News

By Hermione

By Hermione

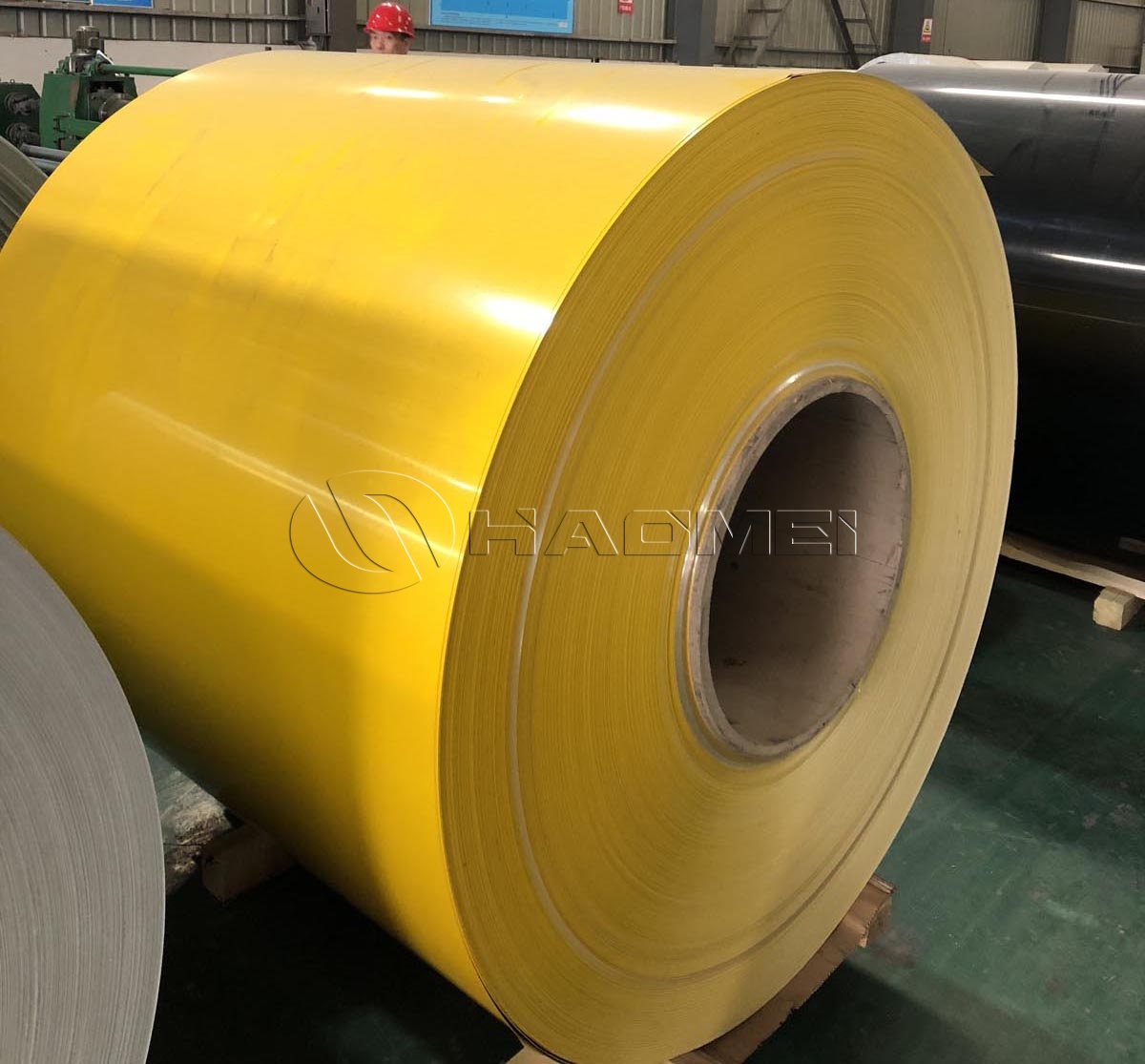

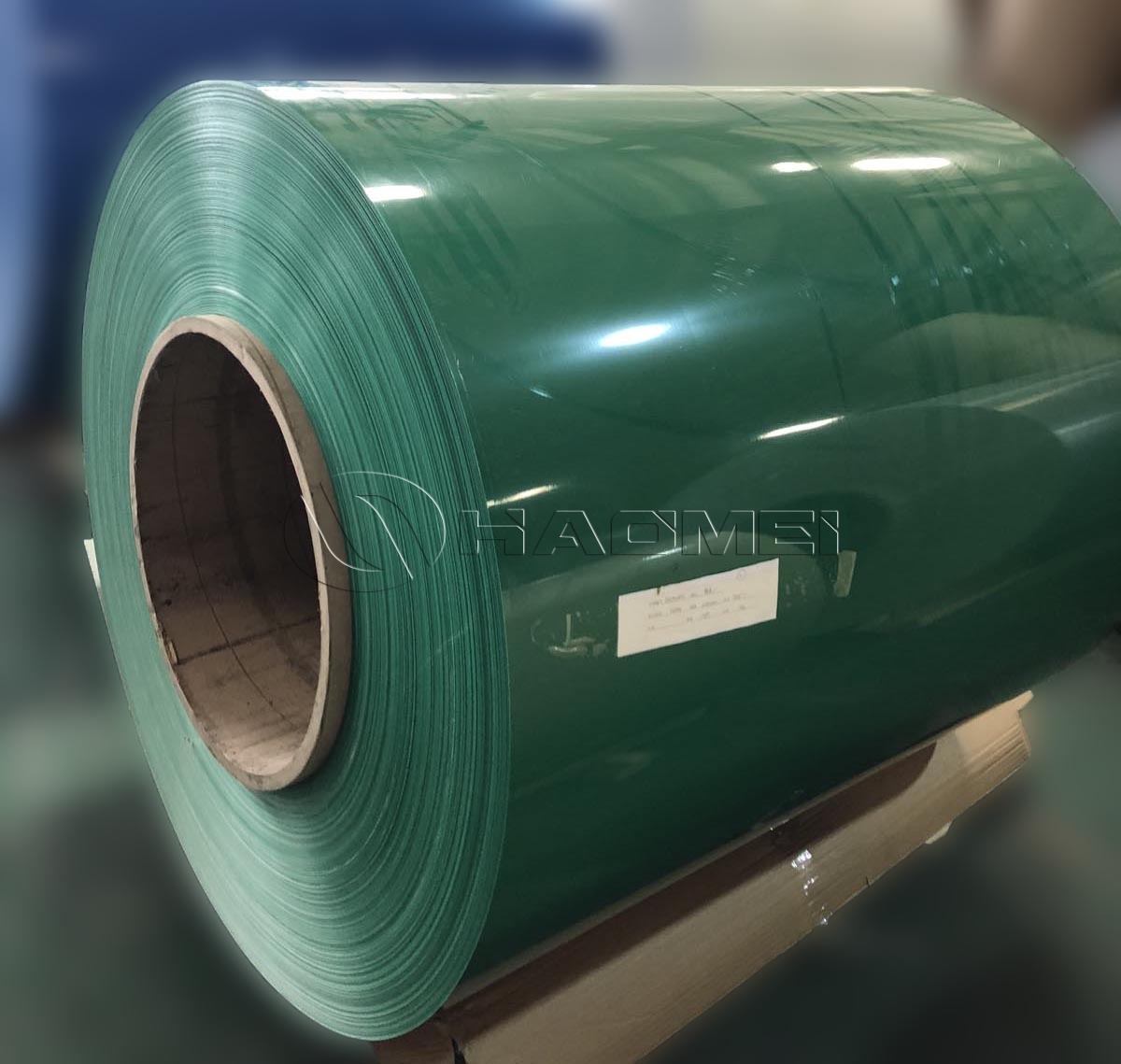

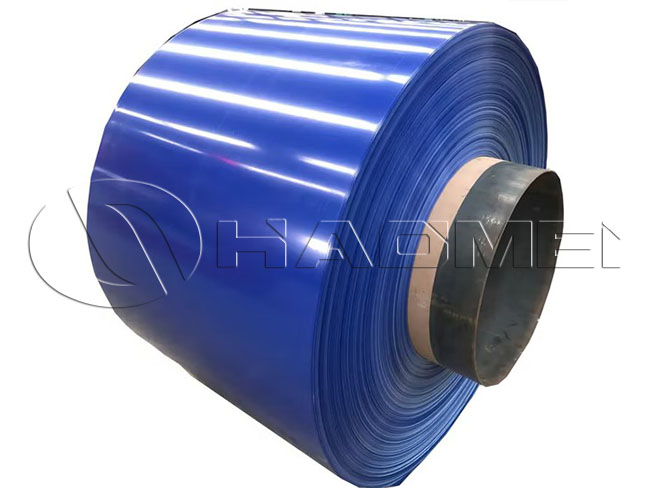

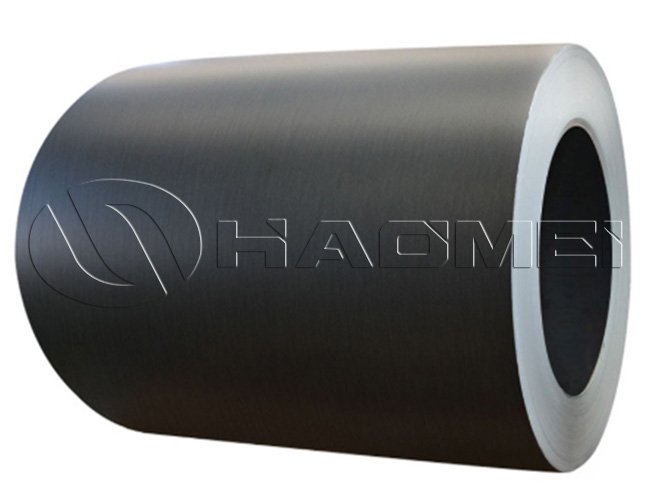

5052 Color Coated Aluminum Coil For Marine Use

Marine environments punish metals with continuous salt spray, UV exposure, wet–dry cycling, and abrasion. 5052 color coated aluminum coil is positioned as a high-reliability marine aluminum coil for exterior cladding and formed components where corrosion resistance, forming performance, and long-term color stability are required-typical scenarios include boat and yacht superstructure panels, coastal building envelopes, port equipment covers, ventilation housings, and decorative trims exposed to sea air.

Why 5052 Alloy Fits Marine Service

5052 is an Al–Mg alloy that is widely selected for marine-adjacent parts because magnesium improves resistance to chloride-driven corrosion while maintaining good strength-to-weight balance. For coil-coated products, this matters in two ways: the substrate must resist underfilm corrosion when scratches or cut edges occur, and it must remain formable after paint bake cycles.

In practice, 5052 supplied in H32/H34 tempers offers a stable combination of yield strength and ductility for roll forming, press braking, beading, and shallow drawing. Compared with non-heat-treatable pure aluminum grades, 5052 better tolerates mechanical handling and assembled service loads; compared with higher-Mg alloys (e.g., 5083), it is typically easier to coat and form in coil processing thickness ranges used for panels and covers.

From a corrosion standpoint, 5052's natural oxide film is already robust, but the marine advantage comes from pairing it with a properly engineered coil coating stack that controls pretreatment quality, primer barrier performance, and topcoat UV durability.

Coating Systems Engineered for Salt, Sun, and Maintenance Cycles

A marine-grade coil coating system is not just about film thickness; it is about the whole interface-from cleaned metal to conversion layer to primer to topcoat-so that adhesion, flexibility, and corrosion resistance remain intact after forming and edge exposure.

Pretreatment (conversion coating) is the foundation. A controlled degrease + rinse + conversion step (often chromium-free systems today) improves paint anchoring and provides initial corrosion protection at the metal/primer interface. For marine service, pretreatment consistency is critical because micro-defects become corrosion initiation points under salt spray.

Primer selection typically favors epoxy or epoxy-modified primers for barrier performance and adhesion retention. In coastal cycles, the primer is the “workhorse” that slows ion transport when the topcoat is micro-scratched.

Topcoat options are chosen based on exposure level:

PVDF (70% resin) topcoats are the go-to for high-UV coastal exteriors thanks to excellent chalking and color retention, along with chemical resistance and ease of cleaning. Where long service life and appearance stability are prioritized, specifying a PVDF Coated Aluminum Coil architecture is common.

PE systems can be appropriate for sheltered marine interiors, equipment housings, or components with lower UV demand, while still providing good aesthetics and formability. For cost-sensitive or semi-exposed uses, PE Coated Aluminum Coil systems are often selected with conservative film builds and rigorous pretreatment control.

For marine parts that will be formed after coating, the coating must maintain flexibility and adhesion through bending radii without micro-cracking. This is managed by resin choice, cure window control, and primer/topcoat balance, rather than simply increasing thickness.

Coil Coating Process Control: Where Marine Performance Is Won

Marine performance is highly sensitive to manufacturing stability. A technically sound coil coating process typically includes: incoming coil inspection, surface cleaning, conversion coating, primer coating and bake, topcoat coating and bake, cooling, and final QA.

Key controls that materially impact real-world marine durability include:

Surface cleanliness and conversion coat weight uniformity to avoid localized adhesion loss.

Oven temperature profile control to fully cure coatings without embrittlement (which can reduce post-forming crack resistance).

Film thickness uniformity to maintain barrier continuity, especially at high line speeds.

Color and gloss control to meet architectural and marine aesthetic requirements, with batch-to-batch reproducibility.

In addition, marine-use coils frequently require tighter standards for edge quality and slit burr control, because cut edges are common failure sites in chloride environments. A good slitting + packaging discipline (interleaf, wrap, moisture barrier) helps prevent transit corrosion and surface marring before fabrication.

Core Specifications (Typical Range)

Table: 5052 Color Coated Aluminum Coil for Marine Use - Core Specifications

| Item | Typical Specification Range | Notes |

|---|---|---|

| Alloy / Temper | 5052 H32 / H34 | Other tempers available per forming needs |

| Thickness | 0.30-3.00 mm | Common for panels, covers, formed trims |

| Width | 600-1600 mm | Subject to line capability and order |

| Coating Type | PE / PVDF | PVDF preferred for high-UV coastal exposure |

| Coating Structure | 2-coat 2-bake (primer + topcoat) | Back coat optional for balanced protection |

| Topcoat Thickness | 18-25 μm (PE), 20-30 μm (PVDF) | Range depends on exposure and color |

| Primer Thickness | 5-8 μm | Epoxy/modified epoxy common |

| Gloss | Matte to high gloss | Defined by project requirement |

| Surface Finish | Solid / metallic / textured | Textured helps hide handling marks |

| Performance Focus | Adhesion, flexibility, salt spray resistance, UV durability | Validated by internal QC and agreed standards |

Practical Marine Applications and Design Considerations

Because 5052 combines corrosion resistance with good forming behavior, it is frequently used as coated coil stock for components that must be shaped and then installed in salt-laden air.

Boat and yacht exterior panels, locker doors, console skins: Coil coating provides consistent color and surface quality across batches, while 5052 supports bending and edge hemming used in marine cabinetry and covers.

Coastal architectural cladding, soffits, and fascia: PVDF systems are favored where appearance retention matters under strong UV and airborne salts.

Port and offshore auxiliary enclosures (instrument boxes, ventilation shells, protective shrouds): The primer/topcoat barrier plus 5052 substrate helps resist corrosion creep from scratches and fastener interfaces.

In service, the most frequent corrosion triggers are cut edges, fastener points, and areas with trapped moisture. For fabricated marine parts, controlling bend radius, avoiding coating damage during forming, and using compatible sealing at joints/edges substantially improves the coating system’s ability to protect the 5052 substrate.

For projects that require a dedicated product page reference, the substrate and coating configuration is commonly specified under 5052 Color Coated Aluminum Coil with the marine exposure class defining whether PE or PVDF topcoats are used, along with film build, pretreatment type, and post-forming requirements.

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

-

Color-Coated Aluminum Coils for Ceiling Applications

In modern architectural decoration, ceilings are no longer merely functional structures for concealing pipelines. They play a critical role in enhancing overall aesthetics, improving durability, and reducing long-term maintenance costs. From large airport

2025-12-26

-

Double-Sided Color Coated Aluminum Coil

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06