Series Color Coated Aluminum Coil for Roofing)

| Item | Typical Range / Option | Notes for Roofing Use |

|---|---|---|

| Alloy | 1050 / 1060 / 1100 / 1200 | 1000 series prioritized for formability and corrosion resistance |

| Temper | H14 / H16 / H24 | Selected to balance strength with roll-forming capability |

| Thickness | 0.201.20 mm | Common roofing panels often 0.300.90 mm depending on profile/design |

| Width | 6001250 mm | Slit widths matched to forming line requirements |

| Coating type | PE / PVDF | PVDF for higher UV durability; PE for general applications |

| Coating structure | Primer + topcoat + back coat | Back coat selected for underside protection and processing |

| Topcoat thickness | 1828 m (typical) | Higher thickness can improve weathering margin |

| Primer thickness | 510 m (typical) | Supports adhesion and corrosion resistance |

| Gloss | Matte / semi-gloss / high-gloss | Chosen by architectural design and glare requirements |

| Surface finish | Solid / metallic / textured | Textured finishes help mask minor handling marks |

| Coil ID | 508 / 610 mm | Standard decoiler compatibility |

| Standards / tests | Film thickness, adhesion, T-bend, impact, salt spray (as specified) | Verification aligned to project durability expectations |

Common 1000 Series Alloys and Typical Roofing Uses

Selecting the right alloy is usually about matching forming complexity, required stiffness, and surface quality needs.

1050 (Al 99.5%): High purity and excellent formability. Commonly used for roof flashings, ridge caps, gutters, downspout accessories, and profiles with tight bends. Product reference: 1050 Color Coated Aluminum Coil.

1060 (Al 99.6%): Slightly higher purity than 1050, with very good corrosion resistance and ductility. Often used for roofing sheets requiring stable forming and good surface finish. Product reference: 1060 Color Coated Aluminum Coil.

1100 (Al 99.0%): Widely used general-purpose pure aluminum with good formability. Suitable for roll-formed roofing panels and trims where consistent processing is important. Product reference: 1100 Color Coated Aluminum Coil.

1200: Another commercial-purity option used in general architectural sheet applications, including roofing accessories, where formability and corrosion resistance are prioritized.

When higher mechanical strength is needed (e.g., longer spans, higher wind uplift design, or dent resistance requirements), projects may consider 3000/5000 series instead; however, 1000 series remains a robust choice for many roofing accessories and profiles due to its forming advantages.

Practical Roofing Applications and Design Considerations

In real roofing lines and construction environments, the following factors affect performance as much as the base alloy:

Profile forming and seaming: 1000 series is well suited for corrugated and cladding profiles, as well as standing seam components requiring repeated bending/hemming.

Fastener and cut-edge management: Proper detailing reduces galvanic risks and helps prevent cut-edge staining in aggressive environments.

Color and weathering selection: PVDF coatings are typically chosen for long-term outdoor color retention; light colors can reduce heat absorption.

Back-side protection: Condensation under roofs makes back-coat selection important, especially for insulated roof systems.

Typical Quality Verification for Roofing Coils

For roofing-grade pre-painted aluminum coil, common verification items include:

Coating thickness (top/back), color difference control

Adhesion (cross-hatch), flexibility (T-bend), impact resistance

Solvent rub/MEK resistance (cure confirmation)

Corrosion testing such as salt spray or humidity exposure per specification

Surface appearance checks (orange peel, pinholes, roller marks) to match architectural expectations

-

5052 Color Coated Aluminum Coil For Marine Use

5052 color coated aluminum coil for marine use delivers salt spray resistance and durability with PVDF/PE systems, controlled coil coating process, and stable H32 properties.

2026-01-23

-

1000 Series Color Coated Aluminum Coil For Roofing

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems.

2026-01-19

-

Is the Coating of 5052 Color-Coated Aluminum Coil PVDF or PE?

5052 color-coated aluminum coils typically have coatings including polyester (PE) or fluorocarbon (PVDF), and are commonly used in building curtain walls, ceilings, and home appliance manufacturing.

2025-12-08