News

By Hermione

By Hermione

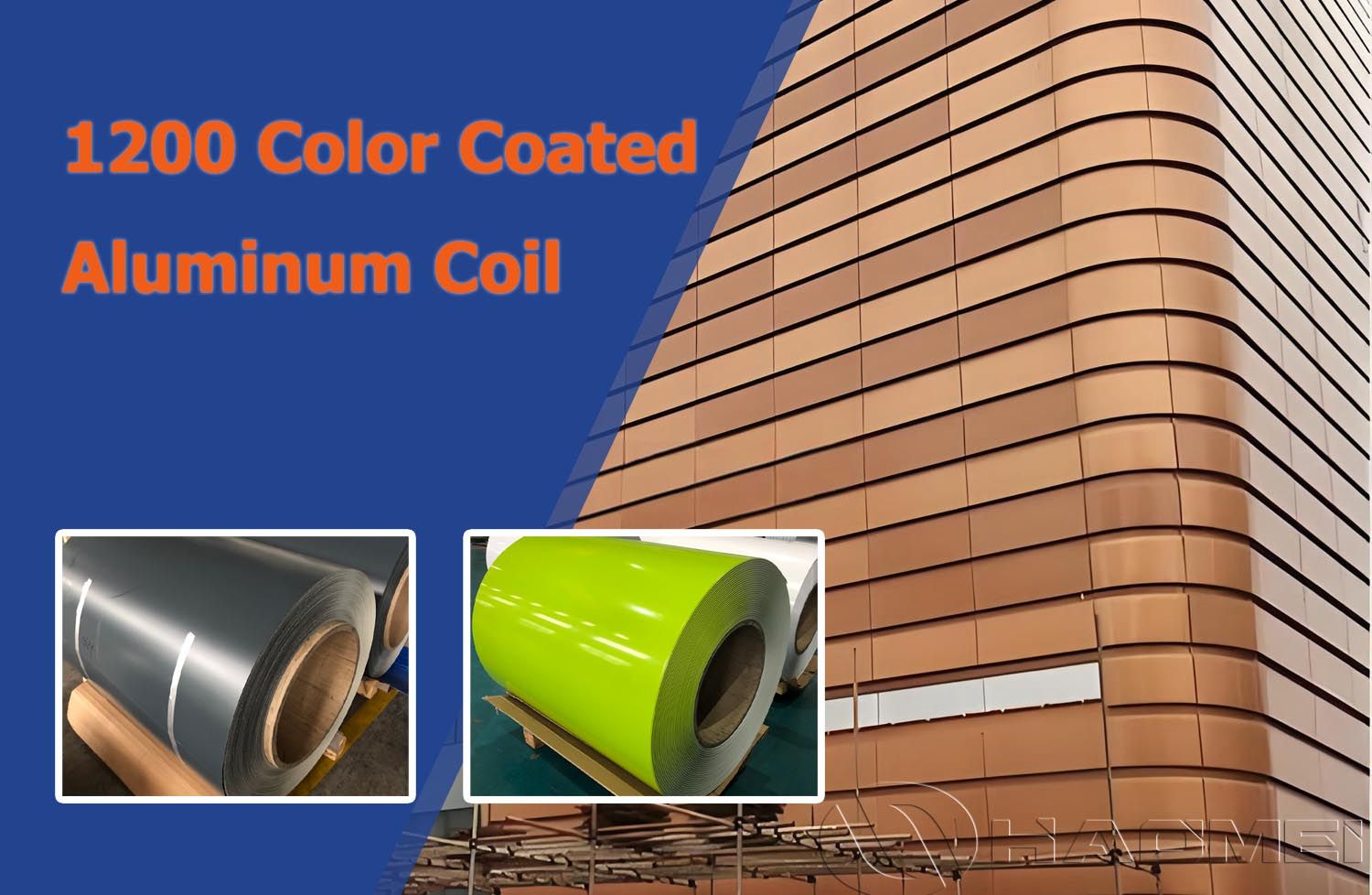

1200 Color Coated Aluminum Coil for Building Facade

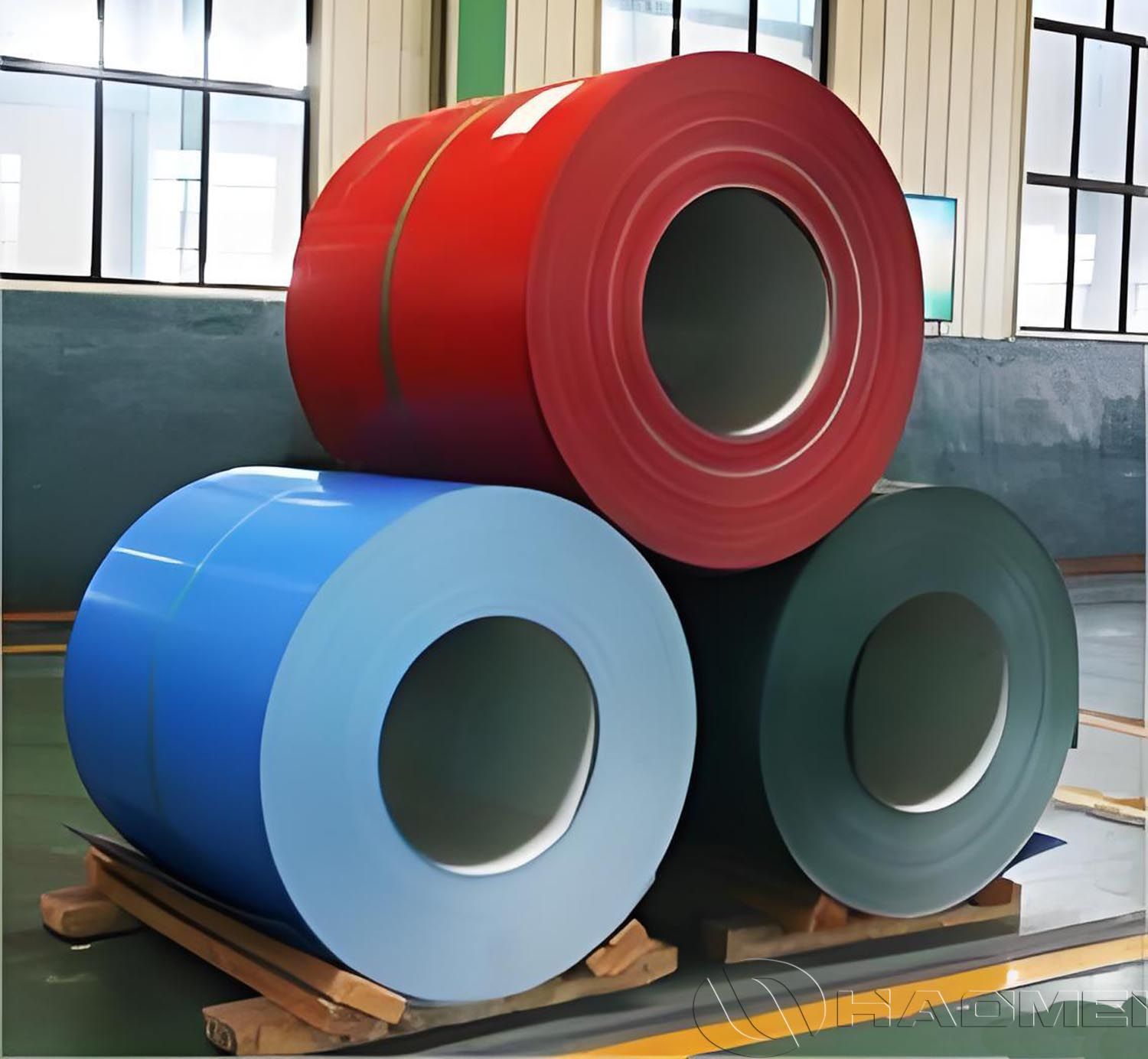

HAOMEI Aluminum's 1200 color coated aluminum coil is produced using 1200 aluminum alloy (aluminum content ≥99.0%) as the substrate. One or multiple layers of organic coating (such as PE or PVDF) are applied to the aluminum coil through a continuous roller coating process and then cured at high temperature, resulting in a high-quality architectural decorative material.

1200 aluminum alloy belongs to the pure aluminum series and offers excellent ductility and formability. It is particularly suitable for building facade systems that require forming and fabrication, such as exterior wall panels, curtain wall aluminum panels, and decorative cladding. It meets stringent requirements for weather resistance, corrosion resistance, and long-term service stability.

Why Choose 1200 Color Coated Aluminum Coil for Building Facades?

Lightweight

Aluminum has a density of only one-third that of steel. Using color coated aluminum panels for exterior walls significantly reduces structural load, lowers foundation requirements, accelerates installation, and maintains long-term durability.Weather and Corrosion Resistance

With high-quality color coating, the surface of 1200 color coated aluminum coil effectively resists UV radiation, rain, and air pollutants, making it suitable for various climatic conditions. When combined with PVDF coating, it is especially suitable for long-term outdoor exposure.Excellent Formability and Processability

1200 aluminum alloy has good plasticity and is suitable for bending, stamping, and roll forming. It can be flexibly fabricated into various sizes and shapes for facade systems, reducing processing difficulty and installation costs.Decorative Appearance

Color coated aluminum coils are available in a wide range of colors and surface finishes, including high gloss, matte, metallic, wood grain, and stone effects, meeting modern architectural demands for personalized facade design.Self-Cleaning Performance

The smooth and dense coating surface resists dust adhesion. Rainwater can easily wash away dirt, keeping the surface clean and significantly reducing long-term maintenance costs.Recyclability

Aluminum is 100% recyclable without loss of its original properties. Most architectural aluminum products contain a high proportion of recycled material, supporting sustainable construction.

Technical Parameters of 1200 Pre-Painted Aluminum Coil

| Alloy | 1200 |

| Temper | H14 / H24 |

| Thickness range | 0.3 - 1.5 mm |

| Width range | 600 - 1600 mm |

| Length range | 1000 - 16000 mm |

| Coating type | PE / PVDF |

| Surface finish | high gloss, matte, metallic, wood grain, etc. |

| MOQ | 1-3 tons |

| Standards | GB / EN / ASTM |

Application Scenarios

Exterior wall decorative aluminum panels

Curtain wall system aluminum panels

Industrial plant and warehouse facades

Commercial complexes and public buildings

Prefabricated building facade systems

Selection of 1200 Coated Aluminum Coil

(1) Coating Type

Polyester (PE): Low cost and rich color options, but relatively weaker UV resistance (UV stabilizers are recommended).

Polyvinylidene Fluoride (PVDF): Excellent UV resistance, washability, and chemical corrosion resistance; maintains color and gloss for over 20 years, though at a higher cost.

(2) Surface Finish Options

Customers can choose colors based on the RAL color chart or provide samples for color matching. Matte, glossy, pearlescent, or wood-grain effects can be selected to match different architectural styles.

(3) Thickness and Temper

Common substrate thickness ranges from 1.5 mm to 3.0 mm, determined by panel size and wind load calculations.

H14 (half-hard) temper is commonly used, balancing strength and formability.

Recommended Aluminum Alloy Coils for Building Facades

For building facade applications that require long-term outdoor exposure and higher demands for weather resistance and strength, experts and manufacturers usually recommend alloy series color coated aluminum coils, particularly 3003 and 5052 color coated aluminum coils.

| Property | 1200 | 3003 | 5052 |

| Main advantages | Low cost, excellent plasticity, lowest density | Higher strength than 1200, good corrosion resistance, widely used | Medium strength, excellent corrosion resistance and weldability, easy to form |

| Mechanical strength | Relatively low | Higher than 1200 | Higher than 3003 |

| Weather resistance | Depends on coating quality; base metal has average resistance | Good | Excellent |

| Suitability for building facades | Usable but not optimal | Recommended | Recommended |

-

5052 Camouflage Coated Aluminum Coil for Automotive Body Panels

Camouflage coatings not only have a decorative effect, but also enhance the weather resistance and corrosion resistance of aluminum, and are widely used in military vehicles, SUVs, off-road vehicles and customized vehicles.

2025-12-02

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

-

1200 Color Coated Aluminum Coil for Building Facade

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25