News

By Hermione

By Hermione

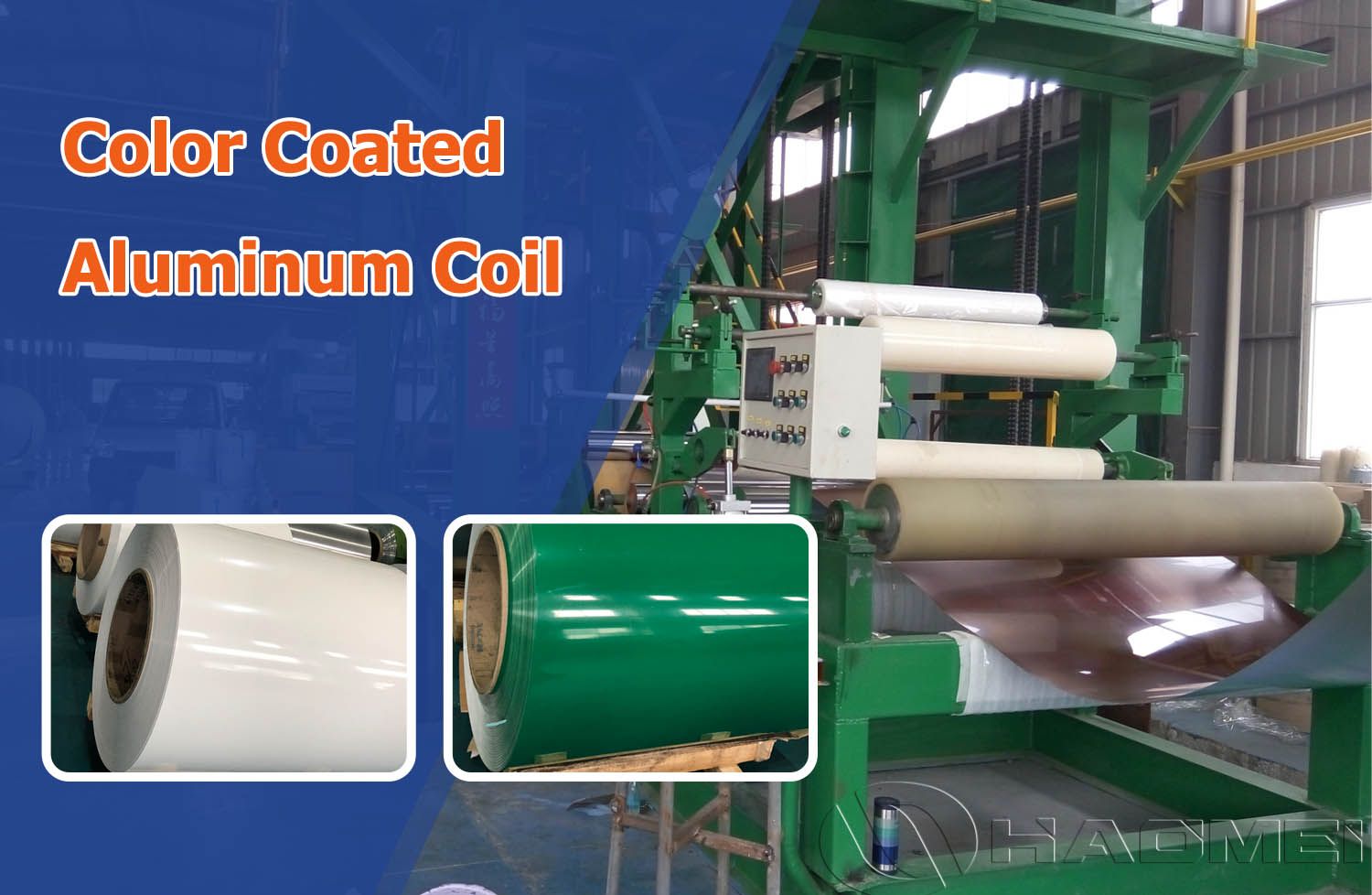

China 1050 / 1100 / 1200 / 3003 / 3004 Color Coated Aluminum Coil for Roofing

HAOMEI Aluminum produces high-quality 1050, 1100, 1200, 3003, and 3004 color coated aluminum coils, which are functional building materials made by applying advanced coating systems onto premium aluminum or aluminum alloy substrates. These products are widely used for roofing sheets, wall panels, corrugated roofing panels, and architectural façade decoration.

Through surface coating, color coated aluminum coils achieve excellent corrosion resistance, UV resistance, weather durability, and aesthetic appearance, meeting modern building requirements for lightweight construction, long service life, visual appeal, and environmental sustainability.

They are suitable for industrial plants, residential buildings, warehouses, logistics centers, commercial buildings, and public infrastructure roofing systems, making them an ideal solution for modern metal roofing applications.

Alloy Selection

1000 Series (Commercial Pure Aluminum)

Represented by 1050, 1100, and 1200, with aluminum content exceeding 99%. These alloys offer excellent corrosion resistance, ductility, and thermal/electrical conductivity, making them easy to bend, stamp, and process. However, due to relatively lower mechanical strength, careful structural evaluation is required for applications exposed to high wind loads or heavy snow. Their surface finish is typically bright and smooth.

3000 Series (Aluminum-Manganese Alloy)

3003 and 3004 are the mainstream alloys for roofing applications. By adding manganese (3003) and manganese plus magnesium (3004), these alloys maintain strong corrosion resistance while offering significantly higher strength than pure aluminum. In particular, 3004 provides superior forming stability, making it well suited for large-span roofs and complex roll-forming processes.

Technical Specifications of Color Coated Aluminum Coil

| Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 5005, 3102, 8011, 3105, 8079 |

| Thickness | 0.02 mm - 1.2 mm |

| Max Width | 2200 mm |

| Standard Width | 1240 mm |

| Special Widths | 1300 mm, 1520 mm, 1570 mm, 1595 mm (available) |

| Coil Inner Diameter | 150 mm / 405 mm / 505 mm |

| Coating Finish | PVDF, Polyester (PE), Acrylic |

| MOQ | 1-3 tons per specification |

| Gloss | Customized according to requirements |

| Total Coating Thickness | PVDF coating ≥ 25 μm |

| Coating Adhesion | ≥ Grade 1 |

| Impact Resistance | No cracking or peeling (50 kg/cm, ASTM D2794:1993) |

| Packaging | Export standard, wooden pallets |

Core Advantages of Color Coated Aluminum Coil for Roofing

1.Exceptional Weather Resistance and Durability

With high-performance coatings such as PVDF fluorocarbon, the surface effectively resists UV radiation, acid rain, and salt spray corrosion. Premium PVDF coatings can offer over 20 years of performance warranty, significantly extending the maintenance cycle of buildings.

2.Lightweight with High Strength

Aluminum has a density of approximately 2.7 g/cm³, about one-third that of steel, greatly reducing structural load. Through alloy strengthening and work hardening, it achieves sufficient strength to withstand wind pressure and environmental stress.

3.Excellent Processability and Installation Efficiency

Color coated aluminum coils are easy to cut, punch, roll-form, and bend, allowing fabrication into various roofing profiles such as corrugated sheets and standing seam panels, ensuring fast and flexible installation.

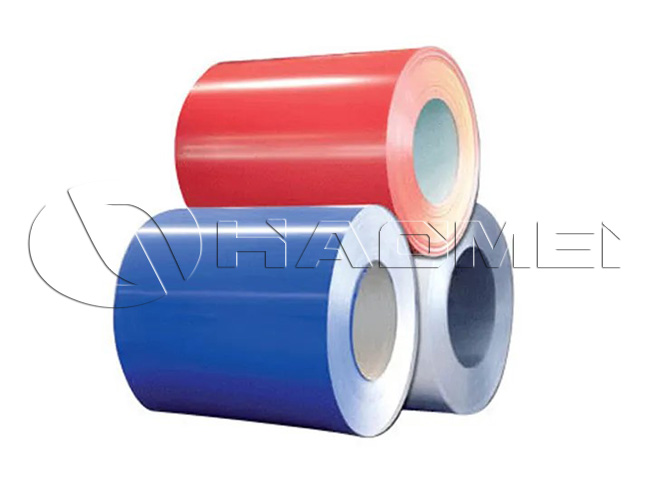

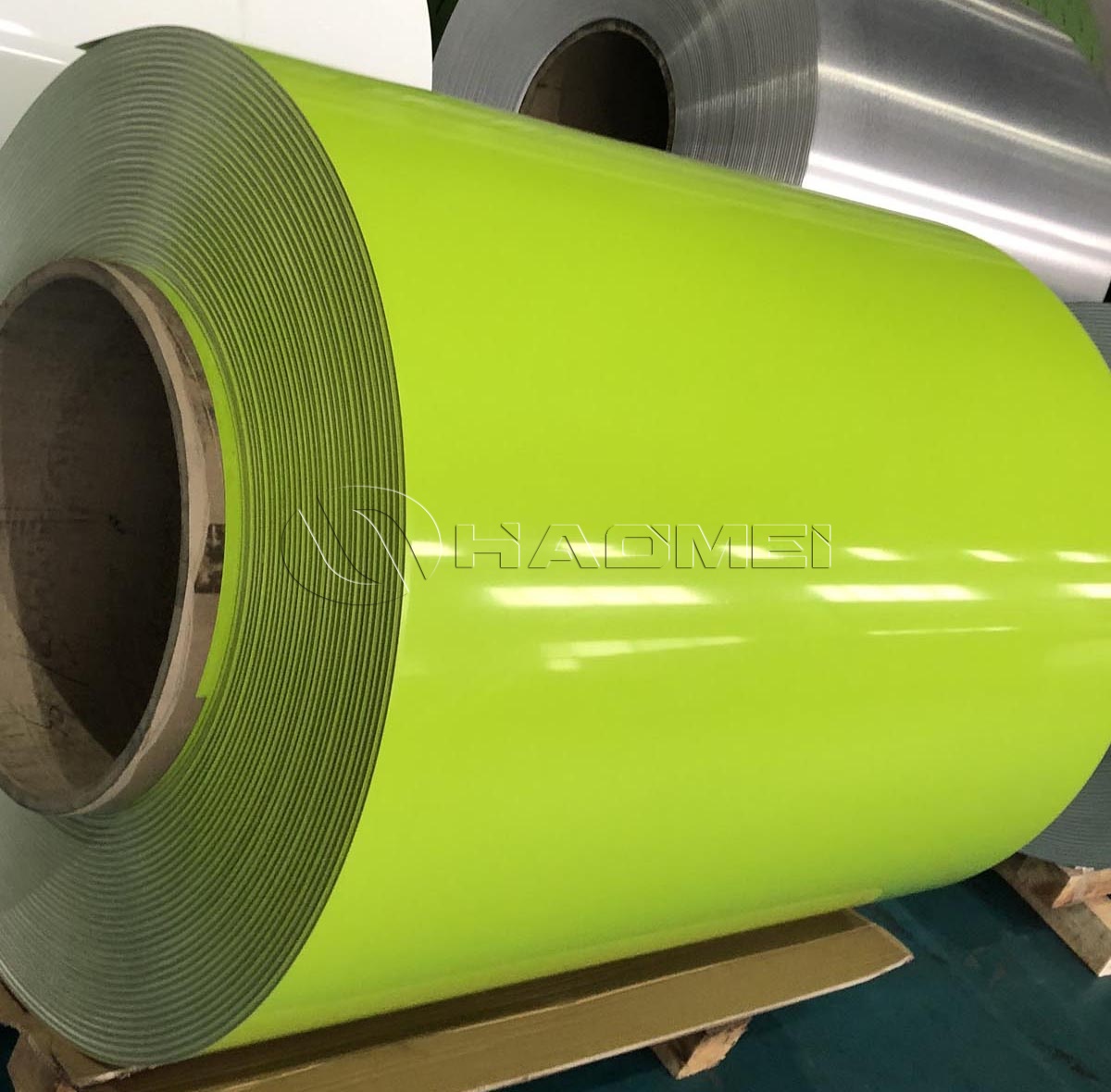

4.Outstanding Decorative Appearance

A wide range of standard and customized colors is available, including wood grain and stone grain finishes, meeting diverse architectural design needs.

5.Environmentally Friendly and Cost-Effective

Aluminum is 100% recyclable, offering low lifecycle cost and minimal maintenance, aligning with green building concepts.

Production Process of Color Coated Aluminum Coil

Substrate Preparation

Aluminum coils are produced via hot rolling or cold rolling (DC/CC) in required thicknesses and tempers such as O, H12, H14, H16, and H18.

Surface Pretreatment

Thorough cleaning and chemical pretreatment create a dense conversion layer to ensure strong coating adhesion.

Continuous Roller Coating

High-speed continuous coating lines guarantee precise control of coating thickness.

High-Temperature Curing

Coatings are cured at 200-250°C, forming a durable, dense, and firmly bonded protective layer.

T-Bend and Cross-Cut Testing

Ensures no cracking or peeling occurs during roll forming and profiling of roofing panels.

Slitting and Recoiling

Coils are cut to customer specifications and packed with moisture-proof and anti-scratch protection.

Application Areas

Industrial Buildings: factories, warehouses, logistics centers

Public & Commercial Buildings: airports, stadiums, exhibition centers, shopping malls, hospitals

Transportation Facilities: railway stations, bus terminals, highway service areas

Residential Housing: villas, residential communities, sloped roofs, decorative components

Export Packaging

Inner Packaging: Waterproof plastic film + moisture-proof paper

Outer Packaging: Reinforced cardboard side protection, steel strapping, fumigated wooden pallets or steel pallets

Loading Methods: Vertical (Eye to Sky) or horizontal (Eye to Wall) container loading to prevent oxidation and movement during sea transportation

Packaging can be customized according to customer requirements.

-

Understanding the Coating Types of Color Coated Aluminum Coil

What Is Color Coated Aluminum Coil?Color coated aluminum coil is produced by applying one or multiple layers of organic coating onto an aluminum alloy substrate through continuous roll-coating followed by high-temperature curing.The coating is the core of

2025-12-01

-

Color coated Aluminum Coils for Roofing, Ceiling, and Wall Systems

Color-coated aluminum coil is widely used in roofing, ceiling, and wall systems, offering advantages such as lightweight construction, excellent weather resistance, strong decorative appeal, and easy processing.

2026-01-04

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04