News

By Hermione

By Hermione

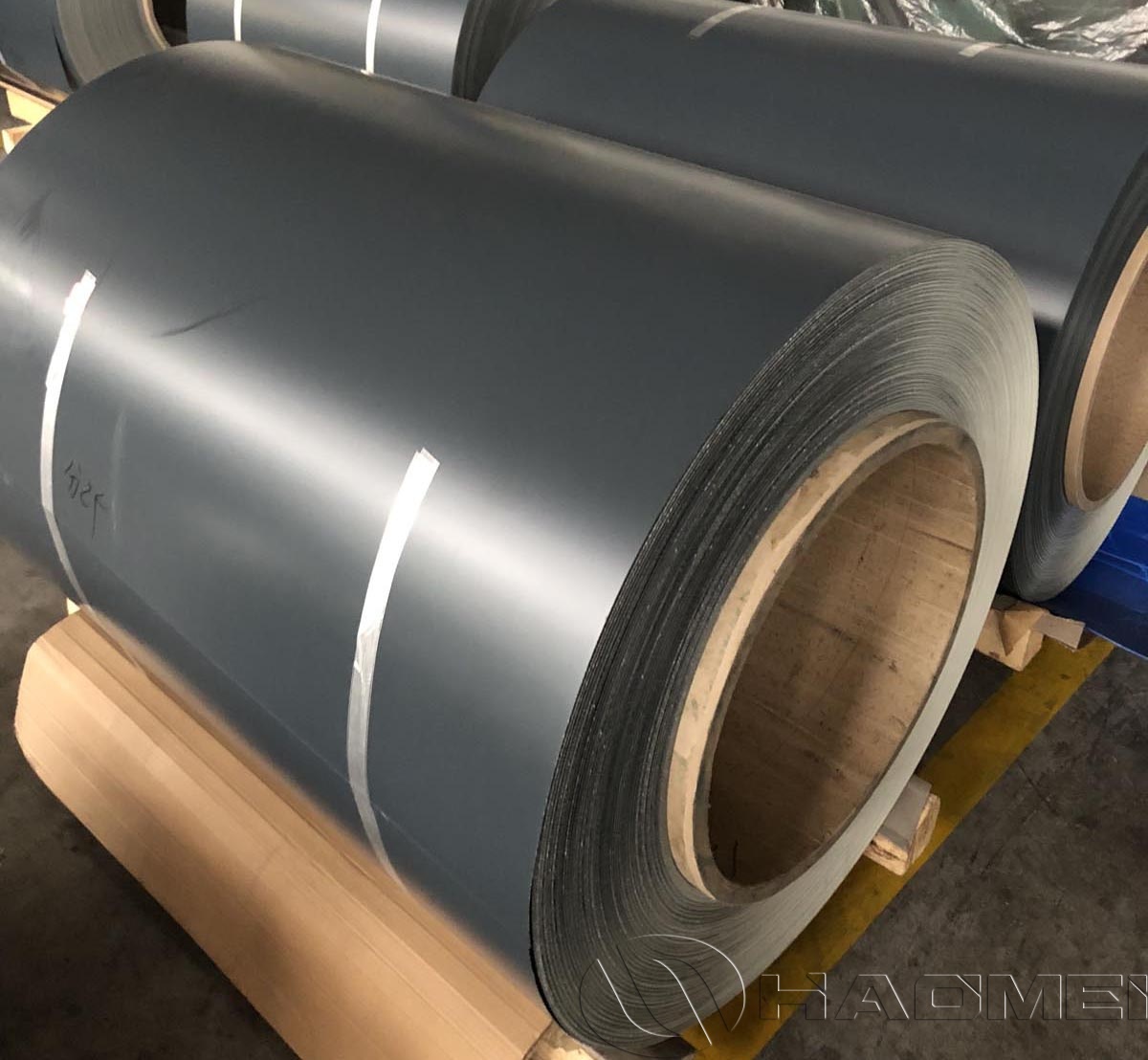

Matte Finish 1000 Series Color Coated Aluminum

Matte Finish 1000 series color coated aluminum is positioned as a lightweight, high-formability prepainted material for projects that need a low-gloss, refined appearance with consistent color from batch to batch. Typical application scenarios include interior ceilings and wall panels, decorative trims, shutter and louver components, appliance and light-gauge enclosures, and selected signage or display panels where a matte surface helps reduce glare and hides minor handling marks.

Why matte on 1000 series: the material logic

The 1000 series (commercially pure aluminum) is valued for its high aluminum content, excellent corrosion resistance in common indoor and mild outdoor environments, and very good ductility. When paired with a controlled matte paint system, it offers a balanced combination of:

Low-glare aesthetics: matte surfaces diffuse light and visually soften large areas such as ceilings or claddings.

Stable forming performance: the base metals softness supports tight bending radii, hemming, and roll-forming with reduced risk of cracking.

Uniform coating appearance: matte topcoats can mask slight substrate texture differences compared with high-gloss systems.

From a design standpoint, 1000 series matte prepainted coil is often chosen when forming and surface uniformity are prioritized over high strength.

Material properties that matter in fabrication

For color coated coil, the substrate and coating must work together during forming, assembly, and service:

Formability and bend performance: 1000 series generally supports sharper bends; correct pretreatment and primer selection are key to preventing edge micro-cracking of the coating.

Corrosion behavior: pure aluminum provides intrinsic corrosion resistance; coating adds barrier protection and color stability.

Surface cleanliness and adhesion: the substrates surface state (oxide, rolling oil residues) directly affects coating adhesion, especially for matte systems where uniformity is more visually sensitive.

Thermal response: aluminums high thermal conductivity benefits certain enclosures and indoor panels, and also affects curing efficiency in the coil coating process.

Manufacturing overview: how matte color coated coil is built

A matte finish is not simply less gloss paint. It is the result of coordinated substrate preparation and paint formulation.

Substrate preparation

Incoming coil inspection (thickness, flatness, surface defects)

Degreasing / alkaline cleaning to remove rolling oils

Chemical conversion pretreatment (chromium-free options common) to improve corrosion resistance and paint adhesion

Coating system (typical two-coat or three-coat build)

Primer application and bake: optimized to anchor the topcoat and enhance flexibility

Matte topcoat application and cure: matte achieved via resin selection, matting agents, and controlled bake profile for consistent gloss

Optional back coat: improves handling, protects the reverse side, and can be tailored for lamination or bonding

Finishing and quality control

Film thickness monitoring, gloss measurement, color difference (E), pencil hardness, adhesion (cross-hatch), impact, T-bend, and solvent rub resistance

Slitting and packaging with surface protection as required (interleaving paper/film)

For coating selection, indoor trim and ceiling systems commonly use PE Coated Aluminum Coil for cost-effective color and processability, while exterior architectural elements that face stronger UV exposure often specify PVDF Coated Aluminum Coil for improved weathering and long-term color retention.

Common 1000 series alloys and where they fit best

Although all are pure aluminum grades, small chemistry and processing differences influence real-world usage:

1050: widely used for decorative trim, ceiling panels, and general sheet metal parts where formability and surface consistency are important. For reference products, see 1050 Color Coated Aluminum Coil.

1060: slightly higher purity than 1050; selected for applications needing better conductivity or enhanced corrosion resistance, such as certain enclosures and indoor functional panels.

1100: a classic commercial purity grade known for excellent workability; often used for nameplates, signage substrates, and formed decorative parts where deep drawing or complex bends are involved.

1200: common for general purpose prepainted applications, balancing availability and processing ease.

1350: primarily associated with electrical uses due to higher conductivity; color coating may be used for identification, protective finishes, or specialty wrapped components.

When higher strength or dent resistance is required (e.g., demanding exterior panels or heavy-use surfaces), designers often transition to 3000/5000 series. However, for matte decorative surfaces and tight forming, 1000 series remains a practical and economical baseline.

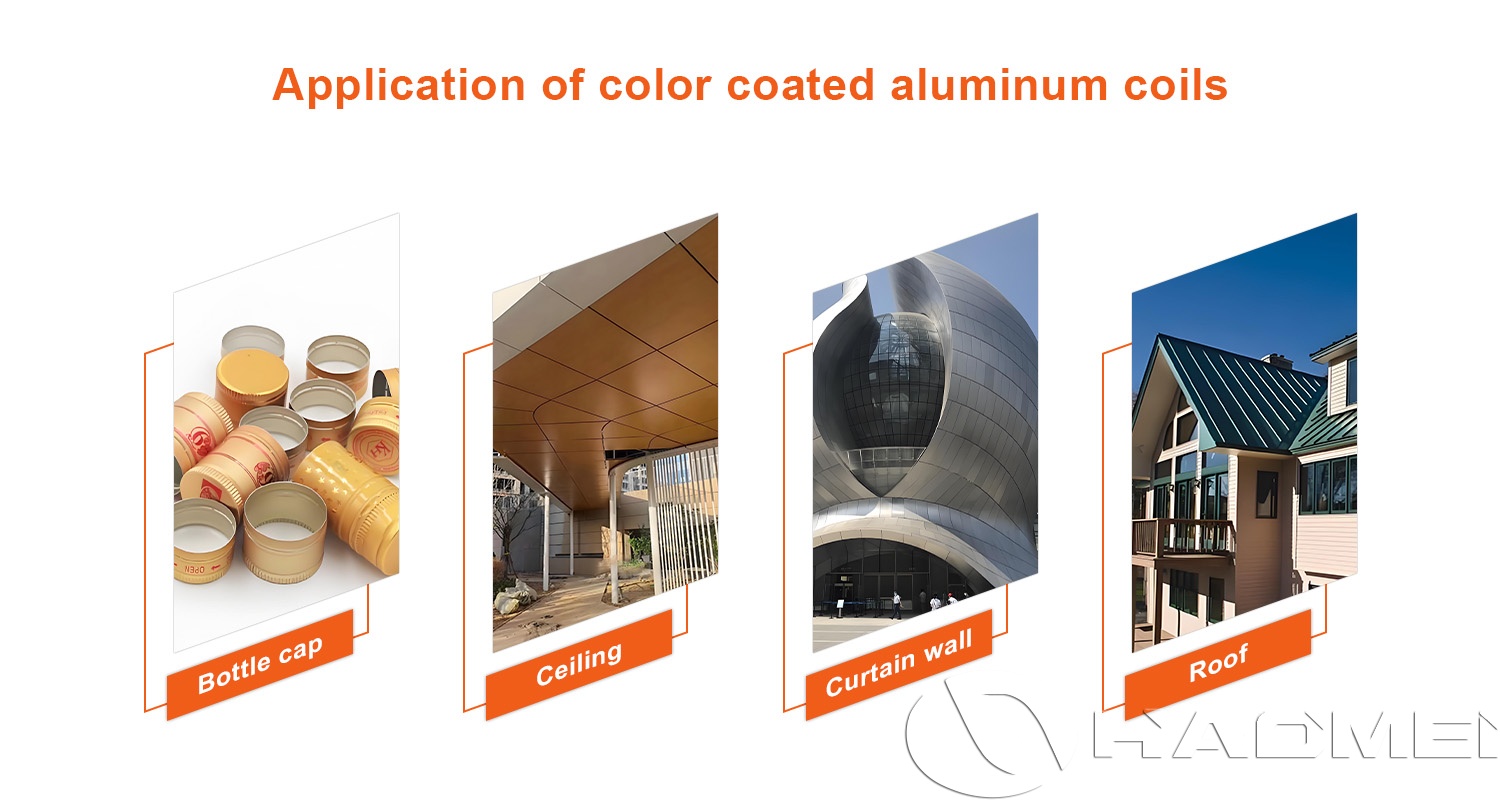

Practical application fit: where matte 1000 series performs well

Matte-finish 1000 series prepainted coil is frequently specified for:

Interior ceilings and baffle systems: reduced glare under office/retail lighting, good roll-forming behavior

Wall cladding (interior) and column covers: stable appearance, easy fabrication

Trims, flashings, and accessory profiles: tight bends, clean edges with proper tooling

Appliance and light-gauge housings: controlled aesthetic, efficient processing

Display and signage backboards: matte finish improves readability and reduces reflections

Core Specifications Matte Finish 1000 Series Color Coated Aluminum

| Item | Typical Range / Options |

|---|---|

| Alloy (substrate) | 1050 / 1060 / 1100 / 1200 / 1350 |

| Temper | O, H12, H14, H16, H18 (selection by forming & flatness needs) |

| Thickness | 0.201.50 mm (common), customized by application |

| Width | 301600 mm (slit or master coil) |

| Coating type | PE coating (indoor/general), PVDF coating (architectural exterior) |

| Finish | Matte (low-gloss), smooth or lightly textured depending on system |

| Coating structure | Topcoat + primer (2-coat) or topcoat + primer + back coat |

| Color | RAL / Pantone / custom matching; solid colors commonly used for matte |

| Film thickness (guide) | Topcoat 1525 m (PE) / 2030 m (PVDF); primer 510 m |

| Coil ID / OD | Common IDs: 150 / 300 / 505 mm; OD per coil weight & logistics |

| Surface protection | PE protective film optional; interleaving paper optional |

| Key tests (typical) | Adhesion, T-bend, impact, solvent rub, gloss, E, salt spray (by spec) |

Notes on selection: balancing matte appearance and durability

Matte finishes can be more sensitive to burnishing (localized gloss increase) if exposed to frequent rubbing. For high-touch trim or transport-intensive handling, it is common to specify protective film, choose a coating with improved mar resistance, and align tooling (rollers, dies, pads) to minimize scuffing. For exterior use, PVDF systems generally provide better long-term chalk resistance and color stability, helping maintain the intended matte aesthetic over time.

-

5052 Color Coated Aluminum Coil for Exterior Walls and Roofing

5052 PVDF-coated aluminum coil features an exceptionally stable fluorocarbon chemical structure, giving it outstanding weather resistance, UV resistance, and color-retention performance, making it especially suitable for architectural applications that re

2025-12-09

-

Double-Sided Color Coated Aluminum Coil

Double-sided color coated aluminum coil uses PE or PVDF coating systems, offering consistent color on both sides, excellent corrosion resistance, and strong weather resistance. It is widely used in architectural decoration and curtain wall systems.

2026-01-06

-

Black Color Coated Aluminum Coil 5052

5052 black color-coated aluminum coils are widely used in building decoration, home appliance housings, transportation and marine engineering.

2025-12-04