News

By Hermione

By Hermione

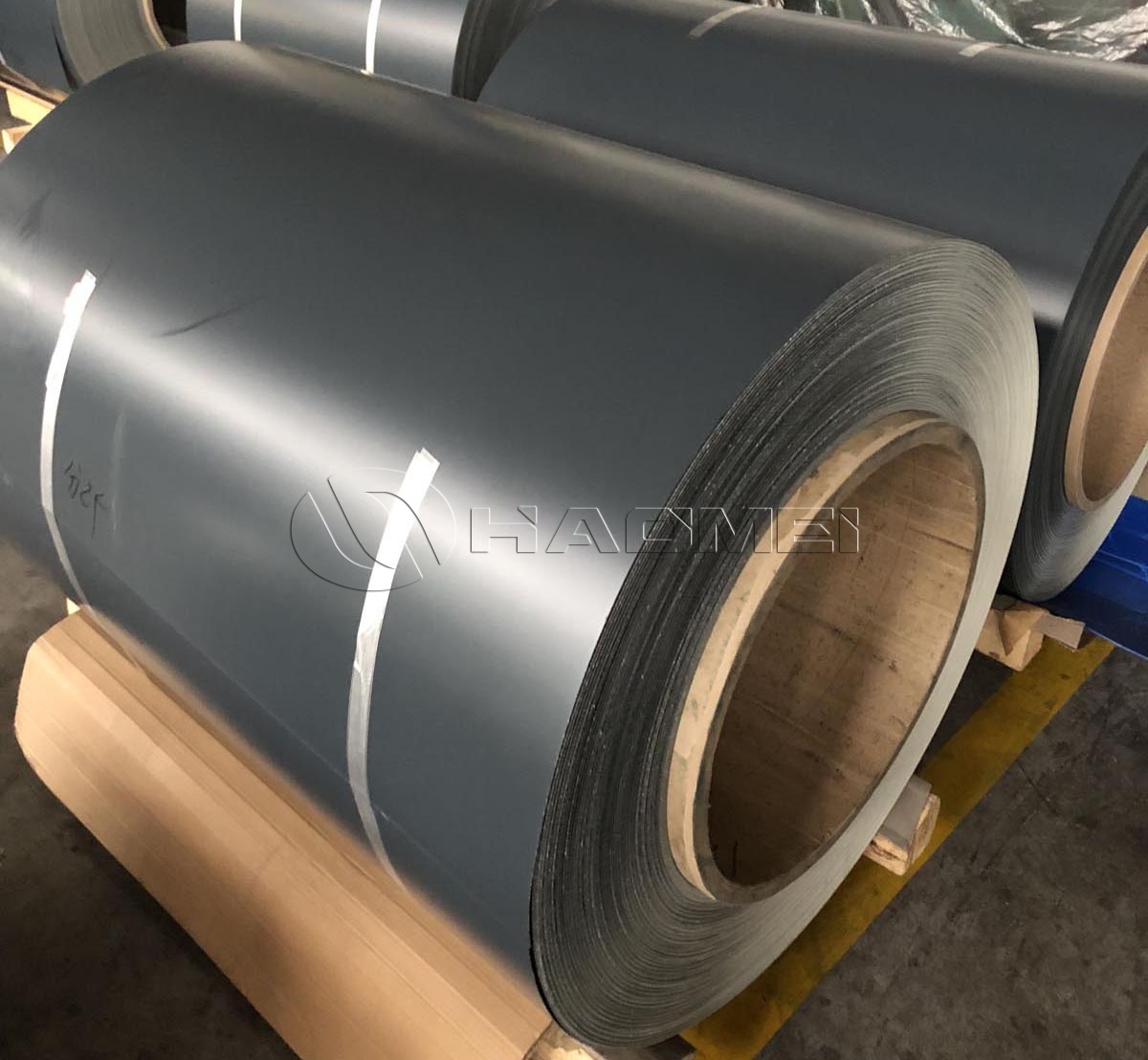

5052 H34 Color Coated Aluminum Coil Inventory

5052 H34 color coated aluminum coil is positioned for projects that need marine-grade corrosion resistance plus reliable forming performancetypical in coastal building envelopes, architectural trim, transportation panels, and equipment housings exposed to humidity or salt-laden air.

Why 5052 H34 is a practical coated-coil substrate

5052 belongs to the 5xxx series (Al-Mg alloys). Compared with many general-purpose alloys, it delivers a strong balance of:

Corrosion resistance: Magnesium-based solid solution strengthening supports excellent resistance in humid/coastal environments, making it a common go-to for exterior metal skins.

Moderate strength with stable formability: The H34 temper indicates strain-hardened and stabilized conditionoften selected when you need improved rigidity versus H32, while still allowing roll forming, bending, and profiling.

Good surface quality for coating: When substrate cleanliness and pretreatment are controlled, 5052 provides consistent coating adhesion and visual uniformity.

Coating systems: PVDF vs PE in real projects

Color-coated aluminum coil performance depends heavily on the coating chemistry and film build, not just the alloy.

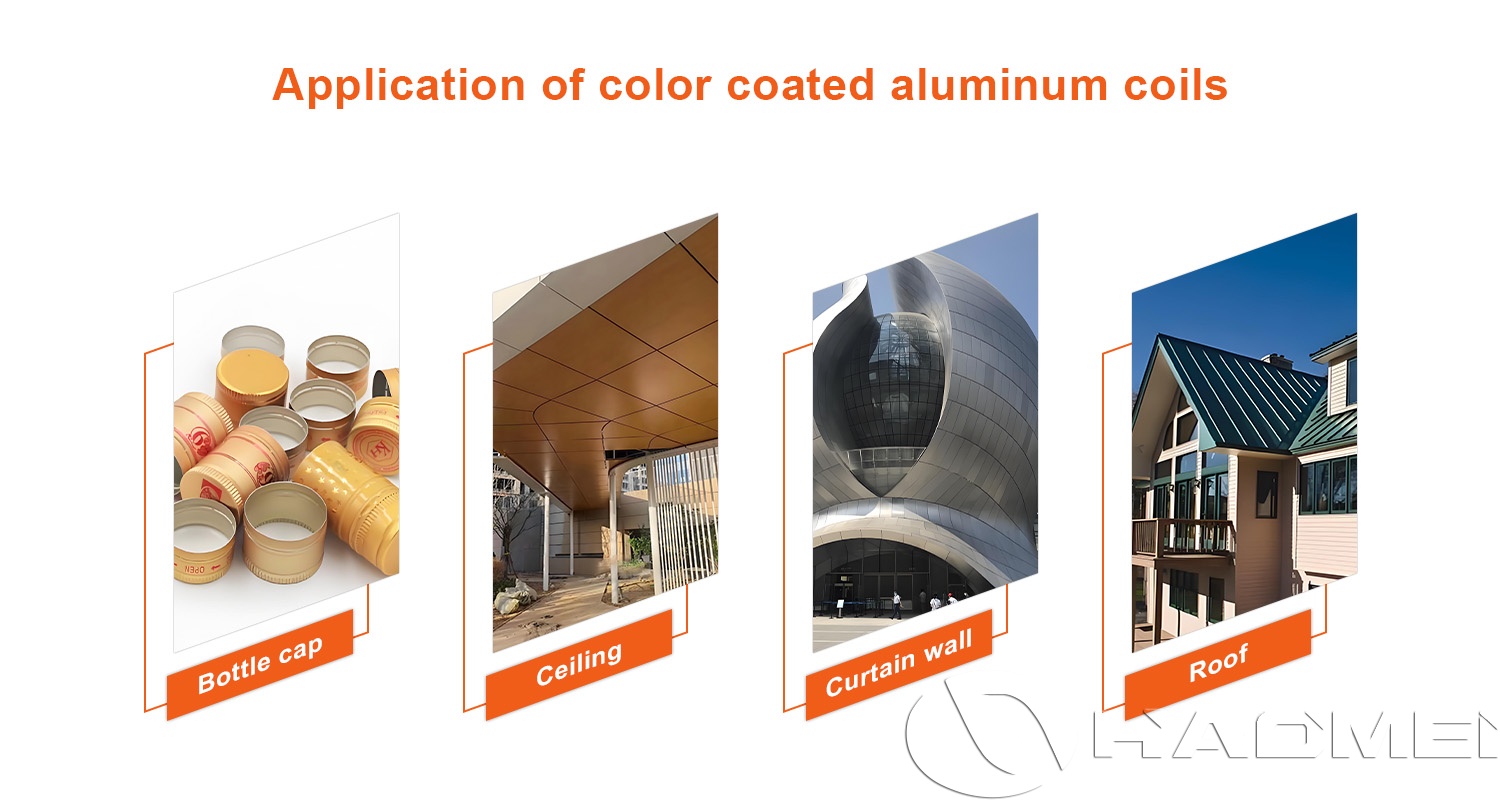

PVDF (fluorocarbon) coatings: Used when long-term UV stability, color retention, and weather resistance are prioritiesoften specified for building faades, curtain walls, and premium roofing in harsh climates. PVDF systems are frequently chosen for multi-year exterior durability requirements (gloss stability and chalk resistance).

PE (polyester) coatings: A cost-effective option typically used for interior ceilings, signage, light-duty cladding, and general building components where exposure is moderate.

When project specs call out fluorocarbon performance, it typically aligns with PVDF Coated Aluminum Coil as the finish baseline.

Manufacturing overview: from coil to finished color-coated stock

A stable coil coating process is designed to protect both appearance and forming performance:

Substrate preparation: Degreasing and mechanical/chemical cleaning remove rolling oils and contaminants.

Pretreatment conversion layer: Improves corrosion resistance and promotes coating adhesion (critical for edge performance and long-term durability).

Primer coating and curing: Provides bonding and corrosion barrier properties.

Topcoat application and baking: Controls color, gloss, and weatherability (PVDF/PE systems).

Film inspection and protection: Film thickness, gloss, color difference, adhesion (T-bend/cross-hatch), solvent rub, and impact are checked; protective film can be applied for transport and fabrication.

For 5052 H34, the process window is often tuned to preserve temper stability while ensuring the coating can withstand subsequent bending and roll forming without cracking.

Core specifications table 5052 H34 Color Coated Aluminum Coil

| Item | Typical Range / Options |

|---|---|

| Alloy / Temper | 5052 H34 |

| Coating Type | PVDF / PE (single or double coat options by requirement) |

| Coating Structure | Primer + topcoat (back coat optional) |

| Thickness (Al) | 0.303.00 mm |

| Width | 5001600 mm |

| Coil ID | 508 / 610 mm |

| Coil OD | Up to ~12001500 mm (depending on thickness and weight) |

| Surface Finish | Solid colors, metallic, matte/high gloss (by coating system) |

| Protective Film | Optional (standard or high-tack for deep forming) |

| Typical Standards | ASTM / EN / JIS equivalent production control (as agreed per order) |

Application fit: where 5052 H34 coated coil performs well

Because it balances corrosion resistance, strength, and workability, 5052 H34 color coated aluminum coil is frequently used for:

Building faade cladding and soffits: Especially for coastal cities or industrial zones where atmospheric corrosion is a concern.

Roofing and flashing systems: Good rigidity and durability when paired with PVDF.

Exterior trim, profiles, and rain-screen components: Stable bending performance reduces edge cracking risk.

Transportation and equipment panels: Lightweight, corrosion-resistant skins for non-structural covers.

Common color-coated aluminum alloys and typical uses

Alloy choice affects forming, strength, corrosion resistance, and final application suitability:

1xxx series (1050/1060/1100): High aluminum purity, excellent formability and conductivity. Often used for interior panels, lamp reflectors, and applications prioritizing deep draw/soft forming over strength.

3xxx series (3003/3004/3105): Al-Mn alloys with good general corrosion resistance and better strength than 1xxx. Common for roofing, siding, ceilings, and general architectural sheet where forming is moderate.

5xxx series (5005/5052/5754/5083): Al-Mg alloys known for superior corrosion resistance and stronger mechanical performance.

5005: Frequently used for architectural anodizing/trim where appearance uniformity is emphasized.

5052: A versatile choice for exterior, coastal, and humid environmentsoften specified as a dependable building envelope substrate.

5754: Often selected for automotive and general engineering where strength and formability balance is needed.

5083: Higher strength; used when structural performance and marine exposure are more demanding.

8xxx series (8011/8079): Common in packaging and special forming uses; selection depends on end-use and coating/lamination system.

In practice, the best performance comes from matching alloy + temper + coating system to the exposure class (UV, salt spray, industrial pollutants) and the fabrication method (roll forming, press bending, stamping).

-

5052 H34 Color Coated Aluminum Coil Inventory

5052 H34 color coated aluminum coil with PVDF or PE finishes, marine-grade corrosion resistance, stable formability, and specs for facade, roofing and trim.

2026-01-21

-

Pe Coated Aluminum Coil Vs Pvdf

Compare PE coated aluminum coil and PVDF coated aluminum coil by resin chemistry, coil coating process, durability, color retention, and end uses.

2026-01-27

-

Double-Sided Color Coated Aluminum Coil

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06