News

By Hermione

By Hermione

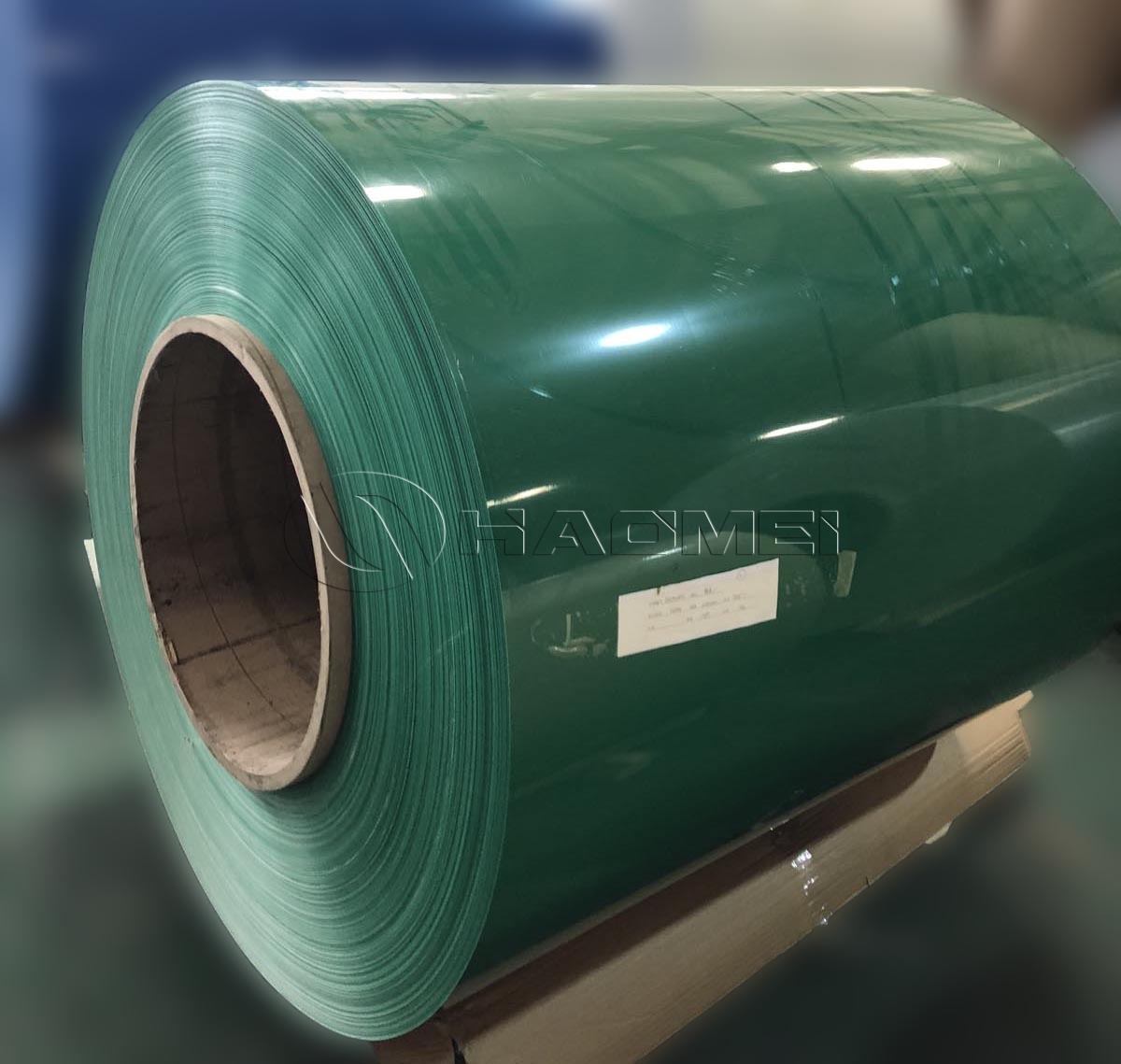

Cold Rolled 1050 1060 1070 1100 1200 Color-Coated Decorative Aluminum Coils

In architectural decoration, home appliance housings, advertising signage, and industrial decoration, cold rolled color-coated aluminum coils are gradually replacing traditional steel materials due to their attractive appearance, excellent processability, and stable corrosion resistance. They have become a key choice for lightweight and high-end decorative materials.

HAOMEI Aluminum offers 1xxx series color-coated aluminum coils (including 1050, 1060, 1070, 1100, and 1200), known for high purity, smooth surfaces, and rich color options, making them ideal for construction, home appliances, transportation, and related industries.

Why Choose 1xxx Series Cold Rolled Aluminum Coils as Decorative Substrates?

Excellent Plasticity and Formability:

The 1xxx series belongs to the pure aluminum family, featuring moderate hardness and outstanding bendability, stamping, and drawing performance. It is highly resistant to cracking, making it suitable for complex decorative shapes.Advantages of the Cold Rolling Process:

Compared with hot rolled substrates, cold rolled aluminum coils provide tighter thickness tolerances, superior surface finish, and more uniform grain structure. This results in smoother painted surfaces without waviness.Outstanding Conductivity and Corrosion Resistance:

The 1xxx series retains aluminum’s natural corrosion resistance. After coating with protective paint, its oxidation resistance can be extended to 15–20 years or more.

Different Alloy Grades

1050 / 1060:

The most commonly used grades, with purity above 99.5%, mainly applied to aluminum composite panel substrates, lighting decoration, and aluminum ceilings.

1070:

Higher purity, often used for decorative components requiring enhanced electrical conductivity or specific reflectivity.

1100 / 1200:

Contain trace alloying elements, offering slightly higher strength than 1050. Suitable for architectural curtain walls or advertising signboards requiring certain structural support.

Technical Parameters for Decorative Color-Coated Aluminum Coils

| Alloy | 1050, 1060, 1070, 1100, 1200 |

| Temper | H14, H16, H18, H24 |

| Thickness | 0.2 mm - 3.0 mm |

| Width | 20 mm - 1600 mm |

| Length | 100 mm - 16,000 mm |

| Coating Type | PE (Polyester) / PVDF (Fluorocarbon) / HDPE |

| Coating Thickness | Single coat ≥ 16 μm / Double coat ≥ 25 μm |

| Surface Finish | High gloss / matte / embossed / wood grain / stone grain |

| Color | RAL system or customized |

| Gloss | 10% - 90% (high gloss / matte / metallic) |

| Bending Requirement (T-Bend) | ≤ 2T (no cracking, no peeling) |

| Delivery Form | Aluminum coil |

| MOQ | 1-3 tons |

Core Advantages of Color-Coated Aluminum Coils for Decorative Applications

Lightweight: Aluminum density is only one-third that of steel, reducing structural load as well as transportation and installation costs.

Corrosion and Weather Resistance: A dense natural oxide layer provides strong atmospheric corrosion resistance. PE/PVDF coatings further enhance durability for long-term indoor and outdoor use.

Excellent Processability: High ductility allows cutting, punching, bending, roll forming, and deep processing to meet complex decorative design requirements.

High Reflectivity and Aesthetics: Natural metallic luster provides a bright base for vivid color presentation.

Eco-Friendly and Recyclable: Aluminum is 100% recyclable, and the color-coating process complies with environmental standards.

Color-Coating Process for Aluminum Coils

Pre-Treatment:

Continuous chemical conversion coating is used to thoroughly remove residual rolling oils and enhance adhesion between the coating and aluminum substrate.

Color Consistency Control:

Computerized automatic color-matching systems ensure color deviation ΔE < 0.5 within the same batch and across different batches, effectively addressing color consistency issues in decorative projects.

Coating Weather Resistance:

PVDF coatings contain over 70% fluorocarbon resin, providing excellent resistance to UV radiation, acid rain, and industrial pollutants, ensuring long-term color stability without fading or chalking.

Application Areas

Building Exteriors and Interior Ceilings:

Aluminum composite panels, aluminum honeycomb panels, integrated ceilings, aluminum louvers.Electronics and Home Appliances:

Refrigerator panels, microwave oven housings, mobile phone back panel decoration.Transportation Facilities:

Road signs, vehicle interior trims, advertising light boxes.Lighting Industry:

Lamp reflectors, grille lighting panels.

TAG :

-

Pvdf Coated Aluminum Coil For Honeycomb Panels

PVDF coated aluminum coil for aluminum honeycomb panels delivers long-term color retention, corrosion resistance, and formability for architectural facade cladding.

2026-02-02

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

-

Cold Rolled 1050 1060 1070 1100 1200 Color-Coated Decorative Aluminum Coils

In architectural decoration, home appliance housings, advertising signage, and industrial decoration, cold rolled color-coated aluminum coils are gradually replacing traditional steel materials due to their attractive appearance, excellent processability,

2025-12-30