News

By Hermione

By Hermione

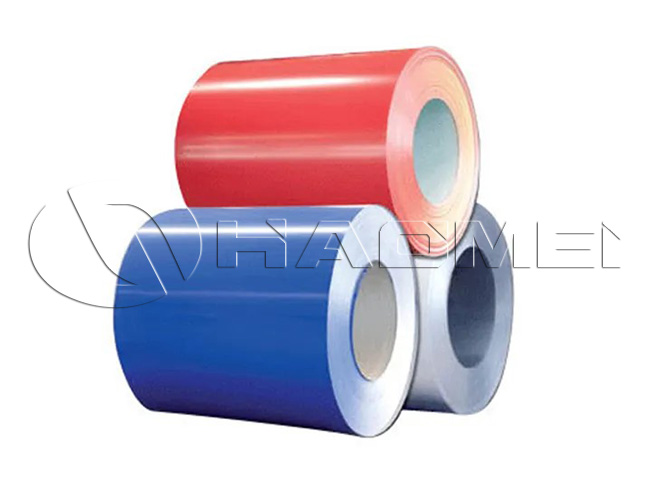

1100 H16 Prepainted Aluminum Coil Factory

Product positioning and where its used

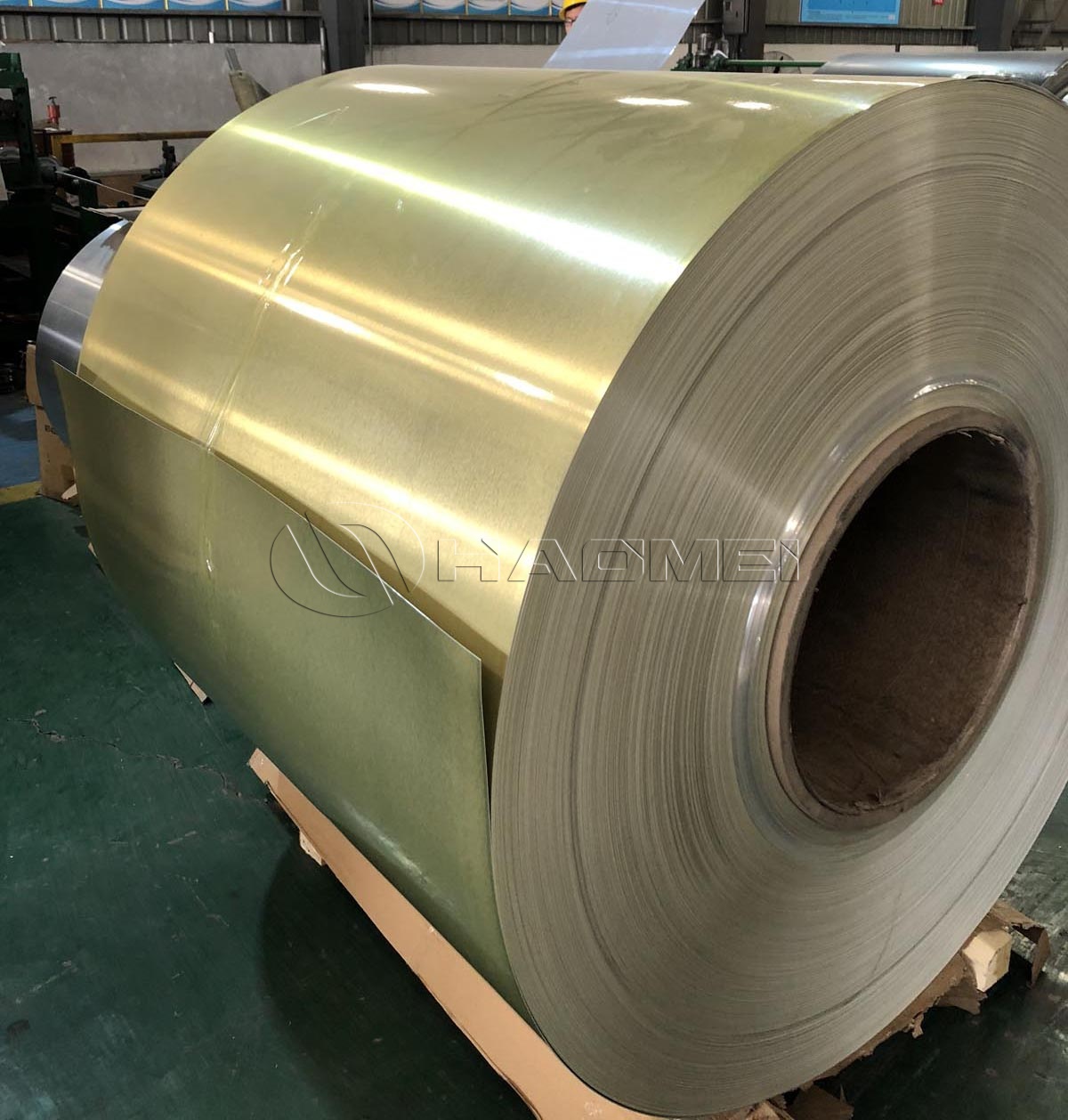

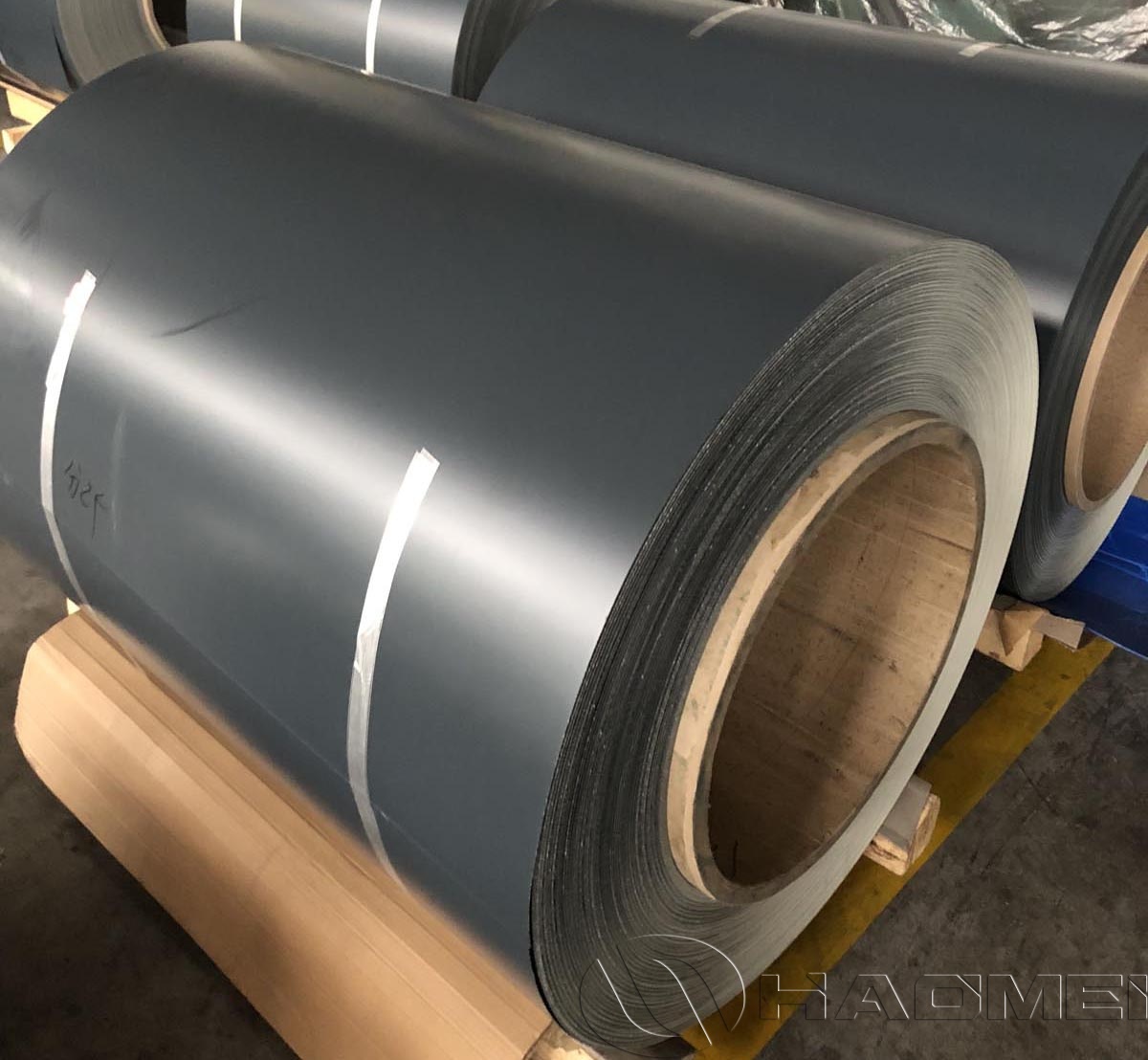

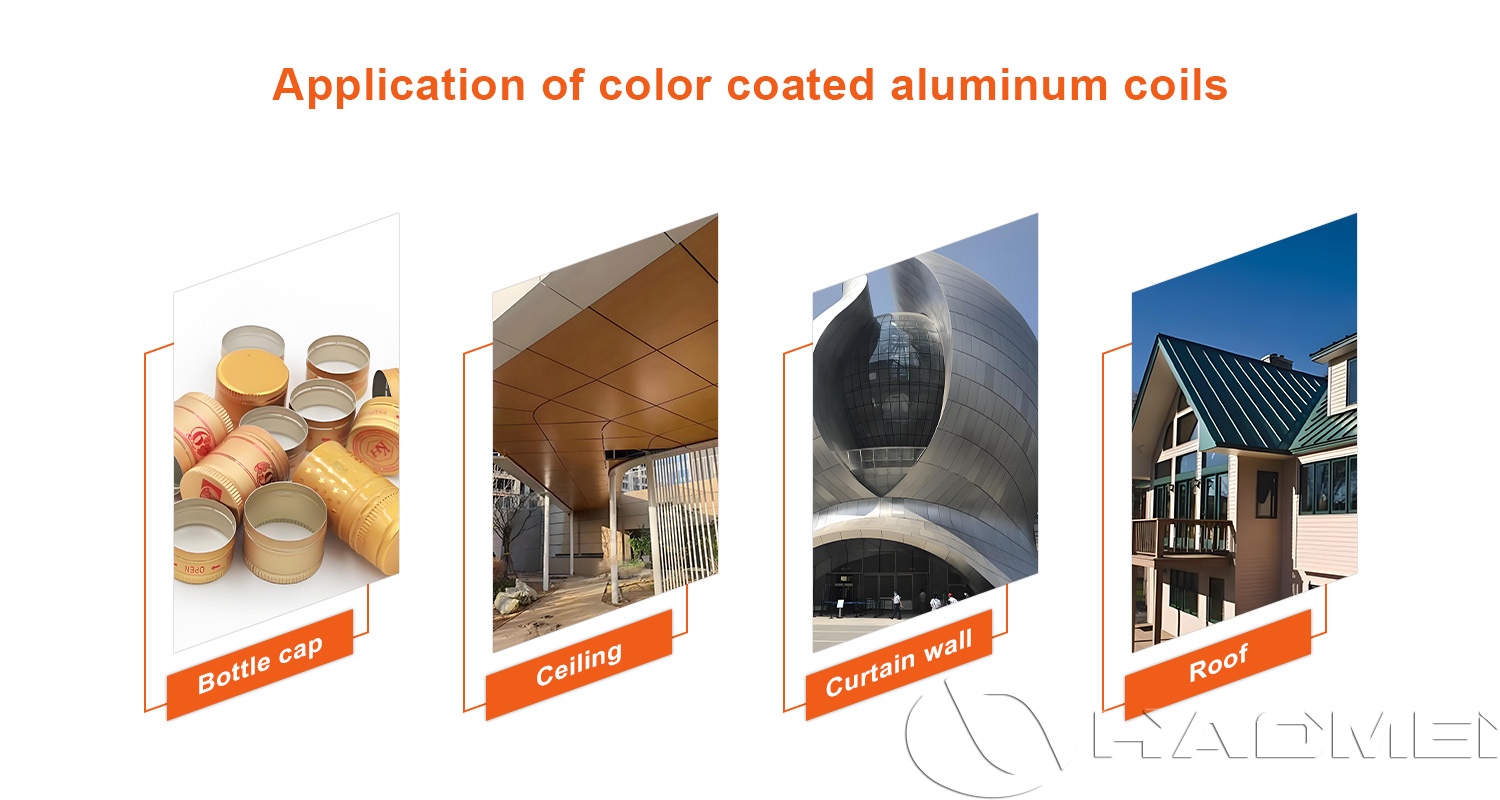

An 1100 H16 prepainted aluminum coil is positioned as a high-formability, corrosion-resistant color coated aluminum coil for roll-forming, bending, stamping, and light structural cladding where surface appearance and consistent coating performance matter. Typical application scenarios include architectural trim and flashings, ceiling and wall panels, interior decorative sheet, light-duty enclosures, and general fabrication parts that benefit from smooth finishing and reliable paint adhesion.

Why 1100 H16 is widely chosen

Alloy characteristics (1100 series)

1100 aluminum is a commercially pure aluminum grade (99.0% Al) known for:

Good corrosion resistance in atmospheric environments

Excellent formability and deep-draw performance

High thermal and electrical conductivity

Smooth surface quality suitable for decorative coating

The H16 temper indicates a strain-hardened condition that improves strength compared with annealed (O) temper, while maintaining good bending performance for common fabrication such as hemming, brake forming, and profiling. In trim coil and panel work, this balance helps reduce edge waviness and handling dents without making forming overly difficult.

Where 1100 H16 fits best

Trim coil / flashings: crisp bending lines, stable flatness after forming

Interior panels & ceilings: uniform color and gloss, low defect appearance

General sheet metal fabrication: good joining compatibility (mechanical fastening, riveting; welding depends on coating removal and process control)

Coil coating systems: PE vs PVDF

Prepainted coils typically use either PE (polyester) or PVDF (fluorocarbon) coating systems chosen based on durability needs.

PE coating: good cost-performance, wide color selection, commonly used for interior applications and moderate outdoor exposure.

PVDF coating: stronger weathering resistance (UV stability, chalking resistance), preferred for long-life exterior architectural cladding and faades.

Manufacturing process in a prepainted aluminum coil factory

A stable coil coating process is the foundation of appearance consistency and long-term performance. In practical factory production, the key process steps are:

Incoming coil preparation: surface inspection, alloy/temper verification, and slit-edge quality control.

Cleaning and chemical pretreatment: degreasing and conversion coating to improve corrosion resistance and coating adhesion (critical for forming edges and cut surfaces).

Primer coating: roll-coating primer to balance adhesion, flexibility, and barrier protection.

Topcoat application: PE or PVDF topcoat applied by precision roll coaters; color/gloss management controlled by viscosity, film build, and line speed.

Oven curing: controlled peak metal temperature to complete crosslinking; insufficient cure affects hardness and solvent resistance, while overbake can reduce flexibility.

Cooling, protective film (optional), and recoiling: to reduce handling marks and protect the finish during transport and fabrication.

Quality verification: film thickness, gloss, color difference (E), adhesion (cross-hatch), impact, bend/T-bend, pencil hardness, MEK rub/solvent resistance, and salt spray (as required by the coating specification).

In day-to-day fabrication, coating flexibility matters as much as color. For 1100 H16, the coating system is typically tuned to pass bending and profiling without micro-cracking at edges.

Core specifications table (1100 H16 prepainted aluminum coil)

| Item | Typical Range / Options |

|---|---|

| Alloy / Temper | 1100 H16 |

| Thickness | 0.202.00 mm (common: 0.301.20 mm) |

| Width | 201600 mm (slit to size) |

| Coil ID | 150 / 405 / 508 mm |

| Coating system | PE / PVDF |

| Paint structure | 1-coat 1-bake / 2-coat 2-bake (per requirement) |

| Topcoat thickness | ~1228 m (project-dependent) |

| Primer thickness | ~410 m |

| Finish options | Solid, metallic, matte, high gloss; protective film optional |

| Surface | One-side or two-side coating; back coat available |

| Standards reference | EN/ASTM/JIS chemistry & coil coating performance per agreed specification |

Common alloys for prepainted aluminum coils and how theyre used

While 1100 is a primary choice for forming-friendly applications, other alloys are frequently selected to match strength, rigidity, or corrosion demands:

1050 / 1060 (pure aluminum series): similar to 1100, often chosen for highly formable decorative sheets, insulation jacketing, and general coated sheet where maximum ductility is desired.

3003 (Al-Mn): better strength than pure aluminum; widely used for roofing, siding, and general building panels that need improved dent resistance.

3004 / 3105 (Al-Mn-Mg): commonly used in architectural cladding, ceiling systems, and roll-formed products requiring higher strength while retaining good formability.

5005 (Al-Mg): good anodizing response and corrosion resistance; used in architectural panels and decorative exterior components.

5052 / 5754 (Al-Mg): higher strength and marine-atmosphere corrosion resistance; used for transportation, equipment housings, and environments with higher corrosivity.

8011 (Al-Fe-Si): often used in packaging-related coated products and closures, where forming and cost balance are important.

Alloy selection in prepainted coils is typically driven by three practical factors: forming radius requirements, stiffness/dent resistance targets, and exposure conditions (interior, exterior, coastal/industrial).

Practical application notes for 1100 H16 color-coated coils

Bending and hemming: 1100 H16 supports tight bends; coating flexibility and cure level are decisive for avoiding edge crazing.

Cut-edge behavior: pretreatment and primer choice influence filiform/cut-edge corrosion performance, especially for outdoor trim.

Color consistency across lots: controlled E targets and gloss tolerance are important for faade components and long trim runs.

Compatibility with sealants and films: coating surface energy and bake condition affect adhesion of tapes, films, and sealants used in installation.

-

Black Color Coated Aluminum Coil 5052

5052 black color-coated aluminum coils are widely used in building decoration, home appliance housings, transportation and marine engineering.

2025-12-04

-

How to Make Aluminum Coil Look Like Wood?

Wood grain coated aluminum coil gives aluminum coils the appearance of natural wood, while offering outstanding durability and lightweight performance, making it an ideal choice for architectural decoration.

2025-12-31

-

5052 H32 Color Coated Aluminum Coil for Sale

The 5052 H32 aluminum coil uses a color coating process that involves continuously rolling a polyester (PE), fluorocarbon (PVDF), or other coatings onto the aluminum coil substrate and then baking and curing it.

2025-12-05