HAOMEI Aluminum has developed brick-pattern, wood-grain, stone-pattern, camouflage, and special patterned decorative aluminum panels. These products feature realistic textures, excellent formability, corrosion resistance, energy efficiency, environmental friendliness, easy installation, and safety, making them an ideal alternative to traditional stone or glass decorative materials.

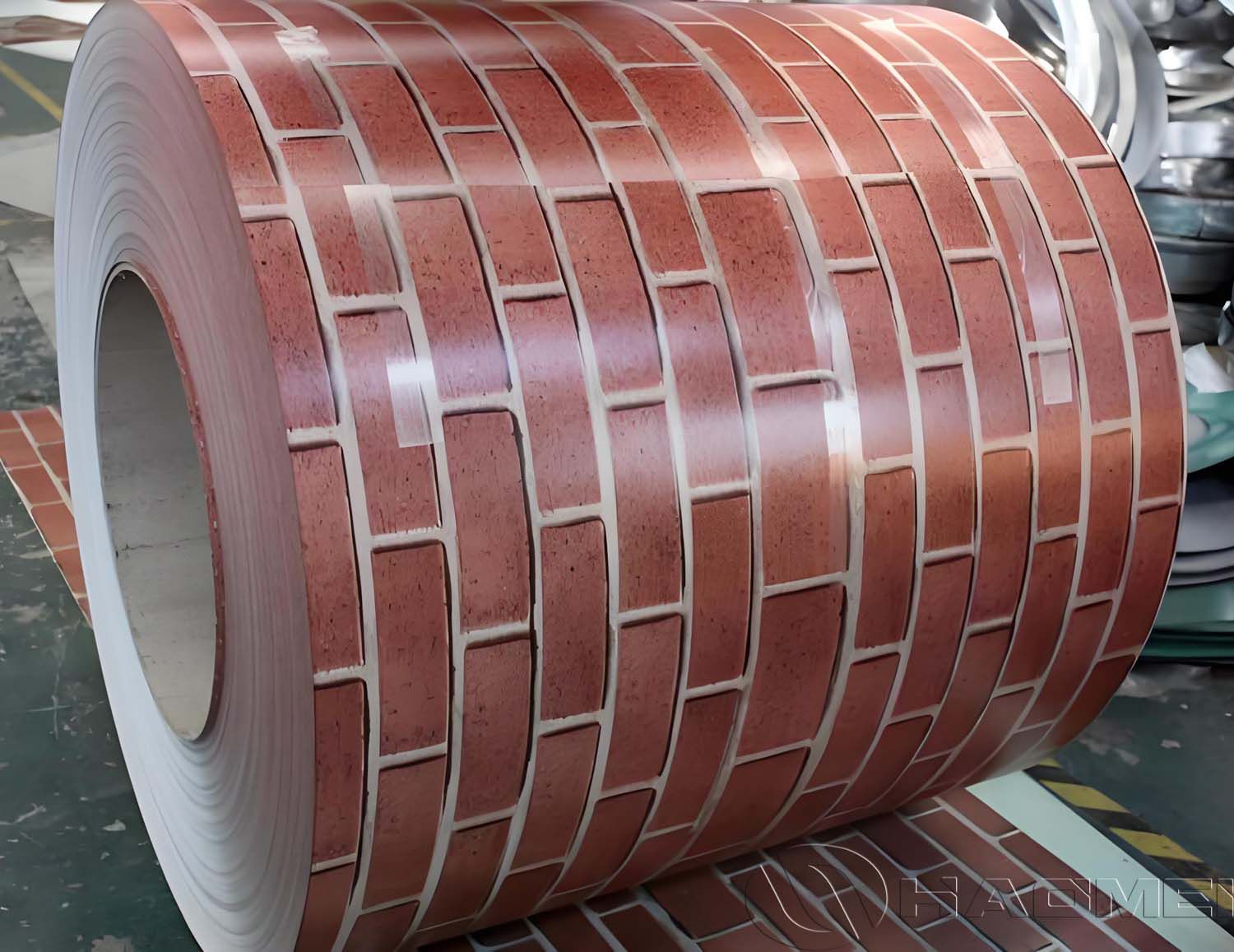

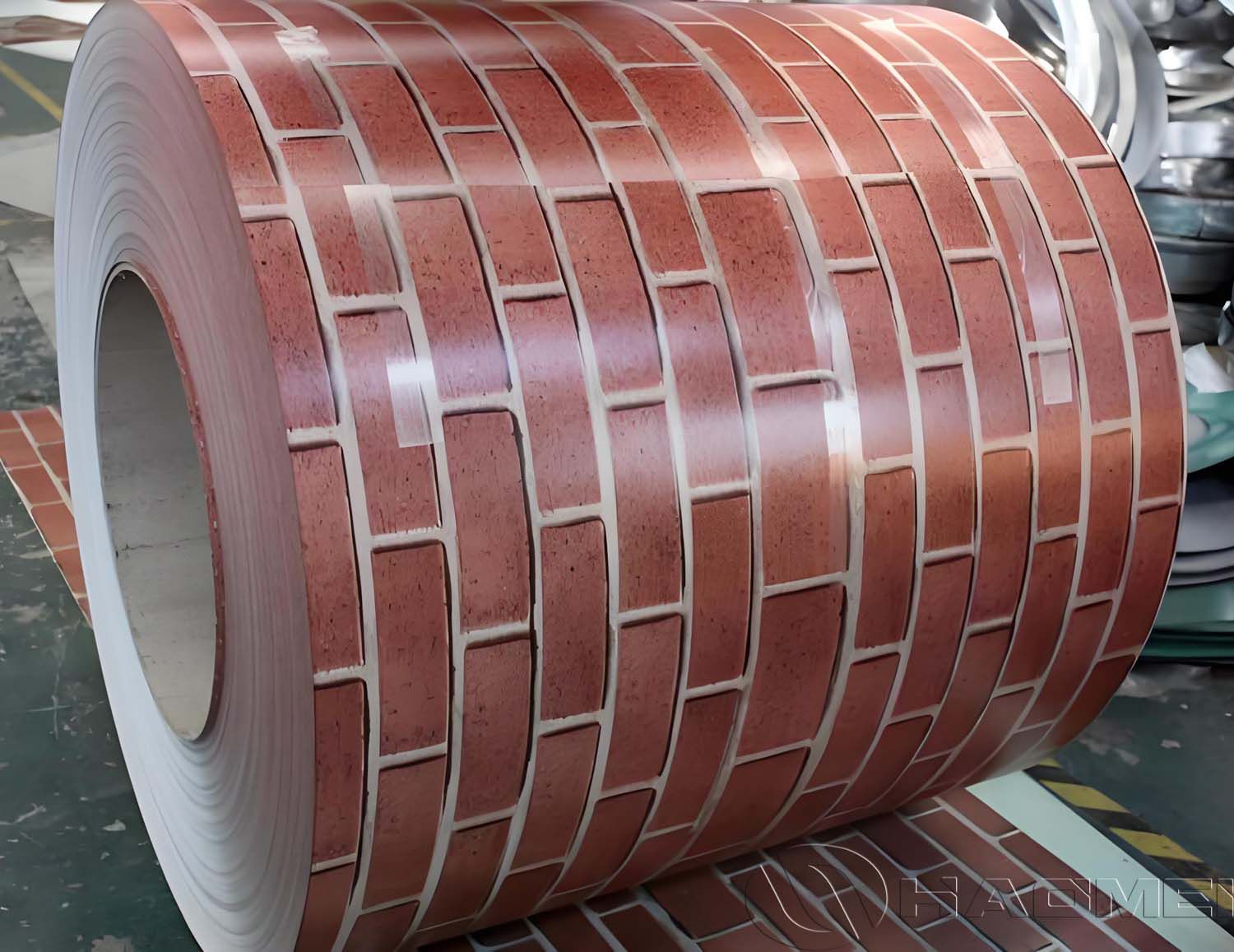

What Is Brick Pattern Color Coated Aluminum Coil?

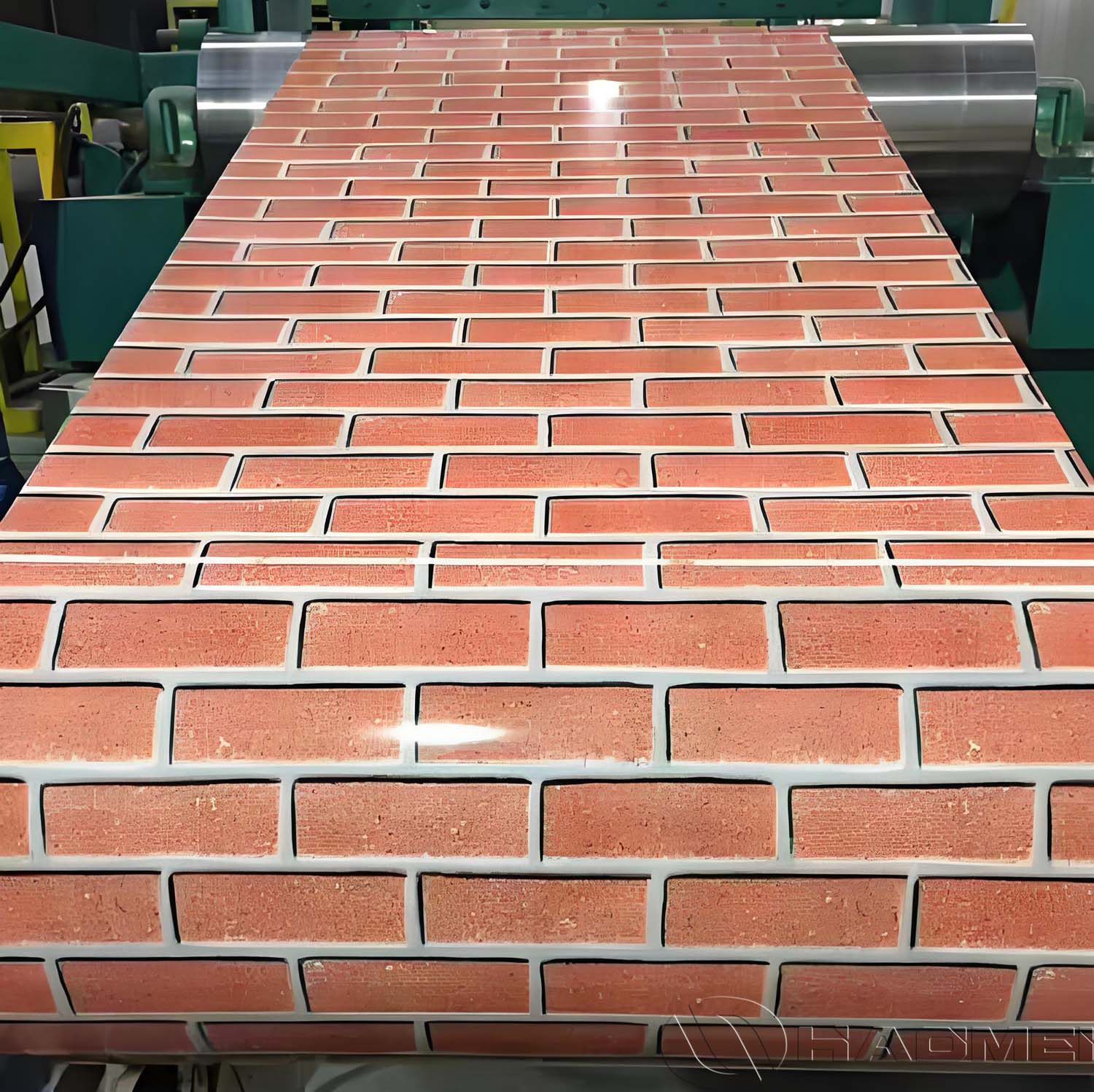

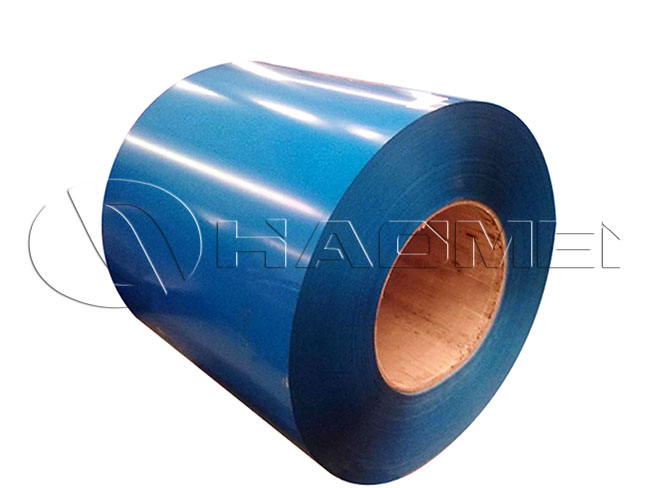

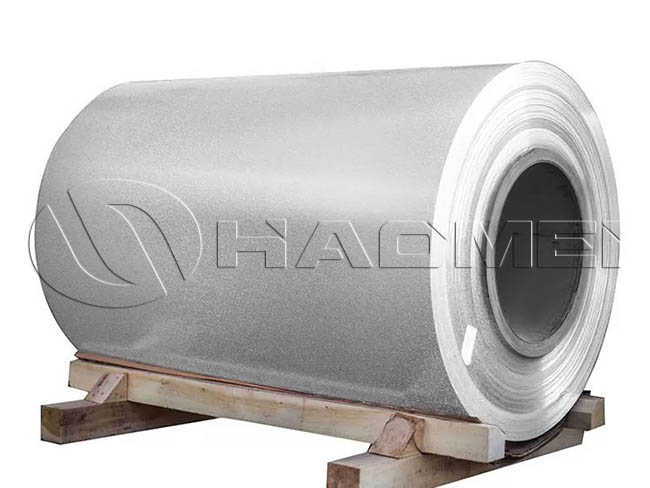

Brick pattern color coated aluminum coil is a new, efficient material for exterior walls and interior decoration. It is made using high-quality aluminum alloy coils (1060, 1070, 3003, 3105, 5052) as the substrate. Through precise pre-treatment and roller coating or transfer printing processes, a highly realistic, three-dimensional brick-pattern coating is applied (e.g., PE, PVDF) and then baked at high temperature to cure.

Brick-pattern aluminum coils offer excellent decorative appeal, flexibility, corrosion resistance, coating adhesion, and color fastness. Due to easy installation, energy efficiency, environmental friendliness, and resistance to pollution, they are an ideal alternative to traditional brick panels in the construction industry.

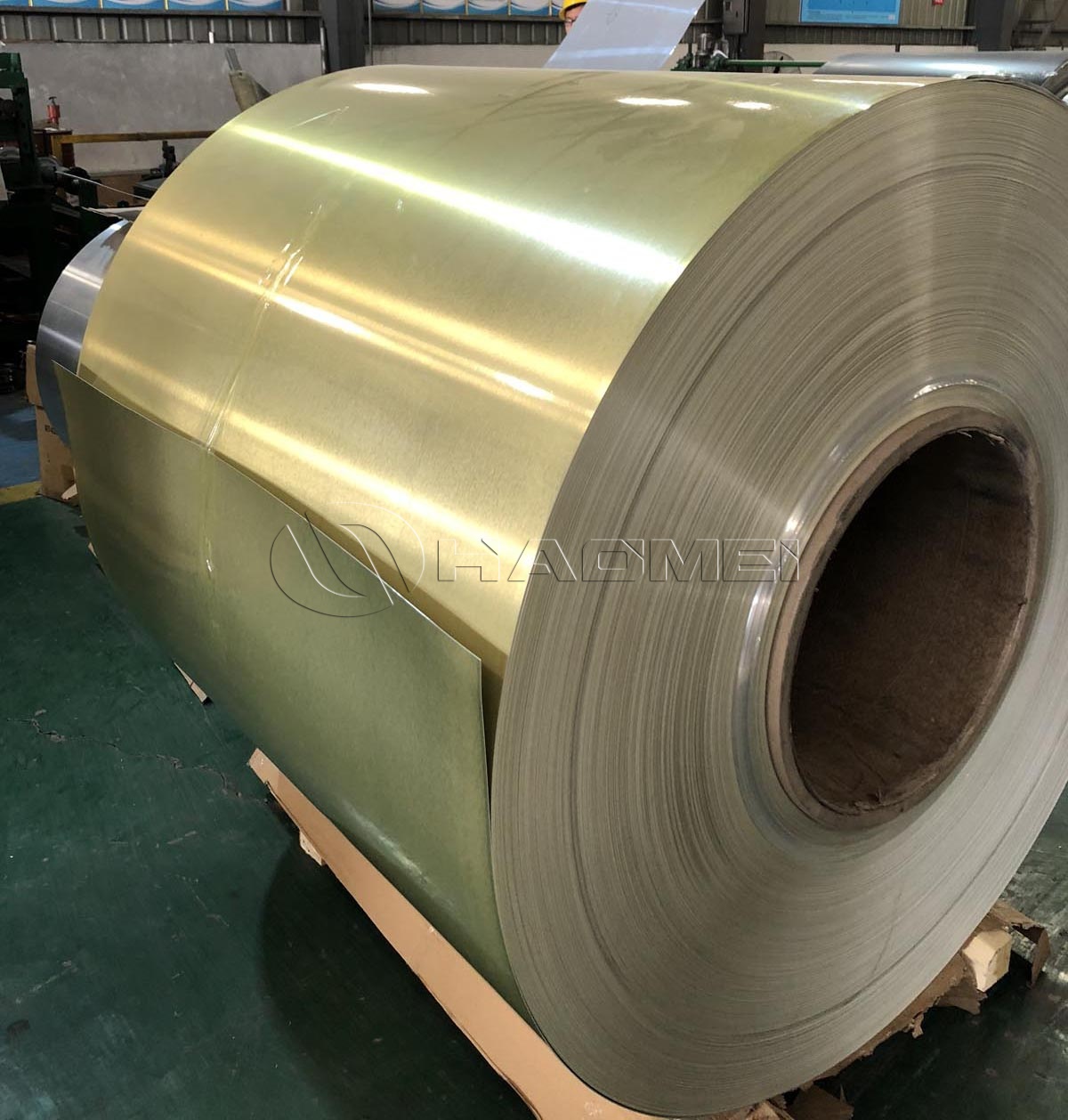

Brick-pattern coated aluminum coils are produced on high-speed continuous coating lines with multiple processes, including chemical pretreatment, primer coating, and finish coating, ensuring superior coating quality compared to single-piece coatings. They are widely used in exterior walls, curtain walls, historic-style building facades, campus fences, shopping mall entrances, container houses, billboards, interior decorative panels, and more.

Technical Specifications of Brick Pattern Pre Painted Aluminum Coil

| Alloy | 1100, 3003, 3105, 5005, 5052, etc. |

| Temper | H14, H16, H24, H26, etc. |

| Thickness | 0.20 mm - 1.50 mm |

| Width | 20 mm - 1600 mm (customizable) |

| Coating Types | PE, PVDF, FEVE, heat transfer printing |

| Coating Thickness | Front: 10-25 μm; Back: 5-10 μm |

| Paint Adhesion | ≤1 grade (GB/T 9286) |

| Bending Performance | ≤2T, no cracks |

| Impact Resistance | No cracks, no peeling |

| Weather Resistance | PE coating: 10 years; PVDF coating: 20+ years |

| Pattern Types | Red brick, gray brick, cultural brick, antique brick, mixed stone pattern |

| MOQ | 1-3 tons |

Performance Features of Brick Pattern Color Coated Aluminum Coil

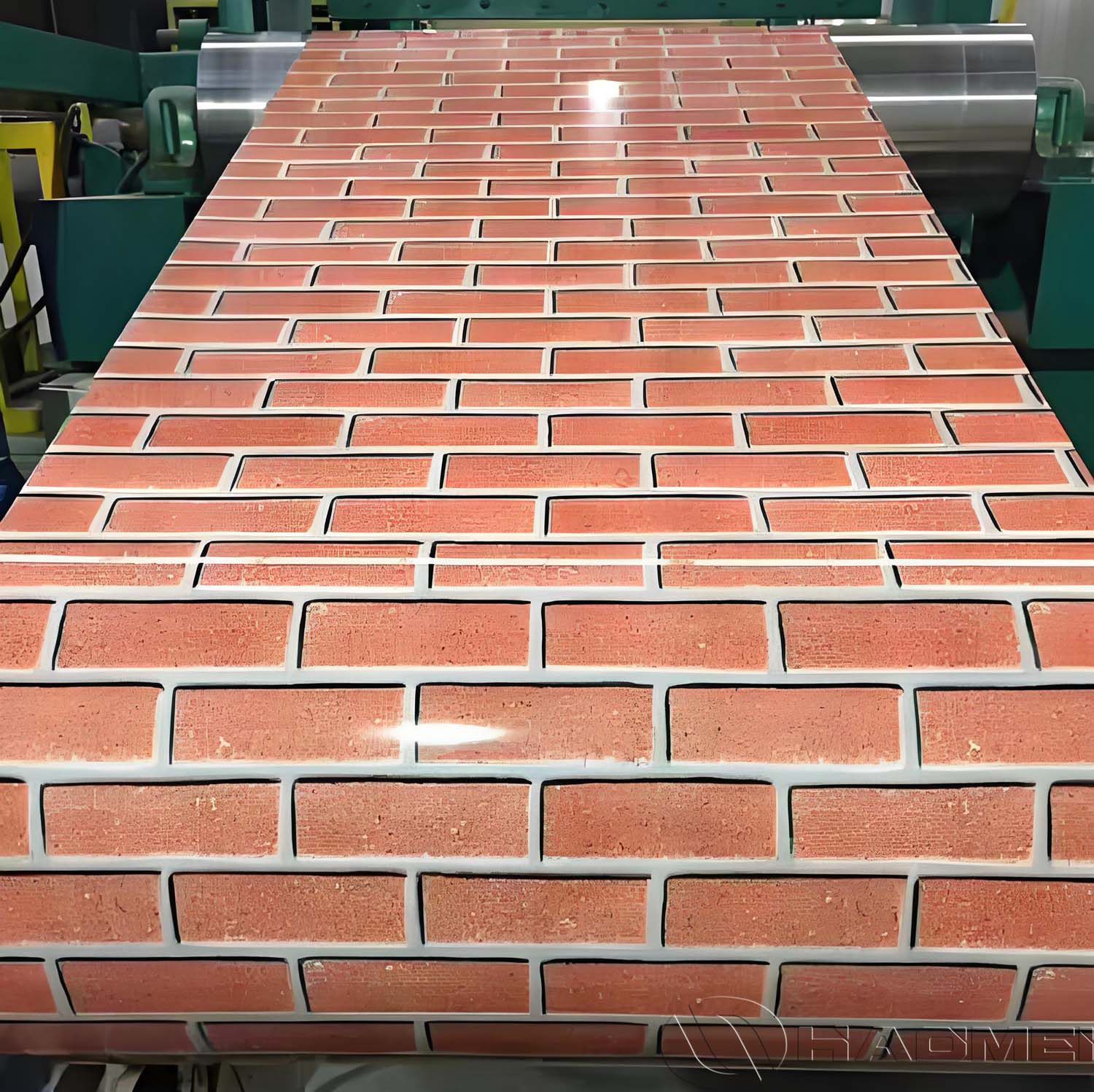

Realistic Visual Effect: High-precision printing and embossing technology create three-dimensional textures and rich color layers, perfectly simulating red bricks, blue bricks, cultural stones, and other traditional brick textures and masonry effects.

Ultra-Long Durability: The surface coating, especially PVDF fluorocarbon coating, provides excellent weather resistance, UV resistance, and corrosion resistance, ensuring long-term outdoor use without fading or peeling.

Lightweight Design: Aluminum is much lighter than traditional brick or stone, significantly reducing the load on building structures, particularly suitable for renovation projects or high-rise exterior walls.

Easy and Efficient Installation: Supplied as coils or panels, it can be quickly cut, bent, and riveted, with short construction cycles, dry installation, and avoidance of cumbersome traditional masonry processes.

Waterproof and Fireproof: Aluminum is non-combustible with high fire-resistance ratings. The coating provides excellent sealing, effectively preventing moisture penetration and protecting wall structures.

Economic and Environmentally Friendly: Low maintenance costs, no need for regular repainting or repair; aluminum is fully recyclable and meets modern green building standards.

Applications of Brick Pattern Coated Aluminum Coil

Exterior Walls and Curtain Walls: Create lightweight, modern building facades with stone-like texture, ideal for high-rise buildings.

High-End Interior Decoration: Used in hotel lobbies, office buildings, shopping malls, and banks for walls, columns, and ceilings, creating luxurious and spacious interiors.

Custom Furniture: For high-end cabinets, wardrobes, and bathroom cabinets, enhancing home quality.

Commercial Spaces: Background walls and storefronts for brand stores, restaurants, and exhibition halls, instantly elevating brand image.

Public Transportation: Interior decoration for subways, high-speed rail, and airports, combining aesthetics, safety, and durability.

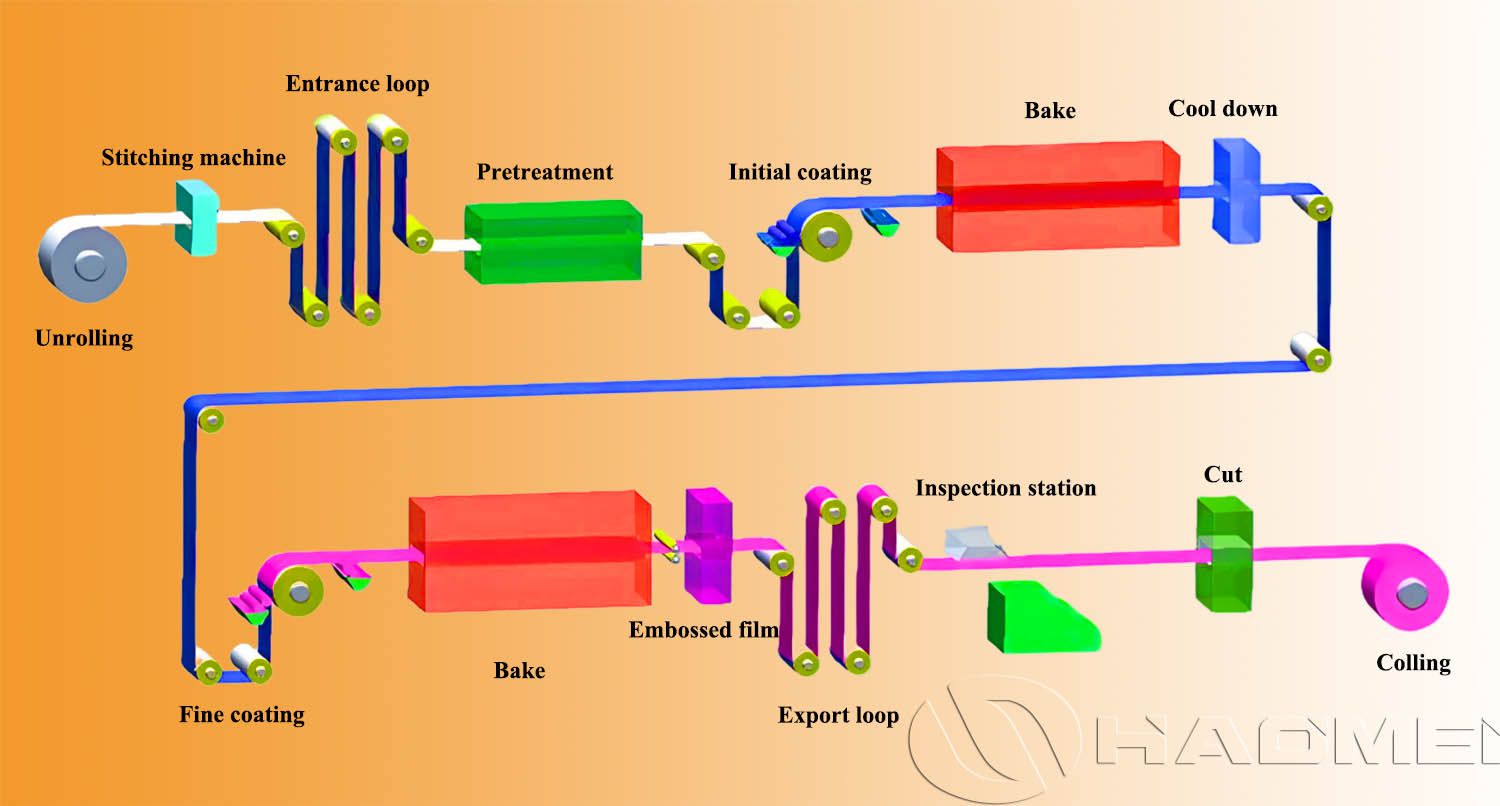

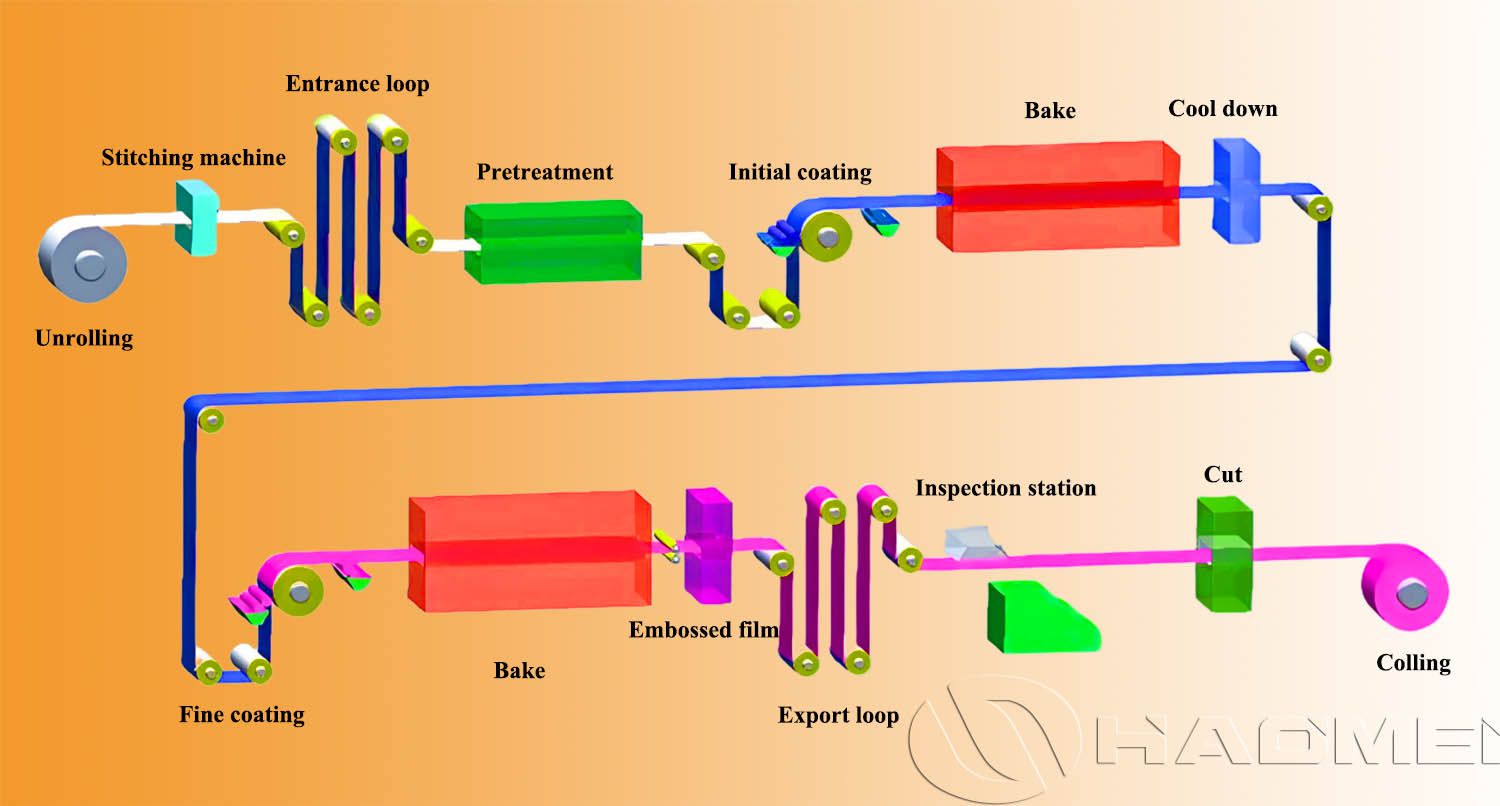

Production Process

Uncoiling → Accumulation → Cleaning → Chromate Coating → Drying → Primer & Back Coating → Oven Curing → Cooling → Topcoat → Oven → Cooling → Printing → Coating Cleaning → Oven → Cooling → Lamination Film → Air Cooling → Accumulation → Protective Film → Rewinding

+86-18703635966

+86-18703635966