News

By Hermione

By Hermione

PVDF Coated Aluminum Coil Fire Rating Standards

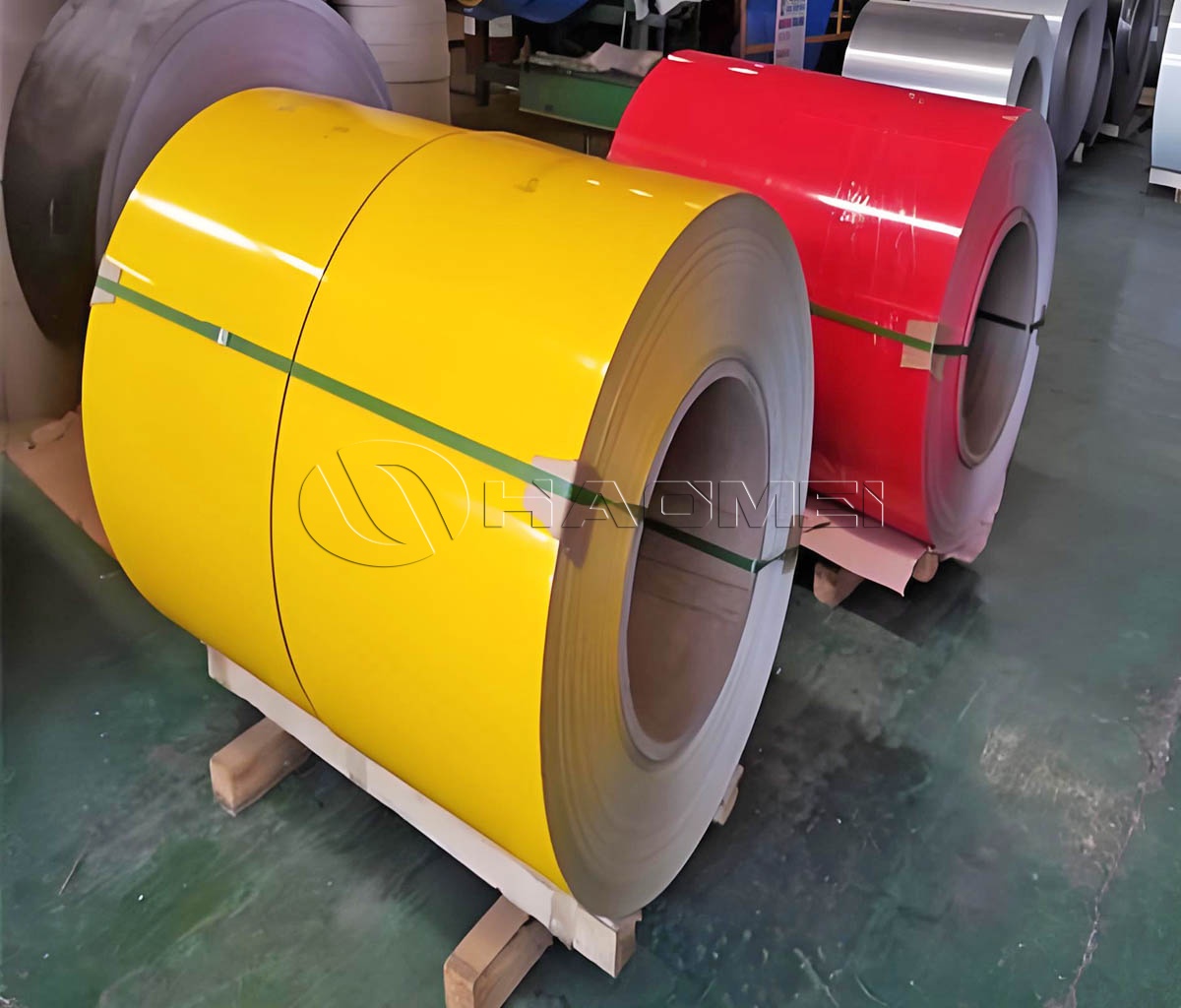

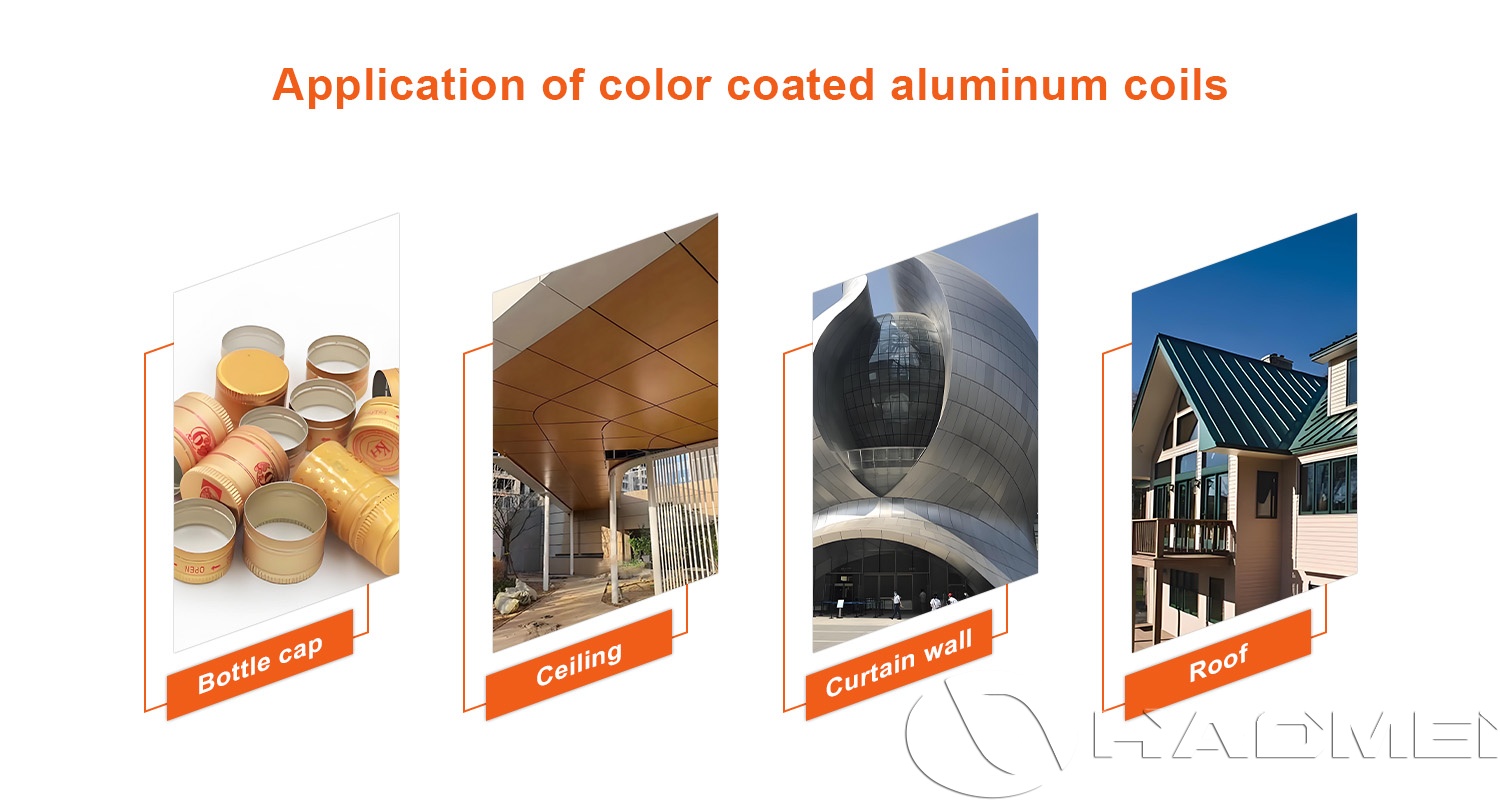

PVDF coated aluminum coil is positioned as a durable, weather-resistant architectural facing material that balances long-term color stability with code-driven safety requirements. Its most common application scenarios include aluminum composite panels (ACP), solid aluminum cladding, soffits, fascia, louvers, roof edge systems, and interior ceiling or wall systems where fire rating standards must be documented alongside corrosion resistance and appearance.

What fire rating standards actually evaluate

When designers ask whether a PVDF coated aluminum coil is "fire rated," the underlying question is typically about how an assembled product behaves under standardized fire exposure, not whether a coil alone can be assigned a blanket class. Fire performance is assessed through different lenses depending on the market:

Reaction-to-fire (how a material contributes to fire growth): common in Europe via EN 13501-1 classifications.

Surface burning characteristics: common in North America via ASTM E84 (also published as UL 723).

Noncombustibility and high-temperature behavior: addressed in tests such as EN ISO 1182 for certain classifications.

Because coated aluminum is a thin organic-inorganic layered system, the practical fire classification depends on the full build-up: alloy and thickness, pretreatment, primer/topcoat chemistry and dry film thickness, any backcoat, adhesives, cores (for ACP), substrates, insulation, air gaps, and installation details.

Material behavior of aluminum coil under fire exposure

Aluminum itself is noncombustible, but it is not "fireproof." Key behaviors that matter when interpreting fire test reports:

High thermal conductivity helps spread heat, which can reduce local hot spots but may transmit heat to adjacent layers.

Aluminum loses strength as temperature rises and melts around 660°C, affecting integrity in severe exposures.

The organic portion of the coating system (primer, PVDF resin, additives) can pyrolyze; the amount of organic mass per square meter is influenced mainly by total dry film thickness (DFT).

In real project specifications, higher metal thickness and well-controlled coating weights can help achieve more favorable reaction-to-fire outcomes for solid cladding systems, but for composite constructions the core and bonding system usually dominate the classification.

PVDF coating systems and their influence on fire classification

Architectural PVDF coatings are typically based on 70% PVDF resin (Kynar/Hylar type) blended with acrylic, pigments, and additives. From a fire-rating standpoint, the most relevant coating design parameters are:

DFT and organic loading: A thicker coating can mean more fuel contribution. Many façade specifications target a controlled topcoat + primer system (often around 25 microns total on the exposed side), with backcoat selected by end use.

Pigment package: Inorganic pigments generally offer better thermal stability than some organic colorants. Metallic and special effect finishes may require additional layers that increase total organic content.

Primer selection: Primers are tuned for adhesion and corrosion resistance; their resin type and solids content affect smoke and heat release behavior.

Backcoat function: For cassette panels or rainscreen systems, the backside coating is often service-focused (anti-abrasion, forming), but it still contributes organic mass in reaction-to-fire testing.

In practice, PVDF is often chosen for exterior durability. When a project is fire-classification-driven (for example, high-rise façades in jurisdictions requiring Euroclass A2 performance for the installed system), the emphasis shifts toward the entire assembly and may require specific product test evidence rather than relying on generic coil data. For product context and typical architectural coating build-ups, see PVDF Coated Aluminum Coil.

Key fire rating standards commonly referenced

EN 13501-1 (Euroclass)

EN 13501-1 classifies reaction-to-fire performance using classes such as A1, A2, B, C, D, E, F, with additional smoke and flaming droplets ratings (s1/s2/s3 and d0/d1/d2). Specifications like A2-s1,d0 are common targets for certain building envelope applications.

Important technical nuance: EN 13501-1 is a classification scheme based on underlying tests (often SBI test EN 13823 and ignitability EN ISO 11925-2, and sometimes noncombustibility EN ISO 1182). A coil supplier typically supports this by providing:

Controlled coating DFT and coating chemistry documentation

Traceable production batches

Test reports for representative constructions (or data used by panel manufacturers)

ASTM E84 / UL 723

ASTM E84 evaluates flame spread index (FSI) and smoke developed index (SDI) for surface burning characteristics. Coated metal surfaces frequently achieve favorable FSI/SDI results, but the report is only valid for the tested product description (thickness, coating type, mounting method).

EN 13501-5 (External fire exposure to roofs)

For roofing-facing applications, roof fire performance may be specified separately (for example Broof(t1) classifications), where the roof build-up (deck, underlayment, insulation, metal skin) governs performance.

How coil manufacturing affects fire-test repeatability

Fire testing is sensitive to seemingly small process variations because these can change organic mass, adhesion, and how layers delaminate under heat. A technically stable PVDF coil program typically controls:

Substrate selection and thickness: common architectural alloys include 3003/3004/3105/5005 series depending on formability and strength targets.

Surface pretreatment: chrome-free conversion coatings or equivalent pretreatments ensure corrosion resistance and adhesion; poor pretreatment can cause early coating lift and altered burning behavior.

Coil coating line curing: precise peak metal temperature and dwell time are required to fully crosslink the primer and topcoat. Under-cure can increase smoke and worsen blistering; over-bake can embrittle films and reduce flexibility.

DFT control: monitored by on-line gauges and verified by QC sampling. DFT drift is a common root cause when field performance is consistent but fire-test replication varies.

Backcoat management: many projects focus on the exposed side, but test standards may expose the backside depending on mounting configuration.

Typical coil-to-component pathways

Most PVDF coil is not installed as-is; it becomes panels or profiles through slitting, roll forming, bending, stamping, or cassette fabrication. These downstream processes can introduce variables that matter for fire classifications:

Edge conditions and cut surfaces

Sealants, tapes, and gaskets

Adhesives (especially in ACP and bonded laminates)

Cavity barriers and insulation selection

As a result, fire compliance documentation is often strongest when the final system manufacturer provides assembly-level test evidence, while the coil supplier provides stable input material properties and traceability.

specifications for PVDF coated aluminum coil

| Item | Typical Range / Option | Notes relevant to fire standards |

|---|---|---|

| Aluminum alloy | 3003, 3004, 3105, 5005 (common) | Alloy choice affects strength and forming; thickness impacts thermal behavior |

| Metal thickness | 0.30 to 3.00 mm | Thicker metal generally reduces deformation under heat in some assemblies |

| Coating type | 70% PVDF topcoat + primer | PVDF selected for UV durability; fire performance depends on total organic loading |

| Exposed-side DFT | ~20 to 30 microns (typical) | DFT control is important for repeatable reaction-to-fire results |

| Backcoat | Service polyester / epoxy / wash coat | Influences organic mass and mounting-dependent test outcomes |

| Gloss | Matte to high gloss | Special finishes may require extra layers that increase DFT |

| Surface pretreatment | Chrome-free conversion or equivalent | Adhesion stability under heat and aging improves classification consistency |

| Coil width | Up to ~1600 mm (typical) | Dependent on line capability and end-product requirements |

| Fire documentation | EN 13501-1 / ASTM E84 (by tested construction) | Classification applies to the tested configuration, not universally to all uses |

Practical application mapping: façade, interior, and roof-adjacent uses

For exterior building envelope applications, PVDF is primarily selected for weathering resistance (UV, chalk, color retention) and corrosion durability, while fire compliance is normally satisfied via system-level testing of the cladding or panel assembly. Common outcomes in practice:

Solid aluminum cladding and cassette panels: coil properties (thickness, DFT, backcoat) can have a more direct influence on reaction-to-fire results because the system contains fewer combustible layers.

ACP and bonded laminates: the core material and bond layers dominate; the same PVDF coil can appear in systems with very different EN 13501-1 classifications.

Interior ceilings/walls: smoke and flame spread requirements (often ASTM E84 in certain markets) become more prominent; mounting method in the test (direct to substrate vs air gap) can change reported indices.

For projects where a different cost-performance balance is needed (for example, non-critical exterior elements or interior trims with different durability targets), PE Coated Aluminum Coil is often evaluated, while ensuring the final assembly still meets the applicable fire test requirements.

Reading fire-test reports for PVDF-coated products without misinterpretation

When verifying compliance against fire rating standards, the most frequent technical pitfalls are:

Treating a coil as having a standalone Euroclass or ASTM E84 rating without matching the tested construction.

Ignoring mounting method details (e.g., end-use orientation, substrate type, air gap), which can shift results.

Substituting coating DFT, primer type, or backcoat without re-evaluating test applicability.

Assuming that "PVDF" implies better fire performance than other polymers; PVDF is chosen for durability, while fire behavior is primarily controlled by system design and total organic content.

Within a controlled manufacturing program, maintaining pretreatment quality, cure windows, and DFT consistency is the most reliable way a PVDF coil supply chain supports stable, defensible fire classification packages for downstream architectural systems.

-

1100 / 3003 Color Coated Aluminum Coil for Signboards and Advertising Boards

1100 / 3003 color-coated aluminum coils are lightweight, weather-resistant, and have good processability, making them suitable for billboards and traffic signs.

2025-12-23

-

Black Color Coated Aluminum Coil 5052

5052 black color-coated aluminum coils are widely used in building decoration, home appliance housings, transportation and marine engineering.

2025-12-04

-

Understanding the Coating Types of Color Coated Aluminum Coil

What Is Color Coated Aluminum Coil?Color coated aluminum coil is produced by applying one or multiple layers of organic coating onto an aluminum alloy substrate through continuous roll-coating followed by high-temperature curing.The coating is the core of

2025-12-01