News

By Hermione

By Hermione

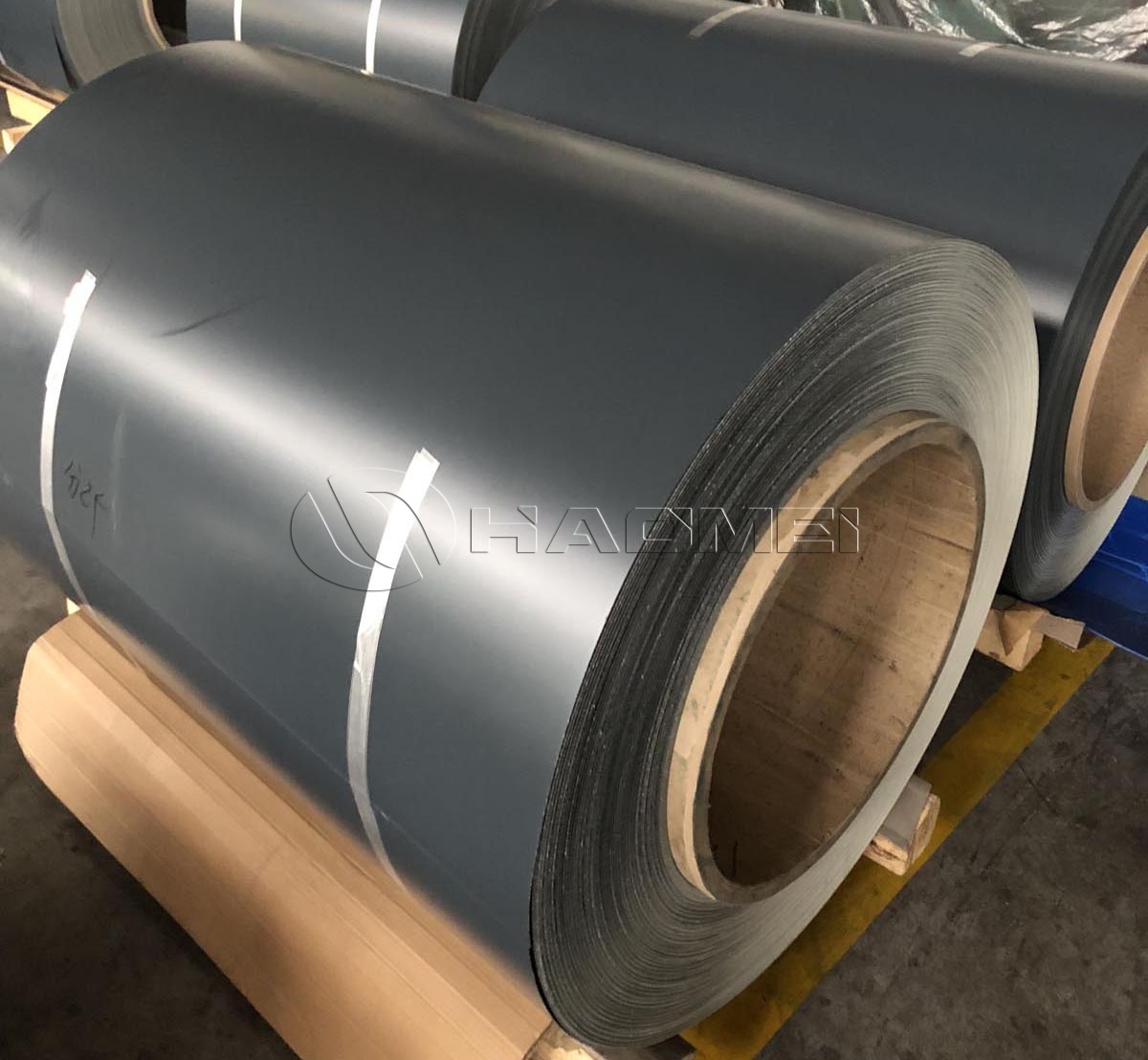

Pvdf Coated Aluminum Coil For Exterior Cladding

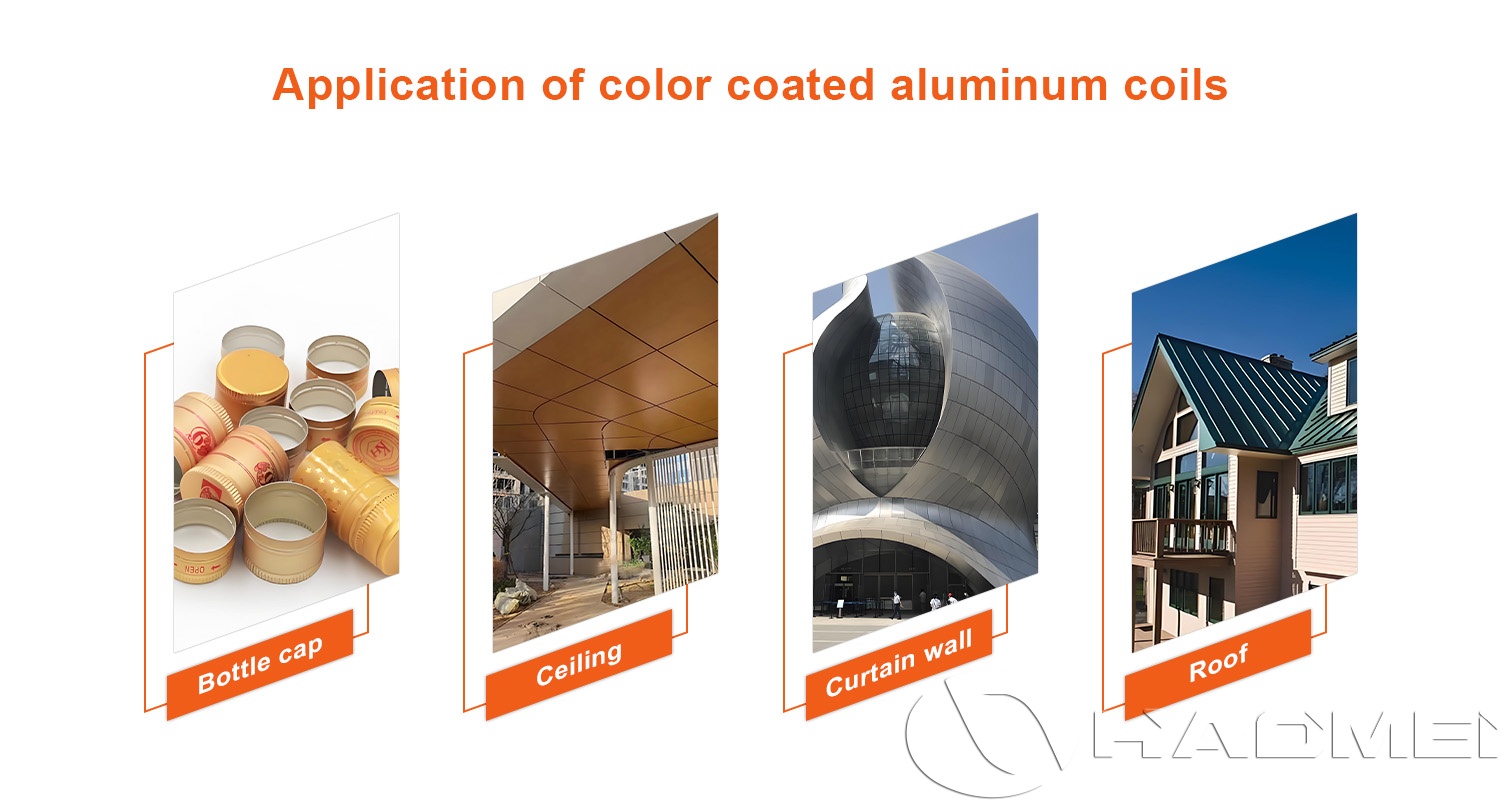

PVDF coated aluminum coil for exterior cladding is positioned as a high-durability, architectural-grade metal skin for building envelopes where long-term color retention and weather resistance are critical. Typical scenarios include high-rise architectural facade panels, rainscreen systems, parapet and fascia covers, soffits, canopies, and metal wall cladding in coastal, high-UV, or industrial environments.

Why PVDF aluminum coil is chosen for exterior cladding

Exterior cladding faces a combination of UV exposure, temperature cycling, airborne contaminants, and moisture. The advantage of PVDF (fluorocarbon coating) is that its C-F bond chemistry provides outstanding resistance to photodegradation and chalking, helping surfaces maintain gloss and color for many years when compared with general-purpose polyester systems.

The substrate also matters. Aluminum's low density supports lightweight facade design and reduces load on substructures, while its formability enables profiling into cassettes, planks, trims, and complex geometries. For exterior cladding, alloy selection is typically driven by strength and forming requirements:

3xxx series (such as 3003/3105) for balanced formability and strength in roll-formed or bent components.

5xxx series (such as 5005/5052) where higher strength and improved corrosion performance are preferred, especially for coastal or humid regions.

A robust coating-plus-substrate pairing is what ultimately determines service stability: the coil provides the mechanical platform, while the PVDF system provides the environmental barrier and appearance retention.

Coating system design: more than just a topcoat

A technically coherent PVDF system for exterior use is built in layers, each serving a defined purpose across adhesion, corrosion protection, and aesthetics.

Pretreatment and conversion layer

Before painting, the coil is chemically cleaned and treated to create a stable, adherent surface. Modern chrome-free conversion coatings are widely used to improve primer anchoring and reduce underfilm corrosion risk. This step is fundamental for long-term performance because many coating failures originate at the metal-coating interface.

Primer: adhesion and corrosion backbone

The primer is selected to match the chosen pretreatment chemistry and the intended environment. For exterior cladding, the primer contributes significantly to:

Adhesion stability under thermal cycling

Edge creep and cut-edge corrosion resistance

Overall system flexibility during bending and forming

PVDF topcoat: weatherability and color stability

The PVDF topcoat (often a 70% PVDF resin formulation by resin system design) is the primary defense against UV radiation, chalking, and fading. It also enables a broad color space, including solid colors and metallic effects, while maintaining consistent appearance across large facade areas.

When projects require higher confidence in exterior durability, PVDF systems are commonly aligned with established performance expectations such as AAMA 2605-level weathering behavior (system-dependent and subject to full test validation).

For product selection details and typical system options, the dedicated PVDF Coated Aluminum Coil page provides a direct reference to available grades and finishes.

How the coil coating process supports consistent facade quality

Unlike piece-by-piece spraying after fabrication, a controlled coil coating process applies paint to flat strip under repeatable line parameters, which is a major reason coil-coated cladding can achieve consistent color, gloss, and film build.

A typical manufacturing flow for PVDF color-coated coil includes:

Aluminum coil incoming inspection (alloy, temper, surface condition, thickness tolerances)

Degreasing and surface preparation

Chemical conversion pretreatment

Primer application with precision coating rolls

Oven curing to achieve target crosslinking and film integrity

PVDF topcoat application and curing

Cooling, protective film lamination (when required), and rewinding

Quality verification: color (ΔE), gloss, dry film thickness, adhesion (cross-hatch), T-bend, impact, and solvent rub resistance

For exterior cladding, the process control focus is typically on curing window stability and film thickness uniformity. Under-curing can reduce chemical resistance and weatherability; over-curing can increase brittleness and reduce forming tolerance. Stable line speed, peak metal temperature control, and paint viscosity management are therefore essential.

Core specifications for PVDF coated aluminum coil (exterior cladding)

| Substrate alloy | 3003, 3105, 5005, 5052 (others available by request) |

| Temper | H14, H16, H18, H24 (selected by forming and strength needs) |

| Aluminum thickness | 0.30–3.00 mm |

| Coil width | 600–1600 mm |

| Coating type | PVDF fluorocarbon (exterior grade) |

| Coating structure | 2-coat (primer + topcoat) or 3-coat (primer + color coat + clear/functional coat) |

| Top-side dry film thickness | 20–35 μm typical (project-dependent) |

| Back-side coating | Service coat 5–10 μm (or as specified) |

| Gloss | Matte, satin, semi-gloss, high-gloss (by color system) |

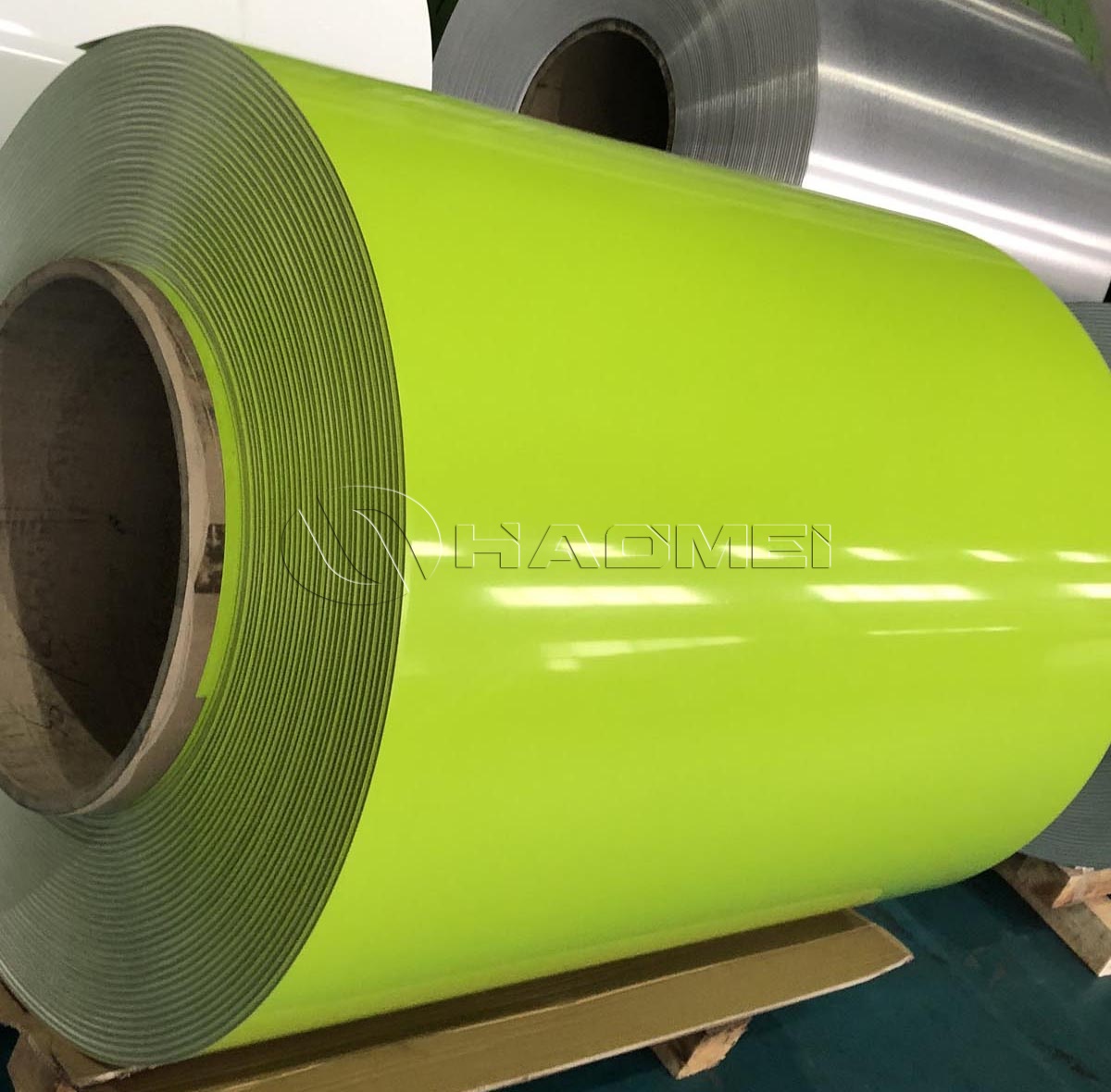

| Colors | RAL/Pantone matching; solid, metallic; special patterns on request |

| Protective film | Optional, for fabrication and transport |

| Reference performance | Systems commonly designed toward AAMA 2605-type exterior durability (validation by test plan) |

Practical use in exterior cladding: design and fabrication considerations

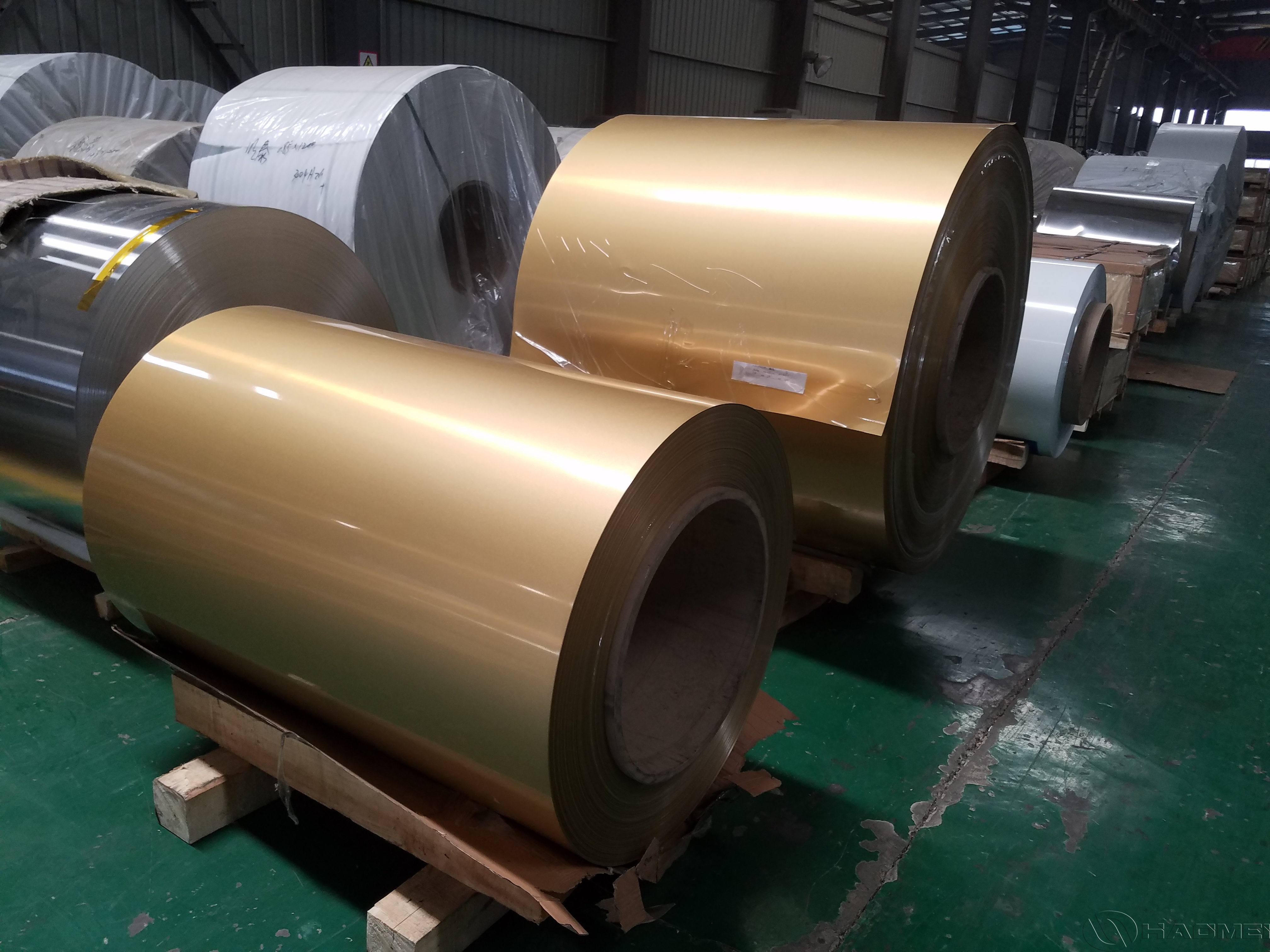

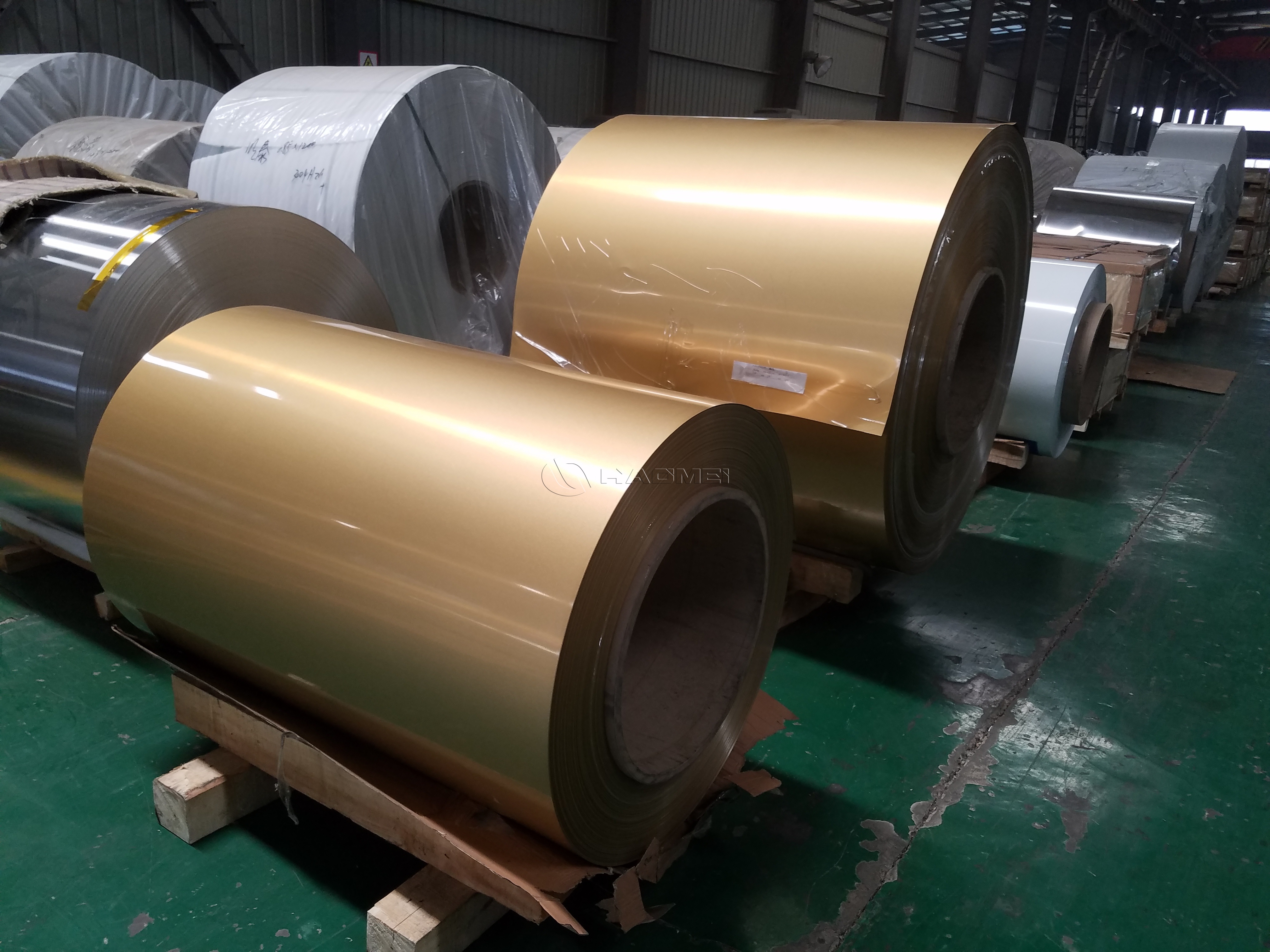

PVDF coated coil is commonly fabricated into aluminum composite panel (ACP/ACM) skins, solid aluminum facade cassettes, profiled siding, soffit panels, and perimeter trims. The coil format improves yield for roll-forming and allows efficient production of long-length components with uniform appearance.

Key engineering considerations in real projects include:

Forming radius and T-bend performance: tighter bends demand a matched alloy/temper and an appropriately flexible primer/topcoat balance.

Cut-edge behavior: aluminum does not rust like steel, but edge protection still matters for aesthetics and long-term cleanliness. Good pretreatment and primer selection reduce edge creep.

Galvanic compatibility: when aluminum cladding interfaces with dissimilar metals (certain steels, copper), isolation design (gaskets, tapes, fastener selection) helps prevent galvanic corrosion in wet conditions.

Sealants and cleaners: PVDF surfaces generally resist staining, but compatibility checks with sealants and periodic maintenance protocols help prevent dirt pickup or chemical attack in harsh environments.

Where projects compare exterior systems, it is common to evaluate PVDF against polyester alternatives based on service life targets and exposure severity. For reference to the general-purpose option, PE Coated Aluminum Coil is typically used in less aggressive exposures or shorter design-life applications.

-

PVDF Coated Aluminum Coil For Architectural Decoration

PVDF coated aluminum coil for architectural decoration delivers durable color, UV resistance and corrosion protection, supported by stable coil coating process and alloy options.

2026-02-04

-

PVDF Coated Aluminum Coil For Industrial Roofing

PVDF coated aluminum coil for industrial roofing delivers long-term color stability, corrosion resistance and reliable coil coating quality for harsh climates.

2026-02-03

-

5052 H34 Color Coated Aluminum Coil Inventory

5052 H34 color coated aluminum coil with PVDF or PE finishes, marine-grade corrosion resistance, stable formability, and specs for facade, roofing and trim.

2026-01-21