News

By Hermione

By Hermione

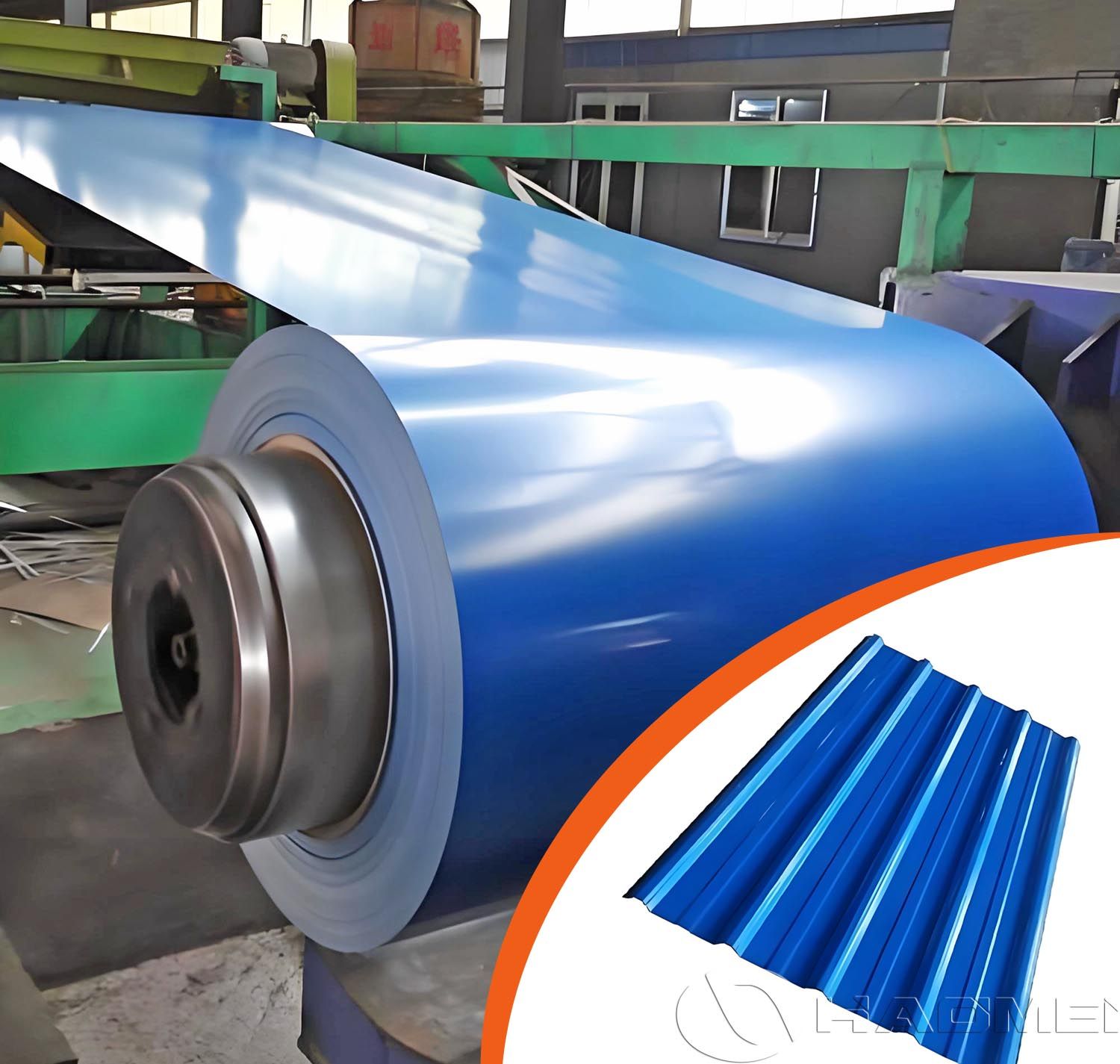

5052 Color Coated Aluminum Coil for Exterior Walls and Roofing

In residential buildings, industrial plants, commercial complexes, airports, exhibition centers, and many other constructions around us, roofing and exterior wall materials play an essential role beyond simple wind and rain protection. Modern architecture demands higher standards in aesthetics, durability, environmental performance, and long-term stability. Traditional galvanized steel or common 3003 aluminum alloy materials are increasingly unable to meet the requirements of high-end projects.

With advantages such as high strength, excellent corrosion resistance, lightweight properties, and superior coating performance, 5052 color coated aluminum coil has become one of the most popular materials for building roofs and exterior wall cladding.

Introduction to 5052 Color Coated Aluminum Coil

5052 aluminum alloy belongs to the typical Al-Mg (5xxx series) anti-rust aluminum, containing about 2.5% magnesium. Compared with 3003, 1100, and other alloys, it offers higher mechanical strength and better corrosion resistance. When the 5052 base metal is coated with PE or PVDF using the coil coating process, it becomes a durable, colorful, and weather-resistant color coated aluminum coil.

Among these, 5052 PVDF coated aluminum coildelivers outstanding weather resistance, UV protection, and anti-fading performance due to the stable C-F chemical bond structure, making it especially suitable for long-term outdoor architectural applications.

Technical Specifications of 5052 Coated Aluminum Coil

| Alloy | 5052 |

| Temper | H32 / H34 / O |

| Thickness | 0.2-3.0 mm |

| Width | 20-1600 mm |

| Length | 1000-16000 mm |

| Coating type | PE / PVDF / SMP |

| Coating thickness | Front: 18-25 μm; Back: 5-8 μm (customizable) |

| Surface finish | Glossy, matte, embossed, stucco, wood grain, stone pattern |

| Tolerance | ±0.02 mm (customizable per order) |

| MOQ | 1-3 tons |

Key Performance Features of 5052 Color Coated Aluminum Coil

1. Exceptional Corrosion Resistance

5052 contains 2.2%-2.8% Mg, giving it natural anti-oxidation properties. Even in harsh conditions such as coastal areas, high salt spray environments, or chemical plants, it remains rust-free and stable.

2. Lightweight but High Strength

With a density only one-third of steel and tensile strength of 210-260 MPa, it greatly reduces building load-ideal for high-rise and long-span structures.

3. Excellent Fatigue Resistance

5052 has superior fatigue strength. It withstands long-term wind loads and vibrations without cracking, improving structural safety.

4. Outstanding Decorative Effect

Available in a wide range of colors (gold, silver, black, etc.) and surface finishes (high gloss, matte, metallic), enhancing architectural aesthetics.

5. Superior Formability

Whether roll forming, stamping, or bending, 5052 maintains coating integrity without cracking or paint peeling-perfect for complex architectural designs.

6. Eco-Friendly and Recyclable

Aluminum is over 95% recyclable, supporting sustainable and green building standards.

Coating Types: PVDF vs. PE

| Feature | PVDF Coating | PE Coating |

| Weather resistance | Excellent; strong UV resistance; long-lasting color retention | Good; suitable for normal climates |

| Service life | 20+ years | About 10 years |

| Ideal environment | Harsh outdoor environments; high UV; high pollution areas | Indoor or mild outdoor use |

| Cost | Higher | More economical |

| Application | High-end exterior walls, roofing, iconic buildings | Interior decoration, displays, temporary structures |

| Surface finish | Wide color and gloss options | Matte or glossy |

Applications of 5052 PVDF/PE Color Coated Aluminum Coil

Large public buildings: airport terminals, railway stations, stadiums (e.g., "Bird's Nest"-style steel roofing systems)

High-end commercial projects: shopping mall facades, hotel exterior cladding

Coastal & harsh environments: seaside residences, chemical plants, offshore photovoltaic structures

Professional metal roofing: aluminum-magnesium-manganese standing seam roofing (high ribs)

5052 vs. 3003 Color Coated Aluminum Coil for Roofing

| Properties | 3003 Coil | 3003 Coil | Comparison Result |

| Alloy type | Al-Mn | Al-Mg | 5052 stronger |

| Corrosion resistance | Good | Excellent | 5052 preferred for coastal projects |

| Tensile strength | 140-180 MPa | 210-260 MPa | 5052 withstands higher wind loads |

| Price | Moderate | Higher | 5052 offers better long-term value |

| Application | Normal inland buildings | High-rise, coastal, landmark buildings | 5052 is more high-end |

Why Choose HAOMEI 5052 Color Coated Aluminum Coil?

Produced from 100% primary aluminum ingots for consistent quality

Fully automatic continuous coating lines, ensuring uniform coatings and zero color difference

PVDF coating lifespan up to 25–30 years

Supports custom color matching & pattern design

Provides corrugated roofing sheets, aluminum panels, and additional fabrication services

Fast delivery and extensive export experience

-

Pvdf Coated Aluminum Coil For Exterior Cladding

PVDF coated aluminum coil for exterior cladding delivers long-lasting color, UV resistance, and corrosion protection via a controlled coil coating process for facades.

2026-01-29

-

5052 H32 Color Coated Aluminum Coil for Sale

The 5052 H32 aluminum coil uses a color coating process that involves continuously rolling a polyester (PE), fluorocarbon (PVDF), or other coatings onto the aluminum coil substrate and then baking and curing it.

2025-12-05

-

Matte Finish 1000 Series Color Coated Aluminum

Matte finish 1000 series color coated aluminum coil with PE/PVDF options, clean forming, and stable color for trim, ceilings, and lightweight panels.

2026-01-20