News

By Hermione

By Hermione

1000 Series Aluminum Coil With PVDF Coating

1000 Series Aluminum Coil With PVDF Coating

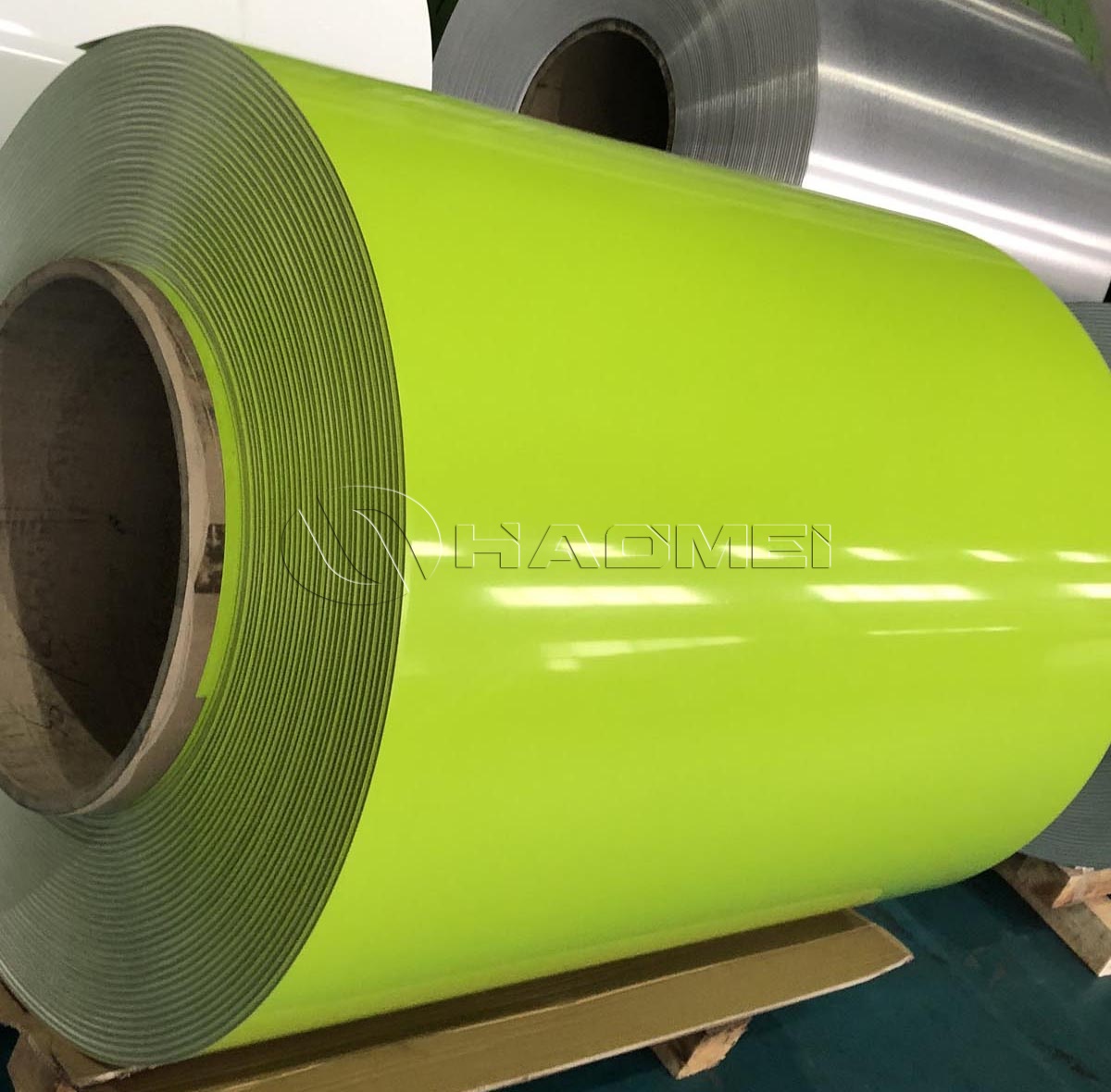

1000 Series Aluminum Coil with PVDF coating is positioned as a premium, high-purity prepainted aluminum solution for projects that require long-term outdoor color stability, excellent corrosion resistance, and reliable formability. It is widely specified for architectural building envelopes (facades, soffits, and ceilings), metal roofing and trim, and high-end signage where appearance retention is critical.

Why choose 1000 series aluminum for PVDF coating?

The 1000 series (commercially pure aluminum) is known for its high aluminum content, which contributes to:

Excellent corrosion resistance in general atmospheres

High reflectivity and a naturally clean surface appearance

Outstanding formability, supporting roll forming, bending, and profiling

Good thermal and electrical conductivity (useful for certain technical panels and enclosures)

When paired with PVDF coating (typically 70% PVDF resin systems for exterior use), the coil becomes a reliable material for long service life in UV-exposed and weathered environments.

PVDF coating performance: built for exterior durability

PVDF systems are commonly selected when the project demands long-term performance. In practical use, PVDF coating provides:

UV resistance to reduce chalking and fading over time

Chemical resistance to many pollutants and mild industrial atmospheres

Stable gloss and color retention, supporting premium architectural standards

Low maintenance surfaces suitable for high-rise and public buildings

How 1000 series PVDF coated aluminum coil is manufactured

A consistent PVDF coil product depends on both coating chemistry and process control. A typical coil coating workflow includes:

Substrate selection (1000 series alloy, specified temper)

Surface pretreatment (cleaning + conversion coating to enhance adhesion and corrosion resistance)

Primer coating and curing (adhesion, flexibility, barrier performance)

PVDF topcoat application and curing (weathering and aesthetic layer)

Inspection and testing (film thickness, gloss, color, adhesion, flexibility, impact)

Slitting/cutting and protective packaging for shipment

From an engineering perspective, matching the coating system to the forming method (roll forming vs. press brake bending) is essential to avoid micro-cracking at tight radii and to preserve edge protection in aggressive environments.

Common 1000 series alloys and recommended uses

While the 1000 series shares many characteristics, different grades are selected based on purity level, mechanical needs, and end-use forming requirements:

1050: Very good formability and surface quality. Common for decorative panels, ceiling systems, trim, and general cladding where deep forming is not extreme.

1060: Slightly higher purity than 1050, often selected when conductivity or consistent surface appearance is prioritized.

1100: A widely used grade balancing formability and availability; suited for architectural profiles, soffits, signage panels, and general exterior sheet/coil applications.

1200: Similar to 1100 with slightly different impurity limits; used for general industrial and building products.

1350: Higher electrical conductivity; typically chosen for electrical applications, but can also be coated for specialized enclosure panels where conductivity is part of the design requirement.

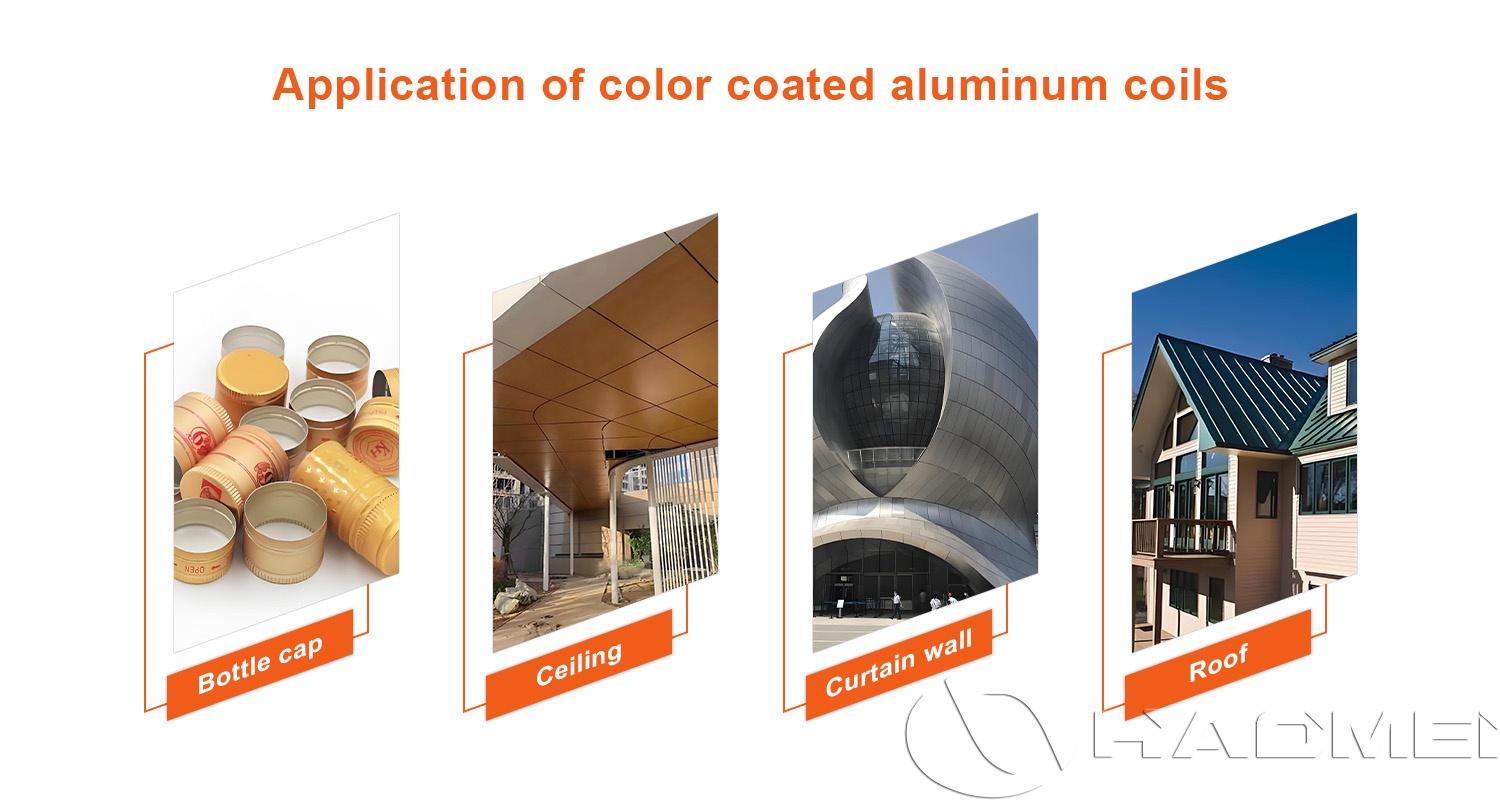

Practical application scenarios

1000 series PVDF coated aluminum coil is commonly converted into:

Exterior wall cladding and facade panels (long-term color retention and clean appearance)

Roofing sheets and flashing (weather resistance, lightweight installation)

Soffits, ceilings, and louvers (stable finish and easy fabrication)

Signage and display systems (smooth surfaces with durable color)

Decorative building components (solid colors or custom finishes)

For harsh marine or heavy industrial exposure, project engineers may consider higher-strength, higher-alloyed substrates (e.g., 3000/5000 series) depending on required mechanical strength and corrosion mechanisms. However, for many architectural environments, 1000 series remains a highly cost-effective and formable solutionespecially when protected by PVDF.

Core Specifications 1000 Series PVDF Coated Aluminum Coil

| Item | Typical Options / Range |

|---|---|

| Base alloy | 1050 / 1060 / 1100 / 1200 / 1350 |

| Temper | O, H14, H16, H18 (customizable by forming requirement) |

| Coating system | PVDF (commonly 70% PVDF for exterior durability) |

| Coating structure | Primer + topcoat (single or double coat systems available) |

| Coating thickness (dry film) | Topcoat typically 2025 m; system total commonly 2535 m (project-dependent) |

| Coil thickness | Commonly 0.23.0 mm (customizable) |

| Coil width | Commonly up to 1600 mm (subject to line capability) |

| Surface finish | Solid colors, metallics (availability depends on coating system) |

| Gloss | Matte / semi-gloss / high gloss (by specification) |

| Protective film | Available for fabrication and transport protection |

| Typical standards & tests | Adhesion, T-bend, impact, MEK rub, salt spray, color difference (per customer spec) |

Selection guidance: getting the best performance in the field

To ensure the coil performs as intended, align the specification with the actual fabrication and service conditions:

Choose O temper for tighter bending and complex forming.

Choose H14/H16/H18 when improved stiffness and dent resistance are needed.

Confirm edge treatment and fabrication steps (cut edges are critical in corrosive environments).

For exterior architectural projects, specify PVDF when long-term UV stability is required.

Conclusion

A 1000 Series Aluminum Coil with PVDF coating is a proven choice for architectural and signage applications that demand a clean appearance, excellent formability, and long-term outdoor durability. By selecting the right alloy grade (such as 1050, 1060, or 1100), matching temper to forming requirements, and specifying a suitable PVDF system, project teams can achieve stable performance and consistent aesthetics over extended service life.

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

-

Is the Coating of 5052 Color-Coated Aluminum Coil PVDF or PE?

5052 color-coated aluminum coils typically have coatings including polyester (PE) or fluorocarbon (PVDF), and are commonly used in building curtain walls, ceilings, and home appliance manufacturing.

2025-12-08

-

Color coated Aluminum Coils for Roofing, Ceiling, and Wall Systems

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04