News

By Hermione

By Hermione

Pe Coated Aluminum Coil Vs Pvdf

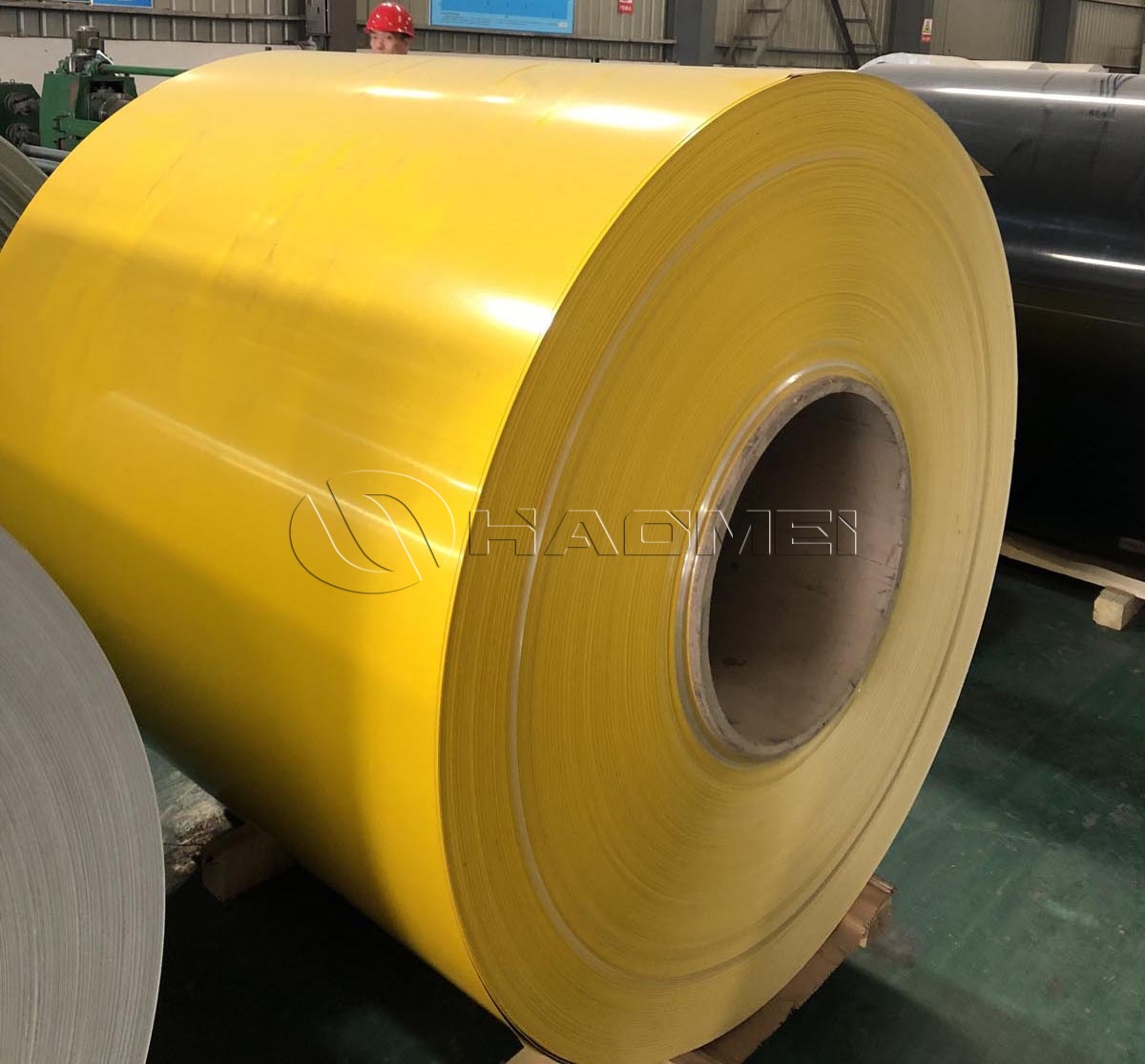

In the color coated aluminum coil market, PE coated aluminum coil and PVDF coated aluminum coil are positioned for different durability targets and cost-performance needs. PE is typically selected for interior metal ceilings, appliance panels, shutters, signage, and general decoration where UV and chemical exposure are moderate; PVDF is designed for demanding outdoor envelopes such as curtain walls, facades, roofing, and long-life architectural trim where long-term color retention and weather resistance are critical.

Material platform: aluminum alloy and pretreatment matter as much as the paint

While "PE vs PVDF" is often discussed as a paint choice, the real-world performance of a color coated aluminum coil is the combined result of alloy selection, surface pretreatment, coating build, and curing control.

Common substrate alloys include 1xxx (high purity, excellent formability) and 3xxx/5xxx (better strength and dent resistance). For formed products like roofing panels, ACP skins, or roll-formed cladding, higher-strength alloys reduce oil-canning and improve handling robustness. However, alloy alone cannot compensate for inadequate surface preparation: pretreatment is the foundation for adhesion and corrosion resistance.

In continuous coil coating, the aluminum strip is typically degreased, chemically treated (chromate-free or chromate systems depending on project requirements), then primed and topcoated. This engineered interface is what prevents underfilm corrosion creep, improves edge stability, and keeps the coating bonded through forming operations.

Coating chemistry and what it changes in service

PE (Polyester) systems: balanced cost and good appearance

PE coatings generally use polyester resins with pigment packages optimized for decorative appearance and process latitude. In practice, PE systems provide:

Good gloss and color richness, easy color matching for signage and interior architecture

Stable mechanical properties for bending, roll forming, and stamping

Practical durability for sheltered or moderate-exposure environments

The trade-off is that standard PE chemistry is more susceptible to UV-driven polymer degradation than PVDF. Over time in strong sunlight and heat, this can show up as faster gloss reduction and color shift (especially for deeper tones).

PVDF (Fluorocarbon) systems: long-term UV and chemical resistance

PVDF coatings (commonly fluorocarbon systems such as 70% PVDF resin blends) are built for long exposure cycles. The fluoropolymer backbone is highly resistant to UV and many airborne chemicals, resulting in:

Superior color retention and slower chalking in outdoor environments

Better resistance to acid rain, salt-laden air, and industrial pollutants

More stable appearance over multi-year architectural life cycles

Because PVDF is often used for premium architectural projects, the entire system is typically specified more tightly: pretreatment quality, primer selection, film build, and cure window are controlled to achieve consistent weathering and corrosion performance.

Coating system design: more than "one topcoat"

A technically coherent comparison must consider the full coating stack:

Pretreatment: Improves adhesion and corrosion resistance; critical for cut edges and forming areas.

Primer: Contributes to barrier performance, flexibility, and intercoat adhesion; also helps manage underfilm corrosion.

Topcoat: Controls UV durability, color/gloss, stain resistance, and cleanability.

Back coat/service coat: Selected for the rear-side environment (condensation, contact corrosion, laminations, or adhesive bonding).

In general, PVDF systems are specified with higher expectations for outdoor stability, and this typically correlates with stricter controls on primer/topcoat compatibility and curing. PE systems can be extremely successful when the environment is appropriate and the pretreatment + primer are well matched to the substrate and forming requirements.

Manufacturing process differences: coil coating discipline drives performance

Both PE and PVDF products are usually made by continuous coil coating process lines: cleaning → chemical pretreatment → primer coating → oven cure → topcoat → oven cure → cooling → inspection → recoiling.

Where the two diverge operationally is not the equipment, but the process sensitivity:

Cure control: PVDF topcoats generally demand tighter peak metal temperature control to fully crosslink without overbaking (which can embrittle films or impact gloss). PE is comparatively more forgiving but still requires disciplined temperature and line-speed control.

Film build and uniformity: PVDF projects often require more consistent film thickness across width and length, because architectural weathering performance is closely scrutinized.

Cleanliness and defect tolerance: Outdoor facade and roofing applications have low tolerance for inclusions, pinholes, roller marks, or color variation-pushing PVDF production toward stricter QC gates.

Core specifications table (typical ranges)

Table: Typical Specifications for PE vs PVDF Color Coated Aluminum Coil

| Item | PE Coated Aluminum Coil (Typical) | PVDF Coated Aluminum Coil (Typical) |

|---|---|---|

| Topcoat resin | Polyester (PE) | Fluorocarbon (PVDF, commonly 70% PVDF blend) |

| Recommended exposure | Interior / moderate outdoor | Long-term outdoor / harsh environments |

| Typical coating structure | Primer + PE topcoat (often 2-coat) | Primer + PVDF topcoat (often 2-coat; higher-end controls) |

| Typical topcoat thickness | 15-20 μm (project-dependent) | 20–30 μm (project-dependent) |

| Typical total dry film thickness | 18-25 μm | 25-35 μm |

| Gloss/color options | Wide, easy color matching | Wide; strong color retention focus |

| Formability | Good; suitable for roll forming and bending | Good; system must be tuned for forming radius |

| Weathering (relative) | Good → Very good (by grade) | Excellent |

| Common applications | Ceiling panels, shutters, signage, appliances | Facades, curtain walls, roofing, architectural trims |

Practical selection by application: what works best in the field

For interior architectural panels, suspended ceilings, and general decoration, a well-designed PE system often provides the best value: it delivers clean appearance, consistent color, and reliable forming without over-specifying long-term UV resistance.

For exterior cladding, roofing, and high-visibility building envelopes, PVDF's advantage is cumulative. UV exposure, thermal cycling, airborne contaminants, and wash-down conditions compound over time; PVDF's chemistry slows down the mechanisms that typically dull coatings-gloss loss, chalking, and fading.

In mixed-use projects (e.g., exterior soffits, semi-sheltered canopies, or areas with partial sun exposure), the decision should be based on the most severe exposure the panel will see, including reflected UV, salt air distance, and cleaning chemicals. In practice, specifiers also consider color depth (dark colors show fade more readily), maintenance plans, and service-life expectation.

When specifying product pages for each system, the relevant references are PE Coated Aluminum Coil and PVDF Coated Aluminum Coil, which align coating selection with end-use exposure and durability targets.

Performance checkpoints that reduce project risk

Regardless of resin type, consistent results come from validating the full system:

Adhesion after forming (T-bend or bend tests aligned with product geometry)

Impact and abrasion resistance for handling and installation

Corrosion resistance with appropriate pretreatment and primer pairing (including scribe testing)

Color difference control between batches and within coil (ΔE management)

Cure verification (solvent rub/MEK resistance and peak metal temperature records)

In short, PE and PVDF are not competing "better vs worse" options; they are engineered solutions for different durability windows. The best outcomes come from matching exposure conditions, coating system design, and coil coating process control to the actual application environment.

-

PVDF Coated Aluminum Coil Maintenance And Cleaning

Learn PVDF coated aluminum coil maintenance and cleaning with practical methods, coating system insights, and process factors affecting durability in architectural cladding.

2026-01-27

-

1000 Series Color Coated Aluminum Coil For Roofing

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems.

2026-01-19

-

1000 Series Aluminum Coil With PVDF Coating

1000 series PVDF coated aluminum coil delivers corrosion resistance, UV stability and smooth formability for cladding, roofing and signage using 1050/1060/1100 alloys.

2026-01-12