News

By Hermione

By Hermione

Pvdf Coated Aluminum Coil Coating Lifespan

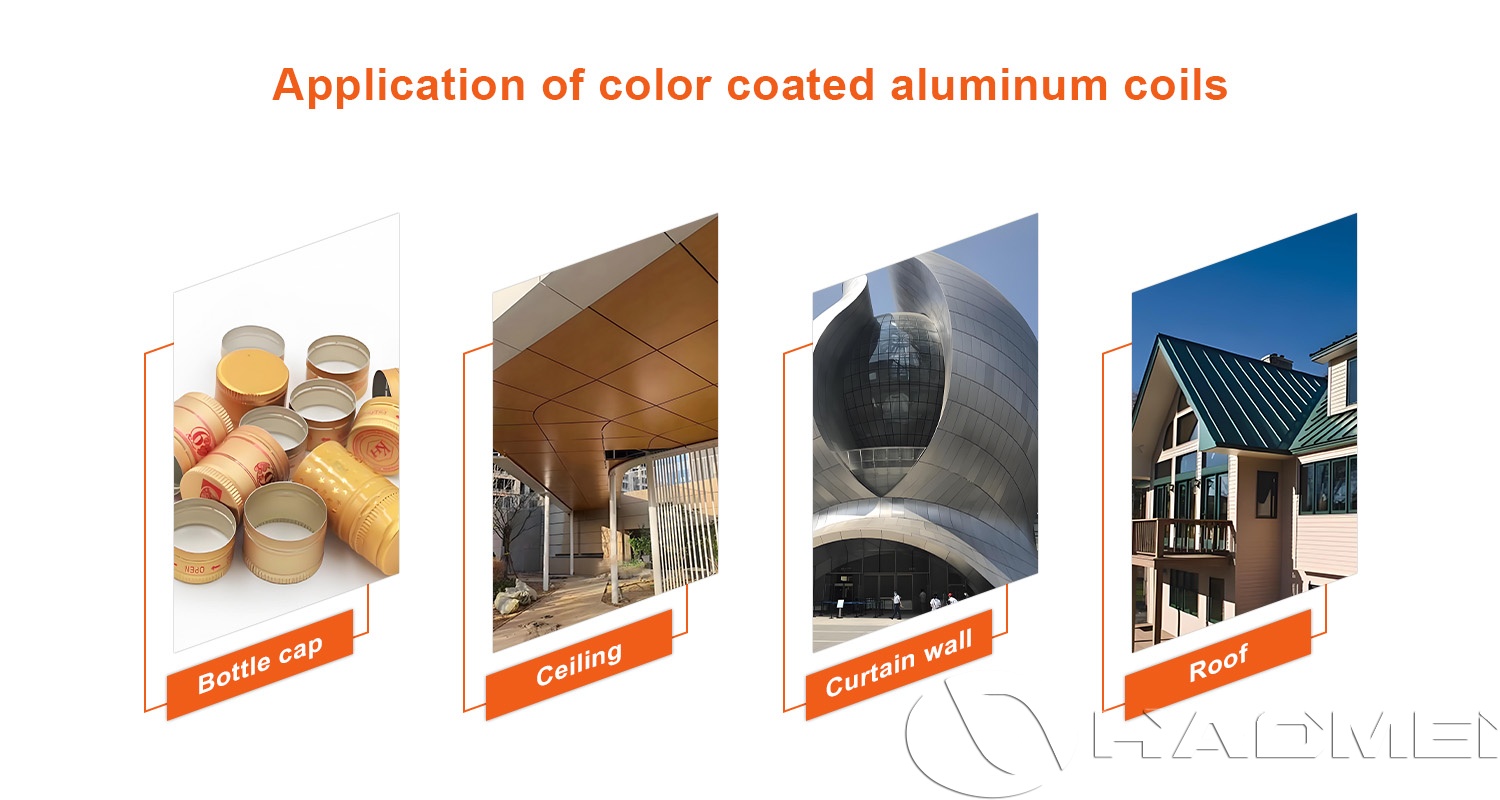

PVDF coated aluminum coil is positioned as a long-life, low-maintenance exterior cladding material where color stability and corrosion protection must be sustained under UV exposure, humidity, salt spray, and industrial pollutants. Typical application scenarios include architectural facades, curtain walls, metal roofing, soffits, composite panels, and other building envelope components that are expected to keep their appearance for decades rather than a few years.

What "coating lifespan" means for PVDF color coated aluminum coil

In engineering terms, coating lifespan is not simply "how long until the surface looks old." It is the period during which a PVDF coating system maintains functional protection (adhesion, barrier performance, corrosion resistance) and an acceptable level of appearance retention (gloss and color). Because most coil-coated PVDF products are specified for exterior construction, performance is typically aligned with standards such as AAMA 2605, where long-term weathering and color change limits are used as a practical benchmark.

A realistic service-life expectation depends on three interacting factors:

Substrate durability: alloy selection, temper, and surface pretreatment influence corrosion resistance and adhesion stability.

Coating system design: resin chemistry, pigment selection, film build, and primer/topcoat matching largely determine UV resistance and barrier properties.

Manufacturing process control: cleaning, conversion coating, curing conditions, and defect control decide whether the designed system is actually achieved on the coil.

Within properly designed and controlled systems, PVDF coil coatings commonly target 10–20 years of durable appearance retention in many environments, with longer functional protection possible when the specification, fabrication, and maintenance conditions are appropriate.

Why PVDF lasts longer: material-level performance drivers

A PVDF topcoat is a fluorocarbon coating built around strong carbon–fluorine bonds. This chemistry provides inherently high resistance to UV degradation, chalking, and color fade compared with many polyester systems.

However, the resin is only one part of the life equation:

Pigments: In exterior PVDF systems, inorganic pigments (and carefully selected special-effect pigments) are favored for lightfastness. Some bright organic pigments can fade faster under intense UV, even when protected by PVDF.

Film integrity: Adequate dry film thickness (DFT) helps resist erosion, microcracking, and permeation of moisture and contaminants.

Substrate condition: Aluminum's corrosion resistance is strong, but edge exposure, crevices, and aggressive ions (chlorides) can still drive underfilm corrosion if pretreatment and sealing are insufficient.

For product selection, this is why PVDF coated aluminum coil is typically chosen for building exteriors, while polyester-coated coil is often reserved for interior panels or short-cycle outdoor use.

Coating system architecture: primer, PVDF topcoat, and back coat working together

A long coating lifespan comes from a balanced system rather than a single "strong" top layer.

Pretreatment + conversion layer: A controlled conversion coating improves corrosion resistance and provides a chemically compatible anchor for primers.

Primer: The primer promotes adhesion, improves barrier properties, and can be tailored for corrosion inhibition. Primer selection matters significantly in coastal or industrial zones.

PVDF topcoat: The topcoat provides UV stability, stain resistance, and long-term color retention. For architectural work, PVDF is commonly specified for exposed faces.

Back coat (service coat): The reverse side coating supports handling resistance, forming performance, and in some build-ups can contribute to barrier protection.

When customers compare PVDF with alternatives such as PE Coated Aluminum Coil, the performance gap is often most visible in long-term fade, chalking resistance, and the stability of gloss on sun-exposed elevations.

Manufacturing process controls that directly impact coating lifespan

Even high-end PVDF chemistry will underperform if the coil coating process is not tightly controlled. In continuous coil coating, several steps have outsized influence on service life:

Degreasing and surface preparation: Residual rolling oil, silicone contamination, or uneven cleaning can create local adhesion failures that later present as blistering or peeling.

Conversion coating management: Bath chemistry, contact time, and rinse quality determine conversion weight uniformity and corrosion performance.

Coating application uniformity: Roller condition, viscosity control, and line speed stability govern film build consistency. Thin spots weather faster; thick spots can introduce cure stress.

Oven curing profile: Accurate peak metal temperature and dwell time are critical. Under-cure can reduce chemical resistance and adhesion; over-cure can embrittle the film and reduce flexibility.

Defect prevention and inspection: Pinholes, trapped particles, and microcraters can become pathways for moisture ingress. Online inspection and coil end checks help prevent premature field failures.

In practice, the "lifespan" customers see is frequently a reflection of how well the process maintained adhesion and cure consistency across the full coil length and width.

Core specifications for PVDF coated aluminum coil (typical ranges)

Table: Typical Specifications for PVDF Color Coated Aluminum Coil

| Item | Typical Range / Options | Notes |

|---|---|---|

| Aluminum alloy | 1xxx, 3xxx, 5xxx series | Selected by forming and corrosion needs |

| Thickness | 0.20-2.00 mm | Commonly 0.30-1.20 mm for cladding |

| Coil width | 20-1600 mm | Depends on line capability |

| Coating type (exposed side) | PVDF fluorocarbon | Often aligned to AAMA 2605 intent |

| Coating structure | Primer + PVDF topcoat | Two-coat, two-bake is common |

| Topcoat DFT | 20-30 μm (typical) | Project specifications may vary |

| Total DFT (front) | 25-40 μm (typical) | Includes primer + topcoat |

| Back coat | 5-15 μm (typical) | Handling and service-side needs |

| Gloss | Matte to high gloss | Controlled by formulation |

| Finish | Solid, metallic, special effect | Pigment choice affects fade risk |

| Protective film | Optional | Removed after installation |

Real-world application considerations that extend or shorten service life

The same PVDF coated coil can perform very differently depending on design, fabrication, and environment.

Environment severity and orientation

Coastal zones: Chloride deposition can accelerate edge corrosion and underfilm creep if cut edges are exposed and not protected by design.

Industrial areas: Acidic pollutants may increase staining risk and surface deposition; periodic cleaning helps preserve appearance.

South- and west-facing elevations (in the northern hemisphere): Higher UV and temperature cycling often drive faster gloss reduction.

Fabrication details: where premature failures often start

Cut edges and penetrations: Coil-coated products protect the flat surface; cut edges need design measures (folds, hems, sealants, isolation) to reduce wetting and galvanic couples.

Bend radius and forming: Excessive strain can microcrack coatings if bend radii are too tight for the chosen film build and temper.

Fastener and accessory compatibility: Dissimilar metal contact and water retention points can cause localized corrosion staining.

Maintenance expectations

PVDF systems are chosen partly because they are forgiving, but they are not "maintenance-free." Low-frequency washing to remove salts and deposits helps preserve gloss and reduces the risk of persistent staining, especially on sheltered areas where rain does not naturally rinse the surface.

Typical applications where PVDF coating lifespan delivers value

Architectural envelopes benefit most from PVDF's long weathering window, including facade panels, roofing sheets, soffits, and formed trims. Many projects specify PVDF for prominent elevations and high-UV zones specifically to reduce repainting cycles and maintain consistent color across large surfaces.

For product context, PVDF Coated Aluminum Coil is commonly selected for these exterior-facing applications where long-term color and gloss retention are part of the building's appearance warranty intent.

How to think about "10-20 years" in PVDF coating lifespan terms

The widely cited 10-20 year range is best interpreted as an appearance-retention expectation under typical exterior exposure, assuming:

a PVDF system designed for exterior durability (appropriate primer/topcoat pairing),

controlled coil coating process (stable pretreatment and cure),

suitable alloy selection and sound detailing of edges and joints,

and reasonable cleaning in severe environments.

Where any of these elements are compromised, the coating may still protect the aluminum substrate but exhibit earlier aesthetic changes such as gloss loss, chalking, or localized staining.

-

Color coated Aluminum Coils for Roofing, Ceiling, and Wall Systems

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

-

Double-Sided Color Coated Aluminum Coil

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06