Color Coated Aluminum Coil,PVDF/PE Coated Aluminum Coil Factory

How to choose the color-coated aluminum coil product that suits your application?

1) Determine the aluminum alloy material and tempering grade.

Different uses have different requirements for mechanical properties.

Home appliance housing panels:1060 H14 / 3004 H24 / 3105 H26

Roofing and Wall Building Construction:3003 H24,3105 H24,5052 H26

Auto industry:5052 H46

Food and beverage packaging:5182 H19 / 5052 H19

kitchen utensils:1060 HO / 1100 HO

2) Choosing the color coated aluminum coil paint type.

on your market's location and climate. Common coatings include polyester (PE), silicone-modified polyester

(SMP), polyvinylidene fluoride (PVDF), and polyurethane (PU).

PVDF coatings are renowned for their exceptional durability and color retention, with color retention

lasting over 20 years. Therefore, PVDF color-coated aluminum coils are widely used on the exterior walls and

roofs of coastal buildings.

3) Color-coated aluminum thickness and width.

Color-coated aluminum thickness: 0.08-3.0 mm, depending on your specific requirements.

Color-coated aluminum width: 100-2650 mm, depending on your specific requirements.

4) Color or pattern selection.

HAOMEI Aluminum can roll-coat aluminum according to Ral, Pantone, wood grain, marble, camouflage, and other standards, and supports customization.

5) A wide range of color-coated aluminum types are available.

Color-coated aluminum coils, color-coated corrugated aluminum sheets, color-coated aluminum strips, color-coated aluminum discs, and color-coated aluminum sheets are available.

Color Coated Aluminum Sheet Specification

|

Product |

Prepainted Aluminum Coil / Color Coating Aluminum Sheet |

|

Thickness |

Thickness of coated aluminum coil: 0.2mm-2.00mm. |

|

|

Thickness of coated aluminum sheet and plate: 2.00mm-6mm. |

|

Width |

30-2750mm (ultra-wide color coating aluminum sheet in coil) |

|

Material |

1050, 1060, 1100, 3003, 3004, 3105, 5052, 5005, 5754, 5083, 6061,8081 etc |

|

Temper |

O, H12, H14, H16, H18, H24, H26, H32, H34, etc |

|

Inner Diameter |

405mm,508mm,610mm |

|

Color |

RAL, Pantone Color Or As Alient’s Demand |

|

Coating thickness |

PVDF Paint Coating: Not Less Than 25um |

|

|

PE Paint Coating : Not Less Than 18um |

|

Coating Properties |

Hardness: > 2H. |

|

|

Adhesion: Level 1. |

|

|

Adhesion: Level 1. |

|

|

Impact resistance: 50kg/cm without peeling or cracking. |

|

Packing |

Export Standard Wooden Pallets (Eye To Wall,Eye To Sky) |

|

Payment Terms |

L/C at sight or 30% T/T in advance as deposit, and 70% balance against the B/L copy. |

|

MOQ |

3 Tons Per Specification |

|

Delivery Time |

Within 30-45 Days |

|

Loading Port |

Shanghai,Ningbo,Qingdao,TInajin Port and Etc |

|

Application |

Aluminum Roofing,ACP,Roller Shutter Window,Roller Shutter Door,Aluminum Ceiling,Aluminum Grilling,Aluminum Downspout System,Home Appliance’s Plate, body tank of cold chain truck,high speed rail,aluminum pull ring,food packaging,outer packing case of capacitor,external contour of letter channel |

| Model |

PE Coating

|

HDP Coating

|

PVDF Coating

|

| Service Life | 5–10 years | 10–15 years | 20–25 years |

| Weather Resistance | ★★ | ★★★★ | ★★★★★ |

| Corrosion Resistance | ★★ | ★★★★ | ★★★★★ |

| Color Performance | ★★★★★ | ★★★★ | ★★★ |

| Dewatering speed | ★ | ★★★★ | ★★ |

| Flexibility | Interior ceilings, temporary projects, decorative use | Industrial & commercial buildings in hot and humid climates | Coastal projects, high-end public buildings, heavy industrial zones |

| Testing Standards | ASTM T-bend, Adhesion test, Hardness (pencil), Gloss retention, MEK rub test | ||

| Quality Control | Dedicated QC team assigned to each production stage, strict sampling inspection | ||

| Packaging | Moisture-proof, anti-oxidation, export standard wooden pallets | ||

| Delivery | 15–30 working days, on-time shipping with tracking updates | ||

Our Company

What is color coated aluminum coil?

Color-coated aluminum coils are a new type of decorative material formed by chemical treatment and coating of aluminum coils or aluminum alloy coils. It uses high-quality aluminum as the substrate, and applies one or more layers of colored paint to the surface through an advanced continuous roller coating process, followed by high-temperature baking and curing to form a durable colored coating. This process allows the aluminum coil to retain not only the inherent lightweight, high strength, and excellent corrosion resistance of aluminum, but also a variety of rich surface effects and enhanced durability, making it a widely used high-performance material in modern architectural decoration and industrial manufacturing.

Color-coated aluminum coils are available in various materials, including 1060, 1100, 3003, 3004, 3105, and 5052. The thickness is generally between 0.2-3.0 mm.

The choice of coating type mainly depends on the application environment and performance requirements. Polyester coating (PE) offers good cost-effectiveness and is suitable for indoor and general outdoor environments; fluorocarbon coating (PVDF) provides superior weather resistance and is suitable for harsh climatic conditions and high-end building projects requiring long-term color retention. In addition, there are polyester-coated aluminum coatings specifically designed for interior decoration and advertising displays, as well as special safety coatings suitable for food packaging. The appropriate coating type should be selected based on the specific application scenario.

Depending on the requirements of the usage environment, single-coat, double-coat, or triple-coat systems can be selected. Single-coat systems (4μm-20μm) are suitable for less demanding indoor environments; double-coat systems (25μm-28μm) offer better coverage and protection, suitable for most outdoor environments; while triple-coat systems (35μm-38μm) provide optimal protection and appearance, suitable for harsh environments and high-end buildings.

Coated aluminum coils offer a variety of surface texture options, including glossy, matte, embossed, and brushed. Different surface textures not only affect aesthetics but also performance and ease of cleaning and maintenance. Color selection requires consideration of coordination with the overall design, heat reflectivity (for outdoor applications), and long-term color retention requirements.

Performance advantages of color-coated aluminum rounds

- Corrosion Resistance: The aluminum base itself forms a dense oxide film on its surface. Combined with the additional protection provided by the coating, color-coated aluminum coils offer double corrosion protection, particularly resistant to acid and alkali corrosion in coastal and industrial areas, significantly extending the material's service life.

- Lightweight: Aluminum's density is only about 1/3 that of steel, making color-coated aluminum coils lightweight and easy to handle, significantly reducing construction loads. Excellent ductility and processability allow for complex on-site cutting, bending, and shaping requirements, improving construction efficiency and reducing installation costs.

- Weather Resistance:Using high-performance international coatings such as PVDF and PPG, prepainted aluminum coils can withstand strong UV rays, acid rain, and air pollution. Even in harsh outdoor environments, they maintain long-lasting color and gloss, ensuring 15–20 years of no chalking and no fading.

- Workability:Prepainted aluminum coils offer excellent flexibility and formability. They can be freely cut, slitted, curved, stamped, drilled, and fixed, making them suitable for processing various complex shapes and installation requirements.

- Fire Resistance:The coatings used for prepainted aluminum coils contain no heavy metals or harmful substances. Most products meet fire safety standards, and some specialized products can even achieve Class A fire resistance.

- Decorative Appearance:Prepainted aluminum coils come in a wide range of vibrant colors and offer a fine, uniform surface texture. Options such as wood grain, stone grain, and marble grain meet diverse design needs and aesthetic preferences.

- Eco-Friendly and Recyclable:The production of prepainted aluminum coils typically uses chromium-free pretreatment solutions, and the roll-coating paints comply with environmental regulations. The material is fully recyclable, contributing to sustainability and environmental protection.

- Economic Value:Although the initial investment is slightly higher than traditional materials, the long service life and high recycling value of prepainted aluminum coils make them more economical over their entire life cycle.

- Easy to Clean:The smooth surface of prepainted aluminum coil is stain-resistant and easy to clean. Simple maintenance is sufficient to keep it looking new, significantly reducing upkeep time and costs.

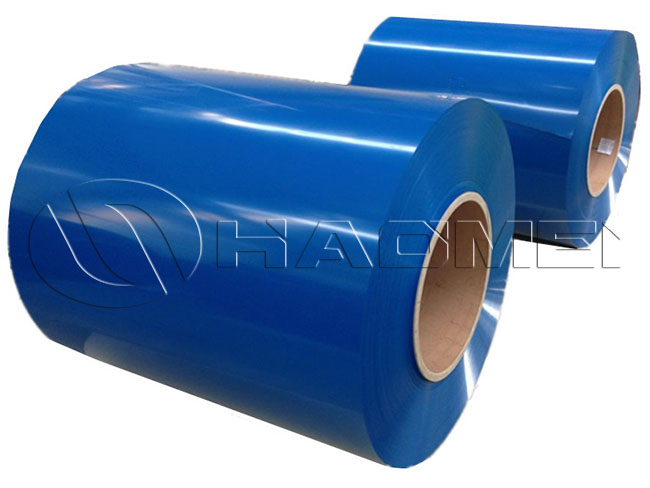

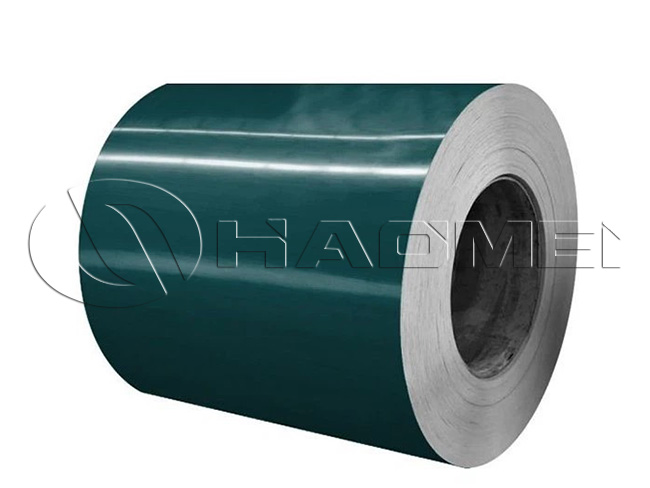

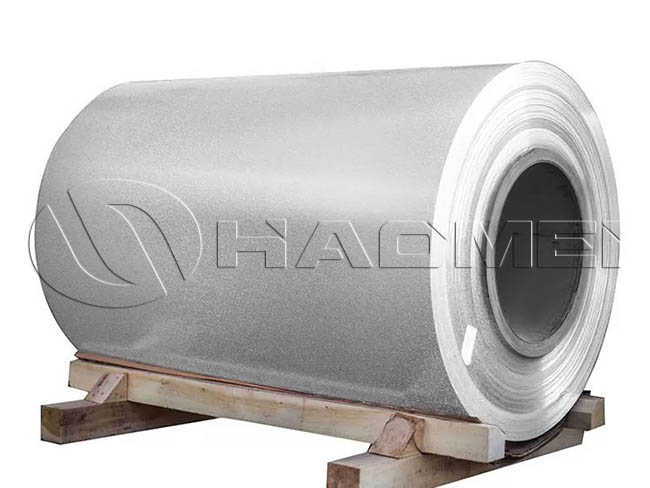

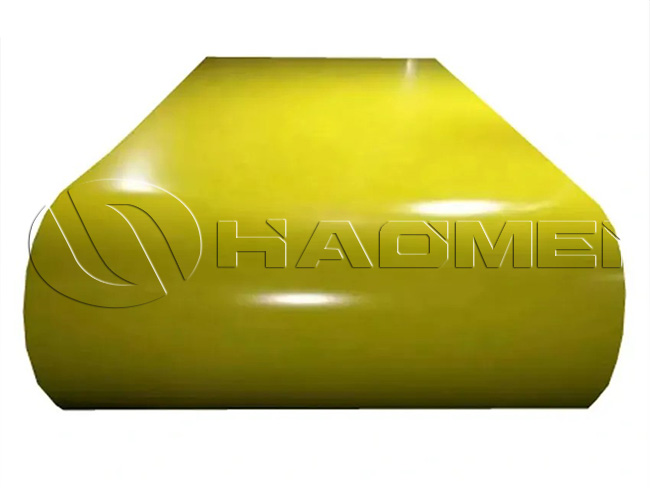

Colors chart of coated aluminum

White

Black

Red

Green

Blue

Yellow

Orange

Gray

Maroon

Lime

Navy

Cyan

Purple

Olive

Teal

Silver

Pink

Light Gray

Gold

Saddle Brown

Dark Slate Gray

Dark Khaki

Indian Red

Tomato

Coral

Dark Orange

Peach Puff

Light Pink

LightSalmon

Orange

OrangeRed

PaleVioletRed

Hot Pink

Deep Pink

Dodger Blue

Steel Blue

Sky Blue

Dark Bronze

Wood Grains

Stone Grains

Mirror

Metallic Colors

Basic Aluminum Mechanical Properties

| Alloy Grade | Common Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|

| 1050 | O, H14, H18, H19 | 85-120 | 35-90 | 20-35 | 61 | 205 | 2.71 |

| 1060 | O, H14, H18, H19 | 90-130 | 40-100 | 20-35 | 63 | 205 | 2.71 |

| 1070 | O, H14, H18, H19 | 80-110 | 30-80 | 25-35 | 63 | 205 | 2.71 |

| 1100 | O, H14, H18, H19 | 90-140 | 40-110 | 20-30 | 60 | 205 | 2.73 |

| 1200 | O, H14, H18, H19 | 80-120 | 30-90 | 20-30 | 61 | 205 | 2.71 |

| 1350 | O, H14, H18, H19 | 80-110 | 30-80 | 25-35 | 63 | 205 | 2.71 |

| 3003 | O, H14, H18, H19 | 130-185 | 55-140 | 20-30 | 36 | 160 | 2.73 |

| 3004 | O, H34, H36 | 160-205 | 150 | 10-20 | 36 | 160 | 2.73 |

| 3105 | O, H14, H24 | 140-185 | 110-150 | 10-20 | 41 | 160 | 2.73 |

| 5005 | O, H14, H18 | 110-160 | 45-120 | 15-25 | 35 | 160 | 2.73 |

| 5052 | O, H32, H34, H36 | 190-240 | 80 | 12-20 | 35 | 160 | 2.73 |

| 5454 | O, H14, H24 | 190-240 | 80 | 12-20 | 35 | 160 | 2.73 |

| 5754 | O, H14, H24 | 190-240 | 80 | 12-20 | 35 | 160 | 2.73 |

| 8011 | O, H14, H16, H18 | 100-180 | 34-170 | 1.7-28 | 56 | 210 | 2.73 |

| 8079 | O, H14, H16, H18 | 150 | 120 | 2.2 | 58 | 230 | 2.73 |