News

By Hermione

By Hermione

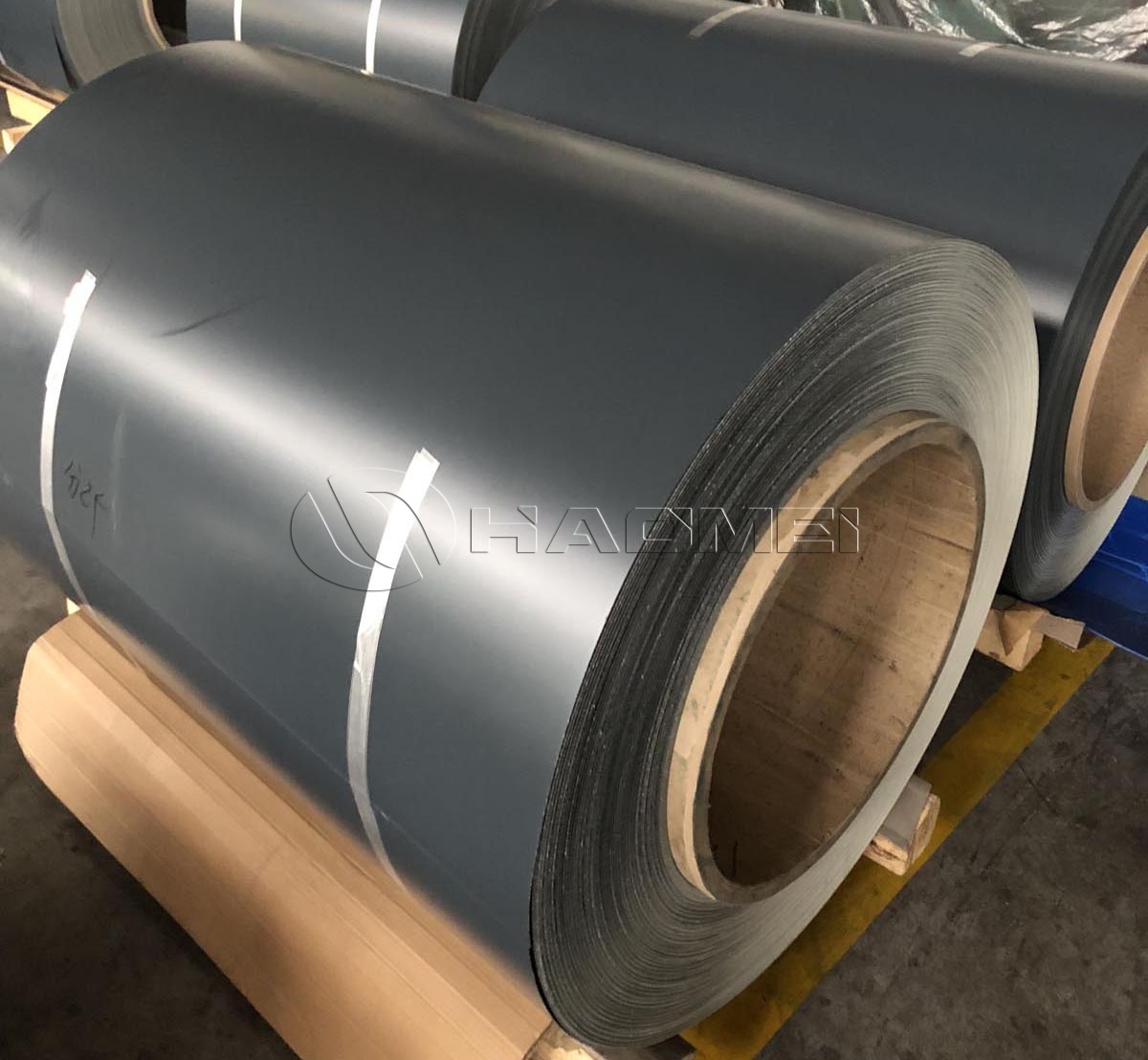

Fireproof 1100 PE / PVDF Color Coated Aluminum Coil

As an important representative of lightweight decorative and functional metal materials, fire-resistant 1100 PE / PVDF color Coated aluminum coil is widely used in architectural curtain walls, ceilings, roofing systems, and interior and exterior decoration. Its popularity is driven by excellent fire performance, outstanding formability, and long-term coating stability.

Basic Information

1100 color Coated aluminum coil uses 1100 aluminum alloy as the substrate, with a high aluminum content (≥99.0%). Although its strength is lower than alloys such as 3003 or 5052, it offers superior ductility and excellent surface quality, making it particularly suitable for high-end coating and decorative applications.

The fire-resistant property is not inherent to the coating but is achieved through advanced technology. On one hand, aluminum itself is a non-combustible material; on the other hand, by incorporating special flame retardants and high-temperature-resistant fillers into PE (polyester) or PVDF (fluorocarbon) coatings, the overall fire rating of the material can be significantly enhanced.

Performance Advantages of 1100 Prepainted Aluminum Coil

1. Outstanding Weather Resistance and Durability

PVDF fluorocarbon coating, in particular, stands out for its exceptional chemical stability. It effectively resists long-term exposure to UV radiation, acid rain, salt spray, and other harsh environments. In the industry, PVDF-coated aluminum coils typically carry a warranty of 20-30 years, ensuring long-lasting appearance and performance.

2. Excellent Fire Resistance and Safety

The combination of specially formulated coatings and a non-combustible aluminum substrate allows the material to meet various building fire protection standards, buying valuable time for evacuation and firefighting in the event of a fire.

3. Lightweight, Strong, and Easy to Process

The lightweight nature of aluminum is a natural advantage. Despite its low weight, prepainted aluminum coil offers sufficient strength and is easy to shear, cut, bend, and form, enabling complex architectural designs and creative shapes.

4. Superior Decorative Performance

Advanced coating technologies allow the surface to simulate wood grain or stone textures, with hundreds to thousands of color options available.

5. Environmentally Friendly and Recyclable

Aluminum is 100% recyclable, fully aligning with green building and sustainable development concepts.

Technical Parameters of 1100 Coated Aluminum Coil

| Alloy Grade | 1100 |

| Temper | H14 / H16 / H18 / O |

| Aluminum Content | ≥ 99.0% |

| Thickness | 0.3 - 3.0 mm (common: 0.5 / 0.8 / 1.0 / 1.2 mm) |

| Width | 600 - 1600 mm |

| Length | 100 - 16,000 mm |

| Inner Diameter | 405 mm / 505 mm |

| Surface Treatment | PE / PVDF prepainted (fire-resistant type) |

| MOQ | 1-3 tons |

Fire Resistance and Performance Indicators (Typical Values)

| Performance Item | Description |

| Combustion Performance | Aluminum substrate is non-combustible; coating meets building fire requirements |

| Smoke Density | Low smoke |

| Toxic Gas Release | Halogen-free, low toxicity |

| Adhesion | Class 0 (cross-cut test) |

| Bending Performance | T-bend ≤ 2T |

| Salt Spray Resistance | ≥ 500 h (PE) / ≥ 1000 h (PVDF) |

| Acid & Alkali Resistance | Good |

| Impact Resistance | ≥ 50 kg·cm |

Application Fields

Architectural Decoration: curtain walls, roofing systems, ceilings, suspended ceilings

Automotive & Transportation: automotive trim, protective covers, radiator covers

Electrical & Home Appliances: air conditioner housings, refrigerator panels

Industrial Equipment: pipeline cladding, machinery enclosures

PE vs. PVDF Coating Selection

| Feature | PE (Polyester) Coating | PVDF (Fluorocarbon) Coating |

| Main Resin | Polyester resin | Polyvinylidene fluoride resin |

| Core Advantages | Rich colors, cost-effective, good flexibility | Exceptional weather resistance, UV resistance, corrosion resistance, excellent self-cleaning |

| Typical Warranty | About 10-20 years | About 20-30 years or longer |

| Coating Structure | Mainly single or double coating | Mainly double (primer + topcoat) or triple coating (with clear coat) |

| Coating Thickness | Usually ≥ 18 μm | Usually ≥ 25 μm |

| Cost Positioning | Economical | High-performance |

| Ideal Applications | Interior decoration, ceilings, furniture, indoor or outdoor components with lower weather-resistance requirements | Curtain walls, metal roofing, airports, stations, large public buildings, coastal or heavily polluted industrial areas |

FAQ

Q1: Does fire-resistant treatment affect the thermal conductivity of the aluminum coil?

A: The impact is minimal. Fire-resistant treatment mainly affects surface properties, while the internal thermal conductivity of aluminum remains unchanged, making it suitable for heat-dissipation applications such as appliance housings.

Q2: Is PVDF coating suitable for indoor use?

A: Yes. PVDF coatings are non-toxic and odorless, comply with food-contact material standards, and are safe for indoor applications.

Q3: What is the service life of fire-resistant aluminum coil?

A: Typically more than 15-20 years, depending on environmental conditions and maintenance.

Q4: Can it be recycled?

A: Yes. Both aluminum and coatings are recyclable materials and meet environmental protection requirements.

-

PVDF Coated Aluminum Coil Maintenance And Cleaning

Learn PVDF coated aluminum coil maintenance and cleaning with practical methods, coating system insights, and process factors affecting durability in architectural cladding.

2026-01-27

-

5052 PPAL Pre-Painted Aluminum Coil for Ceilings

5052 pre-coated aluminum coils combine the mechanical properties of the metal substrate with the decorative and protective functions of the coating, making them suitable for applications such as ceiling panels and building curtain walls.

2025-12-11

-

5052 H34 Color Coated Aluminum Coil Inventory

5052 H34 color coated aluminum coil with PVDF or PE finishes, marine-grade corrosion resistance, stable formability, and specs for facade, roofing and trim.

2026-01-21